Spitwater JETFIRE J20A Operating instructions

1

L-L 283.01-SW

ORIGINAL INSTRUCTIONS

OPERATING AND MAINTENANCE

MANUAL

J20A & J45A

Made in

Italy for:

Spitwater Australia Pty Ltd

953 Metry St

North Albury, NSW

Australia

WARNING:

THIS HEATER IS APPROVED FOR INDUSTRIAL USE ONLY.

Read and understand this instruction manual before operating this

unit and retain for future reference and pass on with the unit in the

event of a change of ownership.

Failure to follow operating, safety and maintenance instructions

outlined in this manual releases Spitwater Australia from any

responsibility for any accidents or damage incurred and may render

any warranty void.

2

L-L 283.01-SW

INTRODUCTION

Spitwater Australia is proudly Australian owned and operated since 1983. Our promise is to

provide our customers with superior quality portable industrial heaters built to the highest of

standards that will see many years of reliable service.

The JETFIRE range of portable industrial heaters are designed to give safe, efficient and

reliable service when the correct operating and safety instructions are followed, and proper

attention is given to all required maintenance procedures in order to maintain the unit in peak

operating condition.

This manual provides the up to date information necessary for the user to operate the unit and

carry out regular inspection and maintenance.

Please note that the information given within this manual may be subject to revision in

compliance with Spitwater Australia’s policy of continual improvement.

The JETFIRE range of heaters should only be used in the manner and purpose for which they

were intended

and in accordance with the recommendations and safety precautions detailed in this manual

and in operating instructions and stickers on the unit itself.

All JETFIRE heaters undergo rigorous safety and operational tests before being dispatched into

the marketplace however it is still imperative that prior to used, all operators have read and

understood all information and instructions provided and are aware of possible hazards.

GENERAL DESCRIPTION & INTENDED USE

Jetfire Heaters are specifically designed to solve all problems relating to heating drying and

desiccating in commercial and industrial applications. Some examples of applications are in

warehouse and factory heating, animal husbandry and greenhouse applications.

SPARE PARTS, ACCESSORIES & SERVICE

Spitwater has an extensive range of spare parts and accessories to suit all your heating needs.

For spare parts, accessories and service please refer to the contact section on

www.spitwater.com.au or contact 1800 SPITWATER (1800 774 892).

3

L-L 283.01-SW

TECHNICAL DATA

MODEL

J20A

J45A

PRODUCT CODE

JGDA020I

JGDA045I

UNIT

PERFORMANCE

HEAT OUTPUT

17.92

36.11

kW

FUEL PRESSURE – REGULATOR

70max/30min

150max/40min

kPa

FUEL PRESSURE – BURNER

70max/30min

150max/40min

kPa

NOMINAL GAS CONSUMPTION

65

130

MJ/h

MINIMUM ROOM VOLUME 350 850 M3

FUEL

FUEL TYPE

Universal

LPG

Universal

LPG

GAS CYLINDER SIZE

45

45

Kg

NOZZLE / INJECTOR SIZE

1.1

1.2

mm

ELECTRICAL

ELECTRICAL SUPPLY

230/1/50

230/1/50

V/~/Hz

CONNECTED LOAD

90

240

W

IGNITION TYPE

AUTOMATIC

AUTOMATIC

DIMENSIONS, WEIGHT AND OTHER

LENGTH

455/505

700

mm

WIDTH

277

317

mm

HEIGHT

500

538

mm

WEIGHT

9.5

16

Kg

MIN. DISTANCE TO COMBUSTIBLE MATERIAL

3

3

m

The manufacturer reserves the right to modify designs, features and technical data without

notice.

4

L-L 283.01-SW

DESCRIPTION OF SYMBOLS

The following symbols are used throughout this instruction booklet in order to mark important

paragraphs or sections that are due particular attention. Their meaning is listed next to them for

your attention.

WARNING

Failure to follow

instruction could

result in injury

or death

WARNING

Failure to follow

instruction could

result in damage to

machine

These are tips

and instructions

to ensure safe

and proper

operation

The following symbols are used on the machine in order to warn user of potential injury if not

cautious. Their meaning is listed next to them for your attention.

WARNING

Hot surface

Do not touch,

will result in

injury

WARNING

Electric shock

Disconnect power

before removing

cover

IMPORTANT SAFETY INSTRUCTIONS AND PRECAUTIONS

WARNING:

This heater shall only be used by persons instructed in its use and who have

been authorized to do so. Before using this heater please pay attention to the

following safety warnings as failure to do so could result in serious injury or

even death.

SAFETY LABELS

Always pay attention to the safety instructions provided on each label. Do not alter or

remove safety labels

5

L-L 283.01-SW

UNIT COMPONENTS, FEATURES AND CONTROLS

11

1 COMBUSTION CHAMBER

2BURNER

3COOLING FAN

4 HANDLE

5IGNITION ELECTRODE

6THERMOCOUPLE (M model)

7 IONISATION ELECTRODE (A model)

8RESET BUTTON

9HEATING SWITCH

10 ROOM THERMOSTAT PLUG

11 POWER CORD

IMPORTANT SAFETY INSTRUCTIONS AND PRECAUTIONS

GENERAL

•This heater must only be operated by persons instructed in its use

who have been especially authorized to do so.

•THIS HEATER IS APPROVED FOR INDUSTRIAL USE ONLY.

•NOT FOR DOMESTIC USE. Space heating only.

•DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILST IN

OPERATION

•DO NOT USE OR STORE FLAMMABLE MATERIALS IN OR NEAR THIS

APPLIANCE

•DO NOT MODIFY THIS APPLIANCE

•DO NOT PLACE ARTICLES ON OR AGAINST THIS APPLIANCE

•USE IN A WELL VENTILATED SPACE.

•Do not operate the heater if it is damaged.

•This heater must be positioned and operated on flat stable ground, not exposed to the

elements (rain, hail etc.) and must be operated in an upright position.

•Never leave the heater unattended while operating.

•Make sure you have read and understood the whole instruction manual before

installing, operating or carrying out any maintenance on the unit.

•Warnings and data plates on the unit provide important directions and information on

the safe use of the unit.

6

L-L 283.01-SW

•In addition to these operating and safety instructions, all accident prevention

regulations as well as any standards relating to the installation and operation of

heaters applicable in your country must be strictly followed.

•This unit is not intended for use by children. Children must always be supervised

when in the vicinity and ensure that they DO NOT play with the unit. Further, it is not

intended for use by persons with reduced physical, sensory or mental capabilities, or

lack of experience or knowledge.

•The heater is not to be installed in an area where there is a risk of fire or explosions;

•

Never operate this heater in basements or below ground level because of gas

stagnation.

•Do not use the heater on floors made with flammable materials.

•Do not store flammable materials in the vicinity of the heater (minimum distance: 3m);

•Ensure no overheating of walls, or ceilings made of flammable materials,

•Ensure all precautions have been taken to prevent fires;

•Ensure the premises in which the heater is installed are sufficiently ventilated for the

burner requirements; in particular, limits regarding air quality in the room to be heated

must conform to applicable laws;

•Ensure nothing is obstructing the aspiration and expulsion of air; movement of air may

be obstructed in various ways including placing covers or other objects on the heater

or positioning the heater too near a wall or other large object;

•Never direct the hot air flow from the heater towards the gas cylinder

•Ensure the heater is regularly monitored during operation and checked before being

started;

•Ensure at the beginning of each use, a check is made that the fan moves freely before

plugging the heater into the electrical power supply;

•Ensure at the end of each use, the mains switch is disengaged and supply power cord

removed, main gas stopcock is closed and gas tube disengaged and sealed.

1. GENERAL ADVICE

The heater must be installed, set up and used in accordance with the applicable

regulations and laws relating to the use of such equipment. Minimum distance from

surrounding walls and/or ceiling: 2m.

2. ELECTRICAL CONNECTION

•The voltage, hertz rating and number of phases on the data plate

must correspond to that of the electrical mains outlet that the unit is

being connected to.

•Only connect the unit to electrical installations made by certified

electricians and in keeping with local electrical regulations and

requirements.

•It is recommended that the electrical supply to this unit should include either a

residual current device that will interrupt the supply if the leakage current to earth

exceeds 30mA for 30 ms or a device that will prove the earth circuit.

•This Class 1 Appliance must only be connected to an earthed power supply fitted with

an appropriately sized fuse.

•The heater may be connected to a room thermostat by connecting to the thermostat plug

(10). Other accessories such as a timer may also be connected.

3. POWER CORD

•Make sure before every use that the power cord assembly

is not damaged or cut. If it is DO NOT connect the unit,

7

L-L 283.01-SW

have it replaced by an electrician or authorized service technician. (Type Y

attachment)

•DO NOT pull on the power cord in order to unplug the unit, remove the plug from the

power outlet.

5. EXTENSION CORD

•If using an extension cord, make sure it is a maximum length of 10

meters and sized according to cross section requirements as shown to

the right.

•Inadequate extension cords can be dangerous. If an extension cord is

used, it must be suitable for outdoor use and the connection must be

kept dry and off ground.

•Make sure the extension cord is fully unrolled, kept dry, away from

traffic, sharp edges and heat to avoid damage or cuts.

•If using an extension cord, make sure it is not connected to mains voltage when

connecting / disconnecting to the unit's power cord.

5. TRIP HAZARD

•Loose extension cords and power cables provide a potential trip hazard,

especially when they cross pathways.

•Take safety measures like placing traffic cones along the cord or tape the

cord to the floor with duct tape.

6. FIRE PREVENTION AND HOT SURFACE CAUTION

•Use only in areas free from flammable materials (flammable vapors,

high dust concentrations etc.)

•Keep combustible materials a safe distance from this unit (minimum

3m)

•An external guard should be place 1m away from the heater outlet to

prevent the approach of combustible material.

•Make sure firefighting equipment is readily available

•To avoid burns, be cautious of hot components like the chimney or the

Hot Air outlet and its vicinity.

•Do not under any circumstances restrict the air inlet or outlet of the unit. Always allow

a clearance of 3m in front (air outlet), 1 m above and behind (air inlet) and 600mm on

the sides.

•Do not operate this heater with the top cover removed.

7. EXHAUST & FLUE GASES

•Unit exhaust fumes (which contain carbon monoxide) can lead to death

if allowed to build up. Make sure the unit is operated in an area where

permanent ventilation to the ouside atmosphere is provided. Mandatory

minimum room size: 350 Meters Squared (M3)

•Allow a minimum room size as listed in the technical specifications.

•Ensure that any exhaust emissions are not in the vicinity of air intakes.

8. FUEL AND LUBRICANTS

•DO NOT smoke or allow flames or sparks in your work area. LPG is extremely

flammable and explosive under certain conditions.

8

L-L 283.01-SW

9. TRANSPORT

•Disconnect the unit from the power supply and allowe it to cool off before moving

between work areas.

•Always use the handle to lift and move the unit.

•If transporting the unit make sure it is appropriatly strapped to avoid hazards.

10.MAINTENANCE AND SERVICE

•The heater must be checked that it is safe and in proper working order

before putting into service and before every use. If the unit is damaged do

not use it.

•Always disconnect the unit from the power supply and allow it to cool off

before carrying out any inspection, service task or disassembling any part

of the heater.

•Never carry out any maintenance work not expressly outlined in this booklet and

never make any modifications to this unit.

•Never tamper with any settings of the unit (sealed or unsealed) and make sure that a

Spitwater authorized service agent carries out all servicing as required as this usually

include checking the correct functioning and setting of all safety devices as well as the

correct combustion of the unit.

•Always use original Spitwater spare parts when parts replacements are required.

•Inspect the unit each day before use. Follow “Daily inspection check list” guide Table-

Bin the Maintenance section.

•Service the unit regularly based on its usage. Follow “Usage vs Service frequency”

Table (Table-A) in the MAINTENANCE section. Always use a Spitwater authorized

service agent where requested to.

•Failure to follow the maintenance guidelines in this booklet releases Spitwater from

any responsibility in reference to injuries and damages to both persons and goods

and may also render any warranty given with the unit void.

ASSEMBLY, INSTALLATION, OPERATING AND STORAGE INSTRUCTIONS

INSTALLATION INSTRUCTIONS

Warning

All of the operations described in this section must be performed by skilled

personnel only.

POWER CONNECTIONS

Warning

Never attempt to switch the heater on or off by connecting the room thermostat

(or other control devices) to the electrical power line.

Installation and connection of room thermostat are described in the specific instructions

enclosed. The electrical diagram in this manual shows only the electrical connection of the

accessory to the existing electrical system of the heater.

Warning

Do not connect any air distribution hose: this will cause a severe fire hazard!

9

L-L 283.01-SW

CONNECTION TO GAS CYLINDERS

If the heater is run continuously on full output frost might form on the GAS cylinder indicating it is

starting to “FREEZE”. This condition is caused by excessive vapour withdrawal and can be

overcome by using various sizes of cylinders or multiple cylinder combinations.

To minimise the “FREEZING” effect we suggest the heater be connected to a minimum size and

quantity of Gas cylinders as follows:

•1 X 45KG CYLINDER (Minimum only – increase bottle size/number if using in low

temperatures)

UNDER NO CIRCUMSTANCES SHOULD THE HOT AIR FLOW FROM THE HEATER BE

DIRECTED TOWARDS THE GAS CYLINDER TO AVOID THIS “FREEZING.”

Warning

Propane Gas Cylinders must be installed and stored in accordance with current

local requirements. Propane Gas Cylinders should always be installed connected

and replaced in a flame free atmosphere. Use Propane vapour off-take cylinders

only.

Warning

All connections have left-hand threads, and must therefore be tightened by

turning anticlockwise.

The heater is supplied complete with gas hose (a) and pressure reducer (c) with fittings (d) for

connection to the gas cylinder.The connection supplied is AU ¼” BSP flare male inlet

connection.

Warning

The installer is responsible for ensuring the correct fitting is used for the

connection to the gas cylinder. Always tighten the cylinder fitting first, and

then the pressure regulator, which has a swivel fitting.

Warning

The seal of the fittings must be checked by pouring liquid soap on them: the

appearance of bubbles indicates a possible gas leak.

10

L-L 283.01-SW

Warning

Propane is heavier than air, therefore any gas leakage can cause gas stagnation

on the floor or in any underlying room.

A safety valve (b) may be ordered for protection in case of a damaged gas hose. Installation of

this valve is mandatory if required by local installation laws and regulations.

Warning

Always make sure that the seal (if required by the fitting) is present between the

reducer and the cylinder.

Make sure that the gas hose has been tightened without being twisted: any

stress from twisting can seriously damage the hose.

OPERATING INSTRUCTIONS

Warning

Before switching on the heater, check that the power supply specifications are

the same as those stated on the identification plate. Do not operate this

appliance before leak checking hoses and gas cylinder connection.

START

ALL MODELS

To start the heater:

• Set the pressure regulator to maximum pressure;

• Slowly open the gas stopcock on the gas cylinder;

Warning

In the case of a suspected gas leak, close the gas stopcock immediately, close

the gas cylinder valve, switch off the heater and unplug from the electricity

supply.

• Make sure the switch (9) is set to “0”;

• Turn on the switch on the main electrical panel;

A MODELS (with or without room thermostat connected)

• Move the heating switch (9):

• to position if room thermostat is not connected

• to position if room thermostat is connected and set it to a temperature higher than room

temperature

• Automatic starting cycle starts and light (8) flashes rapidly until the flame lights up.

If the heater still does not function, see TROUBLESHOOTING GUIDE” to identify the cause of

the malfunction.

To stop the heater:

To stop operation turn the thermostat adjustment down: the flame goes out and the fan motor

stops.

Close the gas supply stopcock and turn off the heating switch.

11

L-L 283.01-SW

Warning

If the heater is not used continuously, stop it by first closing the gas supply

stopcock and then switch it off or by turning down the thermostat this allows the

gas in the gas tube to be fully used and avoids any future leak when removing

the gas tube.

Warning

The reset button (8) may have different light types:

• light off: unit is working normally, flame is regular.

• fast flashing: unit is running on starting cycle.

• slow flashing: unit is in stand-by status, waiting for heating request.

• steady light: lock-out status.

TRANSPORTING AND HANDLING

The space heater can be lifted and moved easily by means of its handle.

Remove all or any packaging before use.

Warning

Before moving the unit:

• Stop the heater as indicated in the “STOP” paragraph;

• Disconnect the power supply by removing the plug from the power socket;

• Close the gas stopcock and disconnect the gas hose;

• Wait until the heater cools.

Warning

During transportation and/or storage, make sure the gas valve group and gas

connection pipes are not knocked or damaged in any way.

12

L-L 283.01-SW

MAINTENANCE

Warning

The operations described in this section must only be performed by authorized

personnel only.

The following procedures must be carried out at regular intervals to ensure efficient operation of

the heater. Ensure heater is disconnected from mains power before starting any work.

The Usage v Maintenance Frequency table below shows the regular maintenance required for

your heater, the maintenance interval and which maintenance can be done by the owner.

Interval

Maintenance Required

Done By

Every day

Check heater

Owner

Every day

Check gas supply line

Owner

Every week

Clean exterior of heater

Owner

Every week

Check electrical connections

Owner

Every 6 months

Clean motor & fan

Authorized service Agent

Every year

Clean burner & combustion chamber

Authorized service Agent

Table A

Time interval for checks and replacement listed above are for units subjected to normal

operating conditions. Should the unit be subjected to abnormal conditions (eg constant

use, extreme temperatures or conditions etc) times should be reduced accordingly.

Warning

Before carrying out any maintenance:

•Stop the heater as indicated in the “STOP” paragraph;

•Switch off the power supply by means of the cut-off on the electrical

panel;

•Wait until the heater cools.

1. CHECKING THE HEATER AND THE GAS SUPPLY LINE

Perform the following checks:

• Ensure heater is not installed where there may be a risk of fire or explosion

• Ensure flammable materials are kept a safe distance away

• If you smell gas:

• Open windows immediately

• Do not touch electrical switches

• Close the gas stopcock

• Find and repair the source of the gas leak

• Do not use the heater if any removed panels have not been remounted

• Ensure room to be heated is sufficiently ventilated

13

L-L 283.01-SW

• Ensure the air intake and outlet are completely unobstructed

• Ensure the heater is not covered by any sheets or covers

• Check that the heater is in a fixed and stable position;

• Ensure the heater is constantly monitored during operation and checked before being started;

2. CLEANING THE EXTERIOR OF THE HEATER

To ensure efficient operation, clean the following parts:

• Pipes, connectors and joints:

• Clean with a cloth.

• External body:

• Clean with a cloth.

• Air inlet/outlet:

• Remove all dirt and debris

• Make sure the air inlet/outlet are not obstructed.

3. CHECKING THE ELECTRICAL CONNECTIONS

After detaching the power cable, check all electrical connections as follows:

• Make sure that all connections are complete and tight.

• If there are traces of dirt or corrosion, contact authorised Spitwater service agent to clean and/or

replace the connections as necessary.

• Contact authorised Spitwater service agent replace any damaged wires or connectors if

necessary.

4. CLEANING THE MOTOR AND THE FAN (TO BE CARRIED OUT BY AUTHORISED

SPITWATER SERVICE AGENT ONLY)

Clean the fan blades and the motor as follows:

• Remove the fastening screws on the fan safety grille.

• Clean the motor with cloth or hard brush

• Clean the fan blades with a hard brush.

• Reinstall the safety grille.

• Close the side inspection panel

14

L-L 283.01-SW

5. CLEANING THE COMBUSTION CHAMBER (TO BE CARRIED OUT BY AUTHORISED

SPITWATER SERVICE AGENT ONLY)

To maintain the burner’s high efficiency and prolong its life, the procedure described in this

paragraph must be done at least once at the end of the work season or more frequently if there

is an excessive build-up of soot. Excessive soot may be caused by poor chimney draught, poor

fuel quality, poor regulation of the burner, or more or less frequent alternation of burner starts and

stops. Pay attention during operation: pulsations at start may be due to excessive amounts of

soot.

To access the combustion chamber:

• Remove the side inspection panel

• Clean with compressed air or a metal brush

• Reinstall the safety grille.

Warning

After any technical work, always check that the heater works correctly.

Warning

Incorrect cleaning of the heater can cause damage to property and/or people.

SERVICE/CARE RECOMMENDATIONS AND TROUBLESHOOTING GUIDE

To maintain this unit in peak working condition during its operating life it is necessary to carry

out regular maintenance operations and replace worn or broken parts immediately upon their

failure. The unit should never be operated if damaged. All checks, maintenance and servicing

other than procedures expressly outlined and authorized in this booklet are to be carried out

by an authorized Spitwater service agent using original spare parts. Ensure all servicing safety

precautions are followed and always isolate the unit from the electrical supply before carrying

out any maintenance or repairs.

For service please contact 1800 SPITWATER (1800 774 892) or refer to the contact section

on www.spitwater.com.au

Time interval for checks and replacement listed above are for units subjected to normal

operating conditions. Should the unit be subjected to abnormal conditions (eg constant use,

extreme temperatures or conditions etc) times should should reduced accordingly.

15

L-L 283.01-SW

OPERATOR INSPECTION AND MAINTENANCE CHECK LIST

Symbols meaning:

Unit is fit,

proceed

task

Do it yourself

refer to our

service tips

Do not use the unit. Contact

Spitwater authorised service agent

immediately

CHECKED AND OK

NEEDS ATTENTION

DAILY PRIOR TO STARTING THE UNIT

Ensure all guards, covers and shields are in place before operating the unit.

Check the power cable for any cuts, abrasions or damage.

Check fuel fittings and lines for leaks.

Check the unit is not damaged.

Check the fan blades rotate freely.

Check that all operator maintenance tasks or servicing has been done according

to Table-A

DAILY ON FIRST UNIT RUN

Check proper function of switches and temperature controller

Check color and smell of exhaust fumes. (Dark or smelly fumes= abnormal)

Table B

16

L-L 283.01-SW

TROUBLESHOOTING

FAULTS

CAUSES

REMEDIES

• The heater fails to start and

fan does not start

• No power supply

• Check power specifications

• Check power connections

• Contact Spitwater service agent

• Mains switch in wrong

position

• Select correct position

• Faulty operation of room

thermostat (A model)

• Check thermostat position

• Check thermostat electrical

connection

• Contact Spitwater service agent

• The heater fails to start

flame and stops while:

A MODEL >> lamp lights up

with steady red light

•Insufficient gas supply

• Check if gas bottle is empty

• Check gas supply line and

remove any debris inside

• Check pressure regulator and

replace if necessary

• Safety thermostat

tripped due to

overheating of

combustion chamber

• Check that the suction and the

flow grills are unobstructed

• Check that the room is well

ventilated

• Check that hot air can escape

freely

• Contact Spitwater service agent

• The flame does not light

up

• Check that the suction and the

flow grills are unobstructed

• Contact Spitwater service agent

• Faulty safety thermostat

• Check room thermostat and

replace it if necessary

• Contact Spitwater service agent

• Ionization electrode

does not detect a flame

(A model)

• Contact Spitwater service agent

• Control unit tripped due

to irregular burner

operation (A model)

• Contact Spitwater service agent

• Faulty electronic control

unit (A model)

• Contact Spitwater service agent

• The heater does not stop

when "STOP" procedure is

followed

• Gas solenoid valve does

not close because of

debris

• Close main gas stopcock on

gas bottle, let the heater

burn remaining gas in gas tube,

and contact Spitwater service

agent

• Faulty room thermostat

(A model)

• Check room thermostat and

replace it if necessary

• Check electric connection of

room thermostat

• Contact Spitwater service agent

• Fan noise or vibrations

• Foreign bodies on fan

blades

• Contact Spitwater service agent

• Insufficient air

circulation

• Eliminate all possible obstacles

to proper air flow

17

L-L 283.01-SW

SAFETY DEVICES

Space heaters are direct-combustion and forced convention units. Air is heated by the thermal

energy generated during combustion and is then conveyed to the room to be heated along with

the combustion products: the room MUST be suitably ventilated to ensure adequate air

circulation. Various safety devices trip in the event of serious malfunction:

Temperature Limit Control:

This heater is equipped with a Temperature Limit Control / overheating thermostat LI designed to

turn off the heater should the internal temperature rise to an unsafe level. If this device activates

and turns the heater off, it may require service.

Electrical System Protection:

The heater's electrical system is protected by a fuse mounted to the PCB assembly that protects

the system components from damage. If the heater fails, check the fuse first, replace if necessary.

Flame-Out Sensor:

The electronic burner control unit trips if the flame is irregular or goes out: in Automatic heater

models the reset button (8) lights up with a steady red light.

In each of the cases described above, the space heater stops working in lock-out condition.

The cause of the malfunction must always be investigated and eliminated before starting the

heater again. Refer to ‘TROUBLESHOOTING guide contained within this manual for advice

and if in any doubt, contact your authorized Spitwater service agent. Note the heater can

restart only if reset button (8) is pressed (red lamp is off).

18

L-L 283.01-SW

Wiring Diagram

C Capacitor

MV Fan motor

FUA Fuse

RV Switch

PR Reset switch

LI Overheat safety thermostat

AP Control box

TA Room thermostat plug

EV Gas solenoid valve

RP Resistence

PA Air pressure switch

EL Ionisation electode

This manual suits for next models

1

Table of contents

Other Spitwater Heater manuals

Popular Heater manuals by other brands

Sime

Sime Dewy Equipe P100 Box Installation and servicing instructions

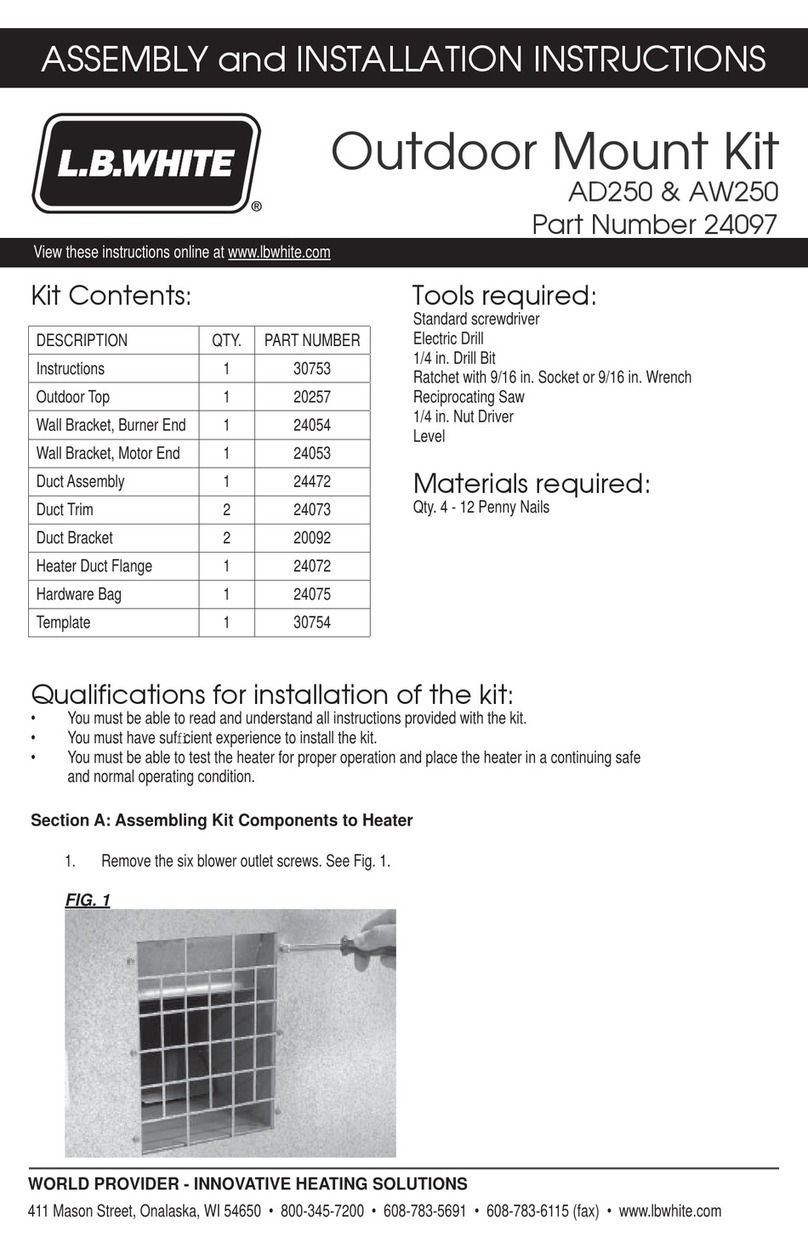

L.B. White

L.B. White GUARDIAN Smart Sense AD250 Assembly and installation instructions

Rinnai

Rinnai ENERGYSAVER RHFE-308FTR How to use

Suntec Wellness

Suntec Wellness Klimatronic Heat Safe 1000 PTC-Turbo manual

Flagro

Flagro THC- 355CDF Operating instructions manual

ECRON

ECRON NSB-200CT user manual