6Page

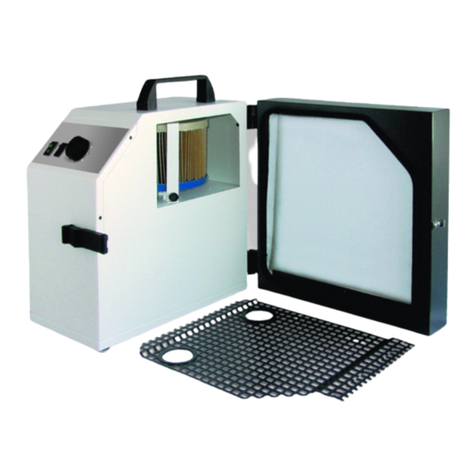

0.4 Functions

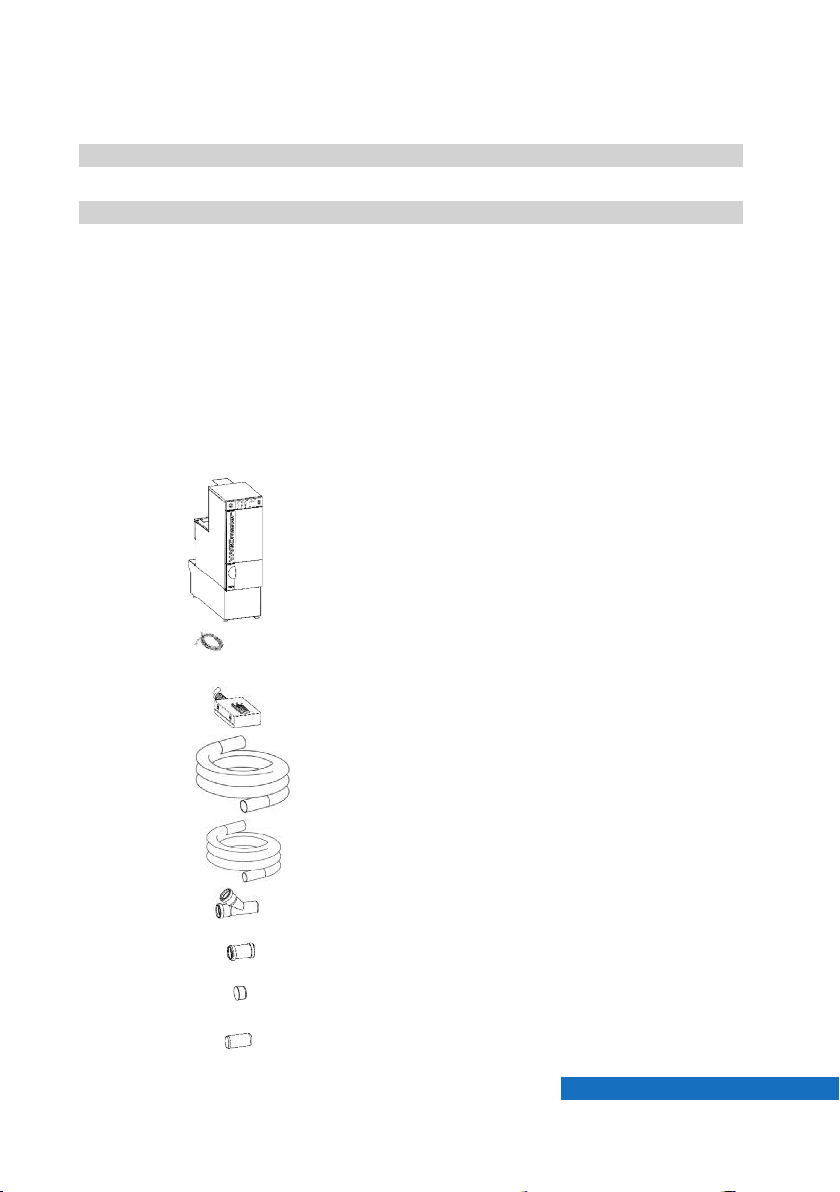

The FZ1 Variomaster vacuum system is a centralized vacuum system for

the operation of up to 2 vacuum positions simultaneously. It may be

expanded to include up to 4 vacuums positions, operated alternatingly.

This vacuum system consists of a central suction unit with integrated fil-

ter technology and independent vacuum position openers at the individual

working positions.

It is possible to connect all devices that generate dry dust in the dental

laboratory.

The vacuum system allows the assignment of four suction levels (1–4)

that can be programmed individually for each vacuum position, depending

on the amount of dust generated. This function is active only for as long

as only a single vacuum position is open.

Level 1234Maximum

Suction power (approx.) 16 l/s 20 l/s 25 l/s 35 l/s 45 l/s

If 2 vacuum positions are open simultaneously, both will have the same

suction power independent of any program settings; this suction power

will correspond to suction level 3 (factory setting). The suction level for

concurrent use can also be programmed.

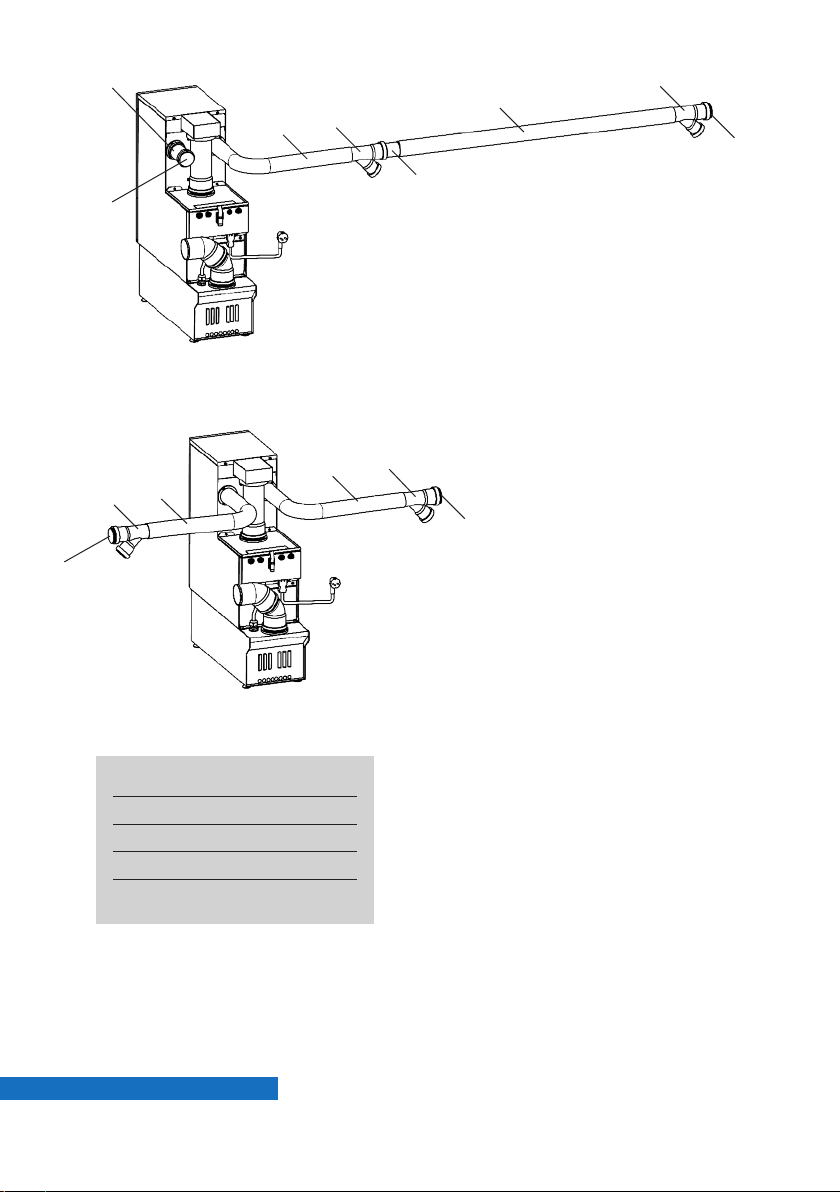

Polishing units with 2 intakes or units that require excessive air volumes

must be connected via dual valves (see special applications).

The FZ1 Variomatic vacuum system keeps the preprogrammed suction

level constant at each vacuum position, automatically compensating for

filter clogging.

The filter will be automatically cleaned as soon as the vacuum turbine has

reached its maximum performance level. In addition, the filter will be

cleaned at preselected intervals in order to keep energy consumption low.

The AP501 automated vacuum position opener automatically opens the

vacuum positions as soon as the dust-generating unit connected to it is

turned on.

The R1400 intake system allows all vacuum positions to be opened

manually.

All opening modules require a control line connecting it to the suction unit

for turning the unit on or off.