SPINEA TwinSpin G Series User manual

SPINEA, s.r.o.

Okrajová 33

080 05 Prešov

Slovakia, EU

ID No.: 31 687 580

Incorporated in Company Register of District Court Prešov,

Section: Sro, File No.: 10314/P

Tel:

E-mail:

Web:

+421 51 770 01 56

www.spinea.com

OPERATING MANUAL

Edition I/2020

High precision reduction gear

TwinSpin® G series

2

Operating manual TwinSpin®G series reducers

1. General information

1.1 Content of this manual

•This manual contains important information about how to safely operate the TwinSpin®G series reducers and properly

assemble, maintain, and dispose of it.

•In the rest of this document TwinSpin®G series reducer is simply referred to as „reducer” or „product”.

•The operator must ensure that these instructions are read and understood in full by everyone assigned or tasked with

installation, operation or maintenance of the reducer.

•These instructions must be kept close to the machine in which the reducer is used and be easily accessible in case of need

•The original of this document was prepared in the Slovak and English languages, all other language mutations are translations

of these instructions only, and issuer accepts no liability for such translation. The document is subject to change without prior

notification.

1.2 Terminology and Types of Warning

Terminology and Type of Warning

Signal word Definition

DANGER

D

This signal word indicates imminent danger and severe injury or death to the user.

WARNING

W

This signal word indicates potential hazard of severe injury or even death to the user.

CAUTION

C

This signal word indicates potential hazard that could cause minor or serious injuries.

NOTE

N

This signal word indicates potential hazard that could cause material damage.

3

Product characteristics

•Only persons who have read and understand this manual may assembly, operate and maintain reducers. Further, the

persons operating with reducers must have qualification required for working with this type of devices.

•Responsible persons/managers/supervisors should prohibit to work with reducers to any person who do not

understand reducer as a product.

•If the end user of the product works in the military field or if the product is to be used for the manufacturing of

weapons, the product may be subject to trade controls and export regulations. Before the exporting of the product

therefore please check the export and trade control terms and conditions and take the required actions.

•If a fault or a malfunction of the product may directly endanger human lives or if the product is used in devices that

may damage the human health (nuclear, space, healthcare facilities, various security systems, etc.), regular checks are

essential. In such a case please contact our sales agent or our nearest business office.

•Although this product has been manufactured under strict quality control, if it is to be used in machines that, in

the event of a malfunction, may seriously endanger human lives or damage equipment, it is essential to adopt

appropriate safety measures.

•Installation should be done only by trained persons with knowledge of drive technology and mechanics.

•Before installing check if the reducer or its parts are not damaged.

•Be careful not to drop reducer on the floor or hit any metal object when moving as this can damage internal

component and cause malfunction of reducer.

•Do not hit any part of reducer with any tool e.g. hammer as this can cause damage to internal components

or malfunction of reducer.

•Do not use hammer or any impact tool to assemble reducer into its final position as this can damage internal

surfaces/components and cause malfunction of reducer.

•Do not touch reducer when running.

•Reducer will heat when running for certain period of time. Be careful not to touch its surface shortly after reducer

has stopped.

•Make sure the reducer with connected drive is turned off the power and cooled down before you exchange

lubricant, make any sort of checking or repair.

•Make sure that reducer and any connected component is not rotating/moving during maintenance, checking

or repair.

•Do not expose reducer to open fire or use in proximity of substances which are easily flammable or explosive.

•Reducers in standard version are not painted or covered with anticorrosive protection. Do not operate in humid

or corrosive environment as this may lead to damage of the reducer.

•Do not operate reducer outside of the specified technical parameters.

•Do not continue in operation if reducer is damaged or temperature on the case has exceed abruptly 60°C.

•Before disposal remove all of the lubricant from inside of reducer.

•Reducer should be disposed of in accordance with national regulations for industrial waste.

2. Safety instructions

2.1 General

2.2 Installation

2.3 Operation

2.4 Disposal

D

N

N

W

W

4

Operating manual TwinSpin®G series reducers

2.5 EU Directive 2006/42/EC

Reducer is a mechanical component only. It is used in machines and systems. Therefore, it is not a machinery or a partly

completed machinery within the meaning of the Directive 2006/42/EC of the European Parliament and of the Council.

A declaration of conformity is not therefore necessary for reducers.

Reducer must not be operated until it has been ensured that machine/system/device in which reducer is installed complies

in full with Directive 2006/42/EC.

5

Product characteristics

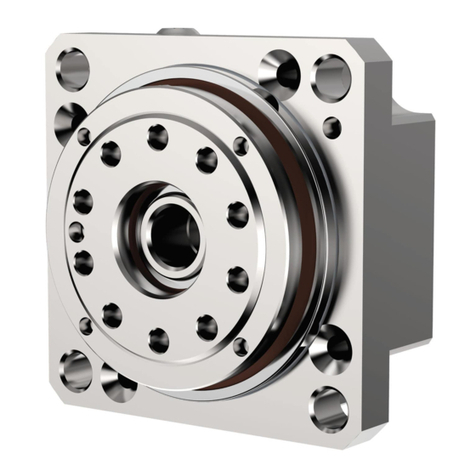

The picture below describes G series reducer and its main components.

•The reducer is delivered completely assembled, without fixing screws and in a protective package.

•Each reducer is identified with a type label, containing the following data:

•manufacturer

•product type and size

•reduction ratio

•model

•serial number

Basic parameters of reducer as torque and allowed speed together with outer dimensions can be found

•in our catalogue

•at our web page www.spinea.com

3. Product description

3.1 Reducer components

3.2 Delivery conditions

3.3 Technical data and dimensions

Input shaft

Case

Main ring

Output shaft

6

Operating manual TwinSpin®G series reducers

3.4 Reducer lubrication

•The reducers as a standard are delivered lubricated with Castrol TRIBOL GR 100-0 PD or TRIBOL GR TT 1 PD grease.

Alternatively, the Castrol OPTIGEAR 150 oil may be used.

•When spline connection is used to connect motor with reducer, always use grease applied on the splined shaft.

Type of the grease is KLUEBER Microlube GL 261.

•The lubricant change interval highly depends on the individual operating conditions. High temperatures, speeds

and loading will reduce the service life of the lubricant. In many cases re-lubrication will not be necessary because

the reducer is filled for a long life. The recommended interval for lubricant change is 20 000 operating hours when

oil is used as a lubricant.

•Fully sealed reducers are always delivered pre-filled with lubricant. In case when open reducer is delivered,

consult our catalogue for proper amount of lubricant to fill in.

•Do not mix various types of lubricant in reducer. Doing so may cause damage or malfunction of reducer.

•Consult our catalogue or our customer service for detailed information about lubrication of reducers.

•The reducers should be transported in closed transport vehicles, in containers secured against movement

or overturning. The mode of transport should follow the mutual agreement between the customer and the supplier.

In addition, the product must be protected against the elements, aggressive vapors, dust, and mechanical damage.

The manufacturer recommends to store reducers in the original transport package.

•The standard packaging in the original package ensures corrosion protection for the period of 6 months during

storage in closed rooms with the ambient temperature from 5°C to 25°C and the relative humidity up to 60 %.

After 6 months it is necessary to preserve the reducer again.

•Never stand under suspended load as this possess risk of injury.

The warranty is specified in the General Delivery Terms of SPINEA, s.r.o. For more information visit our website: www.spinea.com

3.5 Storage and Transport

3.6 Warranty

N

N

W

7

Product characteristics

•To get the maximum performance from the reducer, it is important to pay attention to the installation, assembly accuracy,

sealing and lubrication. Most motor adapter flanges are available on request, please contact the sales department or your local

sales representative for further assistance.

•Reducer is a single stage, zero backlash high precision gear which may be used only when properly assembled. The reducer

can be operated in horizontal or vertical position.

•The reducer surfaces are treated with corrosion inhibitor. Please remove all corrosion inhibitor from all surfaces which are to be

connected to the input and output components / devices. Inhibitor residues negatively impact friction coefficient of clamping

and bolt connections.

•To ensure safe connection of bolt connection we strongly recommend to use 10.9 quality screws and higher.

•Requirements on radial and axial runout with direct connection with motor shaft made according to DIN 42955R

are on the picture below. Please consult DIN 42955R standard for values of the tolerances.

4. Assembly Instructions

4.1 Initial notes

4.2 Assembly preparations

4.3 Assembly tolerances

8

Operating manual TwinSpin®G series reducers

** Screw material 10K

Tightening torques of screws

Screw Tightening torque [Nm] Clamping force [N] Screw material class and specification

M3 1,9 / 2.2 3 100 / 3 700

10.9 / 12.9K*

*10K / 12K

Rm= 1 000 / 1 200 MPa - min. tensile strength of screw material

Rp0.2 = 900 / 1 080 MPa - min. yield strengths

M4 4.3 / 5.1 5 300 / 6400

M5 8.4 / 10.2 8 800 / 10 600

M6 14 / 17 12 400 / 14 900

M8 35 / 42 22 750 / 27 300

M10 70 / 85 36 200 / 43 500

M12 122 / 147 52 900 / 63 500

Allowable torques transmitted through connecting screws

Size

On the output flange On the case / main ring

Number x screw Pitch diameter

[mm]

Transmitted torque

[Nm] Number x screw Pitch diameter

[mm]

Transmitted torque

[Nm]

TS 75 12xM5 38 360 18xM3 69 340

TS 85 12xM5 50 470 18xM3 81 400

TS 95 18xM4 53 450 18xM4 88 760

TS 115 18xM5 68 970 18xM4 108 930

TS 125 18xM6 71 1 190 18xM5 116 1 380

TS 155** 18xM8 96 2 950 28xM5 146 2 670

TS 185** 24xM8 119 4 870 30xM6 177 4 940

TS 225** 32xM8 156 8 500 21xM8 207 7 400

•For the safe transmission of external loads applied to the reducers, it is required to use connecting screws of at least 10.9 grade

and to degrease contact surfaces of friction joints before the installation. Tightening torques of screws are shown in the table

below.

•Allowable torques transmitted through connecting screws on flange and case are shown in the table below.

4.4 Tightening torque

4.5 Assembly procedures

•Please note that this procedures are concerning assembly of fully sealed reducers only.

•Always use protective aids when assembling reducer to motor.

C

9

Product characteristics

•Make sure that all bolt holes, screws and connecting adjacent surfaces are free of grease and dirt.

•Assemble the motor flange to the input side of the Reducer, use prescribed tightening torques.

•Slowly insert the motor with key properly oriented into the reducer input shaft. Please do not use excessive or impact force

to get motor into final position.

•Center the motor and tighten the bolts to the motor flange.

Assembled keyed motor with a reducer – direct connection

4.5.1 Mounting with a keyed motor shaft

Motor

Motor Flange

Reducer

10

Operating manual TwinSpin®G series reducers

•Make sure that all bolt holes, screws and connecting adjacent surfaces are free of grease and dirt.

•Assemble the motor flange to the input side of the reducer, use prescribed tightening torques.

•Make sure that the splined shaft on the motor or the spline adapter is greased with special grease (see chapter

3.4 Reducer lubrication). Failure to do so will damage splined connection.

•Slide the spline adapter on motor shaft, pull over the clamp ring and tighten with correct tightening torque. Use tightening

torque specified by clamp ring manufacturer.

•Slowly insert the motor with spline properly oriented into the reducer input shaft. Please do not use excessive force or impact

to get the motor into a final position. Use gentle movement to adjust the splined shaft into counter-surface inside of the input

shaft.

•Center the motor and tighten the bolts connecting motor to the motor flange.

Motor assembled with a reducer - spline connection adapter

4.5.2 Mounting with a spline connection

Motor

Motor Flange

Clamp Ring

Spline adapter

Reducer

11

Product characteristics

•Make sure that all bolt holes, screws and connecting adjacent surfaces are free of grease and dirt.

•Assemble the coupling to the input shaft of the reducer. Tighten the bolts. When assembling coupling observe instructions

provided by the coupling manufacturer.

•Assemble motor flange to the input side of the reducer, use prescribed tightening torques.

•Slowly slide motor into other side of coupling. Please do not use excessive force or impact to get motor into final position.

•Center the motor and tighten bolts to the motor flange and clamping connection on the coupling. Observe tightening

torques specified by coupling manufacturer.

4.5.3 Mounting with a coupling

Reducer

Motor assembled with a reducer – coupling connection

Motor

Motor Flange

Coupling

12

5. Operation of the reducer

6. Service

•Run the reducer only within its specified technical parameters.

•Use reducer in clean and dry environment.

•Operate the reducer within defined ambient temperature range -10°C to +40°C. Please contact manufacturer when

operating conditions are outside of those limits.

•Ensure that temperature of the reducer surface does not exceed 60 °C. In case your application requires higher running

temperatures on the surface of the reducer contact manufacturer.

•Check reducer for leaks. Sometimes excessive lubrication from sealing dustlip will cause small leakage, wipe it out

and observe if leakage continues.

•Check for noise during running-in and periodically when operating the reducer.

•To request service or information concerning reducers please contact our office listed below.

Operating manual TwinSpin®G series reducers

13

SPINEA, s.r.o.

Okrajová 33

080 05 Prešov

Slovakia, EU

ID No.: 31 687 580

Incorporated in Company Register of District Court Prešov,

Section: Sro, File No.: 10314/P

Tel:

E-mail:

Web:

+421 51 770 01 56

www.spinea.com

OPERATING MANUAL

Edition I/2020

High precision reduction gear

TwinSpin® G series

Table of contents

Other SPINEA Industrial Equipment manuals