Spida Machinery Mini 3 Installation and operating instructions

Mini 3

Operation & Service Manual

Contents

About this document.............................................................................................................. 3

Who will use this manual? ....................................................................................................................................... 3

Prerequisite knowledge ............................................................................................................................................. 3

What's in this document? ..................................................................................................... ...........................................3

Document conventions .............................................................................................................................................. 4

Support ............................................................................................................................................................................ 4

What is a Mini 3....................................................................................................................... 5

Key features .................................................................................................................................................................. .5

Serial plate ..................................................................................................................................................................... 5

Recommendations ....................................................................................................................................................... 6

Handling recommendations .......................................................................................................................... 6

Transport recommendations ......................................................................................................................... 6

Installation recommendations ....................................................................................................................... 6

Machine commissioning .................................................................................................................................. 6

Machinery usage warning..................................................................................................7

Safety information...................................................................................................................9

Safety information .................................................................................................................................................... 10

User warnings ................................................................................................................................................. 11

Safe operating procedures (SOPs) ...................................................................................................................... 12

Minimum company standards - pre-operation procedure ....................................................... 13

Minimum company standards - general ................................................................................................. 14

Minimum company standards - operation ............................................................................................. 15

Minimum company standards - maintenance ....................................................................................... 16

Hazard identification ................................................................................................................................................ 17

Foreseeable misuse .................................................................................................................................................18

Specifications..........................................................................................................................19

Parts identification................................................................................................................21

Mini 3 overview ......................................................................................................................................................... 22

Operator area ............................................................................................................................................................. 23

Operating controls.................................................................................................................................................... 24

Lower head assembly ............................................................................................................................................. 25

Hydraulic motor ......................................................................................................................................................... 26

Hydraulic drive system ........................................................................................................................................... 27

Hydraulic flow control valve ................................................................................................................................. 28

Footprint drawing ..................................................................................................................................................... 29

Mini 3 hydraulic schematic .................................................................................................................................... 30

Jigging ........................................................................................................................................................................... 31

Operating instructions ....................................................................................................... 33

Manual handling ....................................................................................................................................................... 33

Maintenance information ................................................................................................. 35

Maintenance points .................................................................................................................................................. 36

Daily maintenance schedule ................................................................................................................................. 37

Weekly maintenance schedule ............................................................................................................................ 38

Bi-annual maintenance schedule ........................................................................................................................ 39

Annual maintenance schedule ............................................................................................................................. 40

1

Risk assessment ....................................................................................................................41

Operator training checklist................................................................................................51

Warranty ................................................................................................................................. 55

Machinery/equipment information ...................................................................................................................... 56

Training certification .......................................................................................................... 57

Index ......................................................................................................................................... 59

2

ABOUT THIS DOCUMENT

ABOUT THIS DOCUMENT

This section provides information about this document.

WHO WILL USE THIS MANUAL?

This manual is the Mini3 Operation and Service Manual designed to show you how to use the functions

in the current release of Mini3.

PREREQUISITE KNOWLEDGE

This manual assumes you have:

•

Successfully completed proper training in safe working practices; and

•

Conducted a site risk assessment.

WHAT'S IN THIS DOCUMENT?

This document contains the following sections:

If you want to... Read...

Learn about this machine. “What is a Mini 3” on page 5.

Understand safety considerations for this machine. “Safety information” on page 9.

Read the specifications for this machine. “Specifications” on page 19

Learn the location of key components. “Parts identification” on page 21.

Learn how to operate the machine. “Operating instructions” on

page 33.

Read the risk assessment. “Risk assessment” on page 41.

Read the warranty. “Warranty” on page 55.

Complete the mandatory training certification. “Training certification” on page 57.

For more information, see the relevant section.

3

DOCUMENT CONVENTIONS

If accessing this document electronically, this document uses different fonts to indicate specific information as shown

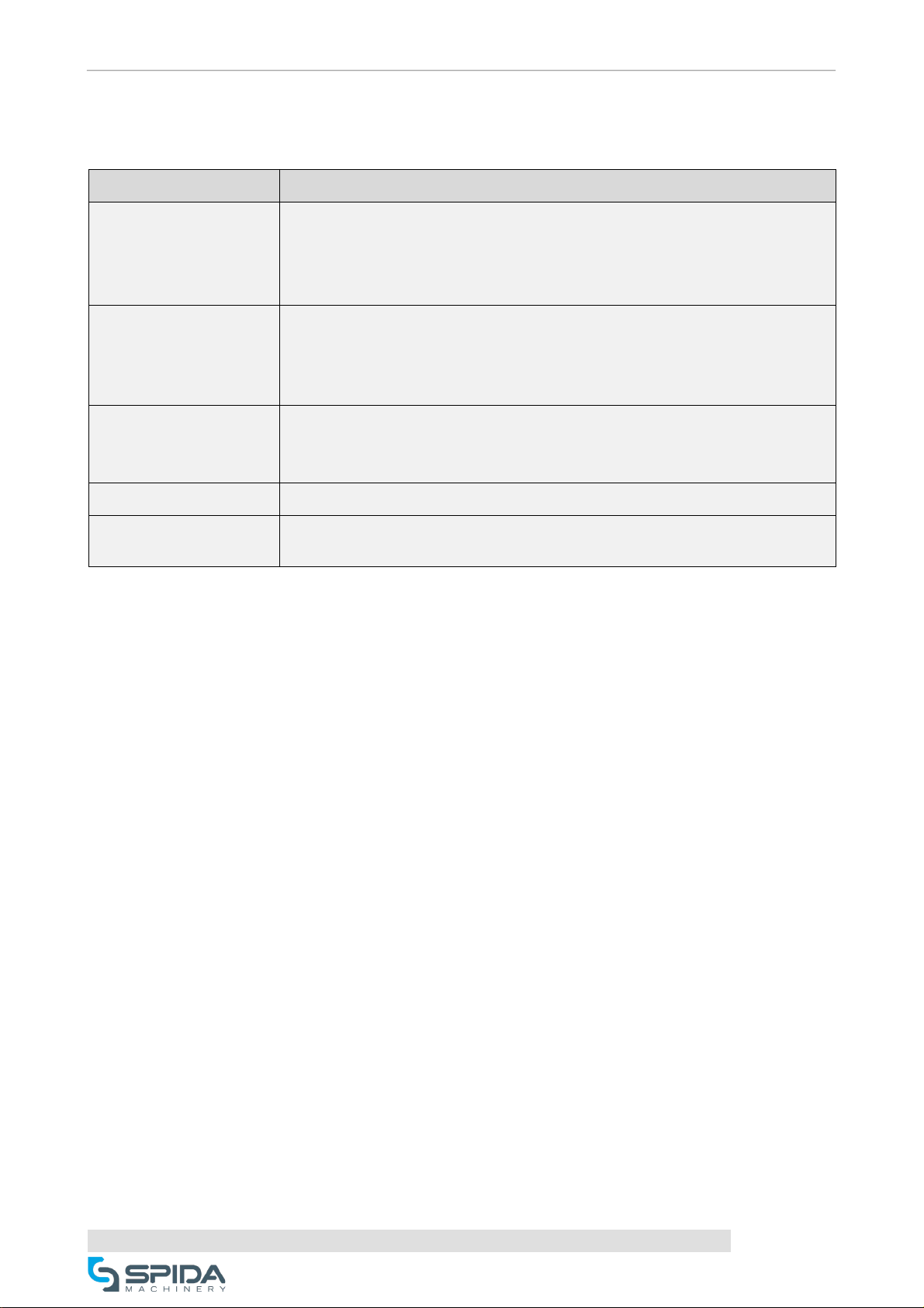

in the following table:

Font Example Indicates...

Bold Bold

Menu option that you can select, or a button/icon that you can click to

activate.

Double quotes

““

Cross-reference to another section in the document. For example, see

“Document conventions” on page 5.

Bold italic Bold italic Reference to another different document. For example, the Mini3

Operation and Service Manual.

Blue underline Blue

underline

Hyperlink that shows additional information. To see the additional

information, click the hyperlink. After clicking the hyperlink, you will see the

additional information, and the colour of the original hyperlink will change

to Purple underline to indicate you have used (or “visited”) the hyperlink.

Note

NOTE: Important information that you should know.

SUPPORT

For all Mini3 support issues, please contact Spida Machinery Support.

ABOUT THIS DOCUMENT

4

WHAT IS A MINI 3

WHAT IS A MINI 3

The Mini3 table press is designed primarily for pressing nail plate into timber.

The Mini3 may have floor strut jigging attached, or other forms of jigging for the holding of timber during the

pressing process, and should be used at all times to ensure a safe and accurate press.

KEY FEATURES

Mini3 has the following key features:

Feature

Variable speed drive to allow fabricators to drive the machine to suit their needs.

Large safety screen to ensure all body parts are kept well clear of pressing area.

30 Tonne pressing capacity.

Adjustable jigging and base plates.

SICK AG Industrial Safety System safety laser scanning system that stops the

press if foreign objects are detected within a specified distance.

(Optional) Floor strut jigging - pneumatic or manual clamping.

SERIAL PLATE

The following serial plate will be attached to your machine:

5

R

ECOMMENDATIONS

HANDLING RECOMMENDATIONS

It is advisable to use two lift trucks or cranes to manoeuvre the machine, due to the length and possible instability of the

ground when transporting the machine from the truck to the operating position.

TRANSPORT RECOMMENDATIONS

When transporting your machine:

1.

Ensure all additional jigging is boxed and secured with the machine.

2.

Ensure that the machine is strapped tightly at both ends.

3.

Do not place loads on top of the machine.

4.

The machine is to be kept free from road grime and rain, and is to be covered at all times when being transported.

INSTALLATION RECOMMENDATIONS

Spida Machinery recommends following the following installation procedure:

NOTE: This procedure may vary depending on customer requirements.

1.

The final operating position of the machine must be free from any rubbish or impediments.

2.

There must be good lighting in the installation area to allow proper positioning of the machine.

3.

The ground upon which the machine rests must not vary by more than 5mm over a 15m x 3m area.

4.

All electrical components must be checked by a qualified electrician prior to powering the machine, to check

for faults and any effects of condensation or other damage.

5.

Electrical commissioning to be to local standards and be performed by a qualified electrician.

MACHINE COMMISSIONING

1.

Remove all strapping and blocking from the machine.

2.

Power up the machine in the presence of a qualified electrician ensuring Stage 4 of installation has

beencompleted.

3.

Remove all other materials from the table (jigging etc.) and ensure that the press head is unhindered in its travel.

4.

Run the machine from one end to the other slowly.

5.

Insert a piece of timber with nail plates under the platen and check pressing capability.

6.

Check for any oil leaks.

7.

Check for undue noise.

8.

Check that all emergency stop switches disable the machine fully.

WHAT IS A MINI 3

6

MACHINERY USAGE WARNING

MACHINERY USAGE WARNING

Spida Machinery takes its obligation to the Australian/New Zealand (AUSNZ) standards on machinery manufacturing

seriously and commissions independent certifiers to assess and approve various hardware equipment configurations.

Spida Machinery commissions independent certifiers to assess and approve our machinery equipment to ensure it

complies withall relevant legislation.

As the Original Equipment Manufacturer (OEM) of Spida machinery, Spida Machinery has a duty of care to advise you

thatthis machine should only be used for its designed and intended use by operators who have received appropriate

training.

As such, you may NOT make any unauthorised changes to the machine. This includes electrical, mechanical, pneumatic or

any changes to any other operational functionality without prior written approval from Spida Machinery.

Spida Machinery takes NO responsibility for potential problems that may arise if you make any unauthorised

modifications to the machine or use in any configuration or for any purpose it was not designed.

7

8

SAFETY INFORMATION

SAFETY INFORMATION

WARNING! Only operators who understand the Operation and Service Manual and are trained in thesafe

operation of a Mini3 are allowed to use this machine.

NOTE: This manual is generic. Depending on the options selected, your actual machine may vary

from the illustrations and information contained in this manual.

The machine must only be used for the purpose specified above and must be set up, maintained and operated in

accordance with the instructions contained in this manual and the best standards of industrial machinery practice.

Equipment will perform better and last longer with regular inspection and maintenance.

Spida Machinery strongly recommends that a risk assessment be carried out on site to ascertain the PPE. At minimum, all

personnel operating this machine use the following personal protective equipment (PPE):

•

Respirator or dust mask;

Each member of the factory personnel shall be instructed in the safe use of the machine using this document as a

guideline and shall sign a copy of this document to indicate that they have been instructed in the safe operation of this

machine and have thoroughly read and understand the Mini3 Operation and Service Manual as well as any

additional supplied information.

A copy of this document should be placed in the personnel file of each employee that receives instruction on the

Spida Machinery Mini3.

A second copy should be made available to each employee for their reference.

This machine must only be operated by personnel who have been properly instructed in all aspects of the machine’s safe

operation.

NOTE: This Mini3Operation and Service Manual is intended as a guide for safe operation of

the equipment by the user; however users should not consider this document all-inclusive

and should conduct their own risk assessment prior tooperating

For all questions about this equipment, please contact Spida Machinery Support.

9

SAFETY INFORMATION

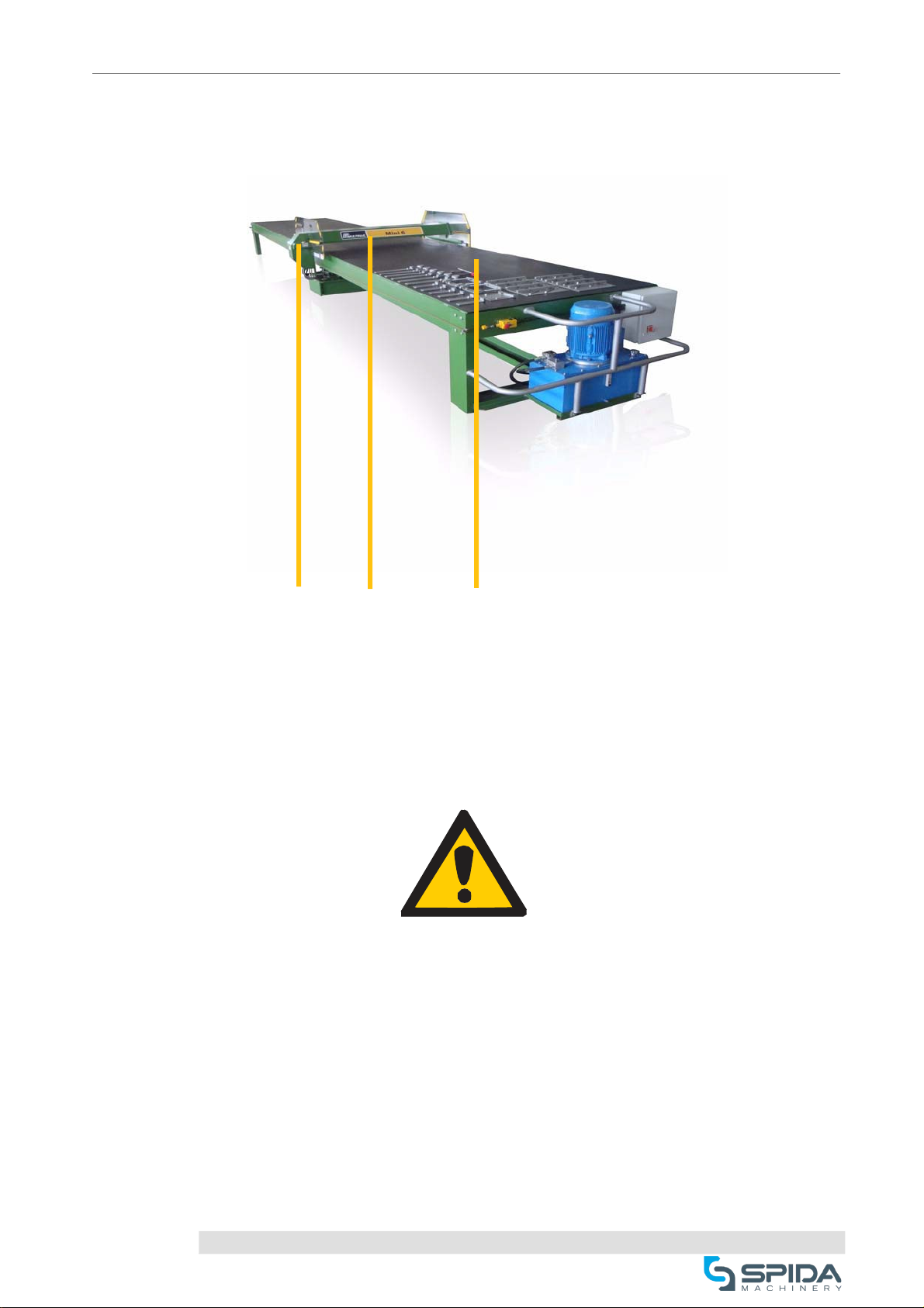

All operators should be aware of the following safety points before attempting to operate the Mini3.

Operator

area

Press

head

Table

•

Operator area - the operator must always stand in this area this when press is in operation.

•

Press head - apart from the timber and nail plates / multistruts, no other materials apart from the jigging

should be placed between the press and the table. Before pressing, remove all surplus tools, timber, and

jigging etc. from the table to prevent damages.

•

Table - all persons apart from the operator must be clear of the table when press is in operation.

WARNING! Only qualified electricians should attempt to alter any electrical components on the press.

SAFETY INFORMATION

10

USER WARNINGS

•

All equipment and components should be inspected upon delivery and at weekly intervals for looseness,

fracture, bends, sharp edges or surfaces and any other condition that may contribute to a human mishap or

further deterioration of the equipment. We suggest a log be kept for this purpose.

•

When broken, damaged or loose parts (or any condition that may represent a hazard) are observed, corrective

action should be taken immediately. Inadequate attention to maintain the equipment can cause the

premature failure of these parts. We suggest this information also be logged.

•

The electrical boxes should be locked at all times to avoid casual entry by unauthorised persons as touching

livecircuits is hazardous.

•

Split, broken, warped, twisted or timber with excessive wane should be avoided or used with caution because

of the greater possibility of the timber not being held securely.

•

The equipment is not to be used for any other purpose than the joining of nail plates / MultiStruts to timber.

WARNING - This machine must only be operated by personnel who have been properly instructed in all aspects of

the machine’s safe operation.

They must also be wearing the recommended protective clothing and have thoroughly read and understood this

operation and service manual.

SAFETY INFORMATION

11

SAFE OPERATING PROCEDURES (SOPS)

You should understand the following SOPs before operating the machine:

Minimum company standards For more information, see...

Pre-operation “Minimum company standards - pre-operation procedure” on page 12.

General “Minimum company standards - general” on page 13.

Operation “Minimum company standards - operation” on page 14.

Maintenance “Minimum company standards - maintenance” on page 15.

For more information, see the next sections.

MINIMUM COMPANY STANDARDS - PRE-OPERATION PROCEDURE

The Mini3 operator will carry out the following safe work procedure before operating the machine:

Potential hazard Safe work procedure

Safety Ask questions if you have any doubts about doing the work safely.

Check and adjust all safety devices.

Poor guarding Ensure all supplied guards are fitted correctly and are adequately guarding

nip points and moving parts.

Make sure guards are in position and in good working condition.

Poor housekeeping Inspect Mini3 and surrounding areas for obstructions and defects.

Clean built up dirt and sawdust from around machine, electrical leads and

power points.

Electrical faults Inspect electrical leads for damage.

Incorrect or damagedcomponents Check machine for cracks, warping or misalignment.

Check for leaking or defective components.

Incorrect machine settings Check hydraulic pressures, travel speed and pressing action.

Material handling Follow safe material handling guidelines.

Inoperable safety switches Check that start/stop buttons, emergency stop buttons and safety bars are

operating effectively.

Incorrect accessories Use only the accessories designed for each specific machine and

application.

Foreign objects Check that foreign objects and tooling etc. are removed from the machine

before turning the power on.

Warning! The Mini3 can be dangerous if not used properly.

SAFETY INFORMATION

12

MINIMUM COMPANY STANDARDS - GENERAL

The Mini3 operator will apply methods of safeguarding and safe working practices:

Potential hazard Safe work procedure

Clothing Do not wear loose clothing or work gloves, neckties, rings, bracelets or other jewellery

that can become entangled with moving parts.

Protective equipment Always wear correct Personal Protective Equipment including: hearing protection,

safetyglasses, safety footwear.

Slip, trips and falls Avoid awkward operations and hand positions where a sudden slip could cause hand or

part of your body to move into the path of machine.

Electric power cords should be above head level or in the floor in such a way that they

are not tripping hazards.

Floor areas and machine table should be level and non-slip.

Clean up spills immediately.

Workplace Use good lighting so that work piece, pressing head, and machine controls can be seen

clearly.

Position or shade lighting sources so they do not shine in the operator/s eyes or cause

any glare or reflections.

Ensure that the floor space around equipment is sufficient to enable you to fabricate the

size of work piece being processed safely without bumping into other workers or

equipment.

Keep work area free of clutter, well swept, and well lit.

Ensure precut stock is stacked in appropriate area to avoid accidental contact with

sharp ends.

Machine capacity Do not use the machine for any other purpose than that for which it is designed.

Housekeeping Clean built-up foreign material, unused jigging/ tooling and dirt from around machine,

electrical leads and power points.

Defects Report all defects to the supervisor for appropriate action.

Warning! Do not operate a defective machine.

SAFETY INFORMATION

13

MINIMUM COMPANY STANDARDS - OPERATION

The Mini3 operator is responsible for adhering to safety rules and requirements while operating the machine:

Potential hazard Safe work procedure

Personal protection Wear safety glasses.

Wear hearing protection that is suitable for the level and frequency of the noise you are

exposed to in the woodworking area.

Wear dust masks when required.

Use gloves to protect hands from splinters when handling wood but do not wear them

near machinery parts where the gloves can catch.

Machine guarding Ensure safety bars are operational.

Make sure all guards are in set positions.

Material defects Inspect stock for nails or other foreign materials before pressing.

Only use material and jigging designed for the machine.

Operator technique Operate levers to manoeuvre the machine.

Make sure machine path is clear.

Do not remove stock from a Mini3 table until the pressing head has been returned to

its “resting’ position. Instruct all other workers to stand clear when the machine is

operational.

User warnings Never place hands, arms or other body parts underneath the pressing platen or in the

path of a moving machine.

Always adhere to all attached safety and warning labels on machine.

Unattended machine Do not leave a running machine unattended – leave only after the machine has been

turned off and it has come to a complete stop.

Warning! Do not distract or startle an operator while he or she is using the equipment. Horseplay can lead to serious

injuries.

SAFETY INFORMATION

14

MINIMUM COMPANY STANDARDS - MAINTENANCE

The Mini3 operator may be responsible for maintenance, cleaning and blade changing of the machine:

Potential hazard Safe work procedure

Cleaning and

maintenance

preparations

Turn the power off, isolate/tag and unplug the power cord (or lock out the power

source) before inspecting, changing, cleaning, adjusting or repairs to the machine.

Also turn the power off when discussing the work.

Do not use compressed air to remove sawdust, etc., from machines or clothing.

Stop/start buttons Make sure that start and stop buttons are in good working condition and within easy

and convenient reach of an operator.

Start buttons should be protected so that accidental contact will not start the

machine.

Hydraulics Ensure that all hydraulic components are in good working order.

Check oil temperature and quality. Inspect and replace filters as per the

maintenancemanual.

Machine settings Check hydraulic pressures, travel speed and pressing action.

Guarding Ensure safety guards are fitted correctly, in good working condition and guard the

machine adequately.

SAFETY INFORMATION

15

HAZARD IDENTIFICATION

This machine has been assessed for the following possible hazard types:

Hazard Additional information

Crushing The possibility of the operator crushing a hand is minimal if the guards are not removed

and press is operated correctly as has been advised.

As there is a possibility of the operator not seeing another person placing their hand in

the press during operation, the machine should only be operated by one person during

the pressing cycle and all other personnel to remain a distance of one metre from

machine.

Cuts The sharp teeth of nail plates could cut the operator.

Care must be taken when handling nail plates.

The operator could be cut by sharp edges on the table or press head caused by damage

to the table or press head.

Electrical The power requirement for the machine is 3 phase + E + N, 415 volts and is equipped

with an overload

Unauthorized persons must not alter or interfere with the electrical supply at any time.

Hydraulic oil Oil spills are possible if the hoses or fittings become loose or damaged.

Hoses could be damaged from constant rubbing against metal parts during operations

and burst.

Slips, trips and falls There is the potential to slip, trip or fall if good housekeeping practices are not adhered to

and the work area is not kept free of saw dust, loose timber and offcuts.

Cleaning The machine must be isolated from the power and locked at the Main Power Isolation

Switch before any cleaning or maintenance is to be performed.

The key is to be removed and kept by the personnel entering the operational area.

Ergonomics The operators are required to be able to move freely around the front and rear of the

machine.

The machine working height cannot be adjusted.

The machine cannot be operated while seated.

The operators are not required to climb onto or into the machine while the machine is

operating, loading or unloading.

The operators must wear approved safety footwear, eye protection and hearing

protection.

Guarding The machine MUST NOT be operated with any of the guards removed.

The machine is fitted with steel mesh guard on the operators control panel, to allow the

operator to see the pressing operation.

Personal protective

equipment

PPE is not supplied with this machine. The employer or end user is responsible to ensure

that the correct type of PPE is supplied, that it is properly maintained and the user is

trained in the correct fitting of the PPE.

SAFETY INFORMATION

16

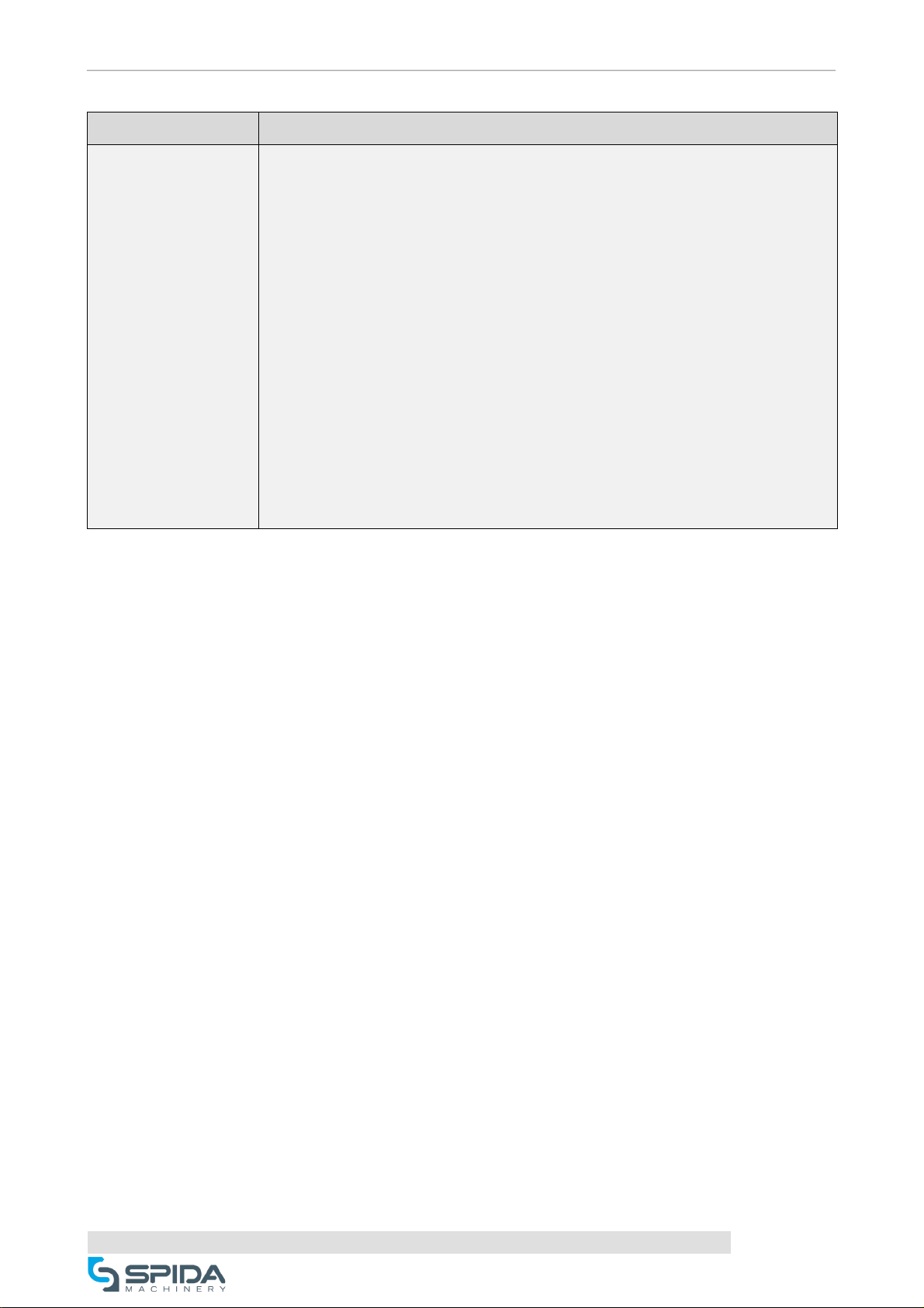

Hazard Additional information

Recommendations That the operator is trained, on induction, of the dangers of crushing or cuts when

operating the machine.

The electrical system is to be serviced by a qualified electrician only.

That all operators are walked through the operator’s manual and all potential hazards are

well known.

That good housekeeping is maintained at all times to avoid the risk of slips, trips or falls.

That approved eye and hearing protection is used at all times when operating the

machine.

That approved safety footwear is worn at all times when operating the machine.

That if the machine is not operating as efficiently as specified, the operator notify their

supervisor who in turn will notify the supplier.

All guards and safety devices are not to be removed.

The potential for a pedestrian to be injured is possible. It is recommended that a yellow

line be painted on the floor on a one metre (1000mm) perimeter surrounding the

workingarea of the machine.

SAFETY INFORMATION

17

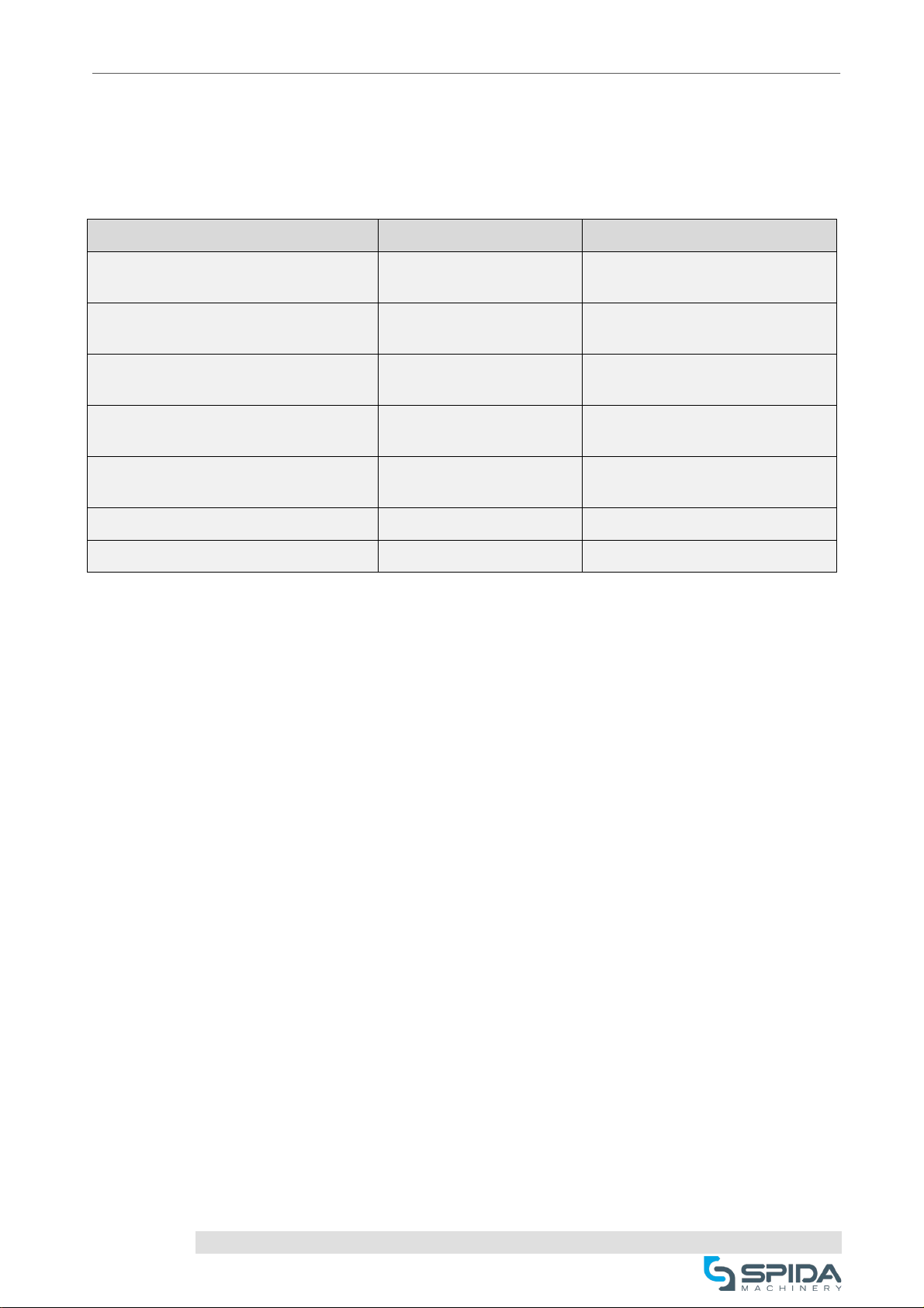

FORESEEABLE MISUSE

Through experience, Spida Machinery’s technical staff have listed (in order of occurrence) the most common misuses of

the machine by operators, the resultant symptoms that result and the rectification required to address the misuse and

return the machine to optimal working order.:

Misuse Symptom Rectification

Harsh accelerating of the head drive. Drive cog wear and

breakage.

Replacement of cogs, retention

ofdrive chain.

Harsh stopping of the head drive. Drive cog wear and

breakage.

Replacement of cogs, retention

ofdrive chain.

Driving the head into the end stop. Leg and head damage. Structural repairs to the head

frameand table ends.

Over-tightening of bolts on jigging

table.

Shearing bolts. Welding, drilling and tapping the

bare holes.

Driving the head without disengagingthe

press from the material.

Drive chain or cog breaks. Replacement chain and / or cogs.

Stamping/pressing. Head damage. Head O/H cylinder seal.

Non-specific material. Damage. Replace.

NOTE: Any other misuse and resultant damage of the machine is deemed non – foreseeable as its

occurrence is not consistent.

SAFETY INFORMATION

18

Table of contents

Other Spida Machinery Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

PGR

PGR PH Series Maintenance and operation instructions

ABB

ABB SACE Emax 2 Installation, operation and maintenance instructions

Kval

Kval Acro-HD Operation and service manual

Meler

Meler MICRON+ GEAR Series instruction manual

PCB Piezotronics

PCB Piezotronics HT356A01 Installation and operating manual

Siemens

Siemens FLENDER N-EUPEX D operating instructions