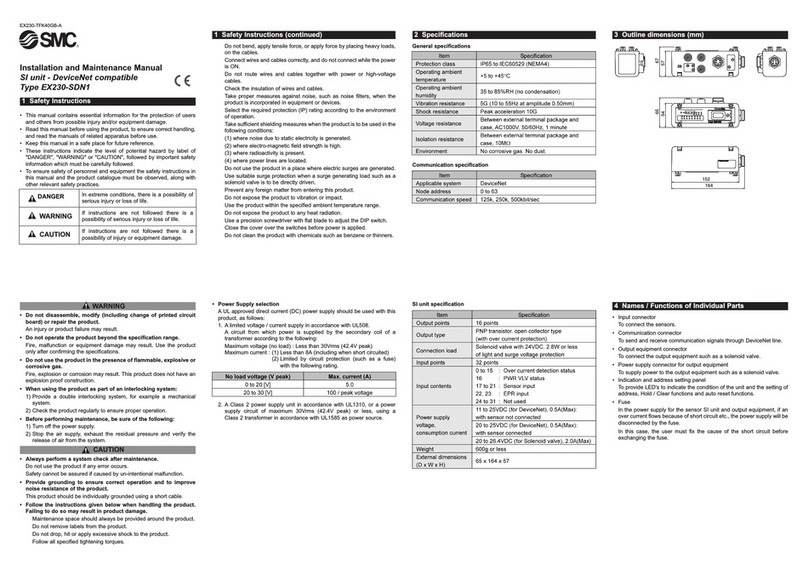

•Connector pin assignment

TD+

Signal name

RD+

TD

-

1

Pin number

2

3

BUS I BUS OUT

Configuration

Display

ST(M)

PWR

PWR(V)

SF

Content

Displays the diagnostic status of the unit.

Displays the status of the power supply voltage for

control and input.

Displays the status of the power supply voltage for

outputs.

Displays the system status.

BF Displays the communication status.

•PROFI ET status

Content

The communication with the master has been established normally,

or the power supply for control and input is OFF.

LED display

OFF.

The communication with the master has been established, but a

diagnosis error has occurred.

ode flashing test command received.

This product has no switches for setting, therefore the display cover should not be opened.

RD

-

4

L/A I

L/A OUT

Content

Displays the communication status of the BUS I side.

Displays the communication status of the BUS OUT

side.

Red SF LED is O .

The configuration data of the master and EX600 are not consistent.

Either of the following conditions:

•The power supply for the master is OFF.

•The cable between the master and SI unit is not connected.

•The master or the SI unit has broken.

•The configuration data of the master and the device name of the

SI unit are not consistent.

BUS OUT side: o Link, o Activity

(Green)

BUS OUT side: Link, o Activity

BUS OUT side: Link, Activity

OFF

O

Flashing

BUS I side : o Link, o Activity

(Green)

BUS I side : Link, o Activity

BUS I side : Link, Activity

OFF

O

Flashing

(1)

Mark A

Mark B

Mark C on the unit

End plate bracket

(EX600

-

ZMA2)

5

(5)Fix the manifold by tightening the DI rail fixing

screws of the EX600

-

ZMA2. (M4 x 20)

Tightening torque: 0.7 to 0.8 m.

The tightening torque at the valve side depends on

the valve type.

Refer to the operation manual of the corresponding

valve manifold.

Wiring

•Connect the M12 connector cable.

The M12 SPEEDCO connector connection method is explained below.

(1)Align mark B on the metal bracket of the cable connector (plug/socket) with mark A.

(2)Align with mark C on the unit and insert the connector vertically.

If they are not aligned, the connector cannot be connected correctly.

(3)When mark B has been turned 180 degrees (1/2 turn), wiring is complete. Confirm

that the connection is not loose. If turned too far, it will become difficult to remove the

connector.

Setting and Ad ustment

LED Display

The status display LED displays the power supply and communication status.

•SI unit common status

Content

The power supply for control and input is OFF.

LED display

OFF.

The unit is in normal operation.

Green LEDs are O .

An internal memory error has occurred in the SI unit.

Red ST(M) LED is O .

The power supply voltage for control and input is abnormal.

Red PWR LED is O .

The power supply voltage for outputs is abnormal.

Red PWR(V) LED is O .

A unit other than the SI unit has been detected.

Green ST(M) LED is flashing.

Either of the following conditions:

•The valve O /OFF counter has exceeded the set value.

•The valve is short circuited or disconnected.

Red ST(M) LED is flashing.

Connection error between units has occurred.

Red/Green ST(M) LED is flashing alternately.

-

10 to 50 oC (Max. surrounding air temperature rating: 50 oC)

Operating temperature range

-

20 to 60 oCStorage temperature range

For use in Pollution Degree 3 Environment (UL508)Pollution degree

24 VDC, 1.0 W or less, DC General per output

Output rating

•Parameter Setting

•Hardware Configuration

•I/O Map

•Diagnostic

10 to 57 Hz: constant amplitude 0.75 mm p-p

57 to 150 Hz: constant acceleration 49 m/s2

for 2 hours each in direction X, Y and Z respectively (De-energized)

Vibration resistance

147 m/s23 times each in directions of X, Y and Z respectively (De-energized)Impact resistance

Troubleshooting

Refer to the LED Display. Refer to the SMC website (URL http://www.smcworld.com)

for more information about troubleshooting.

Specifications

Refer to the product catalogue or SMC website (URL http://www.smcworld.com) for

more information about product specifications.

Outline with Dimensions

Refer to the product catalogue or SMC website (URL http://www.smcworld.com) for

more information about outline dimensions.

ote: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.

© 2013 SMC Corporation All Rights Reserved

Akihabara UDX 15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, JAPAN

Phone: +81 3-5207-8249 Fax: +81 3-5298-5362

URL http://www.smcworld.com

Refer to the SMC website (URL http://www.smcworld.com) for more information

about these settings.

24 VDC Class2, 2 A

Power

supply 24 VDC Class2, 2 AOutput

Control and input

Refer to the SMC website (URL http://www.smcworld.com) for more information

about LED state.

•Mounting the marker

The signal name of the input or output devices and unit

address can be written to the marker, and can be

installed to each unit.

Mount the marker (EX600-ZT1) into the marker groove

as required.

Fieldbus system

Operation Manual

EX600-SPN1 / EX600-SPN2

Summary of Product parts

Status display LED

Description Function

Displays the status of the unit.

Display cover The display cover should not be opened.

MAC address label Displays the 12 digit MAC address which is different for each SI unit.

Connector (BUS OUT) Connector for fieldbus outputs.

Marker groove Groove for an identification marker.

1

o.

2

6

3

4

Connector (PCI) Connector for Handheld Terminal.

Valve plate mounting hole Holes for fixing the valve plate.

Valve plate mounting groove Groove for mounting the valve plate.

5

7

8

Joint bracket Bracket for joining to adjacent units.

Unit connector (Plug) Connector for signals and power supplies to adjacent units.

Connector (BUS I ) Connector for fieldbus inputs.

9

10

11

Seal cap (2 pcs.) Fitted to unused connectors. (BUS OUT and PCI)12

Thank you for purchasing an SMC EX600 Series Fieldbus system.

Please read this manual carefully before operating the product and make sure you

understand its capabilities and limitations.

Please keep this manual handy for future reference.

To obtain more detailed information about operating this product, please

refer to the SMC website (URL http://www.smcworld.com) or contact SMC

directly.

Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or

equipment damage.

These instructions indicate the level of potential hazard with the labels of

"Caution", "Warning" or "Danger". They are all important notes for safety and must

be followed in addition to International standards (ISO/IEC) and other safety

regulations.

CAUTIO indicates a hazard with a low level of risk

which, if not avoided, could result in minor or

moderate injury.

Operator

This operation manual is intended for those who have knowledge of machinery

using pneumatic equipment, and have sufficient knowledge of assembly,

operation and maintenance of such equipment. Only those persons are

allowed to perform assembly, operation and maintenance.

Read and understand this operation manual carefully before assembling,

operating or providing maintenance to the product.

Caution:

Warning:

Danger:

WAR I G indicates a hazard with a medium level of

risk which, if not avoided, could result in death or

serious injury.

DA GER indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious

injury.

NOTE

The direct current power supply to combine should be UL1310 Class2 power

supply when conformity to UL is necessary.

The output rating is tested as a DC output for General use.

Safety Instructions

Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

Do not disassemble, modify (including changing the printed circuit board) or repair.

An injury or failure can result.

Do not operate in an atmosphere containing flammable or explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

If using the product in an interlocking circuit:

•Provide a double interlocking system, for example a mechanical system

•Check the product regularly for proper operation

Otherwise malfunction can result, causing an accident.

The following instructions must be followed during maintenance:

•Turn off the power supply

•Stop the air supply, exhaust the residual pressure and verify that the air is released before performing

maintenance

Otherwise an injury can result.

Provide grounding to assure the safety and noise resistance of the Fieldbus system.

Individual grounding should be provided close to the product with a short cable.

Warning

Caution

After maintenance is complete, perform appropriate functional inspections.

Stop operation if the equipment does not function properly.

Safety cannot be assured in the case of unexpected malfunction.

When handling, assembling or replacing the units:

•Avoid touching any sharp metal parts of the connectors for connecting units.

•When assembling units, take care not to get any fingers caught between units.

Injury can result.

•When disassembling units, take care to avoid excessive force.

The connection parts of the unit are firmly joined with seals and injury can result.

Maintenance

•Maintenance should be performed according to the Safety Instructions.

•Perform regular maintenance and inspections.

There is a risk of unexpected malfunction.

•Do not use solvents such as benzene, thinner etc. to clean each unit.

They could damage the surface of the body and erase the markings on the body.

Use a soft cloth to remove stains.

For heavy stains, use a cloth soaked with diluted neutral detergent and fully squeezed, then wipe up

the stains again with a dry cloth.

Refer to the SMC website (URL http://www.smcworld.com) for more information

about maintenance.

Assembly

Assembling the unit as a manifold

(1)Connect a unit to the end plate.

Digital and Analogue I/O units can be connected in any order.

Tighten the joint brackets to a torque of 1.5 to 1.6 m.

(2)Add more I/O units.

Up to 10 units (including the SI unit) can be

connected to one manifold.

(3)Connecting the SI unit.

After connecting the required I/O units, connect

the SI unit.

The method is as above in (1), (2).

(4)Mounting the valve plate.

Mount the valve plate (EX600

-

ZMV ) to the valve

manifold using the valve set screws. (M3 x 8)

Apply 0.6 to 0.7 m tightening torque to the screws.

(5)Connect the SI unit to the valve manifold.

Insert the valve plate into the valve

plate mounting groove on the side

of the SI unit.

Fix using the valve plate screws

(M4 x 6) supplied, to a torque of 0.7

to 0.8 m.

Installation

•Direct mounting

(1)When joining six or more units, fix the middle

part of the complete EX600 unit with an

intermediate reinforcing brace (EX600

-

ZMB1)

before mounting, using 2

-

M4 x 5 screws.

Tightening torque: 0.7 to 0.8 m.

(2)Mount and tighten the end plate at one end of

the unit. (M4)

Tightening torque: 0.7 to 0.8 m.

Fix the end plate at the valve side while referring

to the operation manual of the corresponding

valve manifold.

Mounting and Installation

Intermediate reinforcing brace

(EX600

-

ZMB1)

(2)Mount the end plate bracket (EX600

-

ZMA2) to the end

plate at the opposite end to the valves, using 2

-

M4 x 14

screws.

Tightening torque: 0.7 to 0.8 m.

(3)Hook the DI rail mounting groove on to the DI

rail.

(4)Press the manifold using its side hooked to the

DI rail as a fulcrum until the manifold is locked.

Intermediate reinforcing brace

(EX600

-

ZMB2)

1

End plate bracket

(EX600

-

ZMA2)

2

3

4

DIN rail

DIN rail mounting groove

•DI rail mounting

( ot available for SY series valves. Refer to the

SY catalogue.)

(1)When joining six or more units, fix the middle

part of the complete EX600 unit with an

intermediate reinforcing brace (EX600

-

ZMB2)

before mounting, using 2

-

M4 x 6 screws.

Tightening torque: 0.7 to 0.8 m.

EX※※-OMQ0014

Red BF LED is flashing.

Red BF LED is O .

Green SF LED is flashing.