Split-fire Sales Fast Freddy Series User manual

Thank You for Purchasing a Fast Freddy

Winder!

We appreciate having you as our customer and wish

you many years of safe and satisfactory operation

with your machine.

SPLIT-FIRE SALES INC.

285633 Airport Road

Norwich, ON N0J 1P0

Canada

1-877-548-3473 / 519-468-3647

Please share a google review about your

Split-Fire experience

Table of Contents

1. Introduction 4

1.1 How to use your Owner’s Manual 4

1.2 Product Identification 6

2. Safety 8

2.1 Safety Labels 8

2.2 Operator Training 9

2.3 Operation & Work Site Safety 10

3. Operating 12

4. Assembly 18

4.1 Fast Freddy 4 & 6 18

4.2 Fast Freddy 2 24

5. Storage 31

5.1 Storage 31

5.2 Storage Accessories 31

6. Warranty 32

7. Parts Breakdown 34

7.1 Model Fast Freddy 2 34

7.2 Model Fast Freddy 4 36

7.3 Model Fast Freddy 6 38

Fast Freddy Hose Winder

Introduction Owners Manual

4

1.1 How to use your Owner’s Manual

By reading the operator’s manual you will help avoid

unnecessary personal injury and/or damage to the winder. The

information recorded in this manual will help you use this

winder safely and effectively. Once you know how to operate

the winder correctly and safely, you can train others to operate

the winder as well.

The Fast Freddy Winder that is used in this manual for

illustration may differ slightly from your model. It will be similar

enough to help you understand our instructions.

Throughout this manual the terms “Back” and “Front” will be

used. The “Front” of the winder is where the crank handle is

located on the side that contains the wound, hose, cable or

rope. The “Back” is the side that houses the bearings. Also, the

terms “Left Hand” and “Right Hand” will be used. These sides

are determined when standing in front of the winder.

Your machine has been tested and inspected to ensure good

performance prior to leaving the factory.

Fast Freddy Hose Winder

Owners Manual Introduction

5

Please carefully read and understand the warnings about safety

concerns relating to machine damage and important servicing

information. Please read all these messages to avoid personal

injury and machine damage. The three main messages will

start with:

WARNING!!!: which suggests, a strong chance of

personal injury to the operator or bystanders if procedures are

ignored.

IMPORTANT: which suggests, a strong chance of

potential damage to the machine may occur if procedures are

ignored.

NOTE: suggests to the operator, general information given to

help the operator to operate or service the machine.

Fast Freddy Hose Winder

Introduction Owners Manual

6

1.2 Product Identification

If you ever need to contact your dealer or the manufacturer for

parts or questions regarding the operation or servicing of the

machine, it is important to have the model number as well as all

the necessary identification numbers. Using the sample picture

below you can find the necessary number to complete the

spaces below.

Date of Purchase: ______________________

Dealer Name: __________________________________________

Dealer Phone Number: ______________________

Frame Serial Number: ( XX XX XX ) ______________________

Made in Canada

Frame Serial Number

Fast Freddy Hose Winder

Owners Manual Introduction

7

The Fast Freddy Winder is manufactured by Split-Fire Sales

Inc., an Original Equipment Manufacturer (OEM) based in

Canada.

Split-Fire products have been designed and engineered to be

safe, productive, long lasting machines using design principals

not found in other comparable products. A combination of smart

engineering and quality manufacturing by highly skilled

technicians results in a quality made-in-Canada product.

SPLIT-FIRE™ is a registered Trademark of

Split-Fire Sales Inc.

Fast Freddy Hose Winder

Safety Owners Manual

8

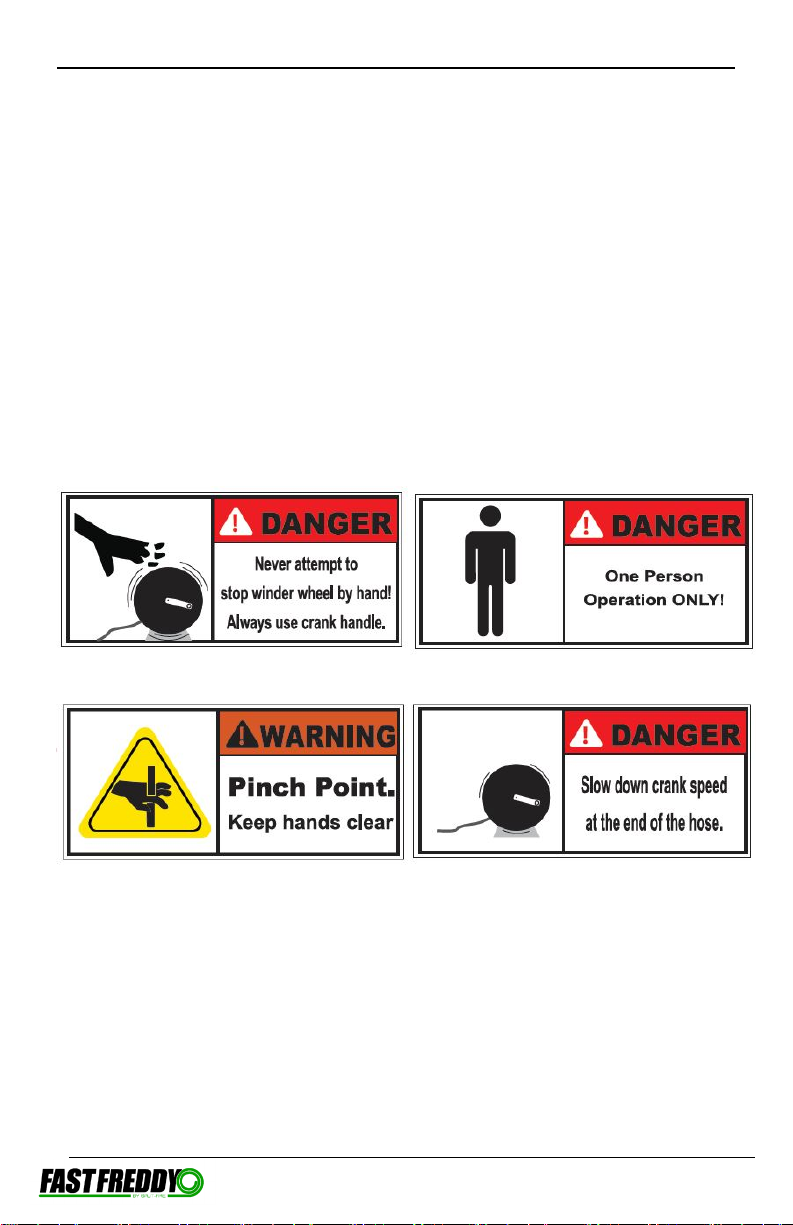

2.1 Safety Labels

The product safety labels shown in the section below are very

important. They are placed in areas on the winder that draw

the attention of the operator to potential safety hazards

associated with the winder. If at any time the stickers are

removed, or come off, contact your dealer or the manufacturer

immediately for replacement decals.

Special attention should be given to these recommendations.

They are outlined for your safety.

Safety Stickers

Fast Freddy Hose Winder

Owners Manual Safety

9

2.2 Operator Training

WARNING!!!

Carefully read and understand all the instructions in the

operator’s manual before operating or servicing your hose

winder. If any doubt or question arises about the safe and/or

correct method of performing anything in this manual, contact

your local dealer or the manufacturer.

Avoid accidents by being alert and recognizing potential

hazards. Not all possible circumstances can be anticipated in

this manual. Keep your winder and work area safe for yourself

and others. Proper care and safety is your responsibility.

Only adults over the age of 18 should operate this manual

hose winder.

The Fast Freddy Winder is designed and intended for use

by one operator only.

All operators must have the necessary training and skills to

operate the winder properly and safely. Read and understand

the owner’s manual and follow the safety warnings and

recommendations. Never allow untrained persons to operate or

service the equipment.

The owner is responsible for accidents and injuries to

themselves and/or other persons operating their winder. If

others are permitted to use this winder it is the responsibility of

the owner to train users.

Fast Freddy Hose Winder

Safety Owners Manual

10

2.3 Operation & Work Site Safety

Inspect your machine each time before use. Special

attention should be taken that all damaged or missing parts are

replaced, and that all the safety decals highlighted in the safety

labels section are in place, clear and visible on the machine.

Only allow responsible adults, over the age of 18, who have

read and fully understand the full instructions to operate the

machine. Only one person may operate the machine at any

time.

Only use the crank handle to turn the winder wheel.

Each time you operate your winder, ensure that the crank

handle and the winder wheel turns freely.

Keep hands and body parts clear of the wheel when

spinning and keep hands away from pinch points (between the

adjustable guide arm and frame) when adjusting the guide arm.

Your machine is designed to reel in and wind up hoses,

cables and ropes. Any other material may cause damage to the

machine and increase the chance of personal injury.

Keep the working area and ground around the winder

organized, lit and free of equipment, tools, unwound hose,

cable, rope and debris. Not doing so could result in injury.

Before operating the winder make sure to disengage the

safety wheel lock and that the winder is firmly sitting on level

ground. Operate the winder on level surface only.

Fast Freddy Hose Winder

Owners Manual Safety

11

Always slow down crank speed when nearing the unwound

end of the hose, cable or rope to prevent whiplashing action.

Take frequent breaks and be alert when using the winder.

Do not operate your winder in enclosed areas or around

other pieces of moving machinery. You will need ample room

to work with your unwound hose, cable or rope.

Never attempt to stop the winder wheel by hand or force.

Always use crank handle provided or wait for momentum of the

wheel to slow down and stop if crank handle control is lost.

Never wear loose clothing and keep long hair tied back when

operating the winder either can get caught and cause injury.

Never operate the winder if anybody is standing nearby.

Nobody other than the operator should be within 25 feet of the

winder. Keep other distractions like electronic devices away.

Never operate winder if under alcohol or drug influence.

Do not over-spin the winder to increase the speed beyond

the operator’s comfort level.

Do not alter; add accessories, or attachments to your winder

without the approval of the manufacturer. If manufacturer

approved attachments have been added, be sure to keep

safety labels visible.

Doing any of the above without the manufacturer’s approval

WILL VOID THE WARRANTY.

Fast Freddy Hose Winder

Operating Owners Manual

12

3. Operation

Make sure that you have read and understand all safety

recommendations before operating the winder.

Disengage the wheel lock on the right side of the machine.

Remove the crank handle from its holder and insert it into the

reel plate stem for turning the wheel.

Fast Freddy Hose Winder

Owners Manual Operating

13

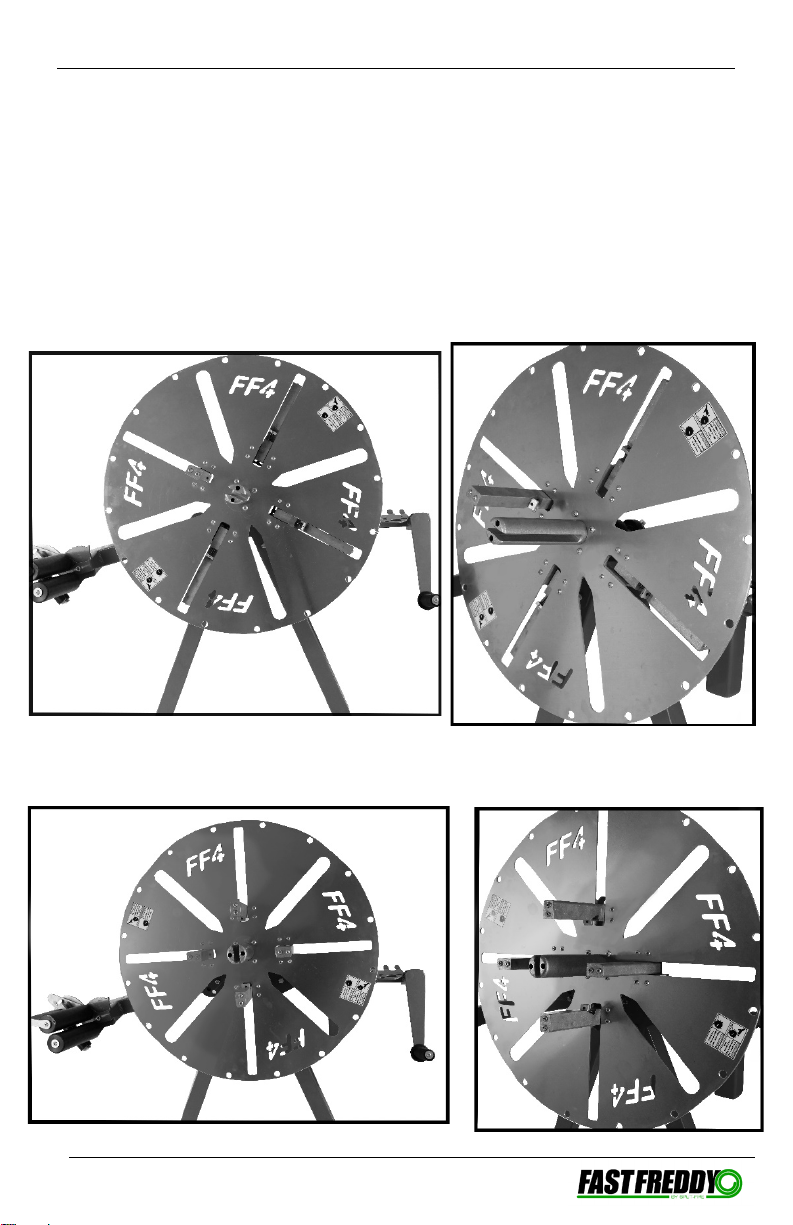

Determine the size of the inner diameter opening you desire

and release one or more of the spring actuated detent arms

and make sure it is locked in place. Using one detent arm only

will give you the smallest opening. Using all four detent arms

will give you the largest opening.

For some applications the detent arms do not need to be used.

One Detent Arm

Four Detent Arms

Fast Freddy Hose Winder

OperatingOwners Manual

14

When winding small diameter cables use the detent shoulders

provided with the winder to prevent the cable from sliding off

the detent arm.

Take the lead end of the hose, cable or rope that is to be

wound and secure it through the reel plate stem.

If the diameter of the hose or cable exceeds ½” place it over the

stem.

Insert the crank handle into the reel plate stem.

Fast Freddy Hose Winder

Owners Manual Operating

15

Secure the hose, cable or rope through the Fair Lead, threading

it flush through the Vertical Rollers and then down through the

Horizontal Rollers.

Use the ratchet action & thumbscrews to adjust the position of

the guide rollers. Ratchet the horizontal rollers down to tighten.

The vertical rollers should be at a 90 degree angle to the hose,

rope or cord being wound and make sure it remains in the

middle of the Fair Lead when winding. If the hose, cord or rope

slips out of the Fair Lead stop turning the crank handle to

prevent kinks and reset the material properly through the guide

rollers.

Fast Freddy Hose Winder

Operating Owners Manual

16

The Guide Arm can swing completely down and out of the way

for manual guiding of the hose by the operator. Turn the guide

arm lock clockwise or counter clockwise to loosen or tighten the

arm. Position the arm to the desired spot and then tighten the

lock to secure it in place.

With the crank handle firmly in place in the reel plate stem,

place one hand on the plastic palm grip on the crank handle

and turn the crank handle clockwise to wind the hose, cable or

rope. The operator should turn the wheel at a comfortable

speed keeping it under control at all times. Slow down the turn

speed when nearing the end of the hose, cord or rope being

wound.

Fast Freddy Hose Winder

Owners Manual Operating

17

Remove wound end from the Fair Lead and tie off the wound

hose, cable or rope with twine or tie straps. The wheel has four

open tie slots cut into the face of the wheel to conveniently

access the wound up hose from two sides when tying it down.

Disengage one or more of the detent arms to slacken the

wound hose enough to pull it off the wheel. Your wound hose,

cable or cord is now ready for stacking or storage.

Fast Freddy Hose Winder

Assembly Owners Manual

18

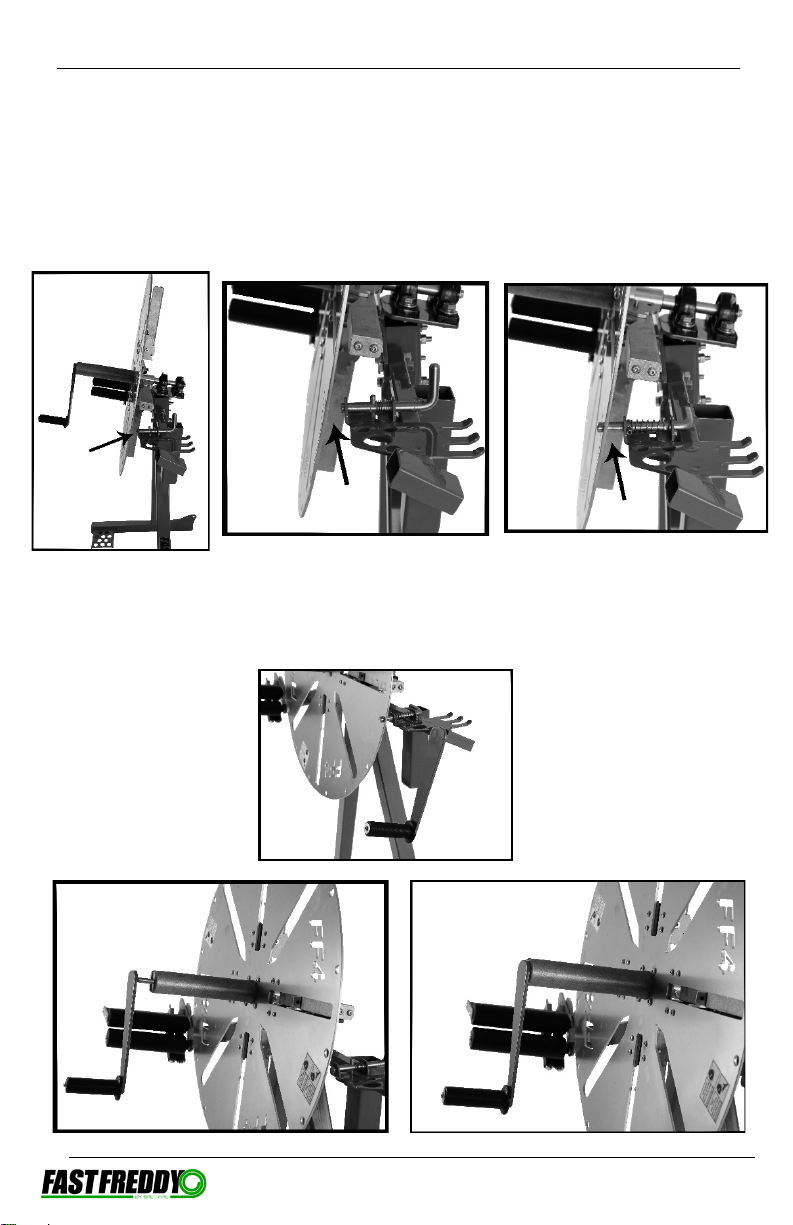

4.1 Assembly – Fast Freddy 4 & 6

Please follow the assembly instructions provided.

Tools required for assembly include:

9/16” Wrench

9/16” Ratchet / Socket

3/16” Allen Key

1/2” Wrench

Large Flat Bar or Wrench (Any Size).

Your Fast Freddy Winder is shipped in a box.

All of the components required to assemble your Fast Freddy

will be packed inside as shown by the illustration. (Packaging

may differ slightly with wall or hitch mount models.)

Fast Freddy Hose Winder

Owners Manual Assembly

19

1. Find the Main Bearing Mount. Note: the 4 bolts, (3 bolts

for Wall and Hitch Mount Models) are assembled in the

bearing mount before shipping. Remove these bolts for

the next step.

2. Assemble the 2 legs to the Bearing Mount. Reinsert the

4 bolts back into the Bearing Mount and tighten. Note:

The nuts must be placed on the back of the Bearing

Mount. There are 4 bolts for leg mount, and 3 bolts for

Wall and Hitch mount. (Note: the Wall and Hitch mounts

have different bolt patterns.)

Fast Freddy Hose Winder

Assembly Owners Manual

20

3. Find the Guide Arm, and remove the hinge bolt and

retract the lock pin. Assemble the Guide Arm to the

Bearing Mount and insert the hinge pin. (Do not tighten

bolt. Bolt must only be snug). Then, add the nut to the

bolt and lock the bolt. This keeps it from loosening while

not over tightening the Guide Arm.

This manual suits for next models

3

Table of contents

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions