PAGE 3 OF 22

WARRANTY

Tates Performance Hobbies guarantees that this model is free from defects both in material and craftsmanship on the date of purchase. This

guarantee does not cover any component parts damaged by use or modification. Tates Performance Hobbies liability will under no

circumstances exceed the original cost of the purchased model. Moreover, Tates Performance Hobbies reserves the right to change or modify

this warranty without notice.

If upon purchasing this product the buyer finds defects to the product as a result of the manufacturing process we recommend that you return

this product to the place of purchase to exchange or refund the product.

Given that Tates Performance Hobbies has no control over the final assembly or use of this product, Tates Performance Hobbies shall assume

no liability for damage caused resulting from the use by the user of the final user-assembled product. By using this product the user accepts all

resulting liability.

If the purchaser of this product is not prepared to accept the liability associated with the use of this product, they are advised to return this model

within 14 days to the place of purchase. The product must be in complete and unused condition along with receipt of purchase at the moment of

return.

WARNINGS

•Never leave the model in direct sunlight for prolonged periods of time.

•Never fly this model near an AIRPORT, check with your local airport authorities for minimum distance to available sites.

•Never use this model near power lines, radio towers, or other locations where there is known high radio wave or electromagnetic activity.

•Do not allow water or liquid to touch the model or any of the components.

•Store the model in a cool dry location as high humidity can damage the model and its components.

•Protect the model from bumps, jolts, and concussions from other hard objects as this could damage the model.

•Keep the model clean of dust, mud and dirt.

•Never place foreign objects on top of the model.

•Use the model ONLY in wide open spaces that are free of people, or at your local RC flight club.

•NEVER use the model near populated pedestrian areas. This could lead to damage of property or injury to bystanders.

•Prior to take off, always check that transmitter and receiver batteries are fully charged and are fresh. As battery power decreases the

quality of the radio signal diminishes and control over the model could fail.

•Please dispose of used batteries and electronic components in accordance with your municipal and federal Regulations relating to these

types of products.

•Keep in mind that those in your vicinity may also use radio control models. Please check prior to take off that you are using a unique

frequency to all those around you. Not doing so may cause you and others to lose control of the model.

•If the model does not properly respond to control inputs, land immediately and do not attempt to use the model until the cause has been

determined and fixed.

•After flying, switch off the power on the model and then the transmitter.

CAUTIONS

•This product is not suitable for children under 14 years of age, adult supervision of children is highly recommended.

•This kit contains a number of small parts which are fragile and may act as choking hazards.

•Please store and assemble this model well out of the reach of small children.

•Only use batteries of the same or equivalent type.

•The power supply terminals are not to be short-circuited.

•Do not use new and old batteries together. Do not mix different brands or kinds of batteries.

•Make sure to insert batteries with correct (+) and (-) polarity.

•If the aircraft gets wet, dry it, and stop operating to avoid short-circuiting that may cause hazards.

•Do not put fingers, hair, or clothes into the shafts or rotating parts of the model.

•NEVER LEAVE CHARGING BATTERIES UNATTENTED!!!!!!

PRODUCT CONTAINS SMALL PARTS - KEEP AWAY FROM YOUNG CHILDREN

NOT SUITABLE FOR CHILDREN UNDER 14 YEARS OF AGE UNLESS SUPERVISED BY AN ADULT

COLORS, SPECIFICATONS AND CHARACTERISTICS MAY BE DIFFERENT FROM PICTURE AND DESCRIPTON ON THE BOX AND

MANUAL.

Tates

Performance

Hobbies

may

be

contacted

by

E

Mail

on

–

[email protected] or Phone 03 52224201

The purchaser/operator accepts all responsibility of any and all structural or mechanical failures.

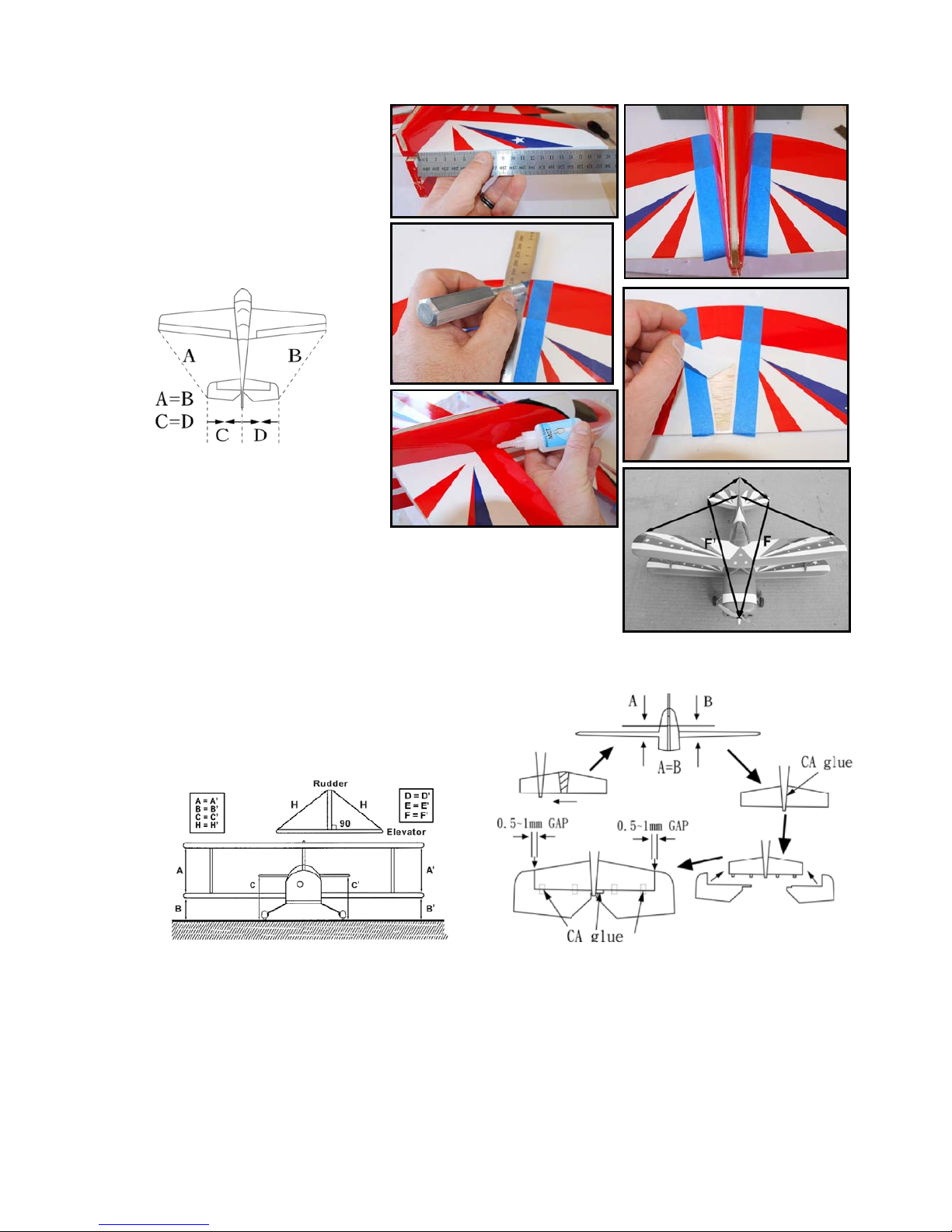

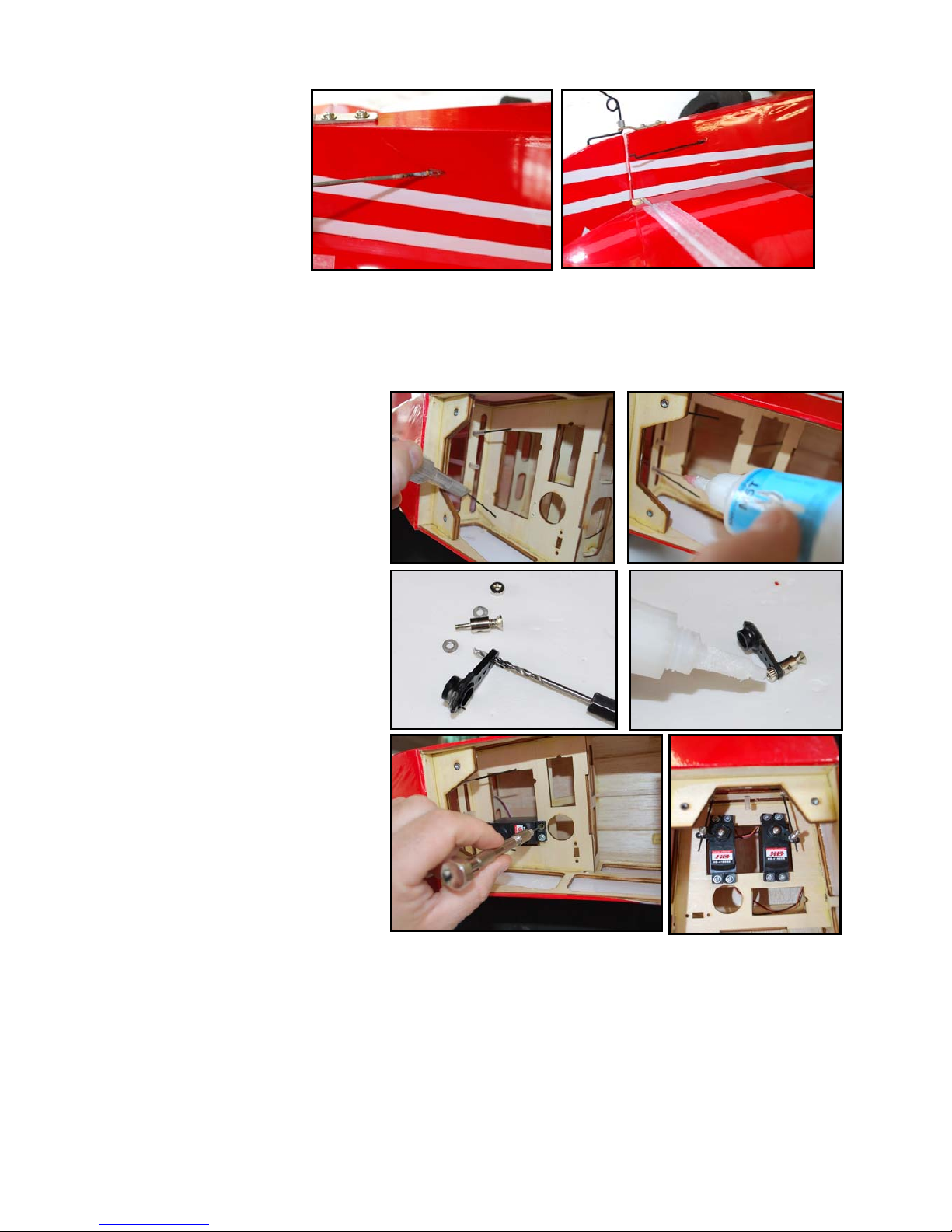

Before beginning the assembly of your Pitts Special, remove each part from its bag for inspection.

IMPORTANT INFORMATION ABOUT THE C/A-STYLE HINGES INCLUDED WITH YOUR AIRPLANE

The airplane uses C/A-style hinges to hinge the control surfaces. These hinges are designed to be glued into place using thin

C/A. Do not glue the hinges into place using any other type of glue, such as thick C/A or epoxy. Use of any adhesive other than

thin C/A could result in failure of the hinges during flight.

For flutter-free control surfaces and crisp control response, it is imperative that the hinges be glued in properly. This is

achieved by having a tight hinge gap (no more than 1/32" (.7mm) wide) and using plenty of thin C/A glue. Poor hinge installation

can lead to control surface flutter, which can result in a catastrophic failure of the airframe.

If the hinge(s) can't be pushed in far enough to achieve the proper hinge gap, you'll need to use a modeling knife to cut the

hinge slot(s) deeper.

Make sure to check the integrity of the hinges after the C/A fully cures.

IMPORTANT It is imperative that the aileron and elevator hinge gaps be sealed. Failure to do this can lead to control surface flutter,

which can cause your airplane to crash. Sealing the hinge gaps will also provide crisper control response and allow the

airplane to track straighter and fly truer, making trimming much easier. Its not as necessary to seal the rudder hinge gap.