Sprinte ASP 116 evolution Instruction Manual

ASP116 EVOLUTION

Controller for powerful lifts

INSTALLATION & MAINTENANCE MANUAL

FOR ADL300 GEFRAN FREQUENCY INVERTER

V6-20

11-2017

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

2

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

3

SUMMARY

1BEFORE STARTING....................................................................................................................................................... 4

2USE OF PROGRAMMING « KEYPAD » .......................................................................................................................... 5

3QUICK START FOR ADL300 WITH ASYNCHRONOUS MOTOR........................................................................................ 7

4QUICK START FOR ADL300 WITH SYNCHRONOUS MOTOR .........................................................................................12

5STARTING GUIDE FOR KONE « ECODISK » MOTOR .....................................................................................................18

6CHOOSING THE TRAVEL MODE (SMART TRAVEL OR STANDARD) ...............................................................................26

6DRIVE SETTINGS .........................................................................................................................................................27

7BRAKE FEEDBACK & A3 CONTROL ..............................................................................................................................32

8HELP...........................................................................................................................................................................34

9DIAGNOSTIC / FAULT LIST ..........................................................................................................................................35

SAFETY INSTRUCTIONS

Risk of death or personal injury if the procedures/indications are not strictly observed.

Risk of personal injury or destruction of materiel if the procedures/indications are not

strictly observed.

Danger due to the presence of electrical voltage.

Risk of damage to the material by electrostatic discharge.

When handling the electronic boards/equipements, always wear a grounded anti-static

wristband or other appropriated equipments

Important information.

General requirement

Unplug before every maintenance operation.

PPE required

Document Reference : B-DP-17-003-00

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

4

1 Before starting

DANGEROUS VOLTAGE

● Please read and understand this installation manual before starting to use the inverter Gefran ADL300. Installation,

settings and repairs, must done by qualified staff.

● Many parts in this inverter, including printed circuit boards, operate at mains voltage. DO NOT TOUCH. Only use tools

with electrical isolation

● Do not touch unshielded components or terminal screws when the unit is on

● Do not short-circuit the terminals C / C1 and BR or the DC bus capacitors.

● Install and close all covers before applying power to the drive.

● Before any maintenance or repairs to the drive

- Cut main power.

- Place a label "DO NOT TURN ON" on the inverter breaker

- Lock the inverter breaker in open position.

●Before working on the inverter, turn off all power including external control power that it is used. WAIT 15 MINUTES

for the DC bus capacitors to discharge. Follow voltage measurement procedure DC bus specified in the installation

manual to verify that the DC voltage is less than 42 V. The inverter DELs are not accurate indicators of the absence of

tension DC bus.

If these precautions are not followed, will result in death or serious injury.

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

5

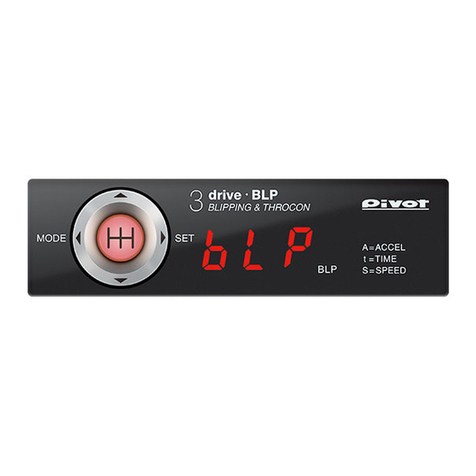

2 Use of programming « keypad »

Key’s functions :

Meaning of DELs

After making parameters change into the inverter, it is ESSENTIAL to save the

changed setting

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

6

- Solution 1 : Press « SAVE » (1) and « E » (2)

12

- Solution 2 : Follow the instructions below :

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

7

3 Quick start for ADL300 with asynchronous motor

3.1 Asynchronous motor startup wizard

Follow the instructions step by step below to start the inverter:

- Rated voltage (V) : Rated voltage of motor (see data plate motor)

- Rated current (A) : Rated current of motor (see data plate motor)

- Rated speed (rpm) : Rated speed of motor (see data plate motor). If on data plate

there is 1500rpm, you need to set 1380rpm.

- Rated frequency (Hz) : Rated frequency of motor (see data plate motor)

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

8

- Nb of poles pairs (p) : Number of poles PAIRS of motor (see data plate motor)

(p = Hz * 60 / rpm) : motor 1500rpm = 2, motor 1000rpm = 3

- Rated power (kW) : Rated power of motor (see data plate motor)

- Rated power factor : Rated power factor of motor (see data plate motor)

When motor data set, follow instruction below on 216SP board :

+

+ …

+ …

Screen under will appear

Then, follow the following wizzard on the drive :

EMERGENCY OPERA

Choose

CONFIGURATION

AUTO TUNING

NO

AUTO TUNING

YES

PUSH ON

UP IN EMCY

ENTER

+

ENTER

-

-

ENTER

CONFIGURATION

FREQ. INVERTER

ENTER

-

-

ENTER

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

9

(1) : Press « E » key to validate

(2) : Press « E » key to validate

(3) : When “Close enable input” is written : Push on UP button on emergency +

(4) : Waiting for display « Progress 100% »

(5) : When “Open enable input” is written : Release UP button on emergency

It’ not necessary to wire encoder to work in temporary operation

Settings and wiring for encoder is in section 3.2)

Do not set, go directly on step 6

Set the maximum rotation speed of motor in rpm (see data plate motor)

Set the maximum travel speed of motor m/s

Do not set, go directly to step 9

Do not set, go directly to step 9

Quick start is now finish, try to move the motor to verify it’s working well in the good direction (up/down) :

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

10

TRY TO MOVE

Go to section 5 If motor working upside down, reverse 2 motor phases on

terminal U, V, W and try again to move

3.2 Wiring and settings of encoder

Wiring of encoder’s shield

Le câble de l’encodeur doit être séparé

des câbles de puissance.

Relier le blindage de l’encodeur dans le

variateur (bride dédiée).

Relier le blindage du câble moteur côté

armoire et également côté moteur.

Encoder cable must be separated from main power cables

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

11

Encoder’s settings

3.3 Switch from open loop to close loop on asynchronous motor

When encoder cable is wired correctly, you need to set inverter in close loop mode : go to below menu and parameter :

Regulation mode :

- Switch from « Flux Vector OL » to « Flux vector CL »

TRY TO MOVE

Go to section 5 If motor not working well, reverse encoder direction (see below)

and try again to move

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

12

4 Quick start for ADL300 with synchronous motor

4.1 Synchronous motor startup wizard

Follow the instructions step by step below to start the inverter :

Encoder wiring

Wiring of encoder’s shield

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

13

Encoder cable must be separate of main power cables

Rated voltage (V) : Rated voltage of motor (see data plate motor)

Rated current (A) : Rated current of motor (see data plate motor)

Rated speed (rpm) : Rated speed of motor (see data plate motor)

Nb of pairs poles (p) : Number of pairs poles of motor (p = Hz * 60 / rpm)

Torque constant (Nm/A) : Torque constant divised by Nominal torque (KT = Nm / A)

EMF constant (Wb) : Torque constant / 1.732 47.2 / 1.732 = 27.25

Example for autotune settings with Sprinte synchronous motor :

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

14

Rated voltage (V) = 380V

Rated current (A) = 14.2A

Rated speed (rpm) = 95 rpm

Nb pairs of poles = 19.1x60 = 12 pairs of poles

95.5

Torque constant (Nm/A) = 670 = 47.18 Nm/A

14.2

EMF constant (Wb) = 47.18 = 27.25 Wb

1.732

When motor data set, follow instruction below on 216SP board :

+

+ …

+ …

Screen under will appear

Then, follow the following wizzard on the drive :

EMERGENCY OPERA

Choose

CONFIGURATION

AUTO TUNING

NO

AUTO TUNING

YES

PUSH ON

UP IN EMCY

ENTER

+

ENTER

-

-

ENTER

CONFIGURATION

FREQ. INVERTER

ENTER

-

-

ENTER

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

15

(1) : Press « E » key to validate

(2) : Press « E » key to validate

(3) : When “Close enable input” is written : Push on UP button on emergency +

(4) : Waiting for display « Progress 100% »

(5) : When “Open enable input” is written : Release UP button on emergency

When motor data set, follow instruction below on 216SP board :

+

+ …

+ …

Screen under will appear

Then, follow the following wizzard on the drive :

EMERGENCY OPERA

Choose

CONFIGURATION

AUTO TUNING

NO

AUTO TUNING

YES

PUSH ON

UP IN EMCY

ENTER

+

ENTER

-

-

ENTER

CONFIGURATION

FREQ. INVERTER

ENTER

-

-

ENTER

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

16

(1) : Press « E » key to validate

(2) : Press « E » key to validate

(3) : When “Close enable input” is written : Push on UP button on emergency +

(4) : Waiting for display « Progress 100% »

(5) : When “Open enable input” is written : Release UP button on emergency

Set the maximum rotation speed of motor in rpm (see data plate motor)

Set the maximum travel speed of motor m/s

Do not set, go directly to step 9

Do not set, go directly to step 9

Quick start is now finish, try to move the motor to verify it’s working well in the good direction (up/down) :

TRY TO MOVE

STEP 1

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

17

Go to section 5 1 –If motor working upside down, not correctly or not at all, reverse

2 phases on terminal U, V, W, do again

and try again

2 –If motor not working well, reverse phases of encoder and follow

Juste after, do again and

3 –If motor not working well, do again « 1 »

4 –If motor not working well, do again « 2 »

: REVERSE DIRECTION OF ENCODER

Modify setting from 0 to 1 or inversely

Motor phase order

Encoder phase order

U, V, W

0 -Not inverse

V, U, W

1 -Inverse

U, V, W

0 -Not inverse

V, U, W

1 -Inverse

Only one solution is available

STEP 1

STEP 1

STEP 2

STEP 2

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

18

5 Starting guide for Kone « Ecodisk » motor

(if not applicable, proceed to chapter 6)

5.1 Mechanical installation of encoder provided in place of existing tachymeter

Remove the existing tachymeter (1), recover the pulley (2) and set it up on the new encoder provided (3). After, set up

the new encoder (3) in place of the tachymeter on Ecodisk motor (4)

(2) Pulley

(1) Tachymeter (3) New encoder provided

(4) Ecodisk motor

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

19

5.2 Synchronous motor startup wizard

Follow the instructions step by step below to start the inverter :

Encoder wiring & shield wiring

E

M

3

MOTEUR

BLINDAGE

5V Rouge

0V Noir

B- Orange

B+ Vert

A- Bleu

A+ Jaune

1

2

3

DT- . 4

DT+ . 5

CK+ . 7

VS- . 8

B- . 10

VS+ . 9

CK- . 6

A- . 12

B+ . 11

A+ . 13

+VE out . 15

OVE out . 14

Encoder cable must be separate of main power cables

ASP116 EVOLUTION –STARTING WIZARD AND SETTINGS FOR ADL300 GEFRAN FREQUENCY INVERTER

Sprinte SAS. All rights reserved, including translation rights.

20

5.3 Encoder configuration for encoder mounted in peripheral of motor’s pulley

Encoder is mounted like the below drawing :

Drawing 1

Set up parameters in following menu « ENCODER CONFIG »:

Set the number of encoder pulses (see encoder data) :

Set the voltage encoder supply (see encoder data) :

Set the encoder mode (set « Digital F ») :

Peripheral encoder mode (set « 1 ») :

External diameter of motor pulley (measure « D » and set up the value in mm, see drawing 1 above)

Encoder pulley diameter (measure « d » and set up the value in mm, see drawing 1 above)

Other manuals for ASP 116 evolution

3

Table of contents

Other Sprinte Controllers manuals