Spicer Consulting SC22 User manual

1 19-Oct-2007

SC22 Magnetic Field Cancelling System

SYSTEM SC22

•

Protects your investment in electron

beam technology by stabilising the

magnetic field environment

•

Cancels and monitors the AC field

•

Low cost, high performance system

•

Intelligent user interface

•

Automated set up

•

Cancels AC fields from 0.5 Hz to 5 kHz

50 x field improvement at 60Hz

•

Full 3 axis (X, Y, Z) system

•

Up to 60 mG (6.0 µT) pk-pk range

•

Adapts to field changes within 100 µs

•

Supports dual sensors for TEMs and

high gradient fields

•

USB monitoring port

Overview

Today’s high performance electron beam tools

are very sensitive to changing ambient magnetic

fields. The fields move the beam causing loss of

resolution and measurement accuracy. The

SC22 system reduces the ambient AC field and

restores the resolution and accuracy.

The SC22 system comprises a Magnetic Field

Control Unit, an AC Magnetic Field Sensor and

three multicore cables, which are installed in the

room where the field is to be cancelled.

Each power amplifier in the control unit drives a

current through its cable to create a field of the

opposite sign to the change in ambient field.

The magnetic field sensor measures the

resulting field and real time negative feedback

reduces the ambient field by the loop gain of the

system.

The system is dynamic, automatically

responding to field changes within 100 µs. AC

Line fields (50/60 Hz) are reduced by 50 x.

The SC22 does not cancel DC field changes

from sources such as elevators, trains and

traffic. The larger SC20 system is available to

cancel both AC and DC fields.

SPICER CONSULTING

SPICER CONSULTING, Eden Laboratory, Broadmead Road, Stewartby, Bedfordshire, England MK43 9ND

Tel: +44 1234 765773 Fax: +44 1234 765778 E-mail: enq@spicerconsulting.com Web: www.spicerconsulting.com

2 19-Oct-2007

Product Description

The SC22 is a fourth generation Magnetic Field

Cancelling System, designed to improve the

performance of electronic instruments that are

sensitive to magnetic fields, such as electron

microscopes and electron beam metrology tools.

The SC22 is a replacement for the SC12 system,

which has an installed base of over 1000 units

world wide.

It is important to note that mechanical vibration,

acoustic noise and ground loops in the electron

beam tool installation can produce imaging

defects similar to magnetic fields. The SC22

cannot improve images which are affected by

these other interfering sources because they are

not magnetic fields.

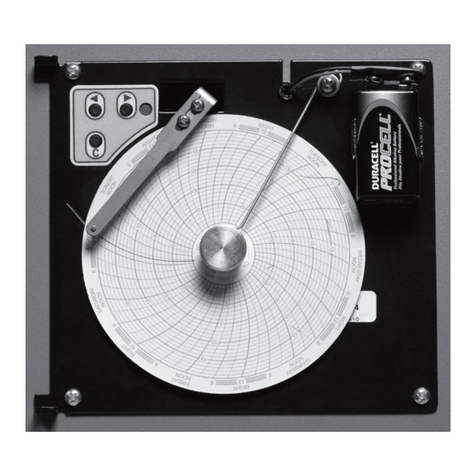

A typical SC22 system installation on an SEM is

shown in Fig. 1. The control unit is not shown.

The cables make one turn and are shown in red,

green and blue. The actual cables are grey and

usually installed in white plastic conduits. Where

the room has a false ceiling, the Z cable is usually

installed above it. The magnetic field sensor is

located close to the bottom of the electron beam

column. An optional mount enables it to be

strapped to the column if required.

The amount by which the field is reduced is

determined by the loop gain of the system, which

is automatically set by the SC22 to 50 times. The

system does not cancel the earth’s DC magnetic

field, nor does it cancel the field everywhere in

Fig. 1 Typical SEM Room Installation

the room. It creates a region around the magnetic

field sensor where the AC field is much reduced.

The volume of this region depends mostly on the

gradient of the ambient field and the positioning

of the field cables.

The SC22 control unit displays the amplitudes of

the X, Y & Z field components and the total

vector field on its LCD panel. Tesla and Gauss

units, RMS & pk-pk can be selected. The

measuring system can resolve 1µG (100 pT) field

changes. The real-time measured fields are

available on front panel BNC’s as analog voltage

levels for oscilloscope display.

The magnetic field amplitude is continuously

monitored and compared with preset “trip levels”

to provide “GO/NOGO” indication of the field

quality. The LCD panel and a small green LED

on the sensor indicate that the field is “OK”.

The SC22 controls are much simpler than the

SC12 and are supervised by the embedded

microcomputer. There are just 3 control buttons

on the front panel. The “units” button enables

choice of the displayed field units. It has no effect

on field cancelling. The “setup” button starts a 4

second program that measures and sets the gain

and phase of the feedback loop. The “cancel/

standby” button turns cancelling on and off.

3 19-Oct-2007

The SC20 Control Unit

Installation options

The SC22 field cancelling cables are made with a

loop and a tail. The loop creates the field and the

tail (which makes no field) connects the loop to

the control unit. The loop parts are shown in Fig.

1 in red, green and blue. SC22 room cables have

X and Y loops 16 metres long and a Z loop 20

metres long. Longer cables are available to

special order.

The Fig. 1 installation is suitable for most SEM

applications where the electron beam column is

typically 1.5 metres from the room walls. The

maximum field which can be cancelled (the

dynamic range) depends on the size and position

of the cable loops relative to the electron beam

column. With 5m x 3m X and Y loops and the

column 1.5m from the walls the dynamic range is

about 25 mG (2.5 µT) pk-pk.

To specify the SC22 performance more

rigorously, we use a reference room cable

installation. This is shown in Fig. 2. The electron

beam column is centred in the 3m x 5m X and Y

loops (which cross over above and below the

column) and the 5m x 5m Z loop. The SC22

specifications on page 6 apply to this reference

room installation.

For leading edge TEM installations, double loop

room sized helmholtz cables are available. These

are recommended for TEM’s fitted with Gatan

Imaging filters (GIF’s). Customers are advised to

consult Spicer Consulting support staff for

design and installation of these special field

cables.

When the room is large or in clean rooms where

there are no local walls, a frame around the

electron beam tool can be used to mount

Helmholtz cables. Fig. 3 shows our current frame

design. A frame limits access to the tool so

should only be used where room cable

installation is not possible. The cancelling

performance with a frame may be inferior to a

room cable installation.

Z FIELD CABLE LOOP

Y FIELD CABLE LOOP

X FIELD CABLE LOOP

CABLE

TAIL(Z)

MAGNETIC FIELD

CONTROL UNIT

E-BEAM

COLUMN

5 METRES

MAGNETIC

FIELD

SENSOR

3 METRES

5 METRES

NOTE: THIS IS A PERSPECTIVE DRAWING.

THE CABLE LOOPS ARE RECTANGULAR AND ORTHOGONAL

Fig. 2. Reference room installation

4 19-Oct-2007

W

INSULATED JOINTS,

ALL 8 PLACES

H

D

A

(ADJUSTABLE

ON SITE)

Y FIELD CABLE

(2 LOOPS) ON

FRAME

Frame is made to order. Customer specifies dimensions H, W, D.

Frame in photo has H=2060, W=1060, D=1060 mm.

Frame is supplied dismantled, for on-site assembly.

Fig. 3 Frame for

Helmholtz Coils

5 19-Oct-2007

Sensor options

The SC22 AC field sensor is shown in Fig. 4 and

on the optional sensor mount in Fig. 5. The sensor

mount is for attaching the sensor to an electron

beam column. Fig. 6 shows a typical installation

on an SEM where the sensor is standing on the

work chamber at the bottom of the column. This

is the most common configuration with one

sensor.

For some applications, there are advantages in

using two sensors. An example is shown in Fig. 7.

When two sensors are used their outputs are

combined by a mixer shown in Fig. 8.

The mixer creates a “virtual sensor” which can

appear to be located inside the column. The mixer

controls enable the apparent position of the sensor

to be adjusted separately for the X, Y, and Z axes

to tune the cancelling system for optimum

improvement in the tool imaging.

AC SENSOR 1 AC SENSOR 2

Fig. 7 Sensors on JEOL TEM

Fig. 4 SC22 AC Sensor

Fig. 6 Sensor on JEOL SEM

Fig. 5 SC22 Sensor mount

Fig. 8 SC22 Mixer

6 19-Oct-2007

Specifications

CO-ORDINATE SYSTEM X, Y, Z rectangular Cartesian

UNITS Gauss, Tesla (switchable)

FIELD CANCELLING

Components cancelled X, Y, Z field components

Dynamic range (X & Y)

(note:1)

60 mG (6 µT) pk-pk (installation Fig. 2)

Dynamic range (Z)

(note:1)

45 mG (4.5µT) pk-pk (installation Fig. 2)

Field cancelling factor 50 X at 50/60 Hz

Bandwidth 0.5 Hz - 5000 Hz

System 1/f noise limit below 0.1Hz < 100 µG (10 nT) pk-pk

System wideband noise limit 1 µG (100pT) RMS 5 Hz - 20 kHz

FIELD MEASUREMENT and MONITORING

Display 3.5 inch LCD TFT colour panel

Measurements displayed X axis field at sensor

(updated every 0.4 secs) Y axis field at sensor

Z axis field at sensor

TOTAL vector field at sensor

Measurement bandwidth 5 Hz -20 kHz

Readout units selectable mG RMS

mG pk-pk

µT RMS

µT pk-pk

nT RMS

nT pk-pk

Display range (reading) X, Y, Z pk-pk 0 - 40.000 mG (0 - 4.0000 µT) (0 - 4000.0 nT)

X, Y, Z RMS 0 - 20.000 mG (0 - 2.0000 µT) (0 - 2000.0 nT)

TOTAL pk-pk 0 - 69.282 mG (0 - 6.9282 µT) ( 0 - 6928.2 nT)

TOTAL RMS 0 - 34.641 mG (0 - 3.4641 µT) ( 0 - 3464.1 nT)

(note: sensor output clip detector displays if pk-pk exceeds 99% of range)

Accuracy

± 1.0 % of reading ± 1µG (100 pT)

Sensor wideband noise limit 1 µG (100pT) RMS

Field OK indicator Green field OK indicator appears when X & Y & Z fields are < 250 µG RMS

Trip indicators X, Y, Z Trip indicator appears if the field on that axis > 250 µG RMS

and disappears after 60 seconds if the field < 250 µG RMS

X, Y, Z REAL TIME FIELD OUTPUTS

Scaling 1.0 V/mG (10V/µT)

Range ± 12 Volts

Source resistance 10 kΩ

Connectors 3 x BNC

Bandwidth 5 Hz - 20 kHz

POWER 120/240 V (+10% -20%) 50/60 Hz , 50 VA

Note 1: Dynamic range is stated when operating at the nominal AC power input of 120 or 240 volts RMS.

de-rate linearly for lower voltages.

SPICER CONSULTING, Eden Laboratory, Broadmead Road, Stewartby, Bedfordshire, England MK43 9ND

Tel: +44 1234 765773 Fax: +44 1234 765778 E-mail: enq@spicerconsulting.com Web: www.spicerconsulting.com

Other Spicer Consulting Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Thermo Scientific

Thermo Scientific SHKE8000 Series Operating and maintenance manual

Thermo Scientific

Thermo Scientific Sorvall T3 user manual

Restek

Restek SilcoCan quick start guide

Tektronix

Tektronix TSG130A instruction manual

Resodyn

Resodyn LabRAM II Installation and user manual

vacuubrand

vacuubrand VHC pro Instructions for use