4

Calibrating the Triggering Controller

1. Choose a test part. It can be a production part or

a piece of cardboard. It will not be coated.

2. Measure the part length as it is hung on the

conveyor. The measurement must be in real

world units, so if you are scaling to inches

measure in inches.

3. Enter Configure controller mode.

4. Make sure Encoder scale is set correctly.

5. Go to the RESET Enc Counts menu.

6. Press the OK key to enter edit mode.

7. Press the Select+ or Select- key to reset the

counts to zero.

8. Press the OK key to exit edit mode.

9. Hang the test part on the conveyor, ahead of the

photoeyes.

10. Start the conveyor.

As the part moves through the photoeyes the

controller measures it in counts. When the part

passes by the photoeyes the scaling adjustment is

set in the controller. This scale is displayed on the

RESET Enc Counts menu.

11. Go to the Encoder CAL menu.

12. Press the OK key to enter edit mode.

13. Use the Select+ and Select- keys to enter the

length of the part you measured in step 2. The

more accurate the measurement is, the more

accurate the triggering will be.

14. Press the OK key to exit edit mode. The

triggering controller is now scaled to real world

units of inches or centimeters.

Setting Trigger Points

Triggering setup consists of determining and setting

three values for each output: pickoff, lead, and lag.

All values are entered in real-world units of inches or

centimeters.

Finding Starting Pickoff Points

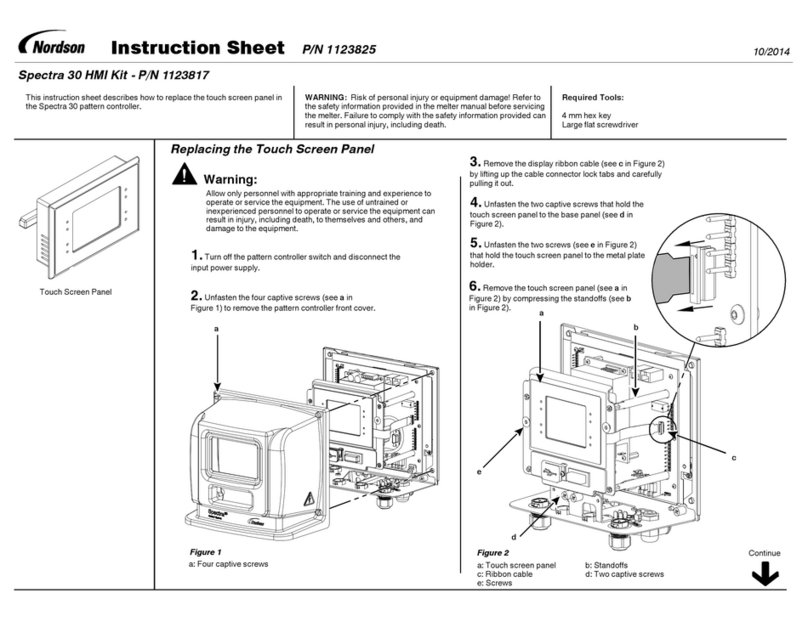

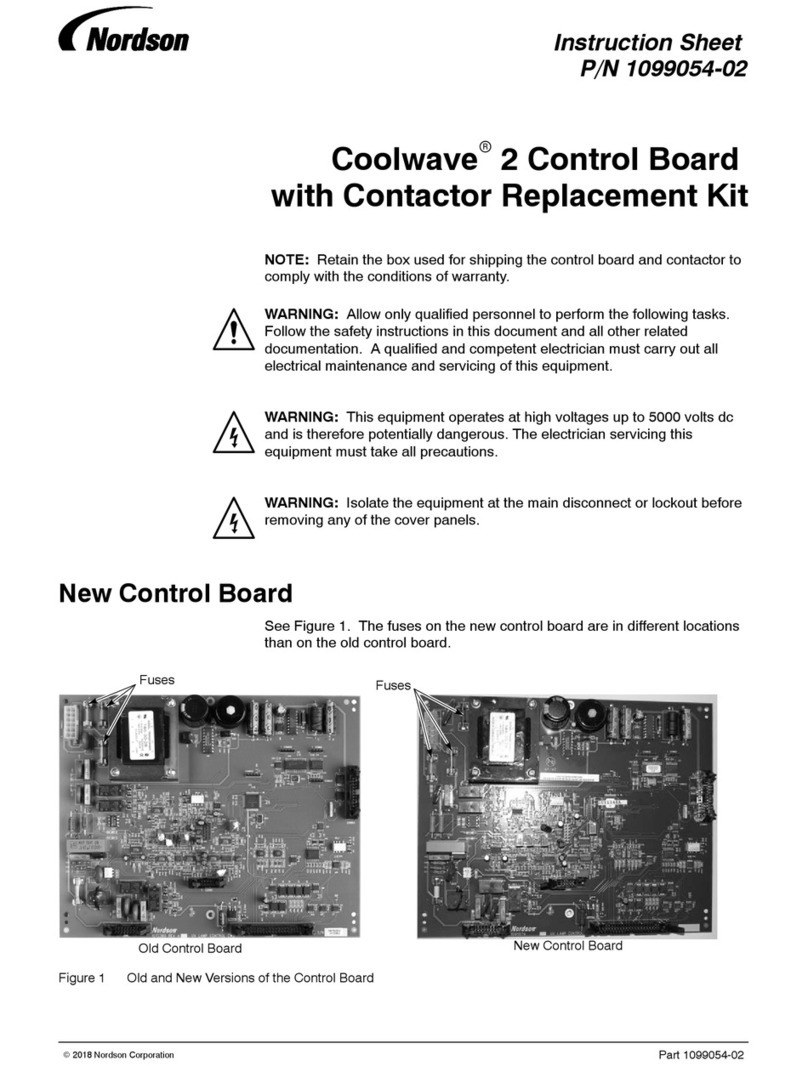

See Figure 2. The pickoff point is the distance from

the sensors to the spray guns, measured in

real-world units (inches or centimeters). Use this

procedure to obtain a starting value for each bank of

guns (outputs), then adjust it as necessary to obtain

the desired accuracy.

NOTE: Once you have the pickoff points adjusted

properly, you do not need to change them unless you

move the sensors or spray guns. Pickoff points can

be hidden once they are set, as described in

Configuration.

1. Enter Configure controller mode.

2. Go to the RESET Enc Measure menu.

3. Press the OK key to enter edit mode.

4. Press the Select+ key to reset the values.

5. Hang a test part on the conveyor, ahead of the

photoeyes. Have another person stand behind

the first bank of spray guns to tell you when the

part reaches them, while you watch the Measure

value.

6. Start the conveyor and note the Measure value

when the leading edge of the part reaches the

spray guns.

7. To determine the pickoff point for any other

vertical banks of spray guns, either repeat this

procedure, or measure from the first bank to the

second and add the distance measured to the

pickoff point for the first bank.

1400255

Sensors

Centerline

Bank 1

Pickoff

Bank 1

Part

Centerline

Bank 2

Pickoff

Bank 2

Conveyor Direction

Figure 2 Finding Starting Pickoff Points