SPI Westek Counter SPI Instruction Manual

TB-5508 3/06 Page 1 of 2

Counter SPI

Operation, Installation and Maintenance

Distributed by: All-Spec Industries • www.allspec.com • [email protected] • Phone (800) 537-0351 • Fax (800) 379-9903

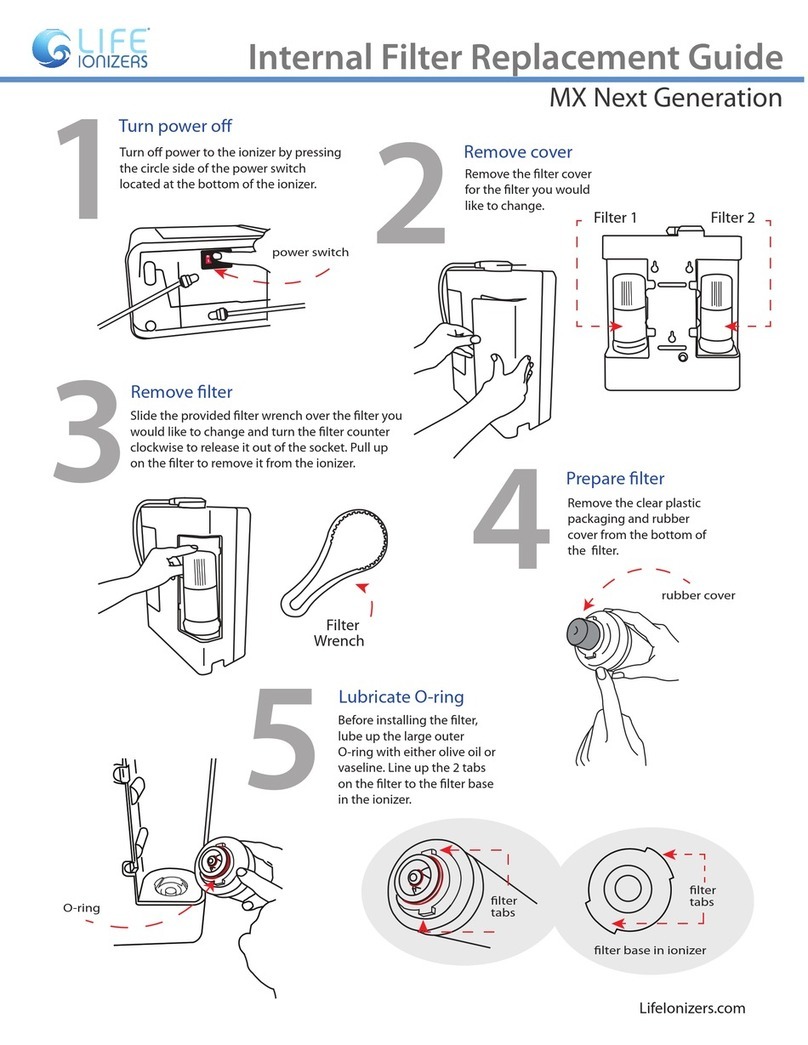

Figure 1. Counter SPI Item 94000

Introduction

The COUNTER SPI is designed to effectively eliminate

localized static charges which exist in the work area.

The Counter SPI is available in two models: Item

94000 is 120 Volt, and item 94001 is 220 Volt. Also

available is item 94002, replacement emitters for the

unit.

HOW TO USE THE COUNTER SPI:

Your COUNTER SPI comes completely balanced and

ready to use.

1. Place your table top unit on a flat, level surface.

2. Plug the COUNTER SPI/WESTEK into any 120V AC

(220V optional) electrical outlet.

3. Turn on/off switch to ON position.

FOR BEST RESULTS:

1. Keep effective area clear and free from obstructions

of ion flow.

2. Position unit so that emitter points are directed

towards area to be ionized.

REMEMBER:

1. Keep work area clear of all static generative

materials.

2. Use only approved static control grounding methods

and material handling equipment.

3. By properly using ionized air, all static potentials in

the work area are greatly reduced, even when

humidity levels decrease.

CAUTION: Care should be exercised during handling

to prevent the unit from falling face down. The delicate

emitter pins will be damaged or broken if this happens.

CLEANING INSTRUCTIONS:

Your Ionizer was designed to be virtually maintenance

free. The emitter points can be cleaned when there is

a visible accumulation of dirt. Generally this would be

twice a year, depending on the cleanliness level of the

working environment.

1. Check the emitter points for dirt accumulation.

2. Be sure the unit is unplugged.

3. Wipe emitter point with a swab dampened in

isopropyl alcohol.

4. The outside case may be wiped down with a soft

damp cloth.

CALIBRATION AND BALANCE VERIFICATION:

The COUNTER SPI is factory set to achieve a

maximum balanced ion output in standard, non-air

assisted applications. To certify calibration, we

recommend EOS/ESD association standard

"EOS/ESD-3.1-1991."

Objective: To observe, test and record performance

levels of ionization units, utilizing readily available

equipment, thereby verifying or certifying calibration.

Equipment Used:

Charged Plate Analyzer (Item 94052)

Procedure:

1. Position the COUNTER SPI 12 inches away from

the 94052 directly facing the unit.

2. With the COUNTER SPI and the 94052 on, adjust

the balance trim pot, located on the lower left side

of the 94000. Balance the 94000 to zero on the

94052. NOTE: there are 3 LEDs located on the

front panel. The one on the left is the on light, the

TECHNICAL BULLETIN TB-5508

Made in America

© 2006 DESCO INDUSTRIES INC.

Employee Owned

other two LEDs are the indicators of the positive and

negative. Note the rate in which the lights switch.

Your unit should be set at a slow rate. Also note

when balancing, the indicator lights, as you offset

the positive and the negative (balance), the on and

off times changes on the lights.

3. Charge the 94052 to 1KV of either polarity ± and

push the decay button. The timer will automatically

time the decay rate. The typical decay is 1,000 to

100 volts in under 60 seconds of both polarities.

There are two adjustments that can be made on the

COUNTER SPI: the BALANCE and the RATE. The

BALANCE of positive and negative ion output can be

adjusted to increase polarity bias by inserting a small

screwdriver through the BALANCE port and slowly

turning the trimpot CLOCKWISE to increase positive

and decrease negative ON time pulses OR COUNTER

CLOCKWISE to increase negative and decrease

positive ON time pulses. The RATE or pulse frequency

can be adjusted down to one pulse per second or up to

5 pulses per second by inserting a small screwdriver

through the RATE port and slowly turning the trimpot

clockwise to increase and counterclockwise to

decrease the frequency.

REMEMBER:

It is important to verify calibration after any adjustments

and before using your COUNTER SPI around sensitive

electronics. Merely repeat above Balance Verification

steps after all adjustments.

Field repairs are not normally encouraged during the

warranty period. Repair attempts by unqualified

personnel may invalidate the warranty.

IMPORTANT:

Your COUNTER SPI ionizer has been designed to

minimize effects of localized charges. If your

processing involves generation of considerable static

charges you may need more aggressive equipment.

SPI has available a complete line of Ionizing Blowers,

Air Guns, Bars and Overhead Room systems to meet

all ionizing requirements.

TB-5508 Page 2 of 2

Distributed by: All-Spec Industries • www.allspec.com • [email protected] • Phone (800) 537-0351 • Fax (800) 379-9903

© 2006 DESCO INDUSTRIES INC.

Employee Owned

Limited Warranty

SPI Westek expressly warrants that for a period of one (1) year

from the date of purchase, SPI Westek Counter SPI Ionizers will

be free of defects in material (parts) and workmanship (labor).

Within the warranty period, the product will be tested, repaired, or

replaced at our option, free of charge. Call our Customer Service

Department at 909-664-9986 for a Return Material Authorization

(RMA) and proper shipping instructions and address. Include a

copy of your original packing slip, invoice, or other proof of

purchase date. Any unit under warranty should be shipped prepaid

to the SPI Westek factory. Warranty repairs will take approximately

two weeks.

If your unit is out of warranty, call Customer Service at 909-664-

9986 for a Return Material Authorization (RMA) and proper

shipping instructions and address. SPI Westek will quote repair

charges necessary to bring your unit up to factory standards.

Warranty Exclusions

THE FOREGOING EXPRESS WARRANTY IS MADE IN LIEU OF

ALL OTHER PRODUCT WARRANTIES, EXPRESSED AND

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE WHICH ARE SPECIFICALLY

DISCLAIMED. The express warranty will not apply to defects or

damage due to accidents, neglect, misuse, alterations, operator

error, or failure to properly maintain, clean or repair products.

Limit of Liability

In no event will SPI Westek or any seller be responsible or liable

for any injury, loss or damage, direct or consequential, arising out

of the use of or the inability to use the product. Before using,

users shall determine the suitability of the product for their

intended use, and users assume all risk and liability whatsoever in

connection therewith.

This manual suits for next models

2