Splash On Tap User manual

P a g e | 1

www.SPLASHwash.com Questions? (888) 784-0802

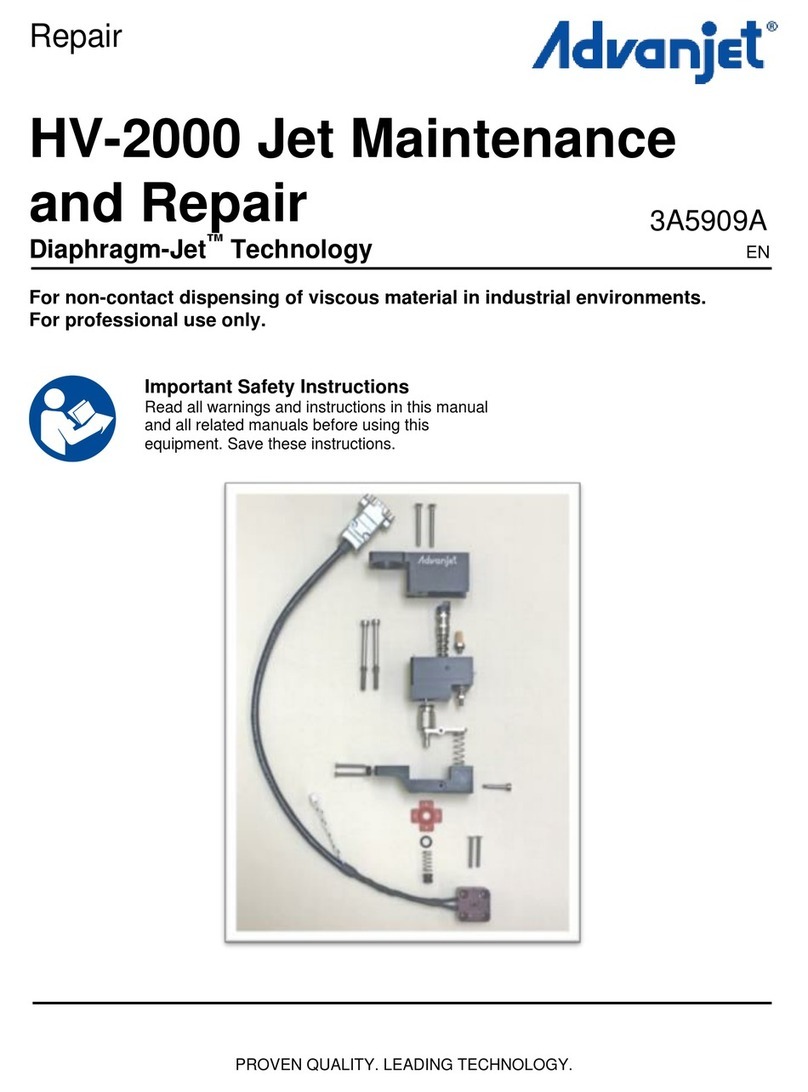

SPLASH On Tap™

Installation Guide

40 Gallon Water Driven Proportioner (#40-SOTWD)

Congratulations on your recent purchase of the SPLASH On Tap proportioner, the future of windshield

washer fluid. If you ever find that you need a replacement part you will be pleased to know that all

parts are available at reasonable prices.

This package contains the following (DOES NOT INCLUDE A BACK-FLOW PREVENTER):

1. (1) 40-SOTWD Proportioner

2. (1) Windshield washer fluid hydrometer

3. (1) Magnetic snap action float

4. (1) Poly Float with chain

5. (4) Magnetic snap action float mounting screws

6. (1) Methanol quick connect

7. (1) Concentrate screen

8. (1) Metal wall bracket

NOTICE: THE METHANOL BARREL MUST BE GROUNDED

NOTICE: A back-flow preventer in compliance with local

and/or state requirements must be installed on the water

line to bring the unit to safety standards.

8. (6) Tank bracket bolts

9. (6) Tank bracket washers

10. (4) 3/8” Lead anchors

11. (4) 3/8” Anchor screws

12. (4) Anchor washers

13. (1) Methanol hose

14. (2) Hose clamps

15. (1) Bung wrench

P a g e | 2

www.SPLASHwash.com Questions? (888) 784-0802

COMPLIANCE WITH LAW

The Equipment is designed to dispense windshield washer fluid containing methanol, which is a

volatile organic compound (VOC). The United States Environmental Protection Agency (EPA) regulates

the use of VOCs and specifically limits the amount of methanol that can be used in products.

The Equipment must be used in compliance with federal, state, and local laws and regulations. The

EPA has regulated that under no circumstances shall there be more than 35% methanol by weight in

the final product. Please see the following website for more details:

http://www.gpo.gov/fdsys/pkg/FR-1998-09-11/pdf/98-22660.pdf. The concentrate provided by the

manufacturer and distributor must be diluted to comply with federal, state, and local VOC regulations.

For example, California, Arizona, Georgia, Texas and Oregon all have state and/or local laws that

further regulate the amount of methanol that can be in products. Other states may have such laws as

well. The customer is responsible for ensuring that he or she properly dilutes the methanol

concentrate to be in compliance with all federal, state, local laws and regulations.

Although the manufacturer has attempted to ensure that its equipment complies with all federal, state

and local laws and regulations, neither the manufacturer nor the distributor can be responsible for nor

guarantee that the customer will use the equipment in accordance with all laws and regulations.

Therefore, customer agrees that neither the manufacturer nor the distributor shall be held responsible

or liable for the use of this equipment in violation of federal, state and local laws and regulations. In

addition, customer acknowledges and agrees equipment must be properly installed according to federal,

state and local laws and regulations, to include a back-flow preventer on the water line. It is customer’s

the responsibility to comply with federal, state and local laws and regulations pertaining to proper use

and installation of the equipment.

NOTICE: THE METHANOL BARREL MUST BE GROUNDED

NOTICE: A back-flow preventer in compliance with local

and/or state requirements must be installed on the water

line to bring the unit to safety standards.

P a g e | 3

www.SPLASHwash.com Questions? (888) 784-0802

40-SOTWD Set-Up Instructions

Step 1: Finding a location for the proportioner

Locate an area for tank installation, if possible near the air pump for the overhead reels and

water line.

Unit must be hung on a concrete wall.

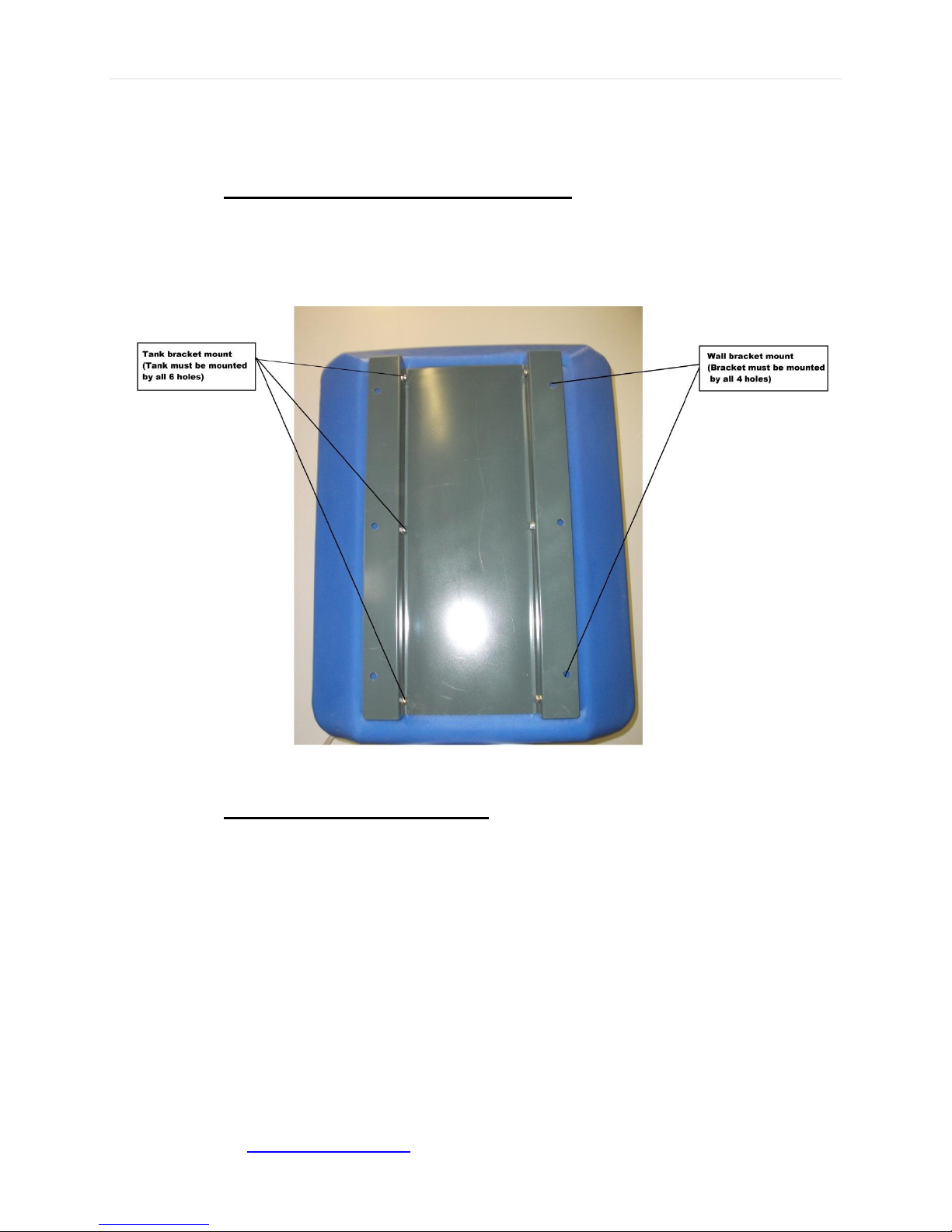

Step 2: Installing the unit on the wall

At the final location of the unit measure and mark a level line 50” from the floor.

Detach metal wall bracket from the back of the unit.

Place the bottom of the metal bracket level with the line and mark the four mounting holes.

Re-attach metal bracket to the proportioner using all six bolts, making sure they are all snug.

Using a hammer drill, drill the four pre-marked holes with a 5/8” bit.

Install the four 3/8” lead anchors into the holes.

Hang unit on the wall using the four predrilled anchors. Secure with the supplied washers and

screws.

P a g e | 4

www.SPLASHwash.com Questions? (888) 784-0802

Step 3: Plumbing the water line

Thread the bung tube into the 55 gal methanol drum.

Secure the quick connect to the bung in the drum. Make sure the quick connect is snug.

Attach the methanol hose from the quick connect to the manifold located in the proportioner.

Make sure the 55 gal drum of methanol is grounded! (Wire and alligator clip is recommended)

Drill a 7/16” hole in the center of the concentrate spout cap.

Locate the concentrate hose inside the proportioner and through the top of the 7/16” hole.

Insert the concentrate screen into the end of the concentrate tube, then screw onto the 5 gal

pail of concentrate.

NOTICE: THE METHANOL BARREL MUST BE GROUNDED

NOTICE: A back-flow preventer in compliance with local

and/or state requirements must be installed on the water

line to bring the unit to safety standards.

P a g e | 5

www.SPLASHwash.com Questions? (888) 784-0802

Step 4: Plumbing the existing air pump

Locate the threaded hole on the back lower right of the tank.

Locate the existing windshield washer fluid delivery pump.

Connect the existing pump to the threaded hole on the proportioner.

Step 5: Product Installation

Locate the nearest water line.

Connect to the back of the magnetic float valve, located on the top of the machine.

Use a ½” line for this procedure. (Which should give you the required flowing 40 PSI)

A back-flow preventer is required by code!

Turn water on and check that the unit has 40 PSI of running pressure. Gauge is located inside

the proportioner.

If 40 PSI is not available, call for service.

P a g e | 6

www.SPLASHwash.com Questions? (888) 784-0802

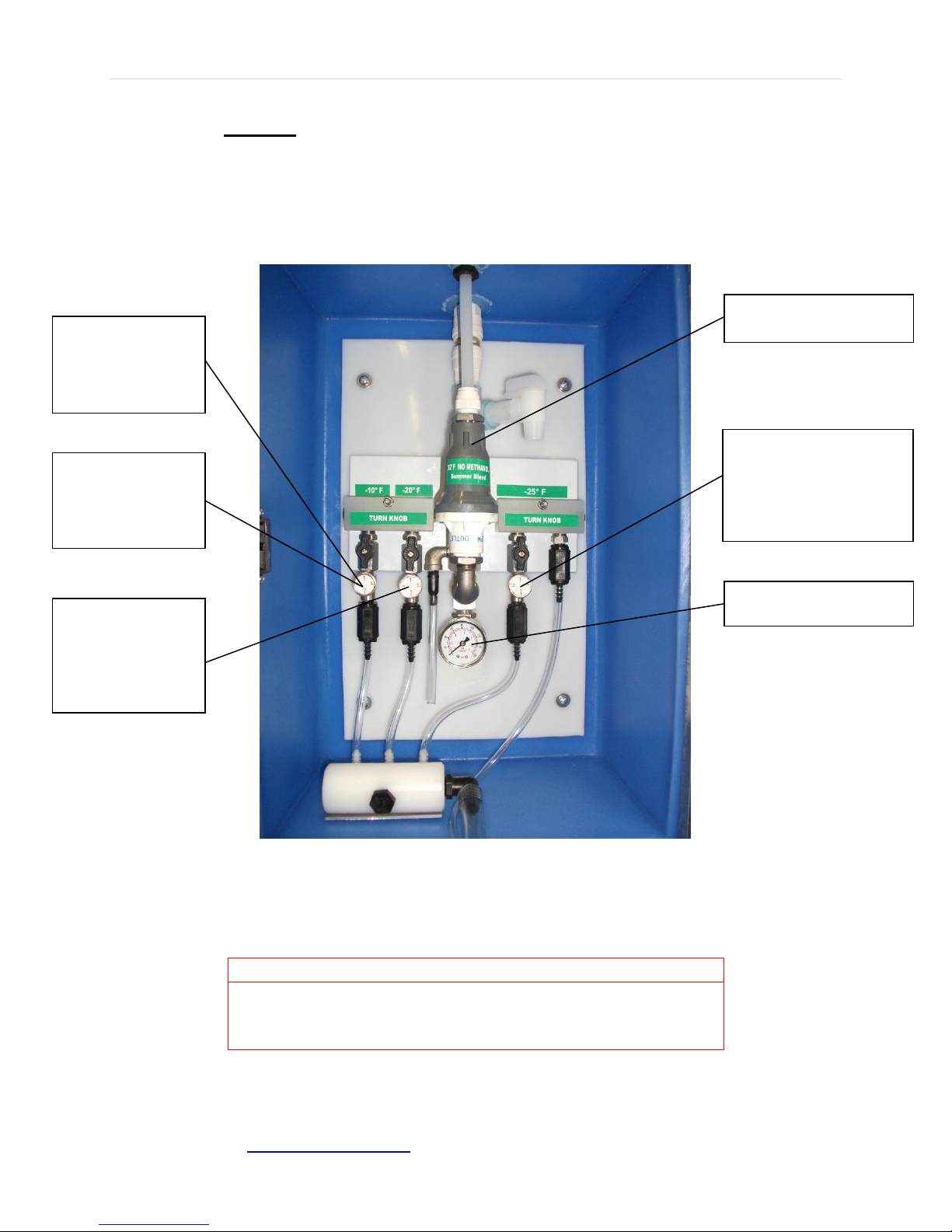

Step 6: Settings

All proportioners are preset at +32F, 0F, -10F, -20F and -25F.

If alternate settings are desired, manually set unit using the supplied hydrometer and the setting

guide provided below.

Also refer to the setting guide for troubleshooting.

NOTICE: THE METHANOL BARREL MUST BE GROUNDED

NOTICE: A back-flow preventer in compliance with local

and/or state requirements must be installed on the water

line to bring the unit to safety standards.

Procedure #1

For a 0˚F product, turn

setting valve 2 turns to

the left and open the

black on/off valve.

Procedure #3

For a -20F product, turn

setting valve 4 turns to

the left and open black

on/off valve. Leave #1

on/off valve open.

For a +32˚F summer time

product, close all black valves.

Procedure #4

For a -25F product, turn setting

valve 5 turns to the left and

open the black on/off valve.

Leave #1 & #2 black on/off

valves open.

Water pressure must be set no

less than 40 psi

40-SOTWD WATER DRIVEN PROPORTIONER

These set-up adjustments are guidelines to assist with setting up your equipment.

Additional testing with the windshield washer hydrometer is required in all set-ups.

Procedure #2

For a -10F product, turn

setting valve 3 turns to

the left and open the

black on/off valve.

P a g e | 7

www.SPLASHwash.com Questions? (888) 784-0802

40-SOTWD Troubleshooting

1. If the blue concentrate is not being mixed with the fluid generally the orifice is clogged.

To remove a clogged orifice, use air hose and apply low pressure air

(5 PSI Recommended) through the hose to remove any build up.

If blowing the hose out does not solve the problem fully submerge the end of the hose and

allow to soak for one hour in water or methanol. After one hour try blowing the line out

again.

2. If a blue color appears in the clear hoses replace the check valve.

3. If product is not a consistent mixture check the water pressure which should never be less than 40

PSI.

Table of contents

Popular Dispenser manuals by other brands

Tork

Tork Image Design 460013 instruction manual

Delfield

Delfield DIS Original instructions

Schroeder America

Schroeder America PEPSI 959 Installation instruction, parts list and configuration guide

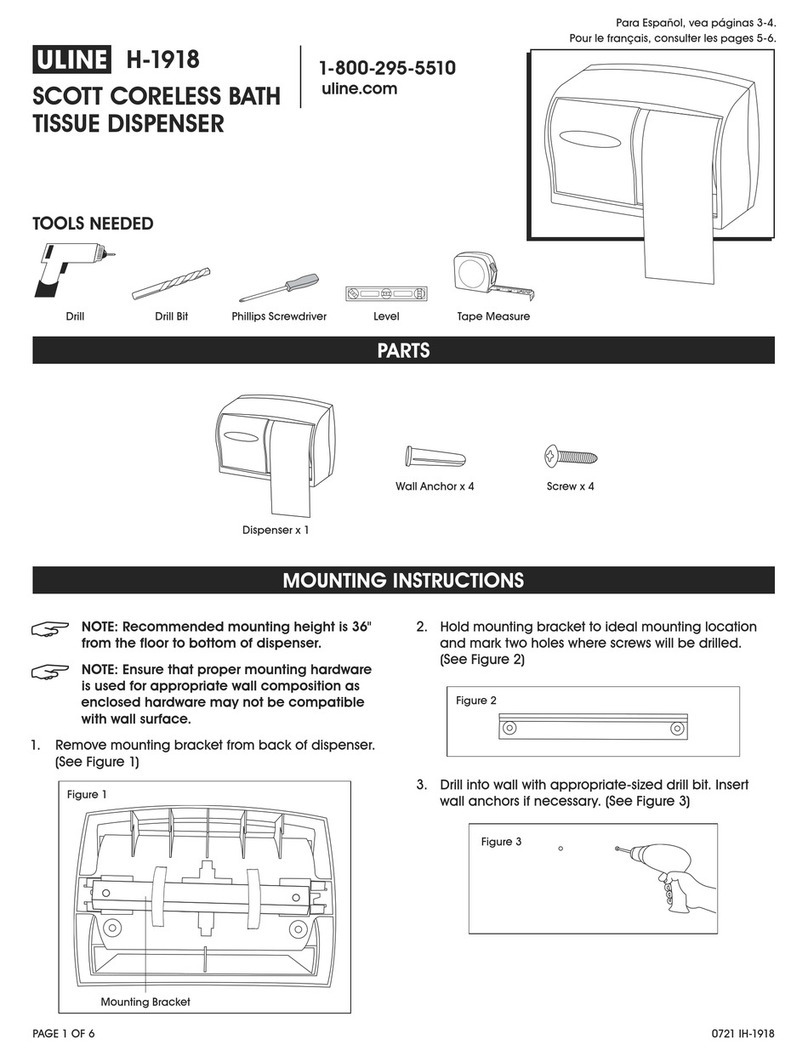

U-Line

U-Line H-1918 manual

U-Line

U-Line TORK H-7859 quick guide

Borg & Overstrom

Borg & Overstrom T1 user guide

Marsh

Marsh TD2100 Technical manual

Bunn

Bunn Ultra NX Maintenance & Troubleshooting guide

Nouvag

Nouvag DP 30 Instructions for use

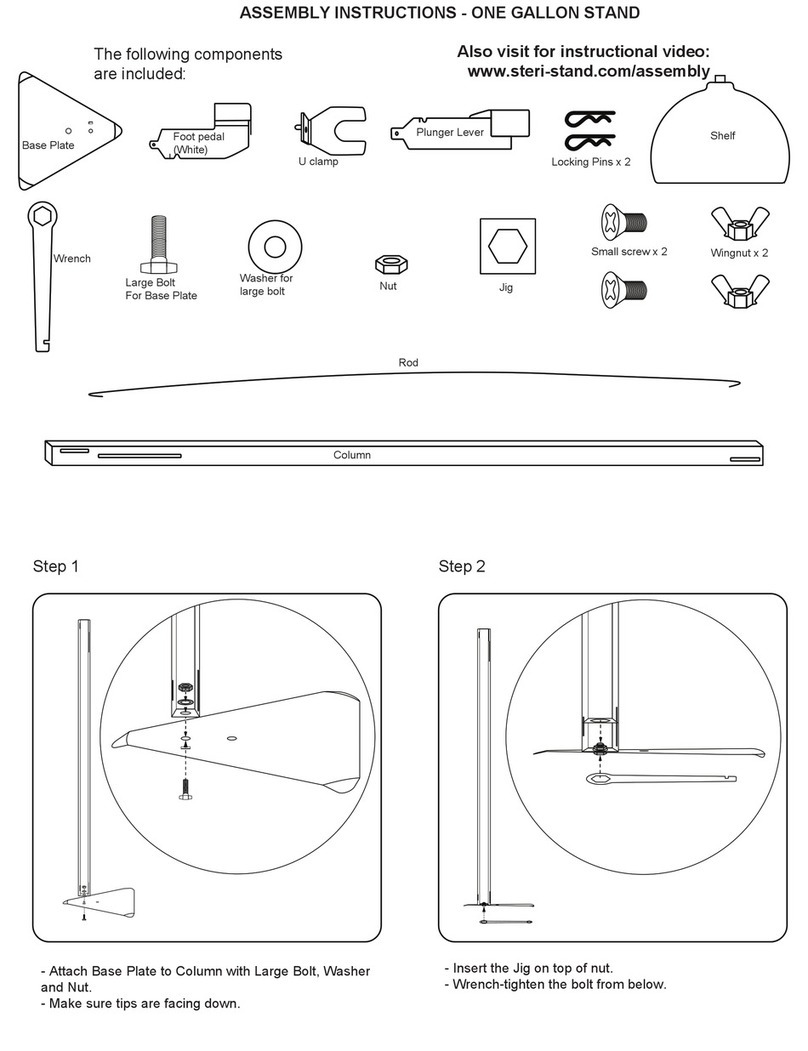

STERI STAND

STERI STAND ONE GALLON STAND Assembly instructions

START International

START International Tape TDA080-NM quick start guide

Nordson

Nordson UltimusPlus Series operating manual