Spid Elektronik MD-01 User manual

1

SPID Elektronik

User manual for controllers

MD-01 / MD-02 / MD-03

for firmware from version 2.0

27th October 2022

2

Table of Contents

Table of Contents .......................................................................................................................................2

General .......................................................................................................................................................5

Block diagram .............................................................................................................................................5

Controller technical data............................................................................................................................6

Panels descriptions.....................................................................................................................................6

Front .......................................................................................................................................................6

Back ........................................................................................................................................................6

How to connect the controller to the BIG-RAS/HR rotor:..........................................................................7

#1 Connection of Azimuth & Elevation motors:.....................................................................................7

Sensors connection ....................................................................................................................................9

#2 Connection of the sensor cable from the rotator to the controller (AZ/EL) .....................................9

Operating..................................................................................................................................................10

NORMAL MODE....................................................................................................................................10

MOTOR ANGLES ...................................................................................................................................11

SPEED CALIBR. ......................................................................................................................................12

Controller configuration...........................................................................................................................15

MOTOR CONFIGURATION ....................................................................................................................16

TEMPLATE.........................................................................................................................................16

Start ..................................................................................................................................................18

Stop...................................................................................................................................................18

Satellite Mode ..................................................................................................................................18

External control (CONTROL xx).........................................................................................................19

Protocol (PROT. xx)...........................................................................................................................20

Motors setting (SET MOTOR 1, SET MOTOR 2) ....................................................................................20

STATE................................................................................................................................................20

TYPE..................................................................................................................................................20

3

KIND..................................................................................................................................................20

INPUT................................................................................................................................................20

GEAR.................................................................................................................................................21

MIN ANGLE.......................................................................................................................................22

MAX ANGLE ......................................................................................................................................22

MAX POWER.....................................................................................................................................22

PULS TIMEOUT..................................................................................................................................23

Setting RS232 port (SET COM0, SET COM1).........................................................................................23

STATE................................................................................................................................................23

BAUD.................................................................................................................................................23

DATA BITS .........................................................................................................................................23

STOP BITS..........................................................................................................................................23

PARITY...............................................................................................................................................23

Setting RS232 virtual port (SET USB COM)...........................................................................................23

STATE................................................................................................................................................23

BAUD.................................................................................................................................................23

DATA BITS .........................................................................................................................................23

STOP BITS..........................................................................................................................................23

PARITY...............................................................................................................................................23

Setting ETHERNET port (SET ETHERNET) ..............................................................................................24

STATE................................................................................................................................................24

Dimensions:..............................................................................................................................................25

ACCESSORY...............................................................................................................................................28

CABLE CONNECTIONS...............................................................................................................................29

ETHERNET MODULE v1.............................................................................................................................35

User installation....................................................................................................................................35

Configuration........................................................................................................................................36

ETHERNET MODULE v2.............................................................................................................................37

4

User installation....................................................................................................................................37

Configuration........................................................................................................................................41

CCM - CURRENT CONTROL MODULE........................................................................................................42

Installation of the CCM module in the MD-01 .....................................................................................42

Installation of the CCM module in the MD-02 .....................................................................................44

Installation of the CCM module in the MD-03 .....................................................................................47

Configuration of CCM module..............................................................................................................50

Operating CCM module........................................................................................................................51

5

General

MD-01 / MD-02 / MD-03 units are electronic rotor controllers. They are multifunction devices allowing various

combinations of work settings. Single rotors (e.g. two Azimuth rotors), double rotors (one Azimuth / Elevation

rotor or one X/Y rotor) can be connected to the controller. The system provides work with DC motors.

From firmware version v2.0 has improved control algorithms,

supports rotors in a mechanical configuration type X / Y,

supports the CAN Bus allowing to read operating parameters m.in from absolute encoders and

inclinometers (required compatibility of the sensor with the protocol supported by the controller),

has implemented satellite mode (SATELLITE MODE), dedicated to tracking satellites in LEO orbit,

increasing the smooth operation of motors and reducing engine loads, gearboxes and relays (note: at

the expense of a slight reduction in accuracy) –only for rotors with HR and CAN Bus sensors,

optimizes start and stop cycles thanks to the calibration mode of minimum engine power

(CALIBRATION).

To verify the installed firmware version before turning on the device, press and hold the F and F2 buttons at

the same time, then while holding turn on the device until the software version is displayed. The installed

firmware version is also displayed for a few seconds after starting the device.

Block diagram

Keyboard

LCD Display

6

Controller technical data

controller supply voltage 15 VDC (Imax –2A)

rotor supply voltage standard models 14-18 VDC (Imax –20A), BigRAS/HR and SDD 24-30 VDC (Imax –

12A) or other voltage if specified in the description of the ordered device

maximum power current of a single motor up to 20 A

2 RS232 ports,

1 USB host port –not active

1 USB device port –visible in the system as a virtual COM port

1 RJ45 Ethernet port

Panels descriptions

Front

MD-01

MD-02

MD-03

1. Keyboard.

2. LCD screen.

3. On/off switch.

Back

MD-01

7

MD-02

MD-03

1. Input socket for Connecting Ground (rest of NC pins).

2. Power input for Rotor motors (fuse 40A).

3. Socket for connecting modules such as CAN, RS485, RS422 or analog inputs.

4. Pulse input for systems with two HALL sensors.

5. Electronics power input (fuse 2A).

6. Outputs for connecting rotor BIG-RAS Elevation. Motor power pins. Elevation of pins from the engine

(3, 4), pins in the controller (1, 2). Each output has its own fuse (20A).

7. Outputs for connecting the BIG-RAS Azimuth Rotor. Motor power pins. Azimuth pins from the motor

(1.2), pins in the controller (1, 2). Each output has its own fuse (20A).

8. Switch for updating driver software (FIRMWARE). To update the software, we use COM0 (point 12),

and set the switch to the OFF position. The normal operating mode of the controller is when the

switch is in the PR position.

9. Universal output –possibility of connecting a module with relays inside the controller. Then the

controller will have the function of an antenna switch.

10. I2C output –used to control the SW-01 switch.

11. USB ports –HOST (plug type A) and DEVICE (plug type B).

12. RS232 ports –COM0 and COM1. COM0 is also used to update driver software (see section 8).

13. Mouse input.

14. Ethernet socket RJ 45.

P IN F U N C T IO N

1NC

2NC

3NC

4NC

5 G R O UND

6NC

P IN F U N C T IO N

1 U 1 + 2 2 V D C

2 G R O UND

3NC

4 U 1 + 2 2 V D C

P IN

F U N C T IO N

1NC

2

W E im p 2 E L

3

W E im p 1 E L

4

W E im p 2 A Z

5

W E im p 1 A Z

6 1 2 V D C

7 1 2 V D C

8 G R O U ND

9 G R O U ND

P I N F U N C T I O N

1 U 2 + 1 5 V D C

2 G R O UND

3 U 2 + 1 5 V D C

P IN F U N C T IO N

1 MO T O R

2 MO T O R

3 W E IMP

4 G R O UND

5 + 1 2 V D C

How to connect the controller to the BIG-RAS/HR rotor:

#1 Connection of Azimuth & Elevation motors:

Pinout description at unit’s back panel

8

The rotor is connected to the controller via the supplied plugs (4-Pin), they are used in to power the Azimuth

and Elevation motors.

In the controllers in the AZ and EL outputs, pins 1 and 2 are always used to power the motors. Remember to

verify the correctness of connecting the polarity of the motor power supply. The pins in the rotor connection

box for AZ are numbered 1 and 2, and for the EL pin in the rotor they are numbered 3 and 4.

Engine polarization

shown for RIGHT

direction while

looking at top of

the rotator

Engine polarization

shown for TO TOP

direction while

looking at the side

of big gear of the

rotator

9

Sensors connection

#2 Connection of the sensor cable from the rotator to the controller (AZ/EL)

The connection from the rotor side is carried out by an eight-pin connector type MIC328, which is located in a

PVC box at the rotator, on the back side of the controller there is a nine-pin connector of type DB9. A shielded

six-wire cable should be used for connection.

Good shielding and its effective grounding is necessary to protect the rotor and controller from the influence

of electromagnetic radiation of the transmitting antennas, otherwise the controller can count false pulses

generated by a RF field inducing voltage in the connection cable.

Connection diagram (left MIC328, right WEIPU Sp17):

10

Operating

The controller can be operated using the keyboard located at the front panel or a computer with the

appropriate software installed (e.g. PstRotator).

Modes:

NORMAL –standard operating mode

,

MOTOR ANGLES –calibration mode of the actual rotator’s position relative to geographical

directions,

SPEED CALIBR. –calibration for SOFTLY and SATELLITE modes

.

To change the operating mode, use the [F] button.

Before using the controller with the rotator, start procedure for setting the minimum motor power (MIN

POWER) which should be able to move and turn the antenna system:

1. Set the SET MOTOR -> MIN POWER [motors 1 and 2] to 100%.

2. Then go to the parameters SET MOTOR -> MAX POWER to determine the minimum power of the

motors, which allows the rotator to move both for AZ and for EL motors [overcoming transmission

resistance, boom and antenna weight, etc.]: by reducing the engine power values from 100%,

experimentally look for the lowest possible value that allows the engines to move without causing a

TIME OUT error. If an error occurs, restart the controller with the main switch and follow the

procedure again.

3. After finding the appropriate values for each of the engines, in order to take into account the

possibility of other operating resistances (e.g. due to low temperature, wind, nonlinearity of loads in

AZ/EL operation, etc.), the margin [e.g. 10-15%, for possible verification in practice] should be taken

into account, and the obtained values should be increased accordingly and entered as appropriate

parameters for both motors in the parameter (note!) MIN POWER, then return to MAX POWER set to

100% or in the range between MIN POWER and 100%, at the discretion of the user, if he does not

expect the rotator to work at full speed.

4. The starting base, for a user who does not want to perform the above procedure, may be MIN POWER

50% and MAX POWER 100% respectively [usually sufficient for standard antenna systems], however, it

should be taken into account that such settings will not work optimally and may generate errors (e.g.

TIME OUT).

5. Completion of the procedure for setting the minimum engine power (MIN POWER) means that the

correct values have been entered for both engines in the MIN POWER and MAX POWER fields. This is

the moment when the user can proceed to calibrate the SOFTLY and SATELLITE (SPEED CALIBR.)

modes.

NORMAL MODE

In this mode the controller can be operated with the [Right], [Left], [Top] and [Bottom] buttons or by

commands send from a PC. The controller supports the communication protocols SPID ROT1, SPID ROT2,

11

YAESU, which in the settings can be assigned to the selected communication port (COM0, COM1, USB D and

ETH). Keyboard function:

The [Right] and [Left] buttons are used to rotate the antenna in the azimuth plane:

odirection Right - the antenna rotates clockwise, the value of the angle on the display increases,

odirection Left –the antenna rotates counter clockwise, the angle value on the display

decreases.

The [Up] and [Down] buttons are used to change elevation of the antenna:

odirection Top –rotor turns to the right looking at its front. The value of the angle on the

display increases,

odirection Down –the rotor rotates to the left looking at its front. The angle value on the

display decreases.

The directions of change elevation of the rotator:

`

After installation the optional CCM (Current Measurement Module), the user can observe the value of the

motors’ current. To activate this function, press the [F2] button once. On the LCD screen, where the rotor

position is indicated, the current values of the respective motors will appear. The occurrence of slight

fluctuations in current indications during the rotor standstill is a normal situation and results from the

internal noise of the measuring sensor. Sample LCD screen during rotor operation:

MOTOR ANGLES

is a calibration mode of the actual rotator’s position relative to geographical directions.

To activate calibration mode press the [F] button. In this mode, user can set any value of the azimuth and

elevation angle, without rotating the antenna. We do this to adjust the displayed values to the actual position

of the antenna.

Up

Down

12

Verification of the actual position of the antenna in relation to the displayed values should also be done

preventively. This is to maintain the operation of the antenna and wiring within the assumed angular limits.

It is suggested that during the operation of the rotor, observe its operation and the position of the antenna

(directly or through the camera) and in the event of irregularities, immediately stop the rotor by switching

off the controller.

To set desired azimuth angle, we use the [Left] and [Right] buttons, and change the elevation angle with the

[Top] and [Down] buttons.

Resetting the azimuth angle is done by pressing the [F1] and [Left] buttons at the same time, and resetting the

elevation angle –with the [F1] and [Top] buttons.

Returning to normal operation by pressing the [F] button (a few times if needed).

SPEED CALIBR.

is a calibration for SOFTLY and SATELLITE modes.

In order to properly calibrate, the procedure for setting the minimum motor power (MIN POWER) capable of

moving the antenna system must be carried out beforehand. Therefore, the rotor should be mounted at the

target location and the antenna system installed on the rotator. This is crucial for the proper operation of

the SOFTLY function, so it should be carried out with due diligence.

Note: both the MIN POWER setting and the SOFTLY mode calibration should be carried out whenever the

load on the motors may have changed significantly, e.g. a change in the antenna system, a significant

change in the outside temperature (due to the higher resistance to movement of the antenna system and

the gears themselves), other factors affecting the resistance to movement and the minimum torque capable

of moving the antenna system. It should be taken into account that the antenna system may pose different

resistance to the rotor motors depending on the selected azimuth and elevation, this may be influenced by,

for example, the balance of the antenna system, the tension of antenna wires, etc.

Calibration procedure:

1. In the MOTOR CONFIGURATION menu for both motors, set START and STOP to SOFTLY. We

approve and save the selection.

2. Start the configuration mode using the F button [MODE: SPEED CALIBR.], to confirm the

choice, press and hold the S button for min. 10s –this will start the calibration procedure. When

confirming the start of the calibration procedure, the user must be aware that the controller will

automatically start the rotor motors –the antenna system and the objects within its range should be

prepared in advance for safe operation. Remember: at any time, the procedure can be interrupted by

turning off the controller with the main power switch!

3. After starting the calibration mode, the controller:

a. will bring the rotor to the position of 0 ° azimuth and 0 ° elevation,

b. for each of the motors will carry out a series of tests consisting in starting in work cycles in the

range of about 0-10 ° respectively for azimuth and elevation, analysing the actual speed of the

set at this time,

c. informs about the progress of calibration indicating the percentage of advancement on the

screen,

d. after the calibration is completed it automatically goes to NORMAL mode.

13

The next step in optimizing the work is to set the ramps of start power gains (START POWER) and stop

power (STOP POWER) of the voltage supplying the motors and periods (START TIME and STOP TIME

respectively):

1. Usually, in the case of even complex antenna systems, it is sufficient to set a single-threshold start

and stop ramp. Example configuration: START POWER:

,

STOP POWER:

equal to or slightly greater than the previously declared MIN POWER,

START TIME 1: 1s:

,

START TIME 2: 0s, START TIME 3: 0s, STOP TIME 1: 1s, STOP TIME 2: 0s, STOP TIME 3: 0s.

2. Note: choosing a time other than 0s in subsequent positions START TIME 2, START TIME 3

(respectively STOP TIME 2, STOP TIME 3) activates subsequent ramps allowing the process of

starting and/or stopping engines to be spread over more stages.

14

3. Explanation of the operation of ramps on the example of the following graphs:

A diagram (above) of the starting ramp, where the controller will start the motors with a power of

START POWER of 20% (in this case such as MIN POWER) and at the time of START TIME 1 (here 2s)

will smoothly increase the power to the value of MAX POWER (in this case to 100%).

In the case of approaching the final set position, the controller will start the deceleration process,

in which for 1s (selected STOP TIME) it will reduce the power of the motors to MIN POWER and

stop them (this last part of the process is not visible on the graph).

15

A diagram of the stop ramp, where the controller will start the stopping process from MAX POWER

(in this case 100%) to STOP POWER (in this case 20%), and this process will take place during STOP

TIME 1 (here 3s).

Comment: if you select the START POWER and/or STOP POWER value smaller than MIN POWER, the

controller will use the MIN POWER value in these places, similarly for the START POWER and/or STOP

POWER value greater than MAX POWER, the controller will use the MAX POWER value in these places,

which means that the MIN POWER and MAX POWIER values declared by the user are superior.

Completion of procedures:

1. minimum engine power settings (MIN POWER),

2. calibration of the SOFTLY function,

3. settings for start and stop increment ramps,

means that the configuration of the motors in the antenna-rotator-controller system has been completed.

After calibration, save the settings and return to NORMAL mode by pressing the [F] button (a few times if

needed).

Controller configuration

Entering the configuration mode is obtained by pressing the [S] button when the controller is in NORMAL

mode.

The configuration structure of the controller is modular. Changing modules is done by using the [Right] and

[Left] buttons. In each module there are appropriate parameters. After selecting the module press the [S]

button to enter into a parameters list. Moving between parameters is done in the same way as changing

16

modules - the [Right] and [Left] buttons, and the parameter value changes with the [Up] and [Down] buttons.

Module selection is done by pressing the [S] button.

The [F] button is used to exit the configuration. After pressing, a question appears about saving any changes in

the configuration. If you want to confirm the changes, press the [Left] YES button, if you want to return to the

previous configuration without saving, press the [Right] NO button.

MOTOR CONFIGURATION

The number before the sign ": " in the TEMPLATE name specifies to which connector on the rear panel the

motor must be connected: 1 –AZIMUTH 2 –ELEVATION

TEMPLATE

The type of motors connected to the controller is set in advance according to the following

templates:

1:NC, 2:NC –no motors connected to the controller,

1:AZ, 2:NC –one motor is connected to the AZIMUTH plug on the rear panel of the controller.

The motor rotates only in azimuth plane,

1:NC, 2:EL –one motor is connected to the ELEVATION plug on the rear panel of the controller.

The motor rotates only in the elevation plane,

1:AZ, 2:EL –two motors are connected to the controller. Motor 1 (AZIMUTH plug) rotates in

the azimuth plane, and Motor 2 (ELEVATION plug) –in the elevation plane,

1:AZ, 2:AZ –two motors are connected to the controller, both rotates only in the azimuth

plane,

1:EL, 2:EL –two motors are connected to the controller, both rotates only in the elevation

plane,

1:AX, 2:EY –two motors are connected to the controller. Motor 1 (AZIMUTH plug) rotates in

the X axis, and Motor 2 (ELEVATION plug) –in the Y axis. In the case of this template, the

corresponding transformation (AZ/EL to X/Y) takes place directly on the controller,

1:XX, 2:YY –two motors are connected to the controller. Motor 1 (AZIMUTH plug) rotates in

the X axis, and Motor 2 (ELEVATION plug) –in the Y axis. Note: this is an advanced mode,

intended only for dedicated solutions in which X and Y parameters ("raw data") are sent

directly to the controller, i.e. the appropriate transformation (AZ/EL to X/Y) does not take

place in the controller but in external software.

Rotator X/Y –important:

17

View of the X/Y rotor with axis marking, motors names and operating ranges

The correct positioning of the X/Y rotor should be done with setting the "zero" initial

position of the rotor on the mast: the positions of the X and Y gears should be set in the

middle of the operating range (90 deg.), which should lead to the position of the

mounting plane of the antenna mounting plate horizontally in both planes (as shown

above).

At a "zero" position, the X and Y axes should be oriented as follows:

oX-axis -> North-South,

oY-axis -> East-West.

Edge values of the X and Y gear positions and the corresponding actual position of the

rotator:

oX(0⁰) = 90⁰ AZ

oX(180⁰) = 270⁰ AZ

oY(0⁰) = 0⁰ AZ

18

oY(180⁰) = 180⁰ AZ

To set the mounting position of the rotor operating in 1:AX, 2:EY template and to

calibrate the indication, switch to 1:XX, 2:YY template.

Do not forget to back to the 1:AX, 2:EY template when setup is done or leave 1:XX, 2:YY

template just when going to send raw X-Y data to the controller (Non-standard setup,

only for specific application!).

The first tests of the rotator's operation after connecting and configuring the controller should be

carried out under constant observation of the rotator's movements, and in the event of any

irregularities, immediately turn off the power supply. Caution is required due to the large forces on

the rotor gears and the potential user error in connection and / or configuration of the controller.

The identified irregularities should be removed before the next start-up.

Start

Motors starting modes:

IMMEDIATELY –the motor starts at the maximum speed, set for each motor separately

accordingly in the modules SET MOTOR 1 and SET MOTOR 2,

SOFTLY –the so-called "soft start" set for each motor in SET MOTOR 1 and SET MOTOR 2.

Stop

Motors stopping mode:

IMMEDIATELY –the motor stops immediately,

SOFTLY –the so-called "soft stop" set for each motor in SET MOTOR 1 and SET MOTOR 2.

Start and Stop –important information:

In manual mode always (i.e. regardless of the selected IMMEDIATELY or SOFTLY mode) at

start-up the following engine power ramp applies: by 1s MIN SPEED and then MAX SPEED,

while the STOP command is executed immediately.

In the SOFTLY manual operation mode, the ramps declared in the settings always apply at

start and stop, but if the direction button was released at a speed lower than MIN SPEED,

the system goes into braking in accordance with the ramp and returns to the position from

the moment of releasing the direction button (thanks to this, vibration of the antenna

system are avoided during manual operation and this makes it easier to select the

expected position).

Satellite Mode

ON - turning on,

19

Properties:

ooptimized to track satellites in LEO orbit,

oincreases smooth operation and reduces the load on motors, gears and relays (note: at

the expense of a slight reduction in accuracy),

oworks only with sensors type HR and CAN Bus.

Description of the algorithm: in Satellite Mode, the system is prepared to accept subsequent

positions from the satellite tracking program much more often and switching the controller

relays after the end of each rotor movement practically does not occur, unless subsequent

positions change the direction of movement of one of the motors and the configuration of the

motors has been made correctly.

Note: with improperly set parameters of ramps and engine power, the frequent exceeding of the

set position may occur (e.g. due to system inertia), which will cause the controller to react and

correct the position when receiving the next command from the tracking program (the user will

observe frequent operation of relays and correction of position during satellite tracking). This is

an indicator that the motors (MIN POWER, SOFTLY configuration and ramps) should be

performed again. However, it should be taken into account that the correction of the position

and thus the operation of relays may also occur with properly configured motors –however, it

will occur relatively rarely.

External control (CONTROL xx)

This parameter determines which communication port of the controller is used to control the

connected motors. Appears only when a template other than 1:NC, 2:NC. When last template 1:AZ, 2:AZ is

selected, a different control port for each motor can be set.

Depending on the selected template, the following subtitles will appear on the screen:

CONTROL A1 –template 1:AZ, 2:NC,

CONTROL E2 –template 1:NC, 2:EL,

CONTROL AE –template 1:AZ, 1:EL,

CONTROL A2 –template 1:AZ, 2:AZ.

CONTROL value:

NONE –no external control, just manual keyboard position change.

COM 0 –external control according to the selected protocol, described below. You can also

control manually.

COM 1 –external control according to the selected protocol, described below. You can also

control manually.

USB –control via USB D port, according to the selected protocol, described below. You can

also control manually.

ETH –control via ETHERNET according to the selected protocol, described below. You can also

control manually.

20

Protocol (PROT. xx)

Choosing communication protocol between the controller and the control device (e.g. a computer with

the appropriate program):

SPID ROT1

SPID ROT2

YAESU

Motors setting (SET MOTOR 1, SET MOTOR 2)

STATE

Read-only parameter. It depends on the choice of template (TEMPLATE) in the configuration of

motors. Specifies whether the motor is ON or OFF.

TYPE

Type of controller input:

DIGITAL –the controller counts pulses (no other options available).

KIND

Read-only parameter. Depends on the choice of TEMPLATE in the MOTOR CONFIGURATION:

AZIMUTH –rotator rotates in azimuth plane,

ELEVATION –rotator rotates in elevation plane,

X–rotator rotates in X axis,

Y–rotator rotates in Y axis.

INPUT

Kind of input sensor (only when DIGITAL is chosen):

ELECTRONIC –electronic motion sensors (vibration-free),

MECHANICAL –reed switches,

CAN BUS –for sensors such as absolute encoder and/or inclinometer, communicating with the

controller via CAN BUS. Note: Requires installation of the extension card and configuration.

CAN BUS sensors configuration:

1. In the configuration menu of motors (SET MOTOR) choose to which motors CAN BUS

encoders are connected, selecting SET MOTOR INPUT to CAN BUS.

Other manuals for MD-01

1

This manual suits for next models

2

Table of contents

Popular Controllers manuals by other brands

Omega Engineering

Omega Engineering HE-XT105 user guide

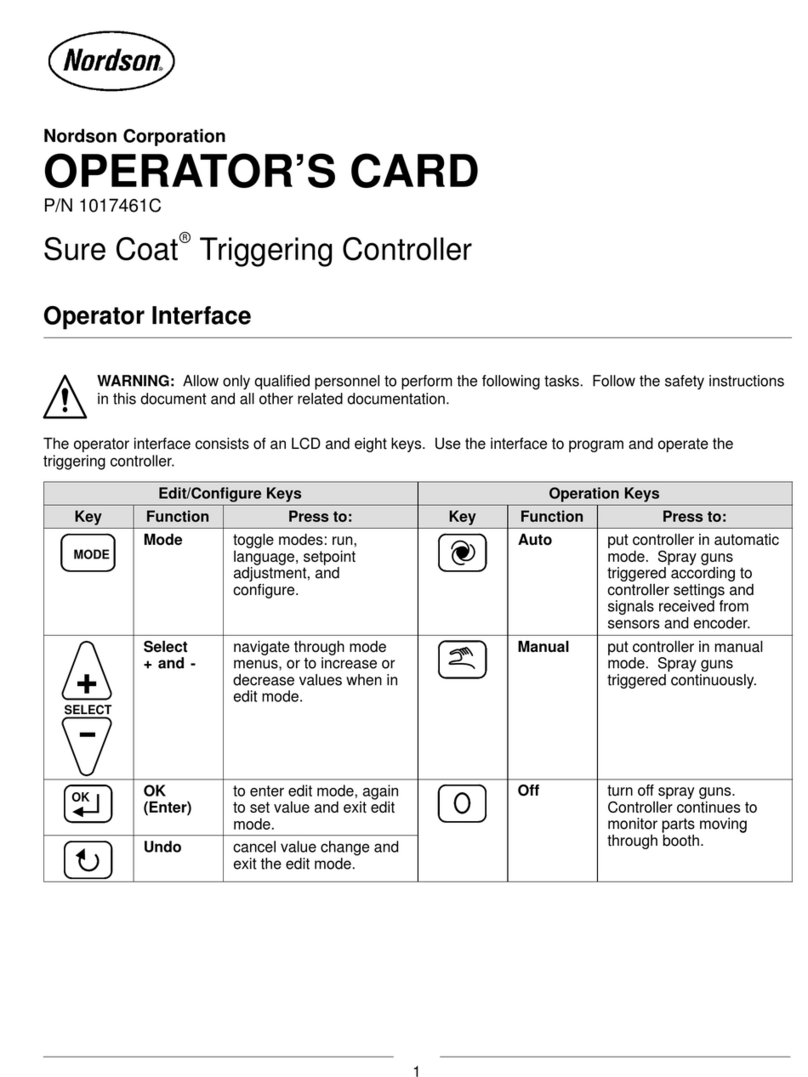

Nordson

Nordson Sure Coat Operator card

PCB Piezotronics

PCB Piezotronics IMI SENSORS 683A101000 Installation and operating manual

Mi-Light

Mi-Light MiBOXER LC2-ZR instruction manual

Mi-Light

Mi-Light MiBOXER RGB-MZ manual

Philips

Philips Dynalite Revolution Series installation instructions