S+S Regeltechnik RYMASKON 400-Modbus User manual

GRYMASKON®400 - Modbus

Rev. 0000 - V10 GB

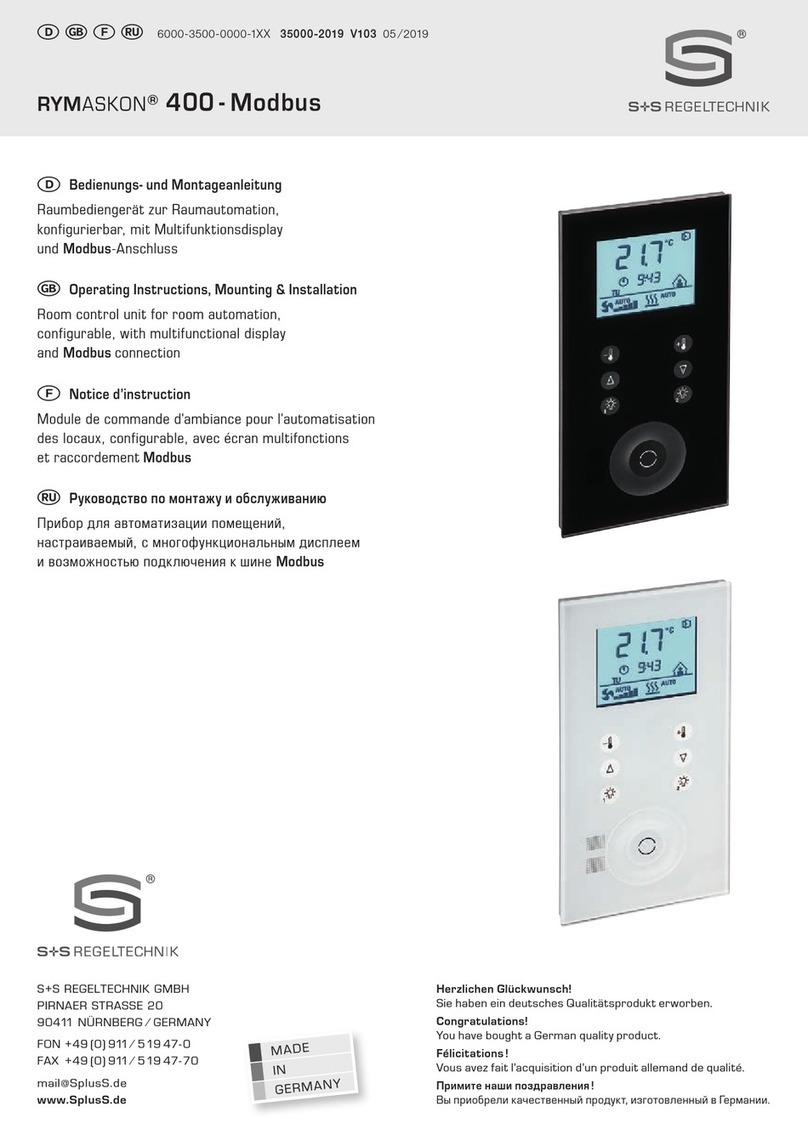

RYMASKON

®

stands for a series of multifunctional room control units. The individually configurable

RYMASKON

®

400 - Modbus

enables automated

monitoring and control of the indoor climate and illumination in a Modbus network. It has two digital inputs and two digital/analogue outputs. Room

climate control and regulation can be accessed from a central point on a higher-level Modbus master and on-site operation can be selectively

or completely disabled. Thanks to its internal outputs, the inputs and settings on the device do not necessarily have to be processed by the master.

This means that it is also possible to have decentralised individual room control at any time. An internal sensor detects the room temperature.

Six freely assignable function buttons on the front panel of the unit can be used for on-site operation and configuration. An integrated rotary encoder

with a central input button enables manual adjustment of settings and parameter assignment on location. Desired functions (such as "Light ON") and

display values can be activated by triggering an approximation sensor when entering the room. The dimmable multifunctional display is designed

specifically for room operation and uses intuitive symbols for a clear view of all available spatial data. Besides the time, weekday and climate

parameters (temperature, humidity, dew point, CO2content), it can also display additional features, such as heating/cooling and fan modes, window

open, lighting, alarm, key lock or room occupancy.

TECHNICAL DATA

Power supply: 24 V DC (± 10 %)

Power consumption: 1.08 W at 100 % backlighting

0.94 W at 15% backlighting

0.89 W without backlighting

(without load at the actuator outputs)

Inputs: 2 digital inputs

without additional 0 V output signal

*

Outputs: RYMASKON 410 : 2 analogue outputs (0-10 V DC)

rated current max. 4 mA

RYMASKON 420 : 2 digital outputs or PWM

rated current 400 mA (short circuit max. 1.2A)

Interface: RS485 Modbus RTU Slave (57600, 38400, 19200, 9600 Baud),

bus termination can be set via DIP switch

Sensor: NTC 10 kΩ, 0...+70 °C, precision ±0.4 K

Operating elements: multifunctional display, 6 touch buttons, 1 rotary encoder, 1 approximation sensor (IR)

Electrical connection: 0.14- 1.5 mm², via plug-in screw terminals

Enclosure: plastic, glass front panel, black or white colour

Dimensions: 88 x 173 x 30 mm (incl. connection terminals)

Mounting: using a plastic mounting plate (see dimensional drawing),

wall mounting or on in-wall flush double switch box

Ambient temperature: +5...+40°C (operation); –10...+50°C (storage)

Permitted humidity: 0...85 % r.H. (without dew formation)

Protection type: IP 20 (according to EN 60 529)

Standards: CE-conformity, electromagnetic compatibility according to EN 61 326,

EMC Directive 2014 ⁄ 30 ⁄ EU

RYMASKON

®

400 - Modbus

– Room control unit for room automation

Type ⁄ WG 02 Communication Output Colour

Display Item No.

RYMASKON

®

410 - Modbus

RYMASKON 411 RS485 2x (analogue) 0-10V black ■1901-5121-2101-000

RYMASKON 412 RS485 2x (analogue) 0-10V white ■1901-5121-2102-000

RYMASKON

®

420 - Modbus

RYMASKON 421 RS485 2x (digital / PWM) black ■1901-5121-2201-000

RYMASKON 422 RS485 2x (digital / PWM) white ■1901-5121-2202-000

PWM = pulse-width modulation

GRYMASKON®400 - Modbus

Rev. 0000 - V10 GB

Schematic diagram

*

Schematic diagram

*

X1.4 A

RS485

X1.8

GND

X1.9

GND

X1.6 X1.7 X1.10

GND

X1.2

GND

X1.5

GND

X1.1

+24V

X1.3 B

RS485

GND

X2.6

DI-2

X2.2

DI-1

X2.1

GND

X2.3

+UB 24V /1

–UB GND

MOD1+

MOD1–

1234

ON DIP

AO-1

X2.4

AO-2

X2.5

RYMASKON 410

X1.4 A

RS485

X1.8

GND

X1.9

GND

X1.6 X1.7 X1.10

GND

X1.2

GND

X1.5

GND

X1.1

+24V

X1.3 B

RS485

GND

X2.6

DI-2

X2.2

DI-1

X2.1

GND

X2.3

+UB 24V /1

–UB GND

MOD1+

MOD1–

1234

ON DIP

DO-1

X2.4

DO-2

X2.5

RYMASKON 420

RYMASKON

®

410 - Modbus

RYMASKON

®

420 - Modbus

Connecting

diagram

Connecting

diagram

RYMASKON

®

410 - Modbus

RYMASKON

®

420 - Modbus

DI-1 X2.1

DI-2 X2.2

GND X2.3

1

3

2

5

6

4

1

3

2

5

4

6

8

7

10

9

X2

X1

+UB 24V DC

RS485 – B (Modbus RTU)

RS485 – A (Modbus RTU)

–UB GND

GND

GND

GND

GND

GND

GND

RYMASKON 410

DI-1 (digital) 0 V

DI-2 (digital) 0 V

Input 1

Input 2

Output 1

Output 2

AO-1 (analogue) 0-10 V DC

AO-2 (analogue) 0-10 V DC

DI-1 X2.1

DI-2 X2.2

GND X2.3

1

3

2

5

6

4

1

3

2

5

4

6

8

7

10

9

X2

X1

+UB 24V DC

RS485 – B (Modbus RTU)

RS485 – A (Modbus RTU)

–UB GND

GND

GND

GND

GND

GND

GND

RYMASKON 420

DI-1 (digital) 0 V

DI-2 (digital) 0 V

Input 1

Input 2

Output 1

Output 2

DO-1 (digital / PWM)

DO-2 (digital / PWM)

* digital inputs (DI1 ⁄ DI2)

In order to connect potential-free contacts,

a GND signal (e.g. terminal X2.3) should be routed

to the desired input via the contact.

DIP Switch

RYMASKON

®

400 - Modbus

RS 485 bus termination DIP 3 DIP 4

activated

O N O N

deactivated OFF OFF

Note:

Always configure the bus termination of the RS 485 interface (DIP 3 and DIP 4)

in pairs!

Important notes

Our “General Terms and Conditions for Business“ together with the “General Conditions for the Supply of Products and Services of the Electrical and

Electronics Industry“ (ZVEI conditions) including supplementary clause “Extended Retention of Title“ apply as the exclusive terms and conditions.

In addition, the following points are to be observed:

– Devices must only be connected to safety extra-low voltage and under dead-voltage condition. To avoid damages and errors at the device

(e.g. by voltage induction) shielded cables are to be used, laying parallel with current-carrying lines is to be avoided, and EMC directives are to

be observed.

– This device shall only be used for its intended purpose. Respective safety regulations issued by the VDE, the states, their control authorities,

the TÜV and the local energy supply company must be observed. The purchaser has to adhere to the building and safety regulations and has to

prevent perils of any kind.

– No warranties or liabilities will be assumed for defects and damages arising from improper use of this device.

– Consequential damages caused by a fault in this device are excluded from warranty or liability.

– These devices must be installed by authorised specialists only.

–

The technical data and connecting conditions of the mounting and operating instructions delivered together with the device are exclusively valid.

Deviations from the catalogue representation are not explicitly mentioned and are possible in terms of technical progress and continuous

improvement of our products.

– In case of any modifications made by the user, all warranty claims are forfeited.

– This device must not be installed close to heat sources (e.g. radiators) or be exposed to their heat flow. Direct sun irradiation or heat

irradiation by similar sources (powerful lamps, halogen spotlights) must absolutely be avoided.

– Operating this device close to other devices that do not comply with EMC directives may influence functionality.

– This device must not be used for monitoring applications, which serve the purpose of protecting persons against hazards or injury,

or as an EMERGENCY STOP switch for systems or machinery, or for any other similar safety-relevant purposes.

– Dimensions of enclosures or enclosure accessories may show slight tolerances on the specifications provided in these instructions.

– Modifications of these records are not permitted.

– In case of a complaint, only complete devices returned in original packing will be accepted.

These instructions must be read before installation and putting in operation and all notes provided therein are to be regarded!

GRYMASKON®400 - Modbus

| Installation and configuration

Installation

The device is attached to the mounting frame, which is mounted onto a local dual device junction box.

The device front panel is then attached to the mounting frame by means of the upper and lower retaining clips.

Putting into operation

First, ensure that both terminal blocks are installed properly and connect them to the RYMASKON® 400.

Wait approximately 20 seconds after connecting the device.

Then press and hold the ENTER key [8] and the 6 o'clock position of the rotary pulse encoder [7] for 5 seconds

to enter the administration mode (see page 16 for a schematic diagram of the front).

The larger display shows the parameter number (e.g. "P 1") and the smaller display shows the current value.

The desired parameter is selected via the rotary encoder.

A value change is initiated by tapping the ENTER key [8] and is indicated by flashing of the current value.

Now you can use the rotary pulse encoder [7] to change the value within the permissible limits.

Tap the ENTER key [8] again to apply and save the set value.

To exit the Administrator mode, press and hold the ENTER key [8] for 2 seconds.

Configuration

The communication interface must be configured from the device (see table on page 15).

All other parameters can also be changed from the Modbus Configurator or the Modbus master.

For a full description, visit

www.spluss.d

e

Please note

– Always ensure that the supply voltage of the individual RYMASKON® 400 devices is based on a common reference potential

(consistent GND signal).

– When using both outputs, make sure that the valves are of the same type.

– Due to large tolerances in thermal actuators, it is not possible to adjust the valve opening precisely via a PWM signal.

– Each module address can only be assigned once.

– Only devices with addresses 1...3 can be addressed via the Modbus Configurator.

For further instructions on how to use your RYMASKON® 400, please visit

www.spluss.de

This manual suits for next models

10

Other S+S Regeltechnik Control Unit manuals

S+S Regeltechnik

S+S Regeltechnik Rymaskon 200-Modbus Series User manual

S+S Regeltechnik

S+S Regeltechnik Rymaskon 600 User manual

S+S Regeltechnik

S+S Regeltechnik RYMASKON 700 Series User manual

S+S Regeltechnik

S+S Regeltechnik Rymaskon 200-Modbus Series User manual

S+S Regeltechnik

S+S Regeltechnik Rymakson 400-Modbus Repair manual

S+S Regeltechnik

S+S Regeltechnik THERMASREG FM Series Repair manual