29339 Ver. 3 GLS Aqua Plus

Page 9 Operating Manual

www.grant.co.uk

5.2.3 Setting the shaking speed

The shaking speed of the bath can be set using the control keys

1. Press the enter key to show ' '.

2. -navigate to the animated tray option:

3. Press the enter key to select the shaking speed; the display will show the present

shaking speed.

4. -et the shaking speed in strokes/min.

The shaking will respond as the value changes.

5. Press the enter key to set the shaking speed to the new value.

If no key is pressed for 4 seconds then the display will revert back to showing the

bath temperature and the shaking speed will remain at its original value.

The maximum speed for a particular application will depend on number and size of

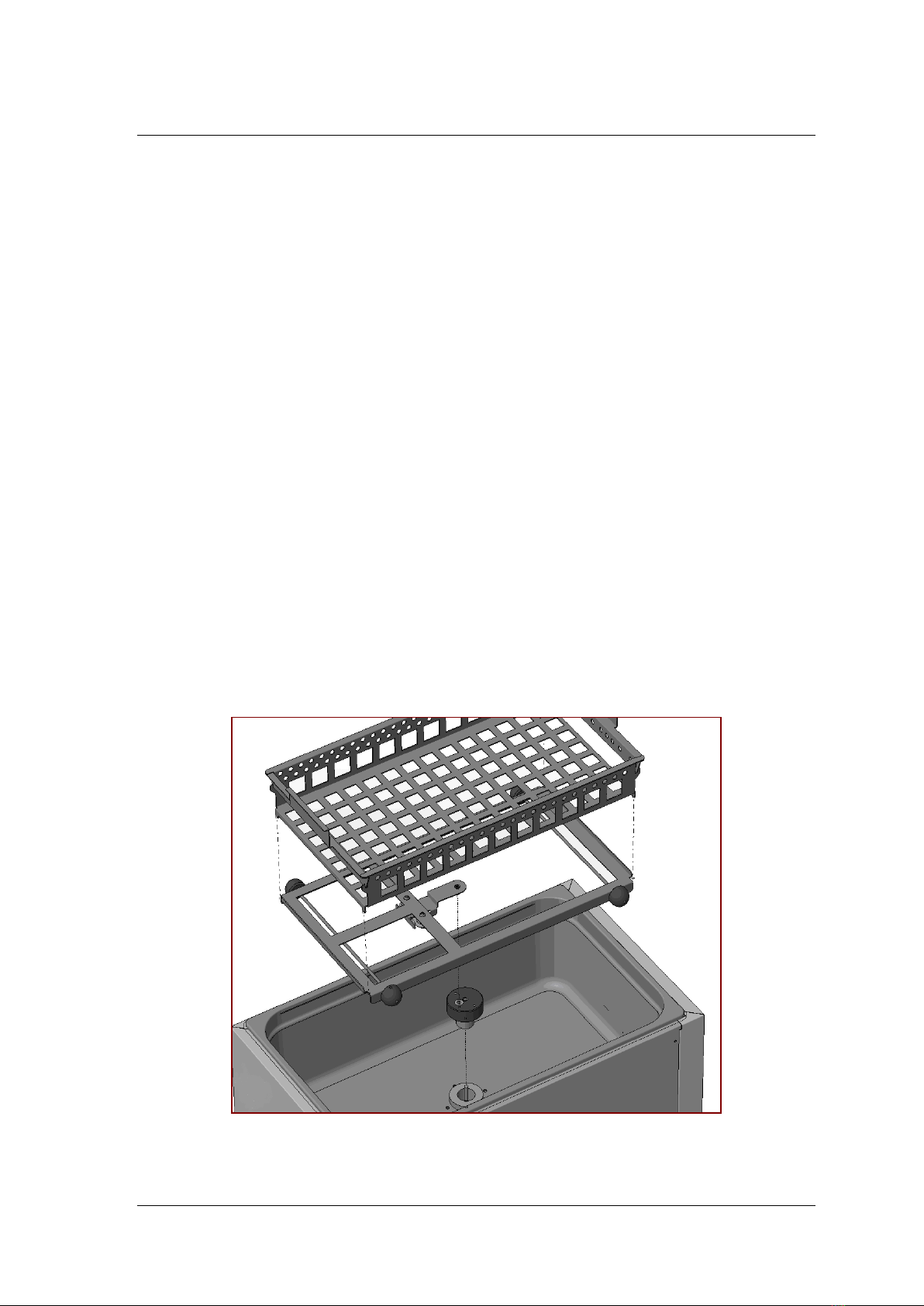

vessels, and the depth of the water. The shaking trolley is driven by a drive magnet

under the tank, magnetically coupled to the trolley through the tank. As the speed is

increased a point is reached where the magnetic coupling de-latches, causing the trolley

either to move erratically or to stop.

5.2.4 Starting & stopping shaking

The stop shaking

function stops the tray immediately whereas the start shaking function ramps up the

start shaking the current speed setting is displayed briefly on the display.

5.2.5 Setting the sample protection thermostat

The bath is fitted with an adjustable sample protection thermostat to protect the sample.

This device is not a safety feature. The sample protection thermostat can be set to be a

few degrees above the bath set temperature.

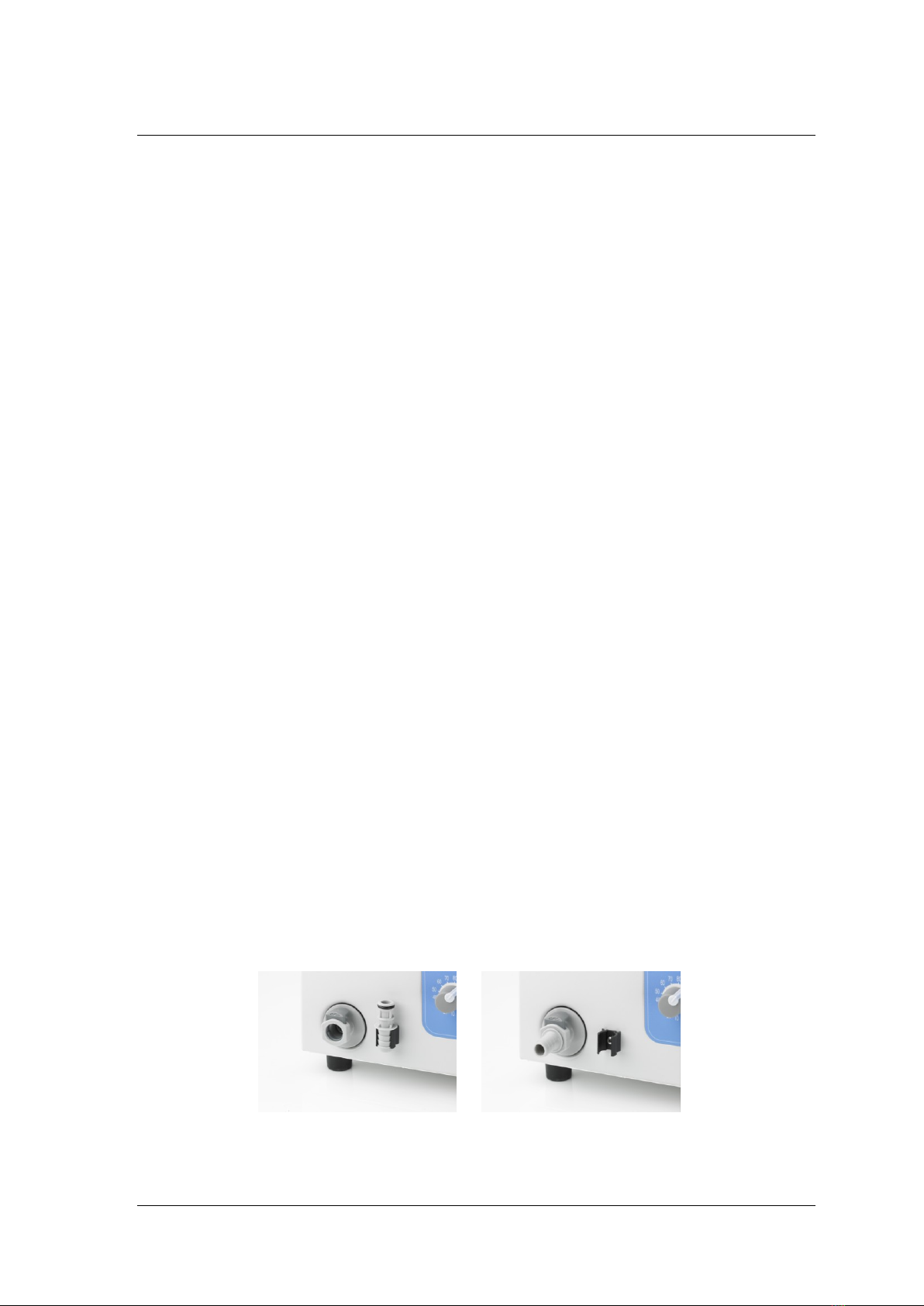

1. Turn the knob of the sample protection thermostat to maximum.

2. Set the control temperature to 2°C above the desired operating temperature and wait

for the temperature to stabilise.

3. Turn the knob of the sample protection thermostat slowly anti-clockwise until a click is

The audible alarm will sound continuously to warn you that the bath is controlling

using the sample protection thermostat.

4. Re-set the control temperature to the desired temperature usi-

The audible alarm will sound continuously until the primary control system is re-

activated.

In the unlikely event of failure of the primary temperature control system, the sample

protection thermostat will maintain the water in the bath at a temperature a few degrees

above the set temperature and with greater fluctuations. The display will cycle between

this happens, first check that the sample protection thermostat is not set to a lower

temperature than the primary control system. If that is not the reason, the bath can

continue to be used without compromising the safety of persons or the surroundings until

current work is completed. However, it is recommended to have the bath checked by a

competent person as soon as conveniently possible.