S+S REGELTECHNIK GMBH |THURN-UND-TAXIS-STR. 22 |D-90411 NÜRNBERG |GERMANY |FON +49 (0) 911 51947- 0 |www.S plusS.de

5

Operating instructions

RYMASKON®600 - BACnet

RYMASKON®600 - Modbus

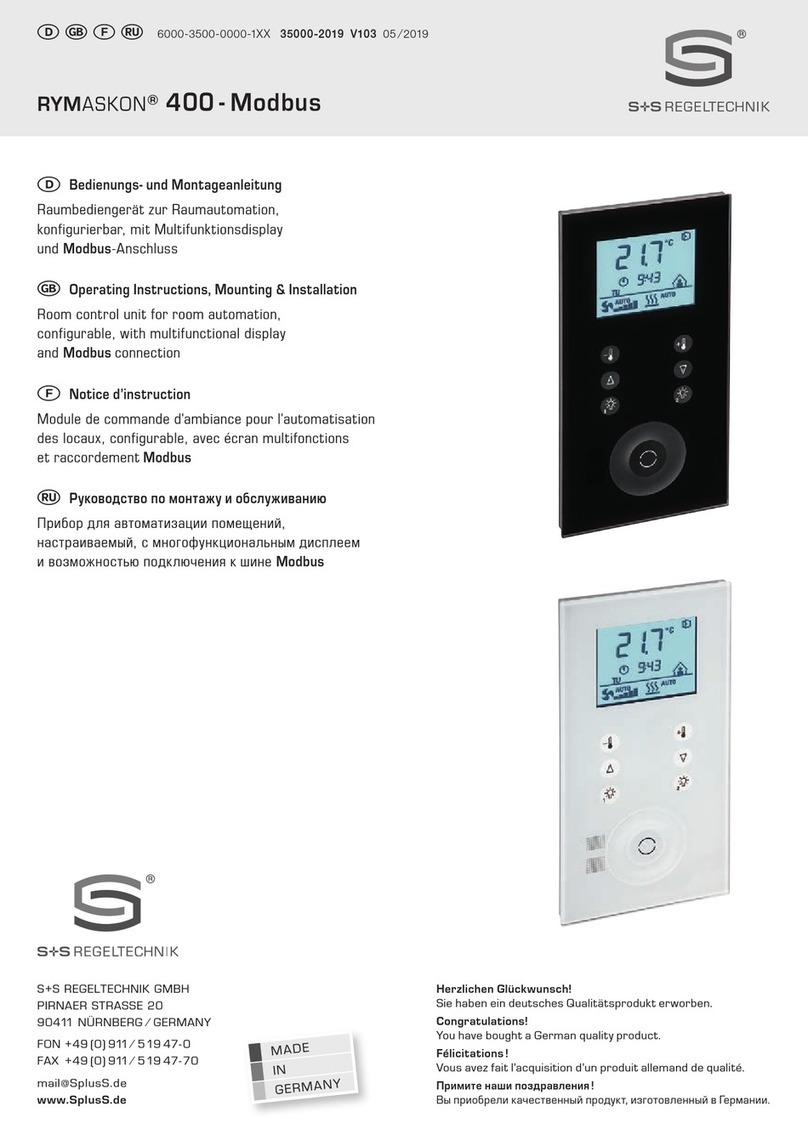

The

RYMASKON

®

500

/

600

/

700

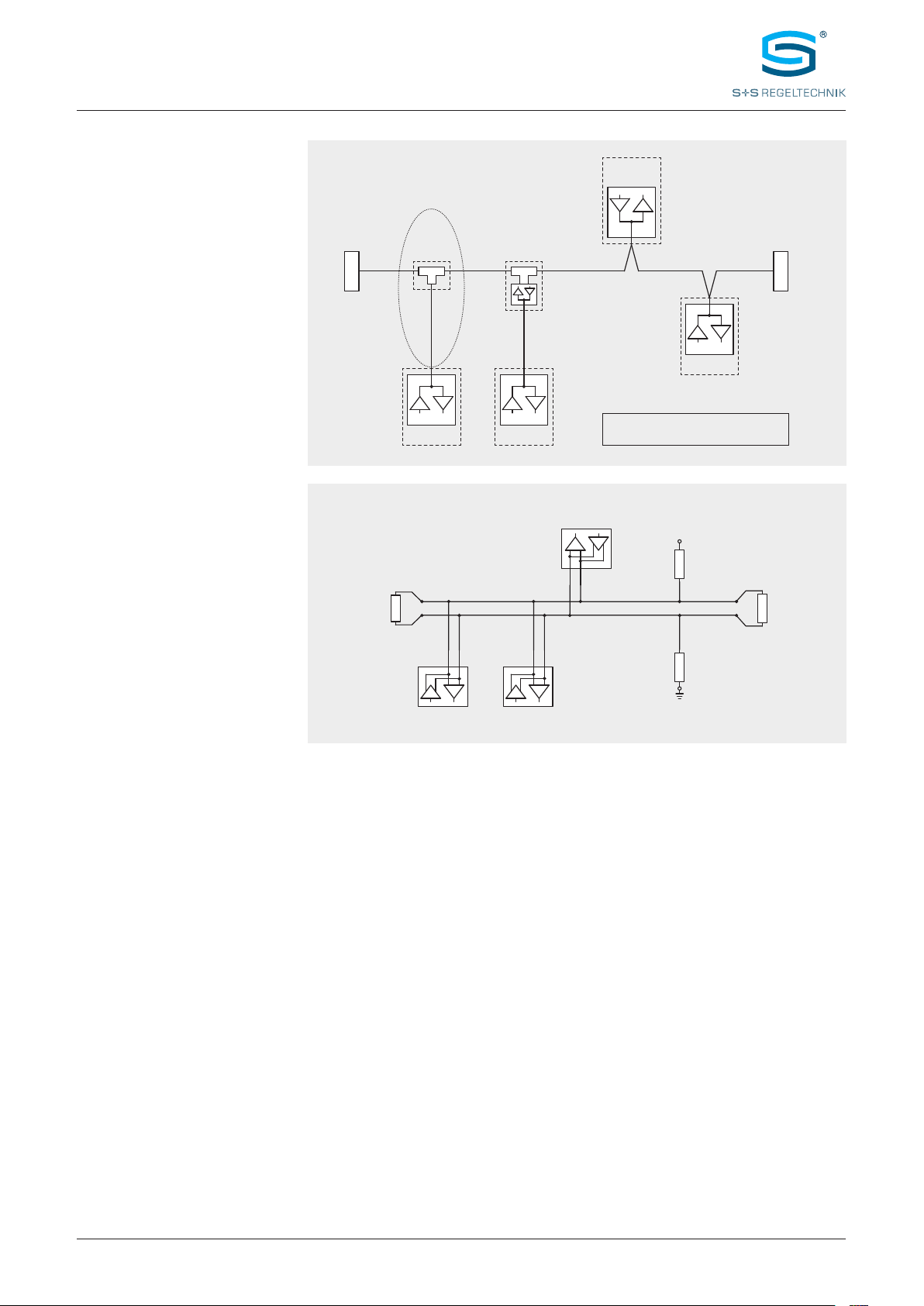

series of room control units are designed for controlling the climatic

zone in residential, hotel and office rooms and individually regulate the heating/cooling steps of the internal

rooms. A colour touch display with modern icons is used for the visual display and operation at the location.

The product range is characterised by the variety of combination options of the individual components.

The

RYMASKON

®

600

Controller

series regulates through analogue outputs (0–10 V) up to two

heating

or cooling valves

(6-way valves can also be controlled) and the

fan

(EC ventilator).

The

sun protection

(blinds, shutters) can be controlled in two zones via the bus. Through the appropriate

symbols, it is possible to control the

light

instead of the sun protection.

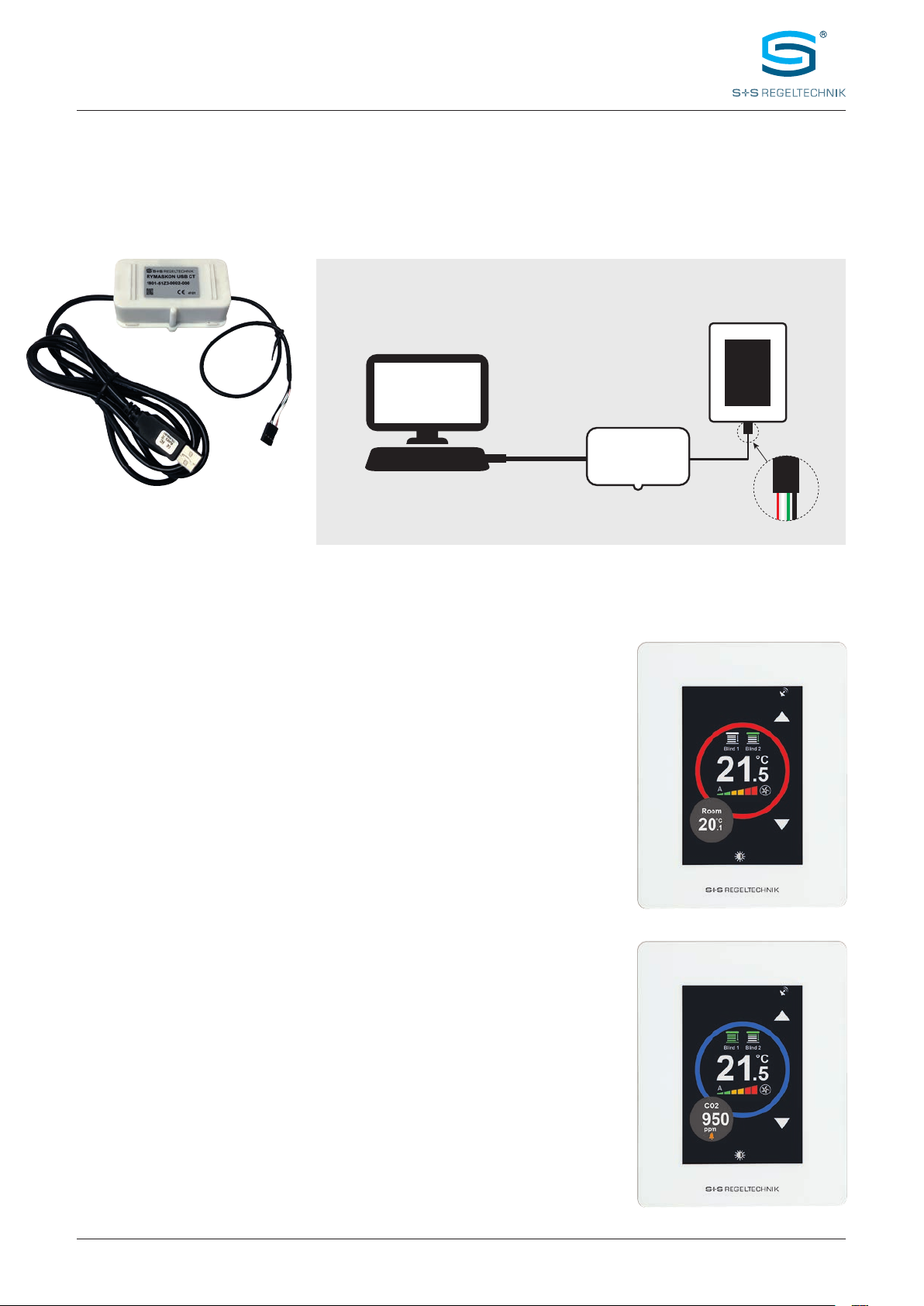

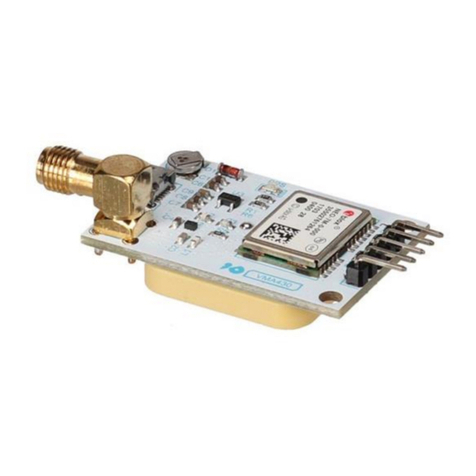

In addition to the integrated temperature sensor, two external temperature sensors (NTC10K) or two

analogue sensors (0–10V) can also be connected. Measuring elements for relative humidity and CO2 are

also available. The devices are used in room climate technology, including convector fans, cooling ceilings

and heating/cooling systems. Wall mounting is performed on standard in-wall flush boxes. The devices are

optionally available with a Modbus or BACnet communication interface and in various type versions (see

number key).

The basic model

RYMASKON

®

610

Controller

with colour touch display (3.5"), in a white housing,

possesses an integrated temperature and humidity sensor (CO2 sensor optional), 2 analogue inputs for

external sensors (0–10 V), 1 digital input, 3 analogue outputs (0–10 V), and optionally with Modbus or

BACnet connection. The room control units are used for controlling temperature, fan, light (1 zone) and

sun protection (2 zones) directly via the analogue outputs or via the bus.

TECHNICAL DATA (Basic model)

Device type: room control unit with controller

Functions: temperature, fan, light (1 zone),

and sun protection (2 zones)

Communication:

Modbus RTU Slave

address range can be configured between 1...247

or

BACnet MS

/

TP

device ID 65100 (default) and MAC address can be configured between

1...127

RS 485 interface, max. 63 devices,

9600 / 19200 / 38400 / 57500 / 76800 Baud,

none / even / odd parity, 1 / 2 stop bits

Power supply: 24 V AC/DC (± 15 %)

Power consumption: max. 1.92 W

Inputs: 2 analogue inputs 0–10V

1 digital input (potential-free), Impedance <1kOhm

Outputs: 3 analogue outputs 0–10V (heating, cooling, fan)

input impedance > 100kOhm

Operating mode: Comfort, ECO, OFF, Boost, Frost Protection

Control element:

3.5" touch display

with backlighting,

cut-out approx. 50 x 75 mm, resolution 320 x 480 pixels, 255,000 colours

TEMPERATURE

Sensor: integrated temperature sensor

Measuring range: –40...+125 °C

Accuracy: typically ±0.5 °C at +25 °C

HUMIDITY

Sensor: integrated humidity sensor

Measuring range: 0...100 % r.H.

Accuracy: typically ±2 % r.H. (20...80 % r.H.) at +25 °C

CARBON DIOXIDE (CO2)

Sensor: optical NDIR sensor (non-dispersive infrared technology),

with automatic calibration

Measuring range: 0...5000 ppm

Accuracy: typically ±50 ppm ±3 % of the measured value at +25 °C

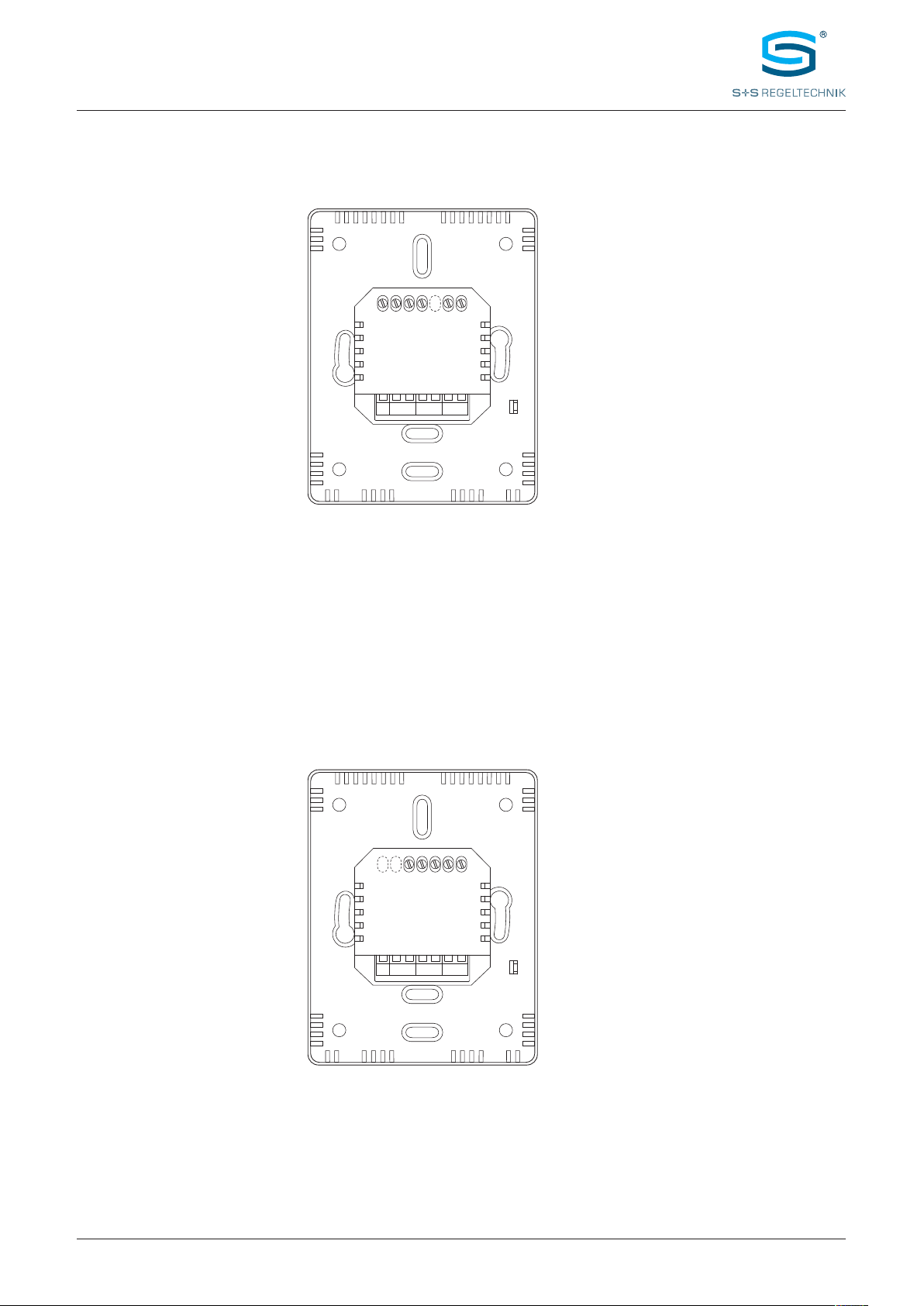

Electrical connection: 0.14–1.5mm², via screw terminals

Housing: plastic, polycarbonate material, self-extinguishing,

white colour (optionally black or chrome), weight approx. 220g

Housing dimensions: approx. 88 x 112 x 14.5 mm (on-wall)

approx. 88 x 112 x 20.5 mm (on-wall with CO2 sensor)

approx. 52 x 53 x 28.5 mm (in-wall)

Mounting: wall mounting on in-wall flush box, Ø 55mm

Ambient temperature: 0...+50°C (operation); –30...+70°C (storage)

Permitted humidity: 0...95 % r. H., (non-precipitating air)

Protection type:

IP 20

(

according to

EN 60 529)

Standards: CE conformity,

according to EMC directive 2004/108/EU, Low-Voltage directive 2006/95/EU,

according to

EN 61000-6-1/3, EN 60730-1, EN 6100-4-2/4/5/11

DESCRIPTION

Introduction and

technical data