CONTENTS Page

Maintenance

Introduction.

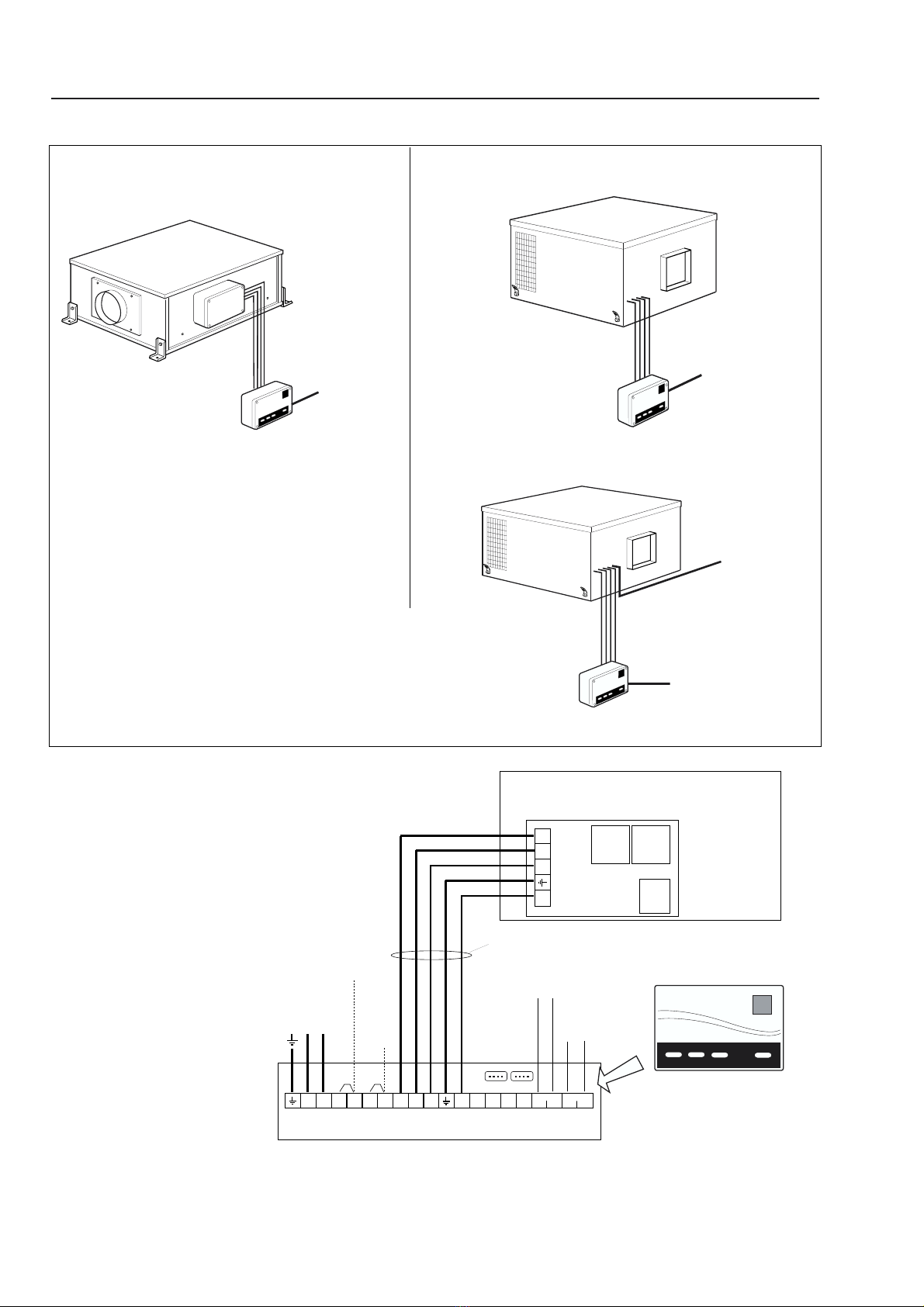

Installing the control unit.

Applications and wiring diagrams

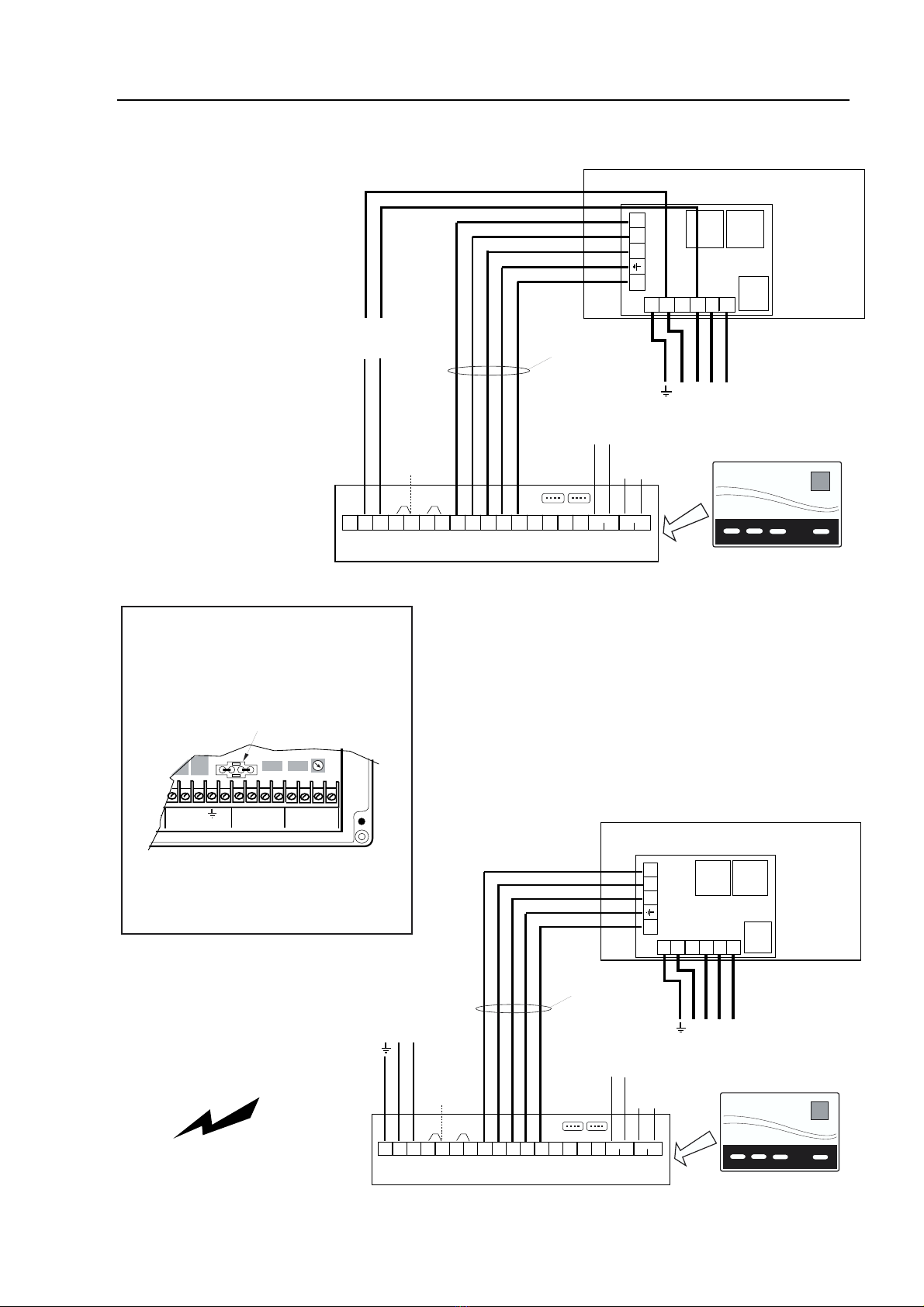

Operating the twinfan mains control.

Terminal connections

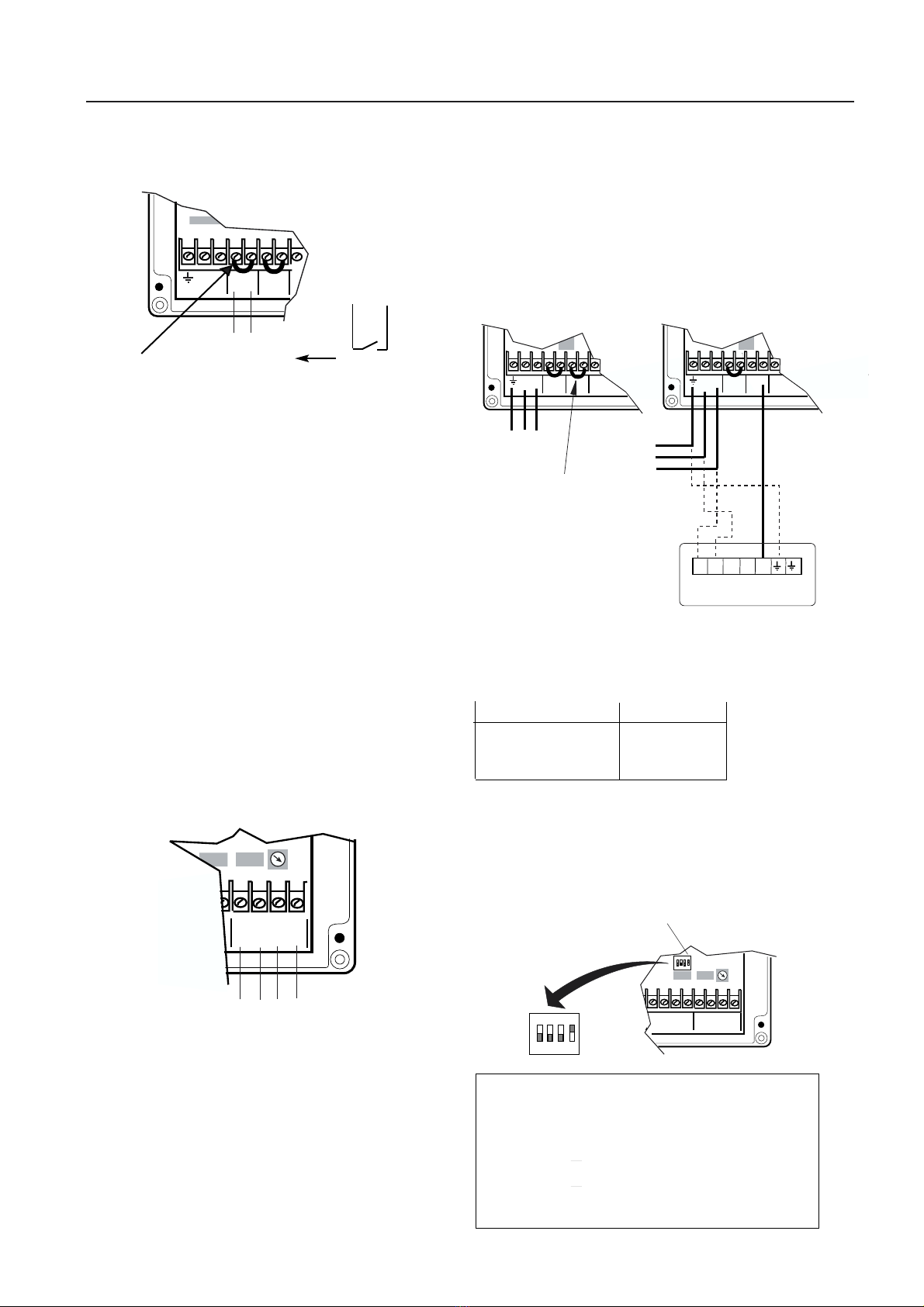

Run on Timer adjustment.

Switched Live connections.

Remote Run / Remote Fail connections.

Connecting a Speed Control.

Resetting Function switches.

Certification

Installation

and Maintenance

Mains ‘C’

Twin Fan Control

CT-A (auto duty share)

CT-M (manual duty share)

NuAire Limited

Western Industrial EstateCaerphilly,

CF83 1XH United Kingdom

Telephone 029- 20 88 5911

Facsimile No. 029 2088 7033

Email: info @ nuaire. co.uk

www.nuaire.co.uk

Leaflet No. 670912

JULY 2001

1

Maintenance

The control requires no maintenance other than cleaning.

Disconnect supply and clean with a damp cloth. Do not spray

any cleaning fluids onto the control

Introduction

This control has been designed specifically to suit NuAire

Quietwin Twinfan Extract units.

Two versions of the control are available.

1) Manual Duty Sharing (CT-M model).

2) Automatic Duty Sharing (CT-A model).

Both models provide automatic change over from a failed fan to

the standby fan. A list of unit features is shown opposite.

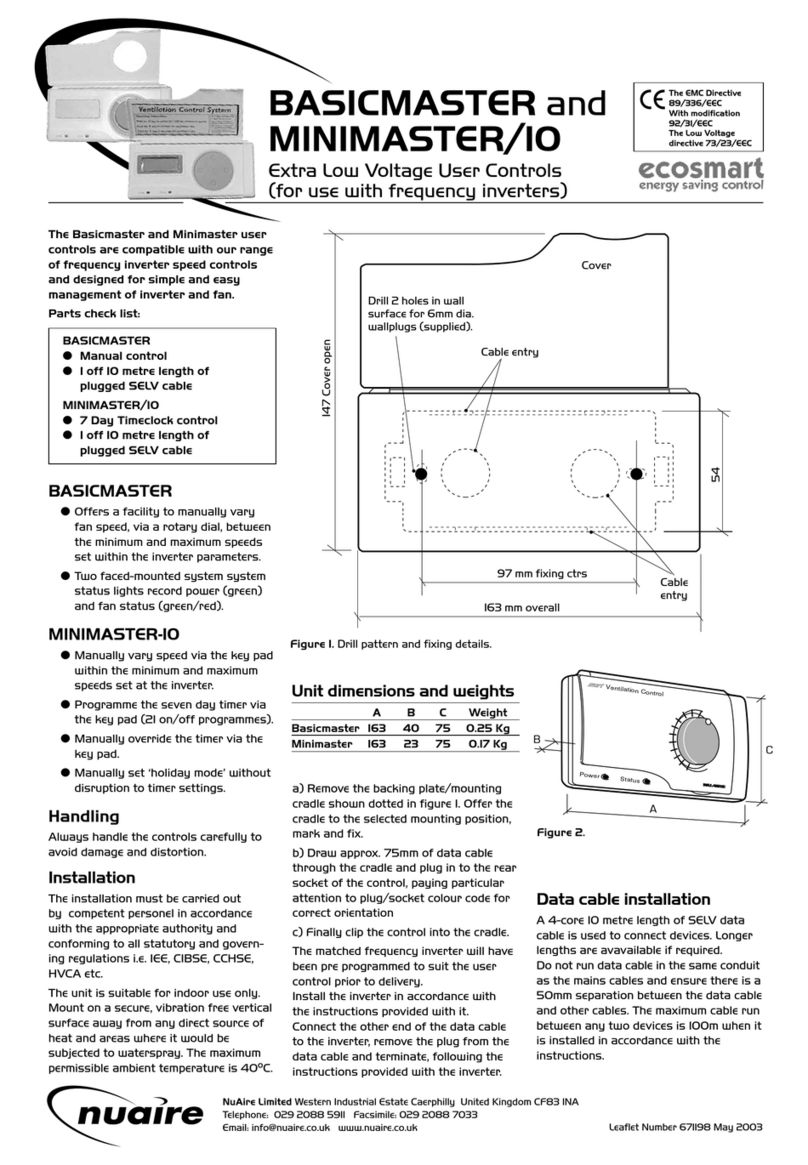

A general view of the unit with overall dimensions is shown in

fig. 1.

Installing the control unit

Carefully remove the case cover (4 screws). Drill the main case

to allow the necessary cable access.

NOTE:

It is the responsibility of the installer to ‘seal’ the cable

entries and to maintain the IP rating of the unit.

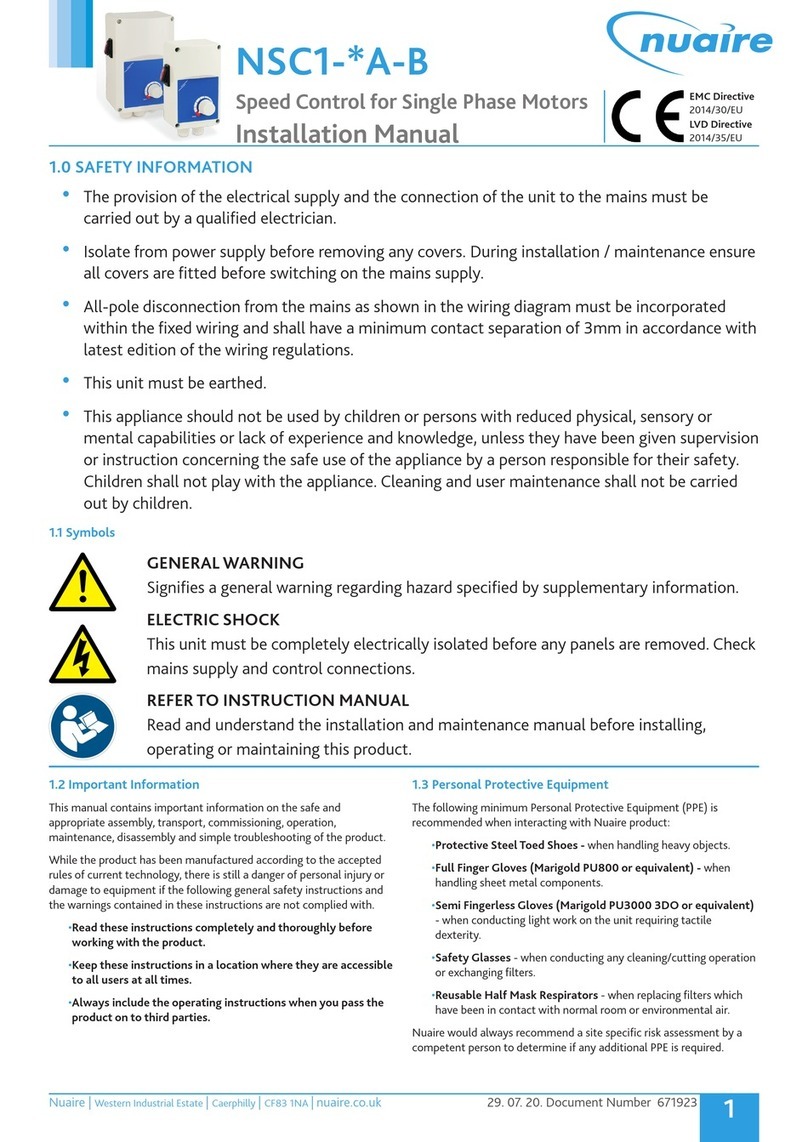

Select a suitable surface mounting position and fix the main cas-

ing to it using the four case mounting holes provided. (fig 2).

ISOLATE THE ELECTRICAL SUPPLY and make your

main electrical supply and fan unit connections to the terminals

inside as shown in fig. 8.

FEATURES

IP 65 (Protection).

Remote Fail (volt free contacts).

Remote Run (volt free contacts).

Switched Live operation.

Adjustable run on 0-60 min.

Audible failure indication.

Visual failure indication.

Auto Duty Share (CT-A only. 12 hr intervals).

Microsave compatible.

Automatic Changeover on failure.

Failure detection of fan by Hall Effect sensors.

IMPORTANT

The installation must be carried out by qualified personnel in

accordance with the appropriate authority and conforming to all

statutory and governing regulations eg. IEE, CIBSE, COHSE etc

.

.

.

.

.

.

.

.

.

.

.

Figure 1. Unit overall dimensions (mm)

Figure 2. Fixing holes

1

1

1

2

4

4

4

5

5

5

5

6

Controls Application Service (CAS)

A team of Engineers and technicians is available to provide

pre and post order support.

We are on hand to provide help and advice from the most

basic use of any NuAire equipment to the more complex

applications, maximising on the versatility of our control

products.

Telephone: 029 2085 8585

Facsimile: 029 2085 8586

The EMC directive: 89/336/EEC

with modification 92/31/EEC

The low voltage directive 73/23/EEC

200 80

150