8

ITEM Basic Specifications

External Input Terminlas:

AI1、AI2 (0~10V / 2~10V / 0~20mA / 4~20mA) input

Multifunction input up/down function

Setting frequency by communication method.

Frequency limit Lower and upper frequency limits

3 skip frequency settings.

Speed control

accuracy

V/F :±2~3%

SLV :± 1%

Run Operation set

Keypad run, stop button

External terminals:

Multi- operation-mode2 / 3 wire selection

Jog operation

Run signal by communication method.

Main

Control

Features

V / F curve setting 18 fixed curves and one customized curve

Carrier frequency 2~16KHz (default value : 4kHz)

Acceleration and

deceleration

control

2 off Acc / dec time parameters.

4 off S curve parameters.

Multifunction input 29 functions (refer to description on group3)

Multifunction output 21 functions (refer to description on group3)

Multifunction

analog output 5 functions (refer to description on group4)

Main features

Overload Detection,16 preset speeds,Auto-run,Acc/Dec Switch (2

Stages),Main/Alt run Command select,Main/Alt Frequency

Command select,PID control, torque boost, V/F start Frequency,

Fault reset,

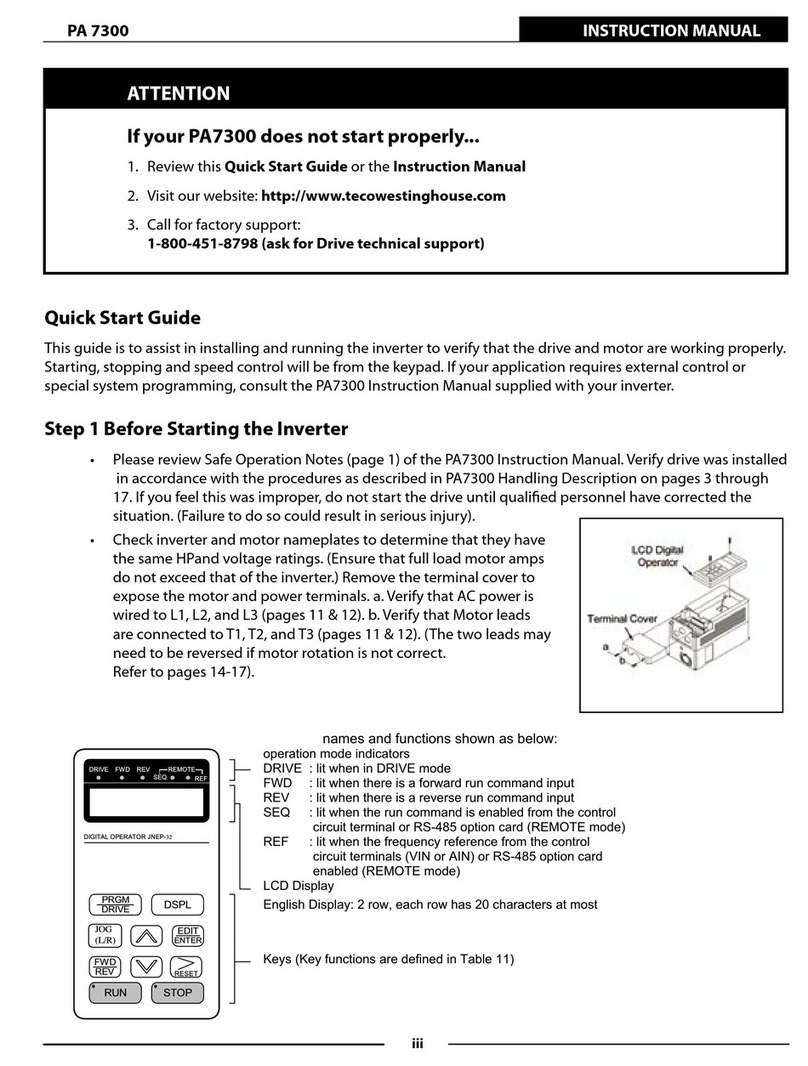

Display

LED

Display :parameter / parameter value / frequency / line speed / DC

voltage / output voltage / output current / PID feedback / input and

output terminal status / Heat sink temperature / Program Version /

Fault Log.

LED

Status Indicator FWD,REV,SEQ,REF

Protective

Functions

Overload

Protection The relays to protect the motor and the inverter. (150%/1min)

Over voltage ·220V: >410V ,380V: >820V

Under Voltage ·220V: <190V ,380V: <380V

Momentary Power

Loss Restart Inverter auto-restart after a momentary power loss.

Stall Prevention Stall prevention for Acceleration/ Deceleration/ Operation.

Short-circuit output

terminal Electronic Circuit Protection.

Ground fault Using current detector protection.

Other protection

features

Protection for overheating of heat sink,The carrier frequency

decreasing with the temperature function,fault output,reverse

prohibit,prohibit for direct start after power up and error

recovery ,parameter lock up

Communication control Standard built-in RS485 communication (Modbus), One to one or

One to many control.

Environment

Operating

temperature

IP20 /NEMA 1:

–10 ~ 50℃ (without stick on type dust cover.)

–10 ~40℃ (with stick on type dust cover.)

Storage

temperature -20~70℃

Humidity 95% RH or less (no condensation)

(Compliance with IEC 60068 - 2-78)

Shock 10Hz≦f≦57Hz:±0.075mm Amplitude;

57Hz≦f≦150Hz:1.0G Acceleration:(依據 IEC60068-2-6 標準)

Protection class IP20/NEMA1

Certification UL、CE、RoHS、REACH