Sponge-Jet 35E User manual

SPONGE-JET 35E 50E USER MANUAL | 1

SPONGE-JET®

35E RecyclerTM

50E RecyclerTM

USER MANUAL

Sponge-Jet, Inc. (USA)

14 Patterson Lane +1-603-610-7950

Newington, NH 03801 www.spongejet.com

Sponge-Jet 35P 50E User Manual - REV B/ ENG

2| SPONGE-JET 35E 50E USER MANUAL

CONTENTS

1.0 Safety 3

2.0 Basic Components 5

3.0 Receipt and Inspection 8

4.0 Media Classification 9

5.0 Electrical Requirements 11

6.0 Normal Operation 12

7.0 Advanced Operation 13

8.0 Routine Maintenance 16

9.0 Rebuild Maintenance 17

Notes 19

IMPORTANT NOTE: While parts, systems, components, operational

procedures may be the same between equipment models, the images

provided in this manual may vary from model to model.

This manual represents the following models:

Model: 35E Weight: 148 kg (325 lb)

Model: 50E Weight: 170 kg (375 lb)

English Language is Original Instructions.

Translated from Original Instructions.

SPONGE-JET 35E 50E USER MANUAL | 3

1.0 SAFETY

Safety Labels

User Manual Caution/Danger

Ear protection Safety Gloves

Hazardous Voltage Two Man Lift

Protective Earth Ground Do Not Operate with

Guards Removed

Lockout/Tagout Eye Protection

Electrical Power Respiratory Protection

Failure to follow all Instructions in manual and any alterations made to

equipment following shipment from Sponge-Jet will void warranty. Direct

attachment, such as welding or bolting of any additional chutes or hoppers,

etc., to vibrating equipment other than those supplied by Sponge-Jet, Inc.

will automatically void warranty.

Any connection made to unit must be flexible.

Before starting unit, operator must be certain unit is free to follow

movement produced by vibrating parts.

In general, feeding and discharge connections must have sucient

clearance to prevent any contact.

Before Starting Unit:

The base must have a substantial foundation around entire bottom of the unit

base ring. The base must be secured to floor or adequate support structure

unless on casters. If, after unit has been started, there are secondary vibra-

tions to foundation or to separator base, unit must be reinforced. With further

questions, consult Sponge-Jet, Inc.

Shipping lugs must be removed.

4| SPONGE-JET 35E 50E USER MANUAL

1. All guards and service doors must be in place.

2. Risks:

a. Operating equipment with guards removed

b. Hazardous voltage

3. Required Personal Protective Equipment:

a. Wear eye protection

b. Wear ear protection

c. Wear safety gloves

d. Wear respiratory protection

4. Unit should only to be operated and maintained by trained personnel.

a. Read and follow all maintenance instructions and guidelines.

User should not operate without reading all guidelines.

b. Licensed electrician for wiring of any electrical equipment is required.

5. Unit must not be used:

a. Do not operate with explosive products or products at

elevated temperatures.

b. Do not operate without all guards and covers in place.

c. Lockout/tagout procedures must be followed before any

inspection, maintenance or cleaning is undertaken.

d. Lockout/tagout procedures must be followed before

adjustments are made to eccentric weight mechanism.

e. User must ensure any cables, hoses or pipes do not

present a slip, trip or fall hazard.

f. Unit should not be climbed on.

g. User is responsible for taking all necessary precautions

dependent on material being screened.

h. Be careful when moving. Move with help.

SPONGE-JET 35E 50E USER MANUAL | 5

2.0 BASIC COMPONENTS

1 Hopper

2 Main Rim

3 Vibratory Section

4 Safety Skirt

5 Large Particle Downspout

6 Reusable Media Downspout

7 Fine Particle Downspout

8 Pan Clamp Hook

9 Pan Clamp

10 Caster

11 On/O Switch

12 Motor

7

9

10

5

1

2

3

4

6

11

12

8

BASIC COMPONENTS (CONTINUED)

Figure A: Sieve Assembly

1Hopper

2Flat Gasket

3Large Particle Downspout

Oversized particles that cannot pass through top screen are discharged through

Large Particle Downspout.

4Top Screen

Stainless Steel mesh screen used to separate oversized items larger than Sponge

Media particle from reusable Sponge Media.

(See section 7.5 Sieve Assembly, for proper screen installation)

5Reusable Media Downspout

Particles that do not fall through Bottom Screen are discharged through Reusable

Media Downspout.

6Bottom Screen

Stainless Steel mesh screen used to separate undersized material (normally con-

sidered waste) from reusable Sponge Media abrasive.

(See section 7.5 Sieve Assembly, for proper screen installation)

7Fine Particle Downspout

Particles that fall through bottom screen are discharged through Fine Particle

Downspout.

8Shallow Funnel

Located under the Bottom Screen, the shallow funnel collects and directs fine particu-

late (waste) into Fine Particle Downspout.

Figure B: Vibratory Portion and Lower Base Assembly

1Flywheel

Vibratory energy generated directly by Flywheel is transmitted to Sieve Assembly.

2Vibratory Portion

Is located over Lower Base Assembly and supports Sieve Assembly.

3Suspension Rod

Vibratory Portion is located over Lower Base Assembly and supports Sieve Assem-

bly.

4Weight

This o center weight causes upper the eccentric Flywheel to move media across

screen.

5Side Cover

This removable cover serves as protection for the components located inside the

Lower Base Assembly.

6Lower Base Assembly

Supports Main Controls, Air Motor, Vibratory Portion and Sieve Assembly.

7Flexible Coupling

Absorbs startup torque from electric motor and passes that energy up through

Vibratory Portion.

1

3

5

6

7

2

2

4

2

2

8

6| SPONGE-JET 35E 50E USER MANUAL

2

34

5

1

7

6

SPONGE-JET 35E 50E USER MANUAL | 7

BASIC COMPONENTS (CONTINUED)

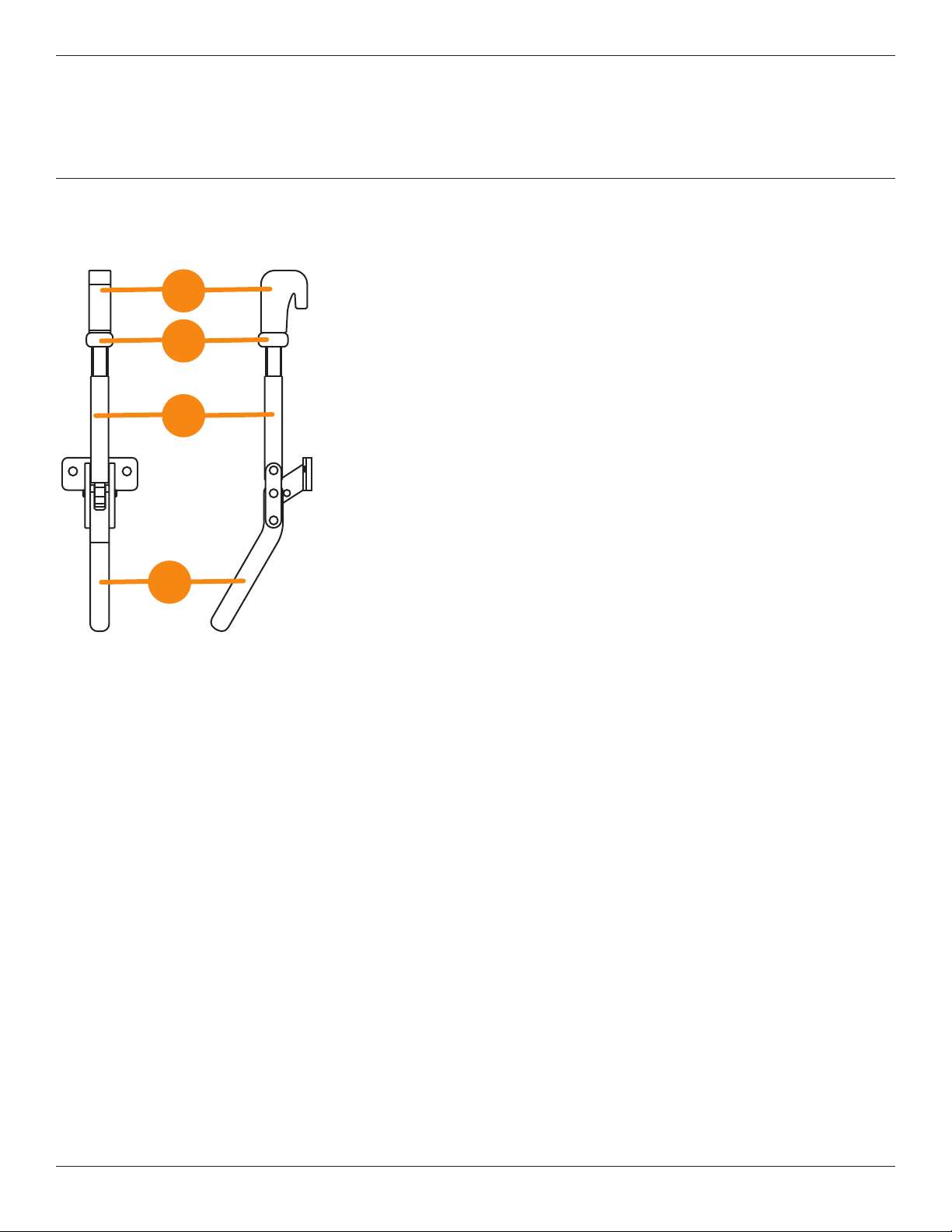

Figure C: Pan Clamps

1Pan Clamp Hook

Adjustment for varying sized gaskets is made by turning Pan Clamp Hook.

2Lock Nut

Used to prevent Pan Clamp Hook from swiveling when dismounting Pan Clamps

(50E only).

3Threaded Rod

Pan Clamp Hook threads onto Threaded Rod.

4Handle

Used to secure Pan Clamp to Sieve Assembly.

1

2

3

4

8| SPONGE-JET 35E 50E USER MANUAL

3.0 RECEIPT & INSPECTION

Upon receipt of shipment, review packing list, immediately check for missing

or damaged parts; open all boxes and crates, and/or any abnormalities; if

missing/broken parts, promptly notify appropriate carrier and your Sponge-

Jet representative.

- Examine all screens and components to insure damage has not occurred

during shipment.

- Operate unit on a sturdy, flat surface. This will assure maximum eciency.

- Vibrating parts should never come in contact with static parts of unit or its

surroundings.

- Check to be sure screen elements are level.

SPONGE-JET 35E 50E USER MANUAL | 9

4.0 MEDIA CLASSIFICATION

Media Classification Process:

(1) Connect unit to an adequate electric supply, and turn on.

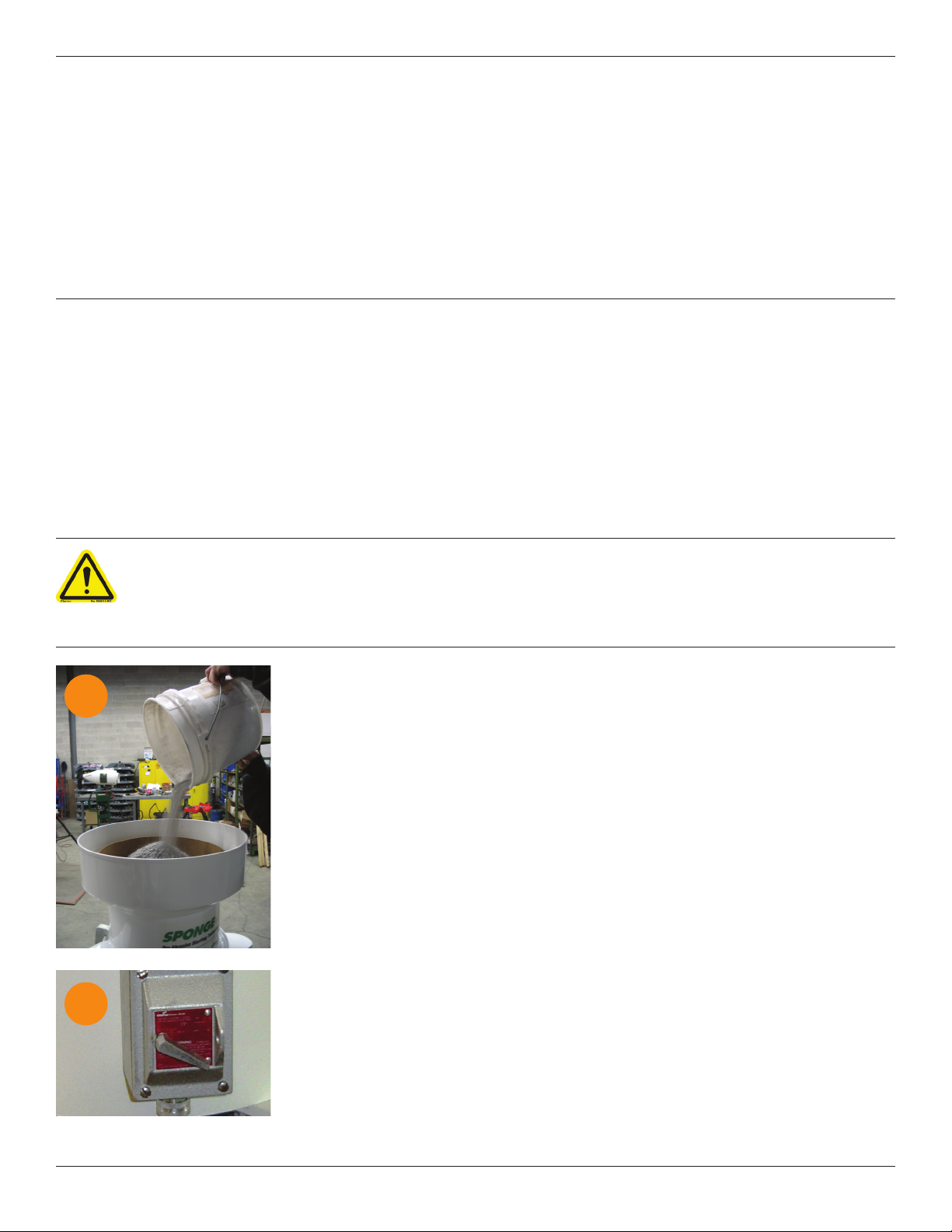

(2) After blasting Sponge Media abrasive, collect and pour it into Hopper.

(3) Sponge Media abrasives and small contaminants pass through Top

Screen, while oversized particles exit via Large Particle Downspout.

(4) Spent Sponge Media abrasives and small contaminants pass below

Bottom Screen, and exit through Fine Particle Downspout, while

reusable-sized Sponge Media abrasives exit above Bottom Screen via

Reusable Media Downspout.

IMPORTANT: Proper separation of oversized and undersized particles from

reusable Sponge Media™ abrasive is critical to reducing airborne dust and

minimizing risk of clogging Sponge-Jet Feed Unit™ while blasting.

BOTTOM SCREEN

LARGE PARTICLE

DOWNSPOUT

FINE PARTICLE

DOWNSPOUT

REUSABLE MEDIA

DOWNSPOUT

2

2

3TOP SCREEN

WASTE

HOPPER

WASTE

REUSABLE

SPONGE MEDIA

4

10 | SPONGE-JET 35E 50E USER MANUAL

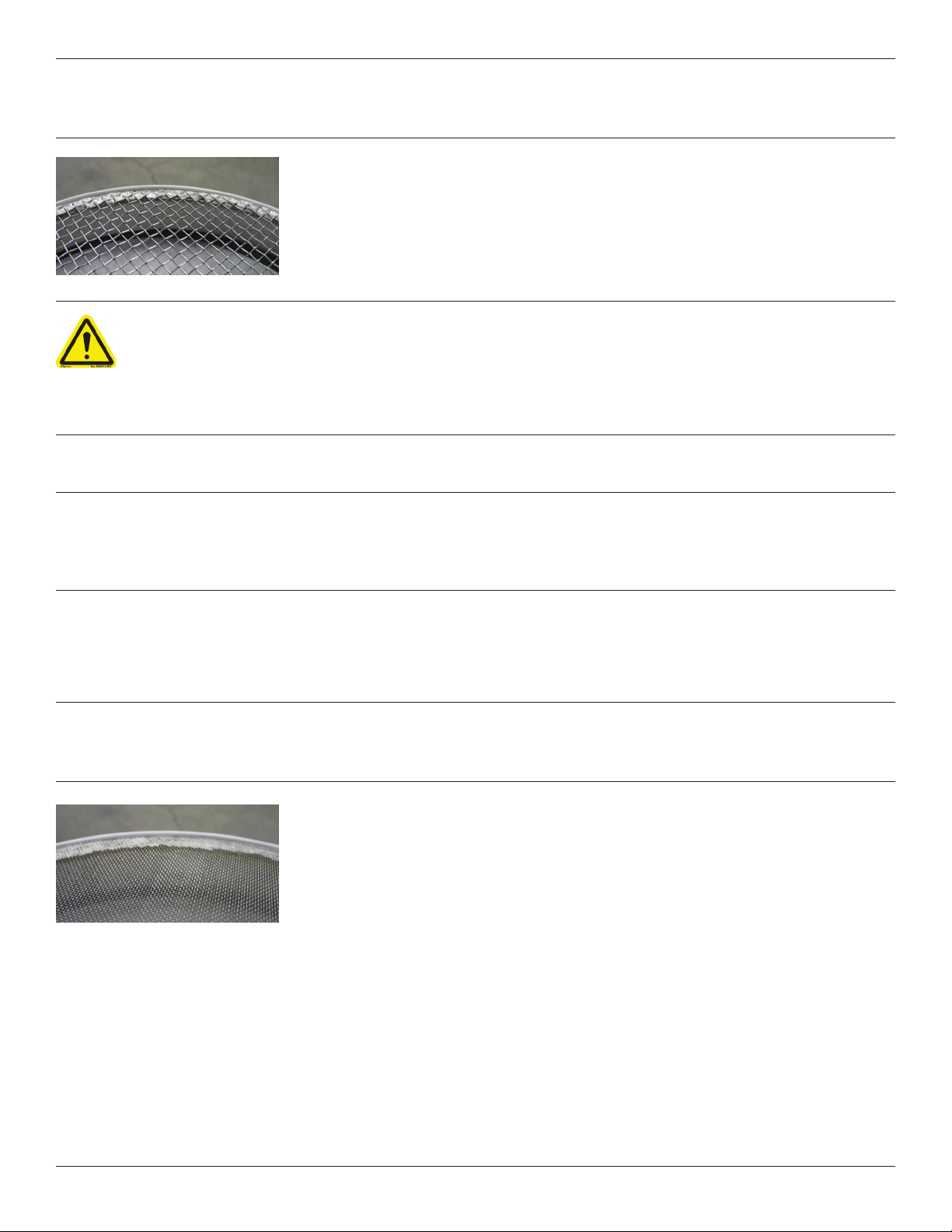

4.1 TOP SCREEN - LARGE PARTICLE

CLASSIFICATION

Top Screen is a standard #3 mesh screen used to separate unwanted foreign

matter larger than most Sponge Media particles. Items such as nuts, bolts

or rocks are separated and discharged as oversized particles through Large

Particle Downspout.

WARNING:

Oversize particles, if re-introduced back into Working Mix, can cause harm or

damage by (1) becoming a projectile capable of injuring people, (2) harming

work surface, (3) piercing pressurized blast hose, (4) clogging Feed Unit and/

or (5) damaging/jamming the drive mechanism.

4.2 REUSABLE MEDIA

Sponge Media that do not pass through Bottom Screen exit unit via Reusable

Media Downspout. Sponge Media abrasive that exit Reusable Media Down-

spout can be reused in Sponge-Jet Feed Unit.

Working Mix: a blend of blasted Sponge Media passed through Recycler (as

reusable Sponge Media) plus a quantity of new Sponge Media added every 2-3

passes through Recycler. Generally this is 1-2 bags per hour, per nozzle.

4.3 BOTTOM SCREEN - FINE PARTICLE

CLASSIFICATION

Bottom Screen is a number #16 mesh screen used to separate foreign mat-

ter smaller than most Sponge Media particles. Fine particles are separated

from Sponge Media and discharged through Fine Particle Downspout and are

normally considered waste. Fine particles usually include paint chips, broken

down (spent) Sponge Media. These fine particles,

if added to the Working Mix, will increase ambient dust levels at work site.

Important: Dust level tolerance can change from project to project and is

subject to guidance from project management. When hazardous materials

such as lead paint, chromates, radionuclides, cadmium, or PCB’s are present,

there are additional demands for managing dust and waste according to best

practices and applicable local, state and federal regulations.

SPONGE-JET 35E 50E USER MANUAL | 11

5.0 ELECTRICAL REQUIREMENTS

Unit is equipped with a 1 HP, Single phase, 115v/230v, auto-sensing 50/60 Hz,

3450 RPM, TEFC motor, which requires 11.2/5.6 amps.

Unit comes equipped with 3m (10ft) of 12 AWG supply wire.

Use of extension cords are strongly discouraged.

WARNING:

Motor is not thermally protected.

12 | SPONGE-JET 35E 50E USER MANUAL

6.0 NORMAL OPERATION

IMPORTANT: It is essential not to restrict movement of vibrating portion of

unit. It is recommended no rigid connections be added to inlet/outlet of unit.

Rigid connections can reduce eciency of unit and lead to extra fatigue of

sheet metal parts and weldments.

6.1 ADJUSTMENT OF PAN CLAMPS

Pan Clamps have a simple adjustment that allows for dierent thicknesses of

Flat Gaskets.

Adjustment is made by turning Pan Clamp Hook. Under normal operation,

adjustment should not be necessary if all Pan Clamps and gaskets are in their

proper location. Pressure required to close the four (4) Pan Clamps should not

exceed 6.8 kg (15 lb) or each at the end of Handle.

WARNING:

Do not apply excessive force while tightening Pam Clamps. Vibration of unit

can cause overtightened clamps to break.

6.2 FILLING THEN STARTING UNIT

1. Sponge Media is added through Hopper located on top of unit.

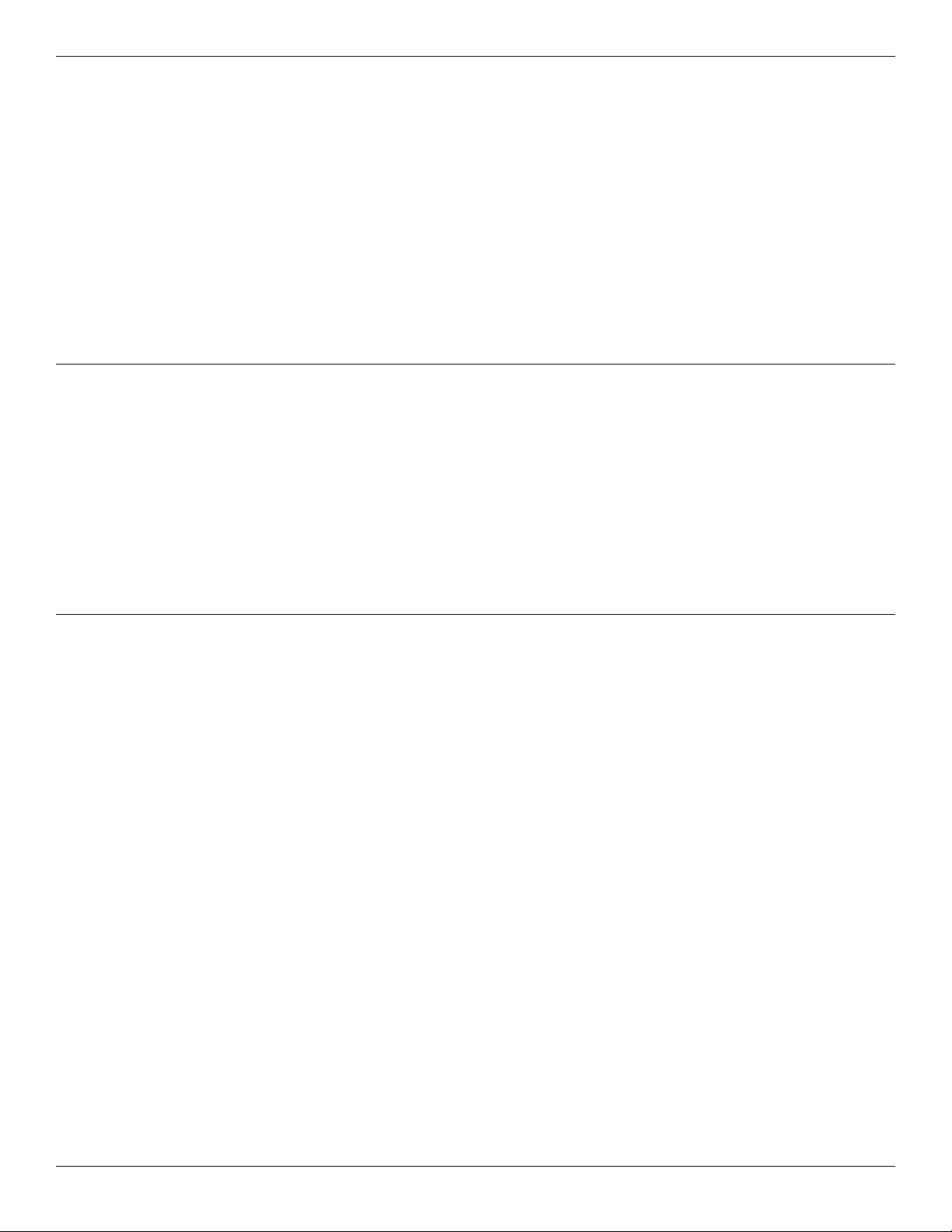

2. After connecting unit to an adequate electrical supply, activate by turning

On/O Switch to “ON”. A powerful gyrating vibration will occur.

1

2

SPONGE-JET 35E 50E USER MANUAL | 13

7.0 ADVANCED OPERATION

IMPORTANT: Before operation, if unit has been disassembled, verify the fol-

lowing has been completed:

- There is no restricted movement of vibrating portion of unit.

- No rigid connections have been added to inlet/outlet of unit. Rigid connec-

tions can reduce eciency of unit and lead to extra fatigue of its sheet metal

parts and weldments.

7.1 AMPLITUDE OF VIBRATION

Adjustment during use of unit should be kept to a minimum. One variable the

operator should be concerned with is amplitude of vibration. Unit has one (1)

Flywheel, which is adjustable to five (5) varying degrees of “o-center”. This

adjustment will modify horizontal amplitude. Located below Flywheel hous-

ing (on flywheel shaft) is an adjustable weight. When the weight is set o cen-

ter from upper flywheel weight, varying amounts of vertical deflection occur.

This deflection is also a function of the RPM from the Flywheel.

7.2 PROCEDURE FOR ADJUSTMENT

OF AMPLITUDE

Adjust Flywheel as follows:

1. Remove Sieve Assembly to expose top bearing housing bracket.

2. In the bracket there will be a ½” “thru-hole”. Rotate Flywheel until the ½”

socket head cap screw comes into view. Amplitude setting numbers will

range from 1 to 3.

3. Remove screw until Flywheel slide weight can be rotated to desired setting

number.

4. Tighten screw securely.

Adjust Kicker Weight as follows:

A second adjustment is available by moving kicker weight. To adjust kicker

weight, remove Side Cover. Kicker weight is located directly above upper cou-

pling flange. One (1) bolt clamps the fan-shaped weight to the shaft.

This weight is set by factory at zero degrees with flywheel weights. To achieve

maximum amplitude, loosen with 5/16” Allen wrench; rotate weight 180 de-

grees and tighten. Settings between 0 degrees and 180 degrees are available.

14 | SPONGE-JET 35E 50E USER MANUAL

ADVANCED OPERATION (CONTINUED)

NOTE: The amplitude setting of the Electric Media Recycler, with the flywheel

shaft running at 3450RPM, should not exceed flywheel setting #3, which is

factory set. Adjustment requires the use of a RPM calibration tool.

WARNING: Failure to use a calibration tool or properly set the RPM rate can

damage the equipment and will void the warranty.

7.3 ALIGNMENT

Prior to shipment, this unit has been adjusted for ecient operation. Under

normal operating conditions, these settings should not need adjustment.

However, shocks can occur during shipment, which may necessitate slight

re-alignment. Ecient operation results when motor and flywheel shaft are

parallel. When this occurs, faces of the flywheel Upper Coupling Flange and

the motor flange are also parallel.

If uneven vibrating or jerking occurs, check that coupling faces are parallel

by measurement. If they are not parallel, adjust by varying length of three

(3) Suspension Rods. To perform this operation, loosening and screw up (or

down), the three (3) pairs of hexagon nuts. Secure base of Suspension Rods

and lower compressed rubber bushings. After adjustment is made, these

nuts must be securely tightened. At the same time, check that the faces of the

flanges are parallel.

7.4 ALIGNMENT OF FLANGES

A minimum clearance of 1 ¼” (32 mm) must be maintained between faces of

the Coupling Flanges. Coupling Flanges must be held parallel to within .010in

(0.254mm). Parallel alignment of flange is performed by adjusting three (3)

lower Suspension Rod nuts. After coupling flanges are proven to be parallel,

installation of flexible rubber coupling may proceed.

NOTE: Flexible Rubber Coupling is 1” (24.5 mm) thick with four (4) 1/8” (3.2

mm) thick bosses.

WARNING: Never run motor with only flexible rubber coupling attached to

motor flange. Failure may result in serious damage and/or injury.

SPONGE-JET 35E 50E USER MANUAL | 15

ADVANCED OPERATION (CONTINUED)

7.5 SIEVE ASSEMBLY

The dismountable Sieve Assembly is constructed

of welded steel. Failure to properly assemble and

fasten Sieve Assembly will sharply shorten life of

weldments.

Sieve Assembly consists of five parts. Assemble as

follows:

1. Place Fine Particle Downspout through hole pro-

vided in Vibratory Portion. Note: Be sure down-

spout is centered.

2. Place Flat Gasket into Shallow Funnel.

3. Place standard #16 Screen into Shallow Funnel

and on top of Flat Gasket. (IMPORTANT: Place

wired side up**)

4. Place Flat Gasket onto Screen making sure to

center Flat Gasket.

5. Place Double Deck Main Rim over Flat Gasket

and Screen and into Shallow Funnel.

6. Place Flat Gasket into Double Deck Main Rim.

7. Place standard #3 Screen into Double Deck Main

Rim and on top of Flat Gasket. (IMPORTANT: Place

wired side up**).

8. Place Flat Gasket onto Screen, making sure to

center Flat Gasket.

9. Place Hopper over Flat Gasket, making sure

Large Particle Downspout is opposite from Re-

usable Media Downspout.

10. Attach Pan Clamps. These must be closed to

secure Sieve Assembly.

1

3

5

7

9 10

2

4

6

8

**IMPORTANT: All screens must be assembled with

mesh on top. Incorrect installation is an easy mistake

and will cause unit to operate unsatisfactorily.

16 | SPONGE-JET 35E 50E USER MANUAL

8.0 ROUTINE MAINTENANCE

IMPORTANT: Under NO circumstances should inspection, adjustment or lubri-

cation be conducted while unit is running or connected to electric supply.

- There is no restricted movement of vibrating portion of unit.

- No rigid connections have been added to inlet/outlet of unit. Rigid connec-

tions can reduce eciency of unit and lead to extra fatigue of its sheet metal

parts and weldments.

8.1 LUBRICATION

Unit has been tested before shipment. DO NOT grease unit until it has been

operated for 500 hours. Grease using 1 to 2 pumps or small amount, every 40

hours of operation. DO NOT OVER-GREASE.

Recommended Lubricants:

1. Citco AP, Citco oil

2. Ore-Lube K2

3. Mobilux Grease #2, Socony Mobil Oil Co.

4. Val-Lith #IP, Valvoline Co.

5. VS SGA

6. Multifak #2, Texaco Inc.

7. Alvanie R#, Shell Oil Co.

WARNING: DO NOT FORCE EXCESSIVE GREASE. Excessive grease can damage

bearings and motor system.

8.2 ACCESS TO GREASE FITTINGS

Two (2) bearings are greased by access through grease fittings on side of unit.

IMPORTANT: This unit was greased before shipment. Add grease using 1 to 2

pumps every 40 hours of operation. If the unit has not been used for one year,

add 1 to 2 pumps of grease.

SPONGE-JET 35E 50E USER MANUAL | 17

9.0 REBUILD MAINTENANCE

9.1 REPLACEMENT OF TOP ROLLER BEARING

1. Remove Sieve Assembly.

2. Remove grease lines.

3. Remove ring (6) 5/16” hex head cap screws, top bearing housing cap and

brass mole connector.

4. Remove top bearing housing with bearing.

5. Loosen top bearing sleeve bolt.

6. Carefully press bearings and seal out of housing and top bearing sleeve.

7. Clean and deburr housing and sleeve - examine parts for wear.

8. Press new bearing and seal into sieve and housing.

IMPORTANT: Re-pack bearing with grease (See recommended lubricants).

9. Replace top bearing sleeve and sleeve bolt.

IMPORTANT: Use thread locker on sleeve bolt (Perma Lok MM115 or equal).

10. Insert top housing cap and 5/16” hex head cap screws.

11. Reattach grease lines.

9.2 REPLACEMENT OF FLYWHEEL BEARING

1. Remove Sieve Assembly.

2. Release Side Cover clamp and open cover.

3. Loosen and remove top (2) flexible rubber coupling locknuts (3/8” - 16

thread).

4. Remove (3) 5/8-11 hex nuts from Suspension Rods above rubber bushings.

5. Remove top sieve weldment.

6. Follow steps 1 through 6 of “Replacement of Top Roller Bearing” (If not

already complete).

7. Loosen (2) 3/8-16 set screws - Remove Flywheel.

8. Loosen (10) 3/8-16 set screws.

18 | SPONGE-JET 35E 50E USER MANUAL

REBUILD MAINTENANCE (CONTINUED)

9.3 REPLACEMENT OF FLYWHEEL BEARING

(CONTINUED)

9. Loosen (1) 7/16” hex head cap screws from ends of shaft, then loosen (2)

3/8-16 socket head cap screws and remove upper coupling flange.

10. Remove (10) 3/8-16 socket head cap screws and grease line.

11. Remove Flywheel housing from top sieve weldment.

12. Loosen ¼” cap screws; remove Flywheel top cap and bottom cap.

13. Slide Flywheel shaft (with bearings) through bottom of housing.

14. Remove circlip; press bearing from shaft.

15. Press outside race of roller bearings from flywheel housing.

16. Remove seals from top and bottom caps.

17. Clean and inspect all parts for wear; deburr all parts as required.

18. Follow steps 1 through 16 in reverse order to reassemble.

IMPORTANT: Follow steps for proper alignment after assembly.

SPONGE-JET 35E 50E USER MANUAL | 19

NOTES

MODEL

SERIAL

This manual suits for next models

1

Table of contents

Other Sponge-Jet Industrial Equipment manuals