SperryMarine NAVIGAT X MK1 Manual

kçêíÜêçé=dêìãã~å=péÉêêó=j~êáåÉ=_KsK=EoÉéêÉëÉåí~íáîÉ=lÑÑáÅÉF

tçäíã~åëíêK=N =√=aJOMM T=√=e~ãÄìêÖI=dÉêã~åó

qÉäKW HQ JQMJO MMJM=√=c~ñW HQ JQMJO MMJNQS=√=bJã~áäW ëÉêîáÅÉKÇÉ]ëéÉêêóKåÖÅKÅçã

léÉê~íáçåI=fåëí~ää~íáçå=~åÇ=pÉêîáÅÉ=j~åì~ä

lêáÖáå~ä=açÅìãÉåí~íáçå=L=hÉÉé=Ñçê=cìíìêÉ=oÉÑÉêÉåÅÉ

k^sf ^q u jh N

aáÖáí~ä= óêçÅçãé~ëë=póëíÉãë

qóéÉ=QVNQJ`^I=píçÅâ=kçK=TQUMT=~åÇ=qóéÉ=QVNQJ``I=píçÅâ=kçK=TQUNN

MQVNQJMNOUJMN

MRSPQPLcI=PM=pÉé=OMNQ

MRSPQPLc k^sfd^q u jh N

© 2014 Northrop Grumman Sperry Marine B.V.

This document and the information herein is the intellectual property of Northrop Grumman

Sperry Marine B.V. NGSM BV] and it’s associate companies and may not be copied, reproduced

or translated without the express permission of NGSM BV.

Specifications were correct at time of press but may be varied in accordance with NGSM BV’s

policy of continuous product development.

Any technical content should be verified with NGSM BV.

Sperry Marine, with major engineering and support offices in New Malden, England, and

Hamburg, Germany, is part of the Northrop Grumman Navigation & Maritime Systems Division

N&MSD.

oÉîáëáçå=oÉÅçêÇ

oÉîK a~íÉ oÉã~êâë

F 30 Sep 2014 Updated version, polar waters recommendations added, recom-

mended install and EMC conditons added, spare parts amended.

E 11 Nov 2013 Factory setting menu (technical pages) amended, service setup 2

amended, installation procedure and power-up function test amended.

D 11 Sep 2013 Updated version, new service setup options (Course Bus, THS/HDT,

ROT filter) added; technical data amended, checklist procedures

added, spare parts added; chapter removal/installation added.

C 08 May 2008 Added new options (AD10 output, alarm mute relay, speed filter).

B 17 Nov 2006 Removed gyrosphere installation/service instructions. These are now

contained in separate documents delivered with the respective gyro-

sphere and container.

All information regarding the master PCB refers to the new PCB, stock

no. 20672.

A 18 Jan 2005 Initial release.

k^sfd^q u jh N MRSPQPLc

ááá

`çåíÉåíë

p~ÑÉíó=fåëíêìÅíáçåë

p~ÑÉíó=kçíáÅÉ=`çåîÉåíáçåëKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK îáá

ÉåÉê~ä=p~ÑÉíó=fåÑçêã~íáçå=Ñçê=íÜÉ=léÉê~íçê KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK îááá

ÉåÉê~ä=p~ÑÉíó=fåÑçêã~íáçå=Ñçê=pÉêîáÅÉ=mÉêëçååÉäKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK ñááá

`Ü~éíÉê=NW fåíêçÇìÅíáçå

NKN póëíÉã=aÉëÅêáéíáçåKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK NJN

fåíÉåÇÉÇ=rëÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKNJN

kçí=fåíÉåÇÉÇ=rëÉKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKNJN

NKO póëíÉã=lîÉêîáÉï=~åÇ=j~áå=`çãéçåÉåíë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK NJO

i~ÄÉä=~åÇ=íóéÉ=ä~ÄÉä KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKNJP

j~áå=ÅçãéçåÉåíë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKNJQ

NKP aÉëáÖå=~åÇ=j~áå=cÉ~íìêÉëKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK NJS

NKQ léÉê~íáåÖ=mêáåÅáéäÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK NJT

eÉ~ÇáåÖ=bêêçê=i~íáíìÇÉ=`çêêÉä~íáçå KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKNJ

NKR bñ~ãéäÉ=póëíÉã=`çåÑáÖìê~íáçåë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKNJNN

pí~åÇ~äçåÉ=dóêçÅçãé~ëëLqj`=póëíÉã KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK NJNN

aì~ä=k^sfd^q u jh N=dóêçÅçãé~ëëLqj`=póëíÉã KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKNJNO

NKS qÉÅÜåáÅ~ä=a~í~KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK NJNP

^ÅÅìê~ÅáÉëKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKNJNP

léÉê~íáçå~ä=`Ü~ê~ÅíÉêáëíáÅë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKNJNP

båîáêçåãÉåí~ä=oÉèìáêÉãÉåíëKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKNJNP

mçïÉê=pìééäó KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKNJNQ

aáãÉåëáçåë=~åÇ=tÉáÖÜíKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKNJNR

fåéìíë=L=lìíéìíë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKNJNR

NKT j~êáåÉ=bèìáéãÉåí=aáêÉÅíáîÉ=b`=aÉÅä~ê~íáçå=çÑ=`çåÑçêãáíóKKKKKKKKKKKKKKKK NJNT

`Ü~éíÉê=OW léÉê~íáçå

OKN léÉê~íáåÖ=`çåÇáíáçåë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJN

OKO aáëéä~ó=~åÇ=léÉê~íáåÖ=hÉóë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJO

`çåíêçä=~åÇ=aáëéä~ó=råáí=E`arF KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJO

OKP bñíÉêå~ä=`çåíêçä=aÉîáÅÉë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJP

OKQ mçïÉêJìé=pÉèìÉåÅÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJQ

OKR pÉäÉÅíáåÖ=íÜÉ=^ÅíáîÉ=eÉ~ÇáåÖ=pçìêÅÉKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJR

OKS ^ÇàìëíáåÖ=íÜÉ=aáëéä~ó=_êáÖÜíåÉëë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJS

OKT léíáçå~ä=cìåÅíáçåëKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJS

jìíáåÖ=^ä~êãë=oÉãçíÉäó KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJS

oÉîÉêëáåÖ=íÜÉ=eÉ~ÇáåÖ=aáëéä~ó=ENUMø=çÑÑëÉíFKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJS

oÉëÉííáåÖL^ÅâåçïäÉÇÖáåÖ=~=`Éåíê~ä=t~íÅÜ=^ä~êã KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJS

OKU léÉê~íáåÖ=jÉåì KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJT

båíÉêáåÖ=~åÇ=nìáííáåÖ=íÜÉ=j~áå=jÉåìKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJT

k~îáÖ~íáåÖ=íÜÉ=jÉåìKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJT

MRSPQPLc k^sfd^q u jh N

áî

pÉäÉÅíáåÖ=m~ê~ãÉíÉê=pÉííáåÖë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJU

bÇáíáåÖ=m~ê~ãÉíÉê=s~äìÉë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJU

OKV pÉäÉÅíáåÖ=~=aáëéä~ó=a~í~=m~ÖÉKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJV

OKNM j~åì~ä=pÉííáåÖë=jÉåì KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJNM

`~éíáçå=Ñçê=pÉäÉÅíáåÖ=~åÇ=bÇáíáåÖ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJNM

j~åì~ä=pÉííáåÖë=Ó=lîÉêîáÉï KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKOJNN

j~åì~ä=pÉííáåÖë=Ó=m~ê~ãÉíÉêë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJNP

OKNN rëÉê=pÉíìé KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJNT

rëÉê=pÉíìé=Ó=lîÉêîáÉï KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJNT

rëÉê=pÉíìé=Ó=m~ê~ãÉíÉêë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK OJNU

`Ü~éíÉê=PW bêêçêë=~åÇ=^ä~êãë

PKN ^ä~êã=fåÇáÅ~íáçå KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK PJN

^ìÇáÄäÉ=^ä~êã=fåÇáÅ~íáçåKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK PJN

sáëì~ä=^ä~êã=fåÇáÅ~íáçå KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK PJN

PKO ^ÅâåçïäÉÇÖáåÖ=^ä~êãëLjìíáåÖ=íÜÉ=^ìÇáÄäÉ=^ä~êã KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK PJO

^ä~êã=^ÅâåçïäÉÇÖÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK PJO

^ä~êã=jìíÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK PJO

PKP bêêçê=ãÉëë~ÖÉë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK PJP

`Ü~éíÉê=QW pÅÜÉÇìäÉÇ=j~áåíÉå~åÅÉ

QKN j~áåíÉå~åÅÉ=çÑ=íÜÉ=k^sf ^q=u=jh=N KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK QJN

`äÉ~åáåÖ=çÑ=`çãé~ëë=eçìëáåÖ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK QJN

`äÉ~åáåÖ=çÑ=^áê=fåäÉí=dêáääKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK QJN

QKO óêçëéÜÉêÉ=j~áåíÉå~åÅÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK QJO

NUJjçåíÜ=j~áåíÉå~åÅÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK QJO

dóêçëéÜÉêÉ=oÉéä~ÅÉãÉåí=L=cáîÉJvÉ~ê=j~áåíÉå~åÅÉKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK QJP

`Ü~éíÉê=RW mêÉîÉåíáîÉ=j~áåíÉå~åÅÉ

RKN mêçíÉÅíáåÖ=íÜÉ= óêçëéÜÉêÉ=Ñêçã=a~ã~ÖÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK RJN

dóêçëéÜÉêÉ=a~ã~ÖÉ=Å~ìëÉÇ=Äó=içï=qÉãéÉê~íìêÉë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK RJN

dóêçëéÜÉêÉ=a~ã~ÖÉ=íÜêçìÖÜ=pÜìí=açïå KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK RJO

RKO oÉãçîáåÖ=íÜÉ= óêçëéÜÉêÉ=`çåí~áåÉê=Ñêçã=íÜÉ=`çãé~ëë=eçìëáåÖ KKKKKK RJP

RKP fåëí~ääáåÖ=íÜÉ= óêçëéÜÉêÉ=`çåí~áåÉê=áå=íÜÉ=`çãé~ëë=eçìëáåÖKKKKKKKKKKKKK RJS

RKQ mçïÉêJìé=cìåÅíáçå=qÉëíKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK RJV

dóêçëéÜÉêÉ=`ìêêÉåí=mêÉäáãáå~êáÉë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK RJ

m~êíëI=ã~íÉêá~äë=~åÇ=íççäë=êÉèìáêÉÇKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK RJNM

mêçÅÉÇìêÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK RJNM

`Ü~éíÉê=SW oÉãçî~äLfåëí~ää~íáçå=çÑ=`çãéçåÉåíë

SKN oÉãçîáåÖ=póëíÉã=`çãéçåÉåíë=Ñêçã=íÜÉ=`çãé~ëë=KKKKKKKKKKKKKKKKKKKKKKKKKKKKK SJN

mêçÅÉÇìêÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK SJO

SKO fåëí~ääáåÖ=póëíÉã=`çãéçåÉåíë=áåíç=íÜÉ=`çãé~ëëKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK SJV

mêçÅÉÇìêÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK SJ

k^sfd^q u jh N MRSPQPLc

î

`Ü~éíÉê=TW póëíÉã=fåëí~ää~íáçå

TKN fåëí~ääáåÖ=oÉÅçããÉåÇ~íáçåë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJN

mä~ÅÉ=çÑ=fåëí~ää~íáçå KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJN

sÉåíáä~íáçå=L=qÉãéÉê~íìêÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJN

bäÉÅíêçã~ÖåÉíáÅ=fåíÉêÑÉêÉåÅÉKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJN

sáÄê~íáçå KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJO

TKO jÉÅÜ~åáÅ~ä=fåëí~ää~íáçåKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJP

qê~åëéçêíáåÖ=íÜÉ=`çãé~ëë=eçìëáåÖ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJP

fåëí~ääáåÖ=íÜÉ=`çãé~ëë=eçìëáåÖ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJP

TKP bäÉÅíêáÅ~ä=fåëí~ää~íáçå KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJQ

^`=pìééäó=mçïÉê=`çåÑáÖìê~íáçå KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJQ

táêáåÖ=ré=íÜÉ=póëíÉã KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJR

TKQ óêçëéÜÉêÉ=fåëí~ää~íáçå KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJS

TKR fåáíá~ä=póëíÉã=`çåÑáÖìê~íáçå KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJT

`çåÑáÖìê~íáçå=çÑ=íÜÉ=póëíÉã KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJT

cáå~äáòáåÖ=íÜÉ=fåëí~ää~íáçå KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJU

TKS ^äáÖåãÉåí=bêêçê=`çêêÉÅíáçå KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJV

TKT j~ÖåÉíáÅ=`çãé~ëë=`~äáÄê~íáçåKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKTJNM

TKU fåëí~ää~íáçå=`ÜÉÅâ=mêçÅÉÇìêÉëKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK TJNP

jÉÅÜ~åáÅ~ä=fåëí~ää~íáçå=`ÜÉÅâ=mêçÅÉÇìêÉKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKTJNP

bäÉÅíêáÅ~ä=fåëí~ää~íáçå=`ÜÉÅâ=mêçÅÉÇìêÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKTJNP

båîáêçåãÉåí~ä=`çåÇáíáçåë=`ÜÉÅâ=mêçÅÉÇìêÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKTJNQ

póëíÉã=`çåÑáÖìê~íáçå=`ÜÉÅâ=mêçÅÉÇìêÉKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKTJNQ

`Ü~éíÉê=UW póëíÉã=`çåÑáÖìê~íáçå

UKN `çåÑáÖìê~íáçå=jÉåì=J=pÉêîáÅÉ=pÉíìé=NKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK UJN

pÉíìé=^ÅÅÉëë=`çÇÉKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK UJN

pÉêîáÅÉJpÉíìé=N=Ó=lîÉêîáÉïKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK UJO

pÉêîáÅÉ=pÉíìé=N=Ó=m~ê~ãÉíÉêëKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK UJS

UKO pÉêîáÅÉ=fåÑç=jÉåì=J=pÉêîáÅÉ=pÉíìé=O KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK UJOM

pÉêîáÅÉ=pÉíìé=O=Ó=^ÅÅÉëë=`çÇÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK UJOM

pÉêîáÅÉ=pÉíìé=O=Ó=lîÉêîáÉïKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK UJON

pÉêîáÅÉ=pÉíìé=O=Ó=m~ê~ãÉíÉêëKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK UJOO

UKP c~Åíçêó=pÉííáåÖë=jÉåì=EqÉÅÜåáÅ~ä=m~ÖÉëF KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK UJOQ

pÉíìé=^ÅÅÉëë=`çÇÉKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK UJOQ

qÉÅÜåáÅ~ä=m~ÖÉë=Ó=lîÉêîáÉï KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK UJOQ

qÉÅÜåáÅ~ä=m~ÖÉë=Ó=m~ê~ãÉíÉêë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK UJOR

`Ü~éíÉê=VW qêçìÄäÉëÜççíáåÖ

VKN qêçìÄäÉëÜççíáåÖ=fåëíêìÅíáçåë KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK VJN

VKO içÅ~íáçå=çÑ=m~êíë=çå=íÜÉ=j~ëíÉê=m`_ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK VJO

bñÅÜ~åÖÉ~ÄäÉ=`çãéçåÉåíëKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK JP

`çååÉÅíçêëKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK JP

qÉëí=oÉëáëíçê=L=qêáãéçíëKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK JQ

aá~ÖåçëíáÅ=ibaëKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK JQ

MRSPQPLc k^sfd^q u jh N

îá

`Ü~éíÉê=NMW `çêêÉÅíáîÉ=j~áåíÉå~åÅÉ

NMKN bñÅÜ~åÖáåÖ=íÜÉ=póëíÉã=pçÑíï~êÉ KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK NMJN

NMKO oÉéä~ÅáåÖ=pçÅâÉíÉÇ=f`ëKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK NMJO

`Ü~éíÉê=NNW k^sf ^q u=jhN=pé~êÉ=m~êíë

NNKN fääìëíê~íÉÇ=m~êíë=iáëí=EfmiF=lîÉêîáÉï KKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKKK NNJN

^ÄÄêÉîá~íáçåë

^ééÉåÇáñ

^ pÉíìé=~åÇ=`çåÑáÖìê~íáçå=q~ÄäÉë

_ aê~ïáåÖë

k^sfd^q u jh N MRSPQPLc

p~ÑÉíó=fåëíêìÅíáçåë îáá

p~ÑÉíó=fåëíêìÅíáçåë

p~ÑÉíó=kçíáÅÉ=`çåîÉåíáçåë

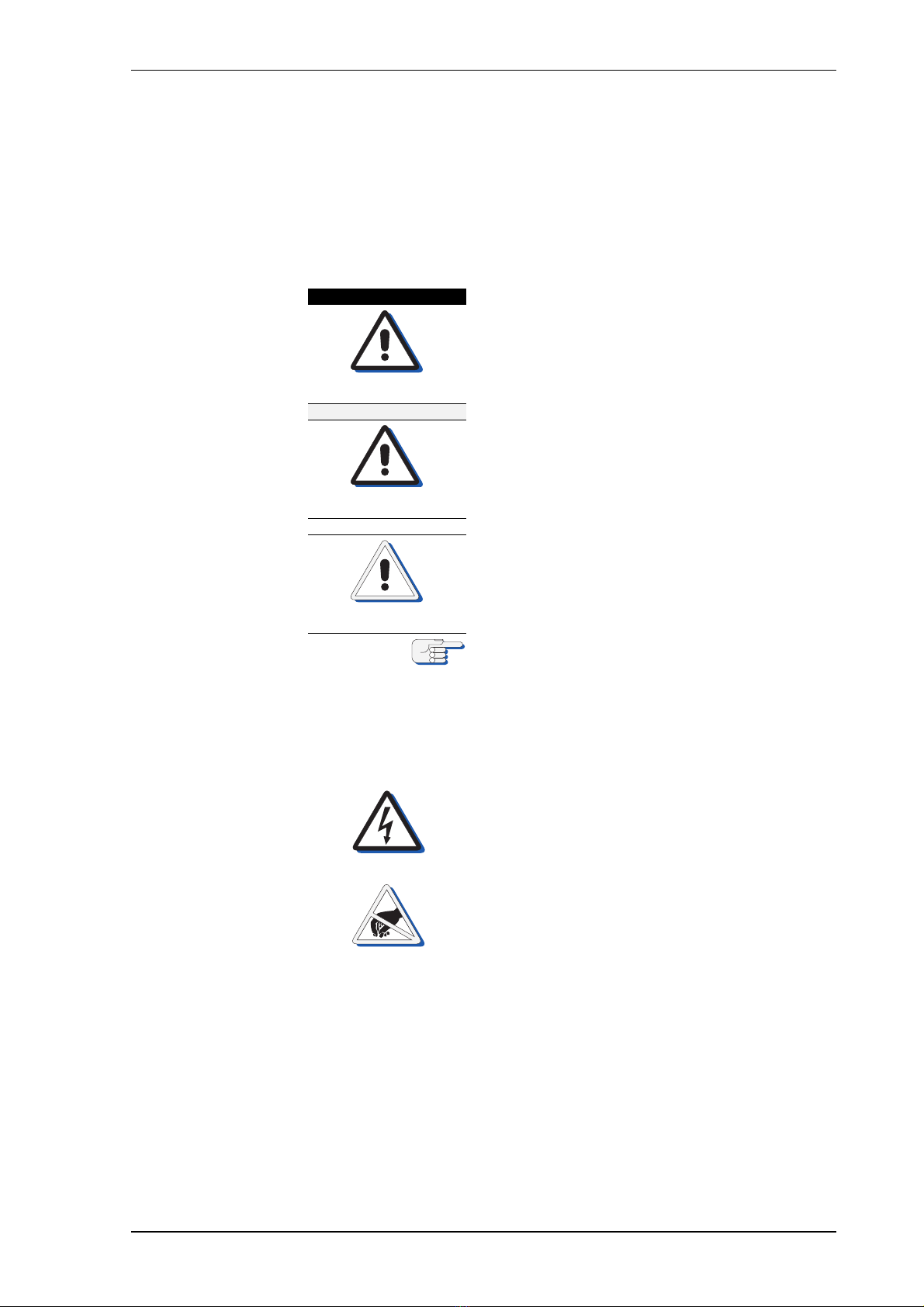

The following safety notice conventions are followed throughout this

manual:

a^k bo

A a~åÖÉê notice begins with the named type of

danger and contains an operating or mainte-

nance procedure, practice, condition, statement,

etc., which, if not strictly observed, ïáää=êÉëìäí=áå=

áåàìêó=çê=ÇÉ~íÜ=çÑ=éÉêëçååÉäK

t^okfk

A t~êåáåÖ notice begins with the named type of

warning and contains an operating or mainte-

nance procedure, practice, condition, statement,

etc., which, if not strictly observed, ÅçìäÇ=êÉëìäí=

áå=áåàìêó=çê=ÇÉ~íÜ=çÑ=éÉêëçååÉäK

`^rqflk

A `~ìíáçå notice begins with the named type of

caution and contains an operating or mainte-

nance procedure, practice, condition, statement,

etc., which, if not strictly observed, ÅçìäÇ=êÉëìäí=

áå=Ç~ã~ÖÉ=íçI=çê=ÇÉëíêìÅíáçå=çÑ=ÉèìáéãÉåíK

kçíÉ

A kçíÉ contains an essential operating or main-

tenance procedure, condition or statement,

which is considered important enough to be

highlighted.

Special safety symbols may be used in this

manual to indicate:

oáëâ=çÑ=ÉäÉÅíêáÅ~ä=ëÜçÅâK

Used in conjunction with a a~åÖÉê or t~êåáåÖ

notice.

Electrical components sensitive to electrostatic

discharge.

Used in conjunction with a `~ìíáçå notice.

MRSPQPLc k^sfd^q u jh N

îááá p~ÑÉíó=fåëíêìÅíáçåë

ÉåÉê~ä=p~ÑÉíó=fåÑçêã~íáçå=Ñçê=íÜÉ=léÉê~íçê

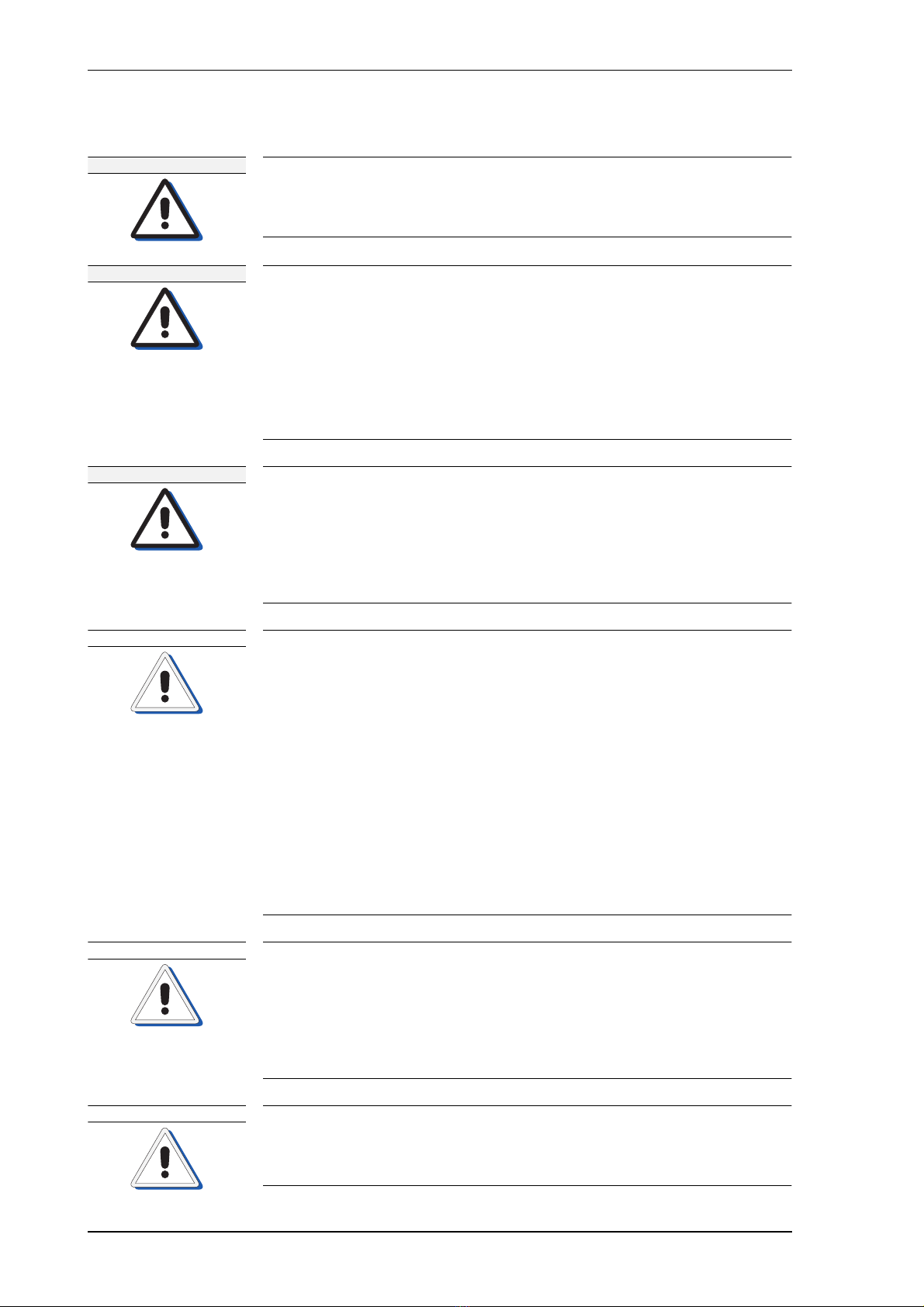

t^okfk

oáëâ=çÑ=ÇÉîá~íáçå

kÉîÉê=êÉäó=çå=çåÉ=ÜÉ~ÇáåÖ=ëçìêÅÉ=~äçåÉ=íç=å~îáÖ~íÉ=~=îÉëëÉäK

^äï~óë=ÅçåÑáêã=íÜÉ=éä~ìëáÄáäáíó=çÑ=íÜÉ=k^sf ^q u jh N=ÜÉ~ÇáåÖ=~åÇ=íÜÉ=

ëéÉÉÇ=~åÇ=éçëáíáçå=áåéìí=Ç~í~=~Ö~áåëí=~ää=~î~áä~ÄäÉ=~áÇë=íç=å~îáÖ~íáçåK

t^okfk

iáãáíÉÇ=ÜÉ~ÇáåÖ=Ç~í~=~ÅÅìê~Åó=ÇìêáåÖ=ëÉííäáåÖ=íáãÉ

^ÑíÉê=~=éçïÉêJìé=Ñêçã=ÅçäÇI=íÜÉ=k^sf ^q u jh N=êÉèìáêÉë=~=ëÉííäáåÖ=íáãÉ=

çÑ=íÜêÉÉ=Üçìêë=ÄÉÑçêÉ=êÉäá~ÄäÉ=ÜÉ~ÇáåÖ=Ç~í~=áë=~î~áä~ÄäÉK

mçïÉê=ìé=íÜÉ=ëóëíÉã=~í=äÉ~ëí=íÜêÉÉ=Üçìêë=ÄÉÑçêÉ=äÉ~îáåÖ=Ü~êÄçìêK

mçïÉê=Ççïå=íÜÉ=ëóëíÉã=ÇìêáåÖ=äçåÖ=ÇçÅâáåÖ=éÉêáçÇë=çåäóK

j~âÉ=ëìêÉ=íÜ~í=íÜÉ=k^sf ^q u jh N=Ü~ë=ëÉííäÉÇ=ÄÉÑçêÉ=ìëáåÖ=áíë=ÜÉ~ÇáåÖ=

~ë=íÜÉ=êÉÑÉêÉåÅÉ=Ñçê=ÜÉ~ÇáåÖ=Åçåíêçä=ëóëíÉãëI=o^a^oI=b`afpI=ÉíÅK

^=ã~ÖåÉíáÅ=Åçãé~ëë=ÜÉ~ÇáåÖ=ëçìêÅÉ=ëÜçìäÇ=ÄÉ=ëÉäÉÅíÉÇ=~ë=êÉÑÉêÉåÅÉ=

çåäó=áå=Å~ëÉ=çÑ=Ñ~áäìêÉ=çÑ=íÜÉ=ÖóêçÅçãé~ëëEÉëFK

t^okfk

oáëâ=çÑ=ãáëìë~ÖÉ

_ÉÑçêÉ=ìëáåÖ=íÜÉ=k^sf ^q u jh NI=çéÉê~íçêë=ãìëí=ÄÉ=~ééêçéêá~íÉäó=

íê~áåÉÇ=~åÇ=Ñ~ãáäá~ê=ïáíÜ=~ää=çéÉê~íáåÖ=éêçÅÉÇìêÉë=~åÇ=ë~ÑÉíó=áåëíêìÅJ

íáçåë=Åçåí~áåÉÇ=áå=íÜáë=ã~åì~äK=qÜÉ=ã~åì~ä=áë=íç=ÄÉ=ÅçãéäÉíÉäó=êÉ~Ç=

ÄÉÑçêÉ=íÜÉ=Ñáêëí=ìë~ÖÉ=çÑ=íÜÉ=k^sf ^q u jh NK

hÉÉé=íÜáë=ã~åì~ä=ÇìêáåÖ=íÜÉ=ÉåíáêÉ=ëÉêîáÅÉ=äáÑÉ=çÑ=íÜÉ=éêçÇìÅí=~åÇ=~äï~óë=

Ü~îÉ=áí=êÉ~Çáäó=~î~áä~ÄäÉ=áå=~=åÉ~êÄó=äçÅ~íáçå=Ñçê=êÉÑÉêÉåÅÉK

`^rqflk

Risk of damage/destruction through low temperatures

The supporting fluid in the gyrosphere container will start freezing at

temperatures below 0° C.

The NAVIGAT X MK 1 must no longer be operated when the ambient tem-

perature at the gyrocompass’ location falls below - 10° C while the com-

pass is in operation or when the ambient temperature falls below 0° C

while the gyrocompass is not in operation.

Always make sure, that the ambient temperature is higher than 0° C

respective 10° C. If this is not possible, the gyrosphere container with

gyrosphere must be removed from the NAVIGAT X MK 1 and transported

to a place with sufficient ambient temperature.

Make sure to remove the gyrosphere from the gyrosphere container if no

place with sufficient ambient temperature is available to eliminate dam-

age from freezing supporting fluid. The removal is to be executed in a

service work procedure by authorized service personnel only.

`^rqflk

Risk of damage through rotating masses

After power-down of the compass system, the gyroscopes need at least

45 minutes to stop rotating. Opening the container or draining off the

supporting fluid during rotating will damage the gyrosphere.

Wait at least 45 minutes after power-down of the compass system and

make sure, that the gyroscopes have stopped rotating before opening the

container or draining off the supporting fluid.

`^rqflk

Risk of damage through inadequate cleaning solvents

Do not clean the compass housing with organic solvents, acetone or any

other substance which could damage or discolour plastic.

Use only soapy water or a mild detergent to clean the compass housing.

k^sfd^q u jh N MRSPQPLc

p~ÑÉíó=fåëíêìÅíáçåë áñ

`^rqflk

Risk of damage through overheating

A polluted or clogged air inlet grill located at the back side of the compass

housing will decrease the functionality of the cooling fan and cause over-

heating of the gyrocompass.

Always maintain the required distances around the compass housing to

enable sufficient air supply and full cooling fan functionality.

Make sure to regularly clean the air inlet grill from dust and dirt and check

the fan functionality to avoid overheating.

`^rqflk

Risk of damage through unauthorized service

Any service and installation work on the gyrosphere is to be carried out

by authorized service personnel only.

Never undertake service or installation work if unskilled for the certain

procedure.

`^rqflk

Risk of damage through unauthorized service

Only authorized service personnel is allowed to remove the gyrosphere

from the gyrosphere container.

Always keep to the mandatory safety requirements and the correct serv-

ice work procedure to remove the gyrosphere from the gyrosphere con-

tainer.

`^rqflk

Risk of damage through unauthorized service

Only authorized service personnel is allowed to remove gyrocompass

system components from the compass housing.

Always keep to the mandatory safety requirements and the correct serv-

ice work procedures to remove gyrocompass system components from

the compass housing.

`^rqflk

Risk of damage to the gyrosphere

The gyrosphere is always to be transported in its carrying box in the orig-

inal transport container.

Do not throw or drop the transport container.

The transport container is to be transported in an upright position only.

`^rqflk

Risk of damage to the gyrosphere

Carry the carrying box containing the gyrosphere by hand only and han-

dle it with extreme care.

Remove the gyroshpere from the carrying box only if required for imme-

diate installation.

`^rqflk

Risk of data loss through shutdown of the compass / power-off condition

After a shutdown of the compasses main and backup power supplies it

cannot be guaranteed that all menu settings remain stored unchanged.

Always check whether the shaft correction angle and alignment error cor-

rection values are noted correctly in the setup tables, before switching-

off the power supplies, see “Setup and Configuration Tables” on page A-

1 Appendix.

Always make sure to separately note the shaft correction angle and align-

ment error correction values before switching-down the compass for

maintenance or repair purposes.

MRSPQPLc k^sfd^q u jh N

ñ p~ÑÉíó=fåëíêìÅíáçåë

`^rqflk

Risk of defective gyrosphere caused by “GYRO FAILURE”

Should a “GYRO FAILURE” alarm occur during power-up, the compass

is not working properly.

De-energize the system and visually check the connections to the gyro-

sphere, the follow-up step motor and the shaft encoder.

If the failure reoccurs when the compass is powered-up again, the instal-

lation has not been carried out correctly or the gyrosphere is defective

and must be replaced.

`^rqflk

Risk of defective gyrosphere

The gyrosphere may not be in operable working condition, if after a time

period of around 45 minutes after power-up the gyrosphere current has

not dropped below 320 mA.

If a visual inspection reveals no obvious cause of malfunction, the power-

up cycle of the gyrosphere must be completely repeated.

If after a time period of around 45 minutes after the second power-up

cycle the gyrosphere current has still not dropped below 320 mA, the

gyrosphere may not be in operable working condition.

Contact the Sperry Marine Service for advice.

`^rqflk

Risk of misleading gyrosphere data / operating values

The temperature and gyrosphere current values are indicated as reading

values at the CDU only.

Both values can be adjusted via correction values, which are set to neu-

tral (= no correction) values by default.

Therefore the indicated values may deviate from real gyrosphere operat-

ing values, which can only be measured at the required checkpoints by

authorized service personnel.

`^rqflk

Risk of inadequate correction values

Any wrongful or not instructed adjustment of the temperature and gyro-

sphere correction values will falsify a correct identification of the

NAVIGAT X MK 1 system‘s operating conditions.

Only authorized service personnel is allowed to change the temperature

and gyrosphere current correction values.

Never alter the correction values unless specifically instructed by Sperry

Marine.

`^rqflk

Risk of inadequate testing / test values

The usage of any voltmeter NOT true RMS for testing will falsify the test

results.

The usage of a multimeter true RMS is absolutely mandatory.

Newer use a voltmeter not true RMS for testing purposes.

`^rqflk

Risk of damage through inadequate operating conditions

Inadequate operating conditions such as e.g. ambient over temperature

or inadequate ventilation, can damage the gyrocompass and decrease

the system performance and the longevity of the system components.

Always keep to the recommended install and environmental conditions

to ensure trouble free operation and best performance of the gyrocom-

pass. Always maintain adequate ventilation at install place.

Additional ventilation may become necessary to meet required ambient

environmental conditions for best performance and system longevity.

k^sfd^q u jh N MRSPQPLc

p~ÑÉíó=fåëíêìÅíáçåë ñá

`^rqflk

Risk of unstable/unreliable heading in polar waters

When operating the vessel in polar waters, the heading information of

the gyrocompass may become unstable/unreliable resulting in possible

deviation.

For safe steering in polar waters, the heading information of the gyro-

compass may therefore NOT be used for navigation and heading infor-

mation of a GNSS (Global Navigation Satellite System) compass be

preferred instead.

kçíÉ

The definition of polar waters follows E190E IMO Guidelines for ships

operating in polar waters and is illustrated in

‘Polar Waters Definition” on page 1-9.

`^rqflk

Risk of damage to the gyrosphere through shut-down

A shut down of the NAVIGAT X MK 1 system, while the vessel is navigat-

ing, will damage the gyrosphere, as the gyrosphere is only self protected

against physical damage, as long as the system is running.

NEVER shut down the NAVIGAT X MK 1, while the vessel is navigating.

A shut down of the NAVIGAT X MK 1 system for good reason is only pos-

sible when the ship is NOT navigating.

kçíÉ

Sperry Marine requires to NOT shut down the NAVIGAT X MK 1 system

as long as the vessel is navigating, even when operating in polar waters

with possible unstable/unreliable heading.

`^rqflk

Risk of damage through overheating

A polluted or clogged air inlet grill located at the back side of the compass

housing will decrease the functionality of the cooling fan and cause over-

heating of the gyrocompass.

Always maintain the required distances around the compass housing to

enable sufficient air supply and full cooling fan functionality.

Make sure to regularly clean the air inlet grill from dust and dirt and check

the fan functionality to avoid overheating.

kçíÉ

A visual inspection of cables and connectors of the gyrocompass should

be carried out regularly to detect any signs of damage or deterioration.

kçíÉ

This Operation, Installation and Service Manual 056343 applies only for

NAVIGAT X MK 1 systems with the new type master PCB and the PCB

transformer on the rear side.

For NAVIGAT X MK 1 systems with the old type master PCB and the PCB

transformer on the front side, only the Operation, Installation and Service

Manual 056310 is applicable.

kçíÉ

In case a „Speed Invalid“ alarm is triggered while the vessel is not in

motion or moving very slowly (e.g. when manoeuvring in harbour), this

is often caused by fast currents of fairway water increasing the - 5.0 kn

minimum speed default value.

In this case, the minimum speed value must be adjusted accordingly.

MRSPQPLc k^sfd^q u jh N

ñáá p~ÑÉíó=fåëíêìÅíáçåë

kçíÉ

The access code for the setup menu to reset the gyrosphere operation

time counter is disclosed to authorized service personnel only and is not

described in this manual.

kçíÉ

Sperry Marine Service:

In case of service refer to www.sperrymarine.com/offices for a list of all

Sperry Marine Offices and Service Agents worldwide.

k^sfd^q u jh N MRSPQPLc

p~ÑÉíó=fåëíêìÅíáçåë ñááá

ÉåÉê~ä=p~ÑÉíó=fåÑçêã~íáçå=Ñçê=pÉêîáÅÉ=mÉêëçååÉä

a^k bo

iáÑÉ=Ç~åÖÉê=íÜêçìÖÜ=ÉäÉÅíêáÅ~ä=ëÜçÅâ

tÜÉå=íÜÉ=Åçãé~ëë=áë=ÉåÉêÖáòÉÇI=íÜÉ=ÖóêçëéÜÉêÉ=çéÉê~íáåÖ=îçäí~ÖÉ=çÑ=

NMM=s^`=]=PPT=eò=áë=éêÉëÉåí=çå=íÜÉ=ã~ëíÉê=m`_I=íÜÉ=ÖóêçëéÜÉêÉ=ëìééäó=

äáåÉëI=~åÇ=~Åêçëë=íÜÉ=ÖóêçëéÜÉêÉ=Åçåí~ÅíëK=

tÜÉå=íÜÉ=^`=ã~áå=ëìééäó=áë=ëïáíÅÜÉÇ=çåI=Ü~ò~êÇçìë=äáÑÉ=îçäí~ÖÉë=~êÉ=

éêÉëÉåí=~í=íÜÉ=äáåÉ=ÑáäíÉê=~åÇ=íÜÉ=éçïÉê=íê~åëÑçêãÉêÛë=íÉêãáå~äëK

j~âÉ=ëìêÉ=íÜ~í=íÜÉ=ã~áå=~åÇ=Ä~Åâìé=éçïÉê=ëìééäáÉë=çÑ=íÜÉ=Åçãé~ëë=~êÉ=

~äï~óë=ëïáíÅÜÉÇ=çÑÑ=~åÇ=ë~ÑÉÖì~êÇÉÇ=~Ö~áåëí=~ÅÅáÇÉåí~ä=ëïáíÅÜáåÖJçå=

ÄÉÑçêÉ=ìåÇÉêí~âáåÖ=~åó=êÉãçî~ä=çê=áåëí~ää~íáçå=éêçÅÉÇìêÉë=çÑ=íÜÉ=ÖóêçJ

ëéÜÉêÉ=Åçåí~áåÉêK

a^k bo

iáÑÉ=Ç~åÖÉê=íÜêçìÖÜ=ÉäÉÅíêáÅ~ä=ëÜçÅâ

tÜÉå=íÜÉ=Åçãé~ëë=áë=ÉåÉêÖáòÉÇI=íÜÉ=ÖóêçëéÜÉêÉ=çéÉê~íáåÖ=îçäí~ÖÉ=çÑ=

NMM=s^`=]=PPT=eò=áë=éêÉëÉåí=çå=íÜÉ=ã~ëíÉê=m`_I=íÜÉ=ÖóêçëéÜÉêÉ=ëìééäó=

äáåÉë=~åÇ=~Åêçëë=íÜÉ=ÖóêçëéÜÉêÉ=Åçåí~ÅíëK=

tÜÉå=íÜÉ=^`=ã~áå=ëìééäó=áë=ëïáíÅÜÉÇ=çåI=Ü~ò~êÇçìë=äáÑÉ=îçäí~ÖÉë=~êÉ=

éêÉëÉåí=~í=íÜÉ=äáåÉ=ÑáäíÉê=~åÇ=íÜÉ=éçïÉê=íê~åëÑçêãÉêÛë=íÉêãáå~äëK

_É=ÉñíêÉãÉäó=Å~êÉÑìä=ïÜÉå=çéÉê~íáåÖ=íÜÉ=Åçãé~ëë=ïÜáäÉ=íÜÉ=ÜçìëáåÖ=áë=

çéÉåK=kÉïÉê=íçìÅÜ=íÜÉ=ã~ëíÉê=m`_I=íÜÉ=ÅçååÉÅíáåÖ=Å~ÄäÉë=íç=íÜÉ=ÖóêçJ

ëéÜÉêÉ=Åçåí~áåÉê=çê=~åó=çíÜÉê=ÅçåÇìÅíáîÉ=ÅçãéçåÉåíë=çå=íÜÉ=Åçåí~áåÉê=

çê=áå=íÜÉ=Åçãé~ëë=ÜçìëáåÖK

^äï~óë=ÉñÅäìÇÉ=~åó=Åçåí~Åí=íç=ÉåÉêÖáòÉÇ=ÅçãéçåÉåíëK

a^k bo

iáÑÉ=Ç~åÖÉê=íÜêçìÖÜ=ÉäÉÅíêáÅ~ä=ëÜçÅâ

tÜÉå=íÜÉ=^`=ã~áå=ëìééäó=áë=ëïáíÅÜÉÇ=çåI=äáîÉ=îçäí~ÖÉë=~êÉ=éêÉëÉåí=~í=íÜÉ=

äáåÉ=ÑáäíÉê=~åÇ=íÜÉ=éçïÉê=íê~åëÑçêãÉêÛë=íÉêãáå~äëK

tÜÉå=íÜÉ=Åçãé~ëë=áë=ÉåÉêÖáòÉÇ=Eã~áå=~åÇLçê=Ä~Åâìé=ëìééäó=éêÉëÉåíFI=

íÜÉ=ÖóêçëéÜÉêÉ=çéÉê~íáåÖ=îçäí~ÖÉ=çÑ=NMM=s^`=]=PPT=eò=áë=éêÉëÉåí=çå=íÜÉ=

ã~ëíÉê=m`_I=íÜÉ=ÖóêçëéÜÉêÉ=ëìééäó=äáåÉë=~åÇ=~Åêçëë=íÜÉ=ÖóêçëéÜÉêÉ=ÅçåJ

í~ÅíëK

j~âÉ=ëìêÉ=íÜÉ=Åçãé~ëëD=ã~áå=~åÇ=Ä~Åâìé=éçïÉê=ëìééäáÉë=~êÉ=~äï~óë=

ëïáíÅÜÉÇ=çÑÑ=~åÇ=ë~ÑÉÖì~êÇÉÇ=~Ö~áåëí=~ÅÅáÇÉåí~ä=ëïáíÅÜáåÖJçå=ïÜÉå=

ÅçåÑáÖìêáåÖ=íÜÉ=ëóëíÉã=Ñçê=íÜÉ=îÉëëÉäÛë=^`=ëìééäó=îçäí~ÖÉI

`^rqflk

Risk of damage/destruction during transport

The gyrosphere is always to be transported in its carrying box in the orig-

inal transport container.

Do not throw or drop the transport container.

The transport container is to be transported in an upright position only.

Carry the carrying box containing the gyrosphere by hand only and han-

dle it with extreme care. Remove the gyroshpere from the carrying box

only if required for immediate installation.

`^rqflk

Risk of damage to NAVIGAT X MK 1gyrocompass system through

inadequate install and environmental conditions

Inadequate install and environmental conditions can damage the gyro-

compass and decrease the system performance and the longevity of the

system components.

Always keep to the recommended install and environmental conditions

to ensure trouble free operation and best performance of the gyrocom-

pass system.

MRSPQPLc k^sfd^q u jh N

ñáî p~ÑÉíó=fåëíêìÅíáçåë

`^rqflk

Risk of erroneous heading accuracy caused by vibration / resonance

frequencies

The NAVIGAT X MK 1 gyrocompass is a highly sensitive instrument.

Resonance frequencies or vibrations caused by incorrect install position

or install and environmental conditions will badly influence the heading

accuracy.

Always keep to the recommended install and environmental conditions.

Never install the gyrocompass in or close the engine room or any posi-

tion where reasonable vibration / resonance frequencies levels are

exceeded. Always make sure to minimise possible resonance frequen-

cies or vibration causes at install place when installing the gyrocompass.

`^rqflk

Risk of erroneous heading accuracy caused by electromagnetic

interference (EMC)

The NAVIGAT X MK 1 gyrocompass is a highly sensitive instrument.

Electromagnetic interference of other devices or their power lines will

badly influence the heading accuracy.

Always keep to the recommended minimal clearance requirements at

install position of the gyrocompass.

Never install other electronic equipment or high voltage power lines

close to or across the compass housing.

Always make sure to minimise possible electromagnetic interference of

other devices when installing the NAVIGAT X MK 1 gyrocompass.

`^rqflk

Risk of inadequate testing / test values

The usage of any voltmeter NOT true RMS for testing will falsify the test

results.

The usage of a multimeter true RMS is absolutely mandatory.

Newer use a voltmeter not true RMS for testing purposes.

`^rqflk

Risk of damage/destruction after power-down

After power-down of the gyrocompass system, it may take up to

45 minutes for the gyroscopes to stop rotating and the gyrosphere is

therefore extremely sensible against any movement. Should the gyro-

sphere touch the wall of the container, the momentum of the rotating

gyroscopes will make it topple and damage the centre pin.

Avoid any movement of the gyrocompass system during power-down

time. Always be extremely careful in case the gyrosphere container must

be handled during power-down time.

`^rqflk

Risk of damage of electrostatic-discharge-sensitive components

The NAVIGAT X MK 1 contains electrostatic sensitive components.

Electrostatic discharge may permanently damage components.

When servicing the NAVIGAT X MK 1, take considerable precautions to

prevent electrostatic discharge. Avoid touching any of the electronic cir-

cuitry.

`^rqflk

Risk of loss of parameter settings through software exchange

It cannot be guaranteed that parameter settings in the User and Setup

menus and the entries made in the Magnetic Compass Calibration table

are left intact when the software is exchanged.

Before exchanging the system software IC, record all parameter settings

to be able to re-enter them manually, if required.

k^sfd^q u jh N MRSPQPLc

p~ÑÉíó=fåëíêìÅíáçåë ñî

`^rqflk

Risk of malfunction through wrong wiring

Wrong wiring, especially as running wires from one side of the compass

housing to the other or across the master PCB will cause malfunction.

Always use the cable inlets on both sides of the compass housing for

accurate wiring and keep all wires running inside the housing as short as

possible.

Always avoid to run wires from one side of the compass housing across

to the other.

`^rqflk

Risk of earth faults

Wrong wiring of the cable shields makes the cables act as antennas

resulting in earth faults.

Always make sure to correctly draw back the cable shields and fasten the

cables to avoid earth faults.

kçíÉ

In case of earth faults, it is recommended to always check first the cable

wiring for correctly connected cable shields.

`^rqflk

Risk of ROT filter malfunction

The selected ROT filter setting in the manual settings menu needs addi-

tional activation to gain ROT filter functionality

For activating the ROT filter setting in the service setup 1, it is mandatory

to pre-install a wire link at the master PCB TB2 19/20.

kçíÉ

To make sure, that the ROT damping time constant setting for the ana-

logue ROT output becomes effective, check if the mandatory wire link

between the master PCB TB2 19/20 is correctly installed.

`^rqflk

Risk of damage through aggressive cleaning agents

Do not clean the compass with organic solvents, acetone or any other

substance which could damage or discolour plastic.

Only use water and soap or a mild detergent to clean the compass.

`^rqflk

Risk of damage through overheating

A polluted or clogged air inlet grill located at the back side of the compass

housing will decrease the functionality of the fan and cause overheating

of the gyrocompass.

Always maintain the required distances around the compass housing to

enable sufficient air supply and full fan functionality.

Make sure to regularly clean the air inlet grill from dust and dirt and check

the fan functionality to avoid overheating.

`^rqflk

Risk of defective gyrosphere

The gyrosphere may not be in operable working condition, if after a time

period of around 45 minutes after power-up the gyrosphere current has

not dropped below 320 mA.

If a visual inspection reveals no obvious cause of malfunction, the power-

up cycle of the gyrosphere must be completely repeated.

If after a time period of around 45 minutes after the second power-up

cycle the gyrosphere current has still not dropped below 320 mA, the

gyrosphere may not be in operable working condition.

Contact the Sperry Marine Service for advice.

MRSPQPLc k^sfd^q u jh N

ñîá p~ÑÉíó=fåëíêìÅíáçåë

kçíÉ

A visual inspection of cables and connectors of the gyrocompass should

be carried out regularly to detect any signs of damage or deterioration.

kçíÉ

In case a „Speed Invalid“ alarm is triggered while the vessel is not in

motion or moving very slowly (e.g. when manoeuvring in harbour), this

is often caused by fast currents of fairway water increasing the - 5.0 kn

minimum speed default value.

In this case, the minimum speed value must be adjusted accordingly.

kçíÉ

For installation and service procedures of the gyrosphere and gyro-

sphere container, the following separate Installation, Maintenance and

Service Procedures, delivered with the gyrosphere, apply:

- 04911-0125-001, for gyrosphere type 2, gyrosphere container mod. 7/2

- 04911-0125-002, for gyrosphere type 2, gyrosphere container mod. 10/2

- 05000-0125-001, for gyrosphere type 3, gyrosphere container mod. 10/3

- 05000-0125-002, for gyrosphere type 3, gyrosphere container mod. 10/3

with the NAVIGAT X MK 1 in DP vessel application.

kçíÉ

The Shaft Correction Angle of the gyrosphere is a specific value for each

single item and indicated at the right front corner of the baseplate.

kçíÉ

For recording all parameter settings, use the ‘Setup and Configuration

Tables” in the appendix of this manual.

kçíÉ

For recording installation/ overhaul service work, use the

NAVIGAT X MK 1 Installation/Overhaul Checklist & Record Sheet,

04914-0125-10, as appended in this manual.

k^sfd^q u jh N MRSPQPLc

póëíÉã=aÉëÅêáéíáçå NJN

`Ü~éíÉê=NW fåíêçÇìÅíáçå

NKN póëíÉã=aÉëÅêáéíáçå

fåíÉåÇÉÇ=rëÉ

The NAVIGAT X MK 1 is a digital gyrocompass system for the maritime

navigation of vessels and must be operated only from appropriately

trained and educated personnel familiar with all mandatory safety and

operating procedures.

The NAVIGAT X MK 1 provides North-speed error corrected true heading

data as well as rate of turn (ROT) data for the navigation of maritime

vessels.

The NAVIGAT X MK 1 can operate as a standalone system or as part of a

multi gyrocompass system environment (Heading Management Sys-

tem, HMS).

kçí=fåíÉåÇÉÇ=rëÉ

The NAVIGAT X MK 1 and/or the provided true heading and ROT data of

the NAVIGAT X MK 1 are not allowed to be used for the navigation of

inland water vessels and river boats. Any exception to this restriction

must be regulated by specific certification of an entitled organisation or

administration, for further details see certification information under

”Design and Main Features” on page 1-6 and ”Marine Equipment Direc-

tive EC Declaration of Conformity” on page 1-17.

Although the NAVIGAT X MK 1 is a highly accurate system for providing

true heading and ROT data, operators must not rely on it solely as the

only heading source. The plausibility of the NAVIGAT X MK 1 heading

and ROT data and the speed and position input data (as secondary data)

must always be confirmed against all other available aids to navigation.

Since the NAVIGAT X MK 1 system can additionally be used for display-

ing secondary navigation data (speed and position input data) gener-

ated from other connected devices, the operator must not take

displayed secondary data for granted and is obliged to confirm the

validity of secondary data independently.

When navigating in polar waters (according to E190E IMO Guidelines

definition), the heading information of the gyrocompass may become

unstable/unreliable, due to physical principles, resulting in possible

deviation. For safe steering of the vessel in polar waters, the heading

information of the gyrocompass may therefore not be used and heading

information of a GNSS (Global Navigation Satellite System) compass be

preferred instead.

MRSPQPLc k^sfd^q u jh N

NJO póëíÉã=lîÉêîáÉï=~åÇ=j~áå=`çãéçåÉåíë

NKO póëíÉã=lîÉêîáÉï=~åÇ=j~áå=`çãéçåÉåíë

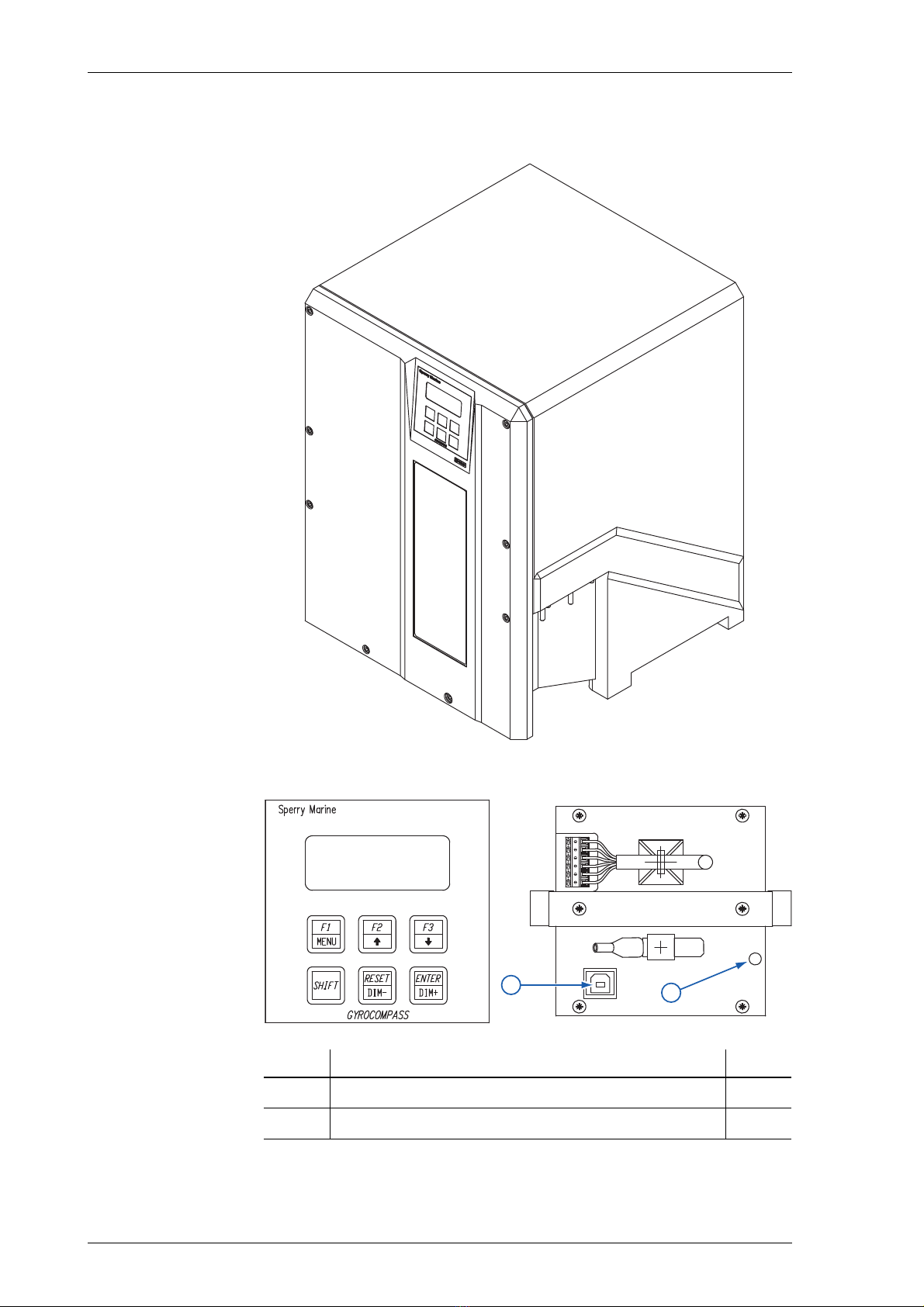

cáÖìêÉ=NJNW

k^sfd^q u jh N=ÜçìëáåÖ

cáÖìêÉ=NJOW

`çåíêçä=~åÇ=Çáëéä~ó=ìåáí

E`arF=Ñêçåí=~åÇ

Ä~Åâ=îáÉï

kçK fíÉã níóK

1USB service interface 1

2Dimmer (CDU display) 1

12

k^sfd^q u jh N MRSPQPLc

póëíÉã=lîÉêîáÉï=~åÇ=j~áå=`çãéçåÉåíë NJP

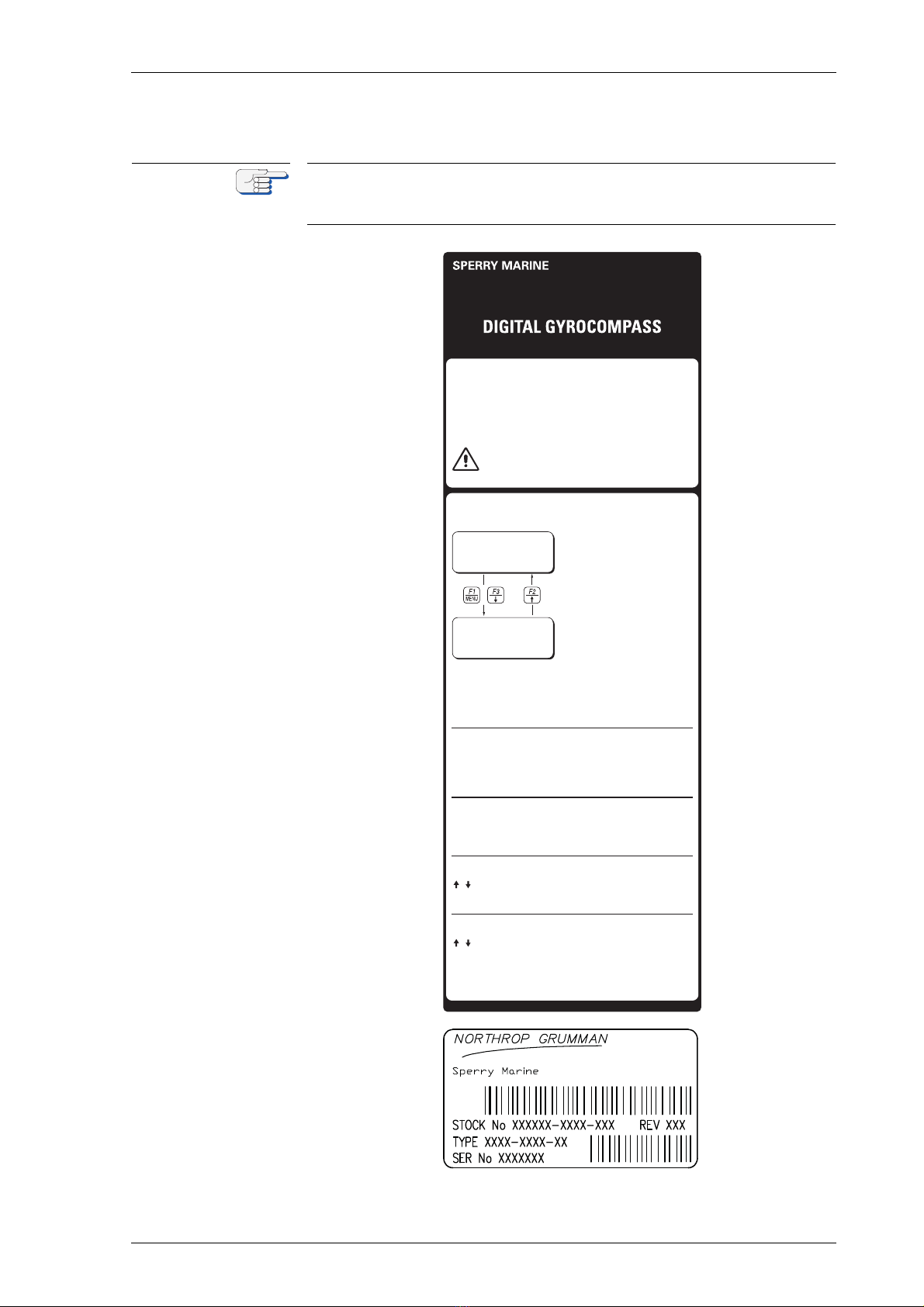

i~ÄÉä=~åÇ=íóéÉ=ä~ÄÉä

cáÖìêÉ=NJPW

k^sfd^q u jh N

ä~ÄÉä

cáÖìêÉ=NJQW

k^sfd^q u jh N

íóéÉ=ä~ÄÉä

kçíÉ

The label at the front door shows the power-up sequence and a quick

guide to the operation menu for a single NAVIGAT X MK 1 gyrocompass

system only.

SHIFT+F1: Display Data

select display data screen

SHIFT+F2: Manual Settings

set operating parameters

SHIFT+F3: Setup Menu

access user and service

setup menus

Energize the gyrocompass.

1) System performs self-test.

2) Main PCB status message is shown.

3) Heading display screen is shown.

After a cold start, the gyrocompass system

requires a settling time of up to three hours

before reliable heading data is produced.

Main Menu Screen

Operation

Heading Display Screen

SHIFT+F1: Gyro 1

select heading reference Gyro 1

SHIFT+F2: Gyro 2

select heading reference Gyro 2

SHIFT+F3: Magnetic Compass

select heading reference Mag.

F2 GYRO 1 271.2°

>F1 GYRO 1 271.3°

F3 MAGN.C. 270.9°

DIFF G1/M 5° ü

MAIN MENU û

F1 DISPLAY DATA

F2 MANUAL SETTINGS

F3 SETUP MENU

/

Setting Display Brightness:

Dim+: brighter

Dim–: darker

On Alarm:

SHIFT+F1: acknowledge alarm (clears error message

from screen and mutes audible alarm)

SHIFT+RESET: mute audible alarm only

Selecting Parameters:

/ : show next / previous option

SHIFT+ENTER: confirm input and go to next line

/ : increase / decrease input value

Dim+ / Dim–: move cursor forward / back

SHIFT+ENTER: confirm input and go to next line

SHIFT+RESET: clear input (value is set to zero)

Entering Data:

WARNING

Power-up Sequence

NAVIGAT X MK 1

26789-B

This manual suits for next models

4

Table of contents

Other SperryMarine Marine Equipment manuals

Popular Marine Equipment manuals by other brands

Garmin

Garmin GPSMAP 8000 Glass Helm Series instruction manual

poly-planar

poly-planar IXM-10 user guide

Furuno

Furuno Color LCD Sounder FCV-620/585 Operator's manual

Teledyne RD Instruments

Teledyne RD Instruments SENTINEL V SELF-CONTAINED Operation manual

Bosch

Bosch FNM-420V-A-WH installation guide

AMEC

AMEC Camino-108 user manual