SPS PRO X 200 User manual

INSTRUCTION MANUAL

Pro X 200

T h e C o l u m n G a g e

Sterling ProMeasure Systems

2

Instruction Manual

Pro

X

200

Contents

i. Contact information

1. Introduction

1.1 General information ..........................................................................................................: 4

1.2 Measuring and display features ........................................................................................: 4

1.3 Front and rear view ..........................................................................................................: 5

1.4 Dimensions ......................................................................................................................: 6

1.5 Hole pattern for interconnection .......................................................................................: 6

1.6 Technical data .................................................................................................................: 7

2. Getting started

2.1 Delivered items .................................................................................................................: 8

2.2 Fitting the base ................................................................................................................: 8

2.3 Fitting the Bus modules ....................................................................................................: 8

2.3.1 Removal of PROX200 column cover .......................................................................: 8

2.3.2 Connecting the Bus modules ..................................................................................: 9

2.3.3 Fitting of bus terminator...........................................................................................: 10

2.3.4 Fitting Bus modules into the PROX200 column gauge .............................................: 11

2.3.5 Fitting of PROX200 column cover ...........................................................................: 11

2.4 Measuring input addresses ..............................................................................................: 12

2.5 Connecting several column gauges ..................................................................................: 13

2.6 Power supply connection ..................................................................................................: 14

2.7 Connecting a foot or hand switch ......................................................................................: 15

2.8 Connecting adapters for tolerance outputs ........................................................................: 15

2.9 Connecting a PC, multiplexer or statistic printer ................................................................: 16

2.10 Connection of wireless module .........................................................................................: 16

2.11 Connection of probes, air plug gauges, sensors and measuring instruments .....................: 17

2.12 Power on / Self-test ..........................................................................................................: 19

3. Programming the column gauge

3.1 Encoder functions ............................................................................................................: 20

3.2 Foot and hand switch functions ........................................................................................: 20

3.3 Quick programming guide for programmers in a hurry ......................................................: 21

3.4 Description of the calibration mode ...................................................................................: 22

3.4.1 Zero adjustment / Calibration ..................................................................................: 22

3.4.2 Probe setup ............................................................................................................: 23

3.4.3 Restrictor adjustment on pneumatic measuring converters .....................................: 23

3.5 Description of the programming menu ..............................................................................: 24

3.6 Basic Setup ......................................................................................................................: 29

3.7 Restoring factory settings .................................................................................................: 33

3.8 Error messages / Corrective actions .................................................................................: 34

3.8.1 Operating and programming errors .........................................................................: 34

3.8.2 System errors .........................................................................................................: 35

4. Working with the column gauge

4.1 Initial operation .................................................................................................................: 36

4.2 Measuring operation .........................................................................................................: 36

4.3 Mechanical setup of inductive probes ...............................................................................: 36

4.4 Restrictor adjustment on modules ……………………………………………………............… : 37

4.5 Automatic zero adjustment of gauges ...............................................................................: 38

4.6 Automatic gauge calibration .............................................................................................: 38

4.7 Multi gauging (C1...C8) ....................................................................................................: 38

3

Instruction Manual

Pro

X

200

I.Contact Information

4

Instruction Manual

Pro

X

200

1. Introduction

1.1 General information

1.2 Measuring and display features

�Static measuring mode

�Dynamic measuring modes : Min, Max, Tir, Mean

Bore measuring mode with automatic function

�Multi-gaging measuring modes : Manual or automatic selection of 1 to 8 gages

�Measuring range / Resolution : ± 3.0 mm / 0.1 µm, 0.12 / 0.00001 inches (inductive probes)

± 30 mm / 1 µm, 1.2 / 0.0001 inches (inductive probes)

24 bit (incremental measuring systems)

�Units : mm and inches

�2-digit numeric display : Gage number C1 … C8

Measuring input P1 … P8

Basic setup menu L0 … LA

�Numeric display ranges

Relative measurements : ± 9.9999 mm / ±99.999 mm, ±.99999 inches / ±9.9999 inches

Absolute measurements : 0 to 99.9999 mm / 0 to 999.999 mm, 0 to 9.99999 inches / 0 to 99.9999 inches

Number of grades : 1…30

The

PROX

200

electronic

column ga

ge is an extremely ve

r-

satile instrument, allowing the connection of 1 to 8 induc-

tive or incremental probes, pneumatic gage heads, sensors

with analog current or voltage outputs and gages with digi-

tal interfaces. The extreme flexibility concerning the con-

nection of sensors and gages is achieved due to the modu-

lar design and the usage of Bus modules.

The column gage allows manual selection as well as auto-

matic selection of 1 to 8 gages, including static and dy-

namic measuring programs and the optional classification

(grading) of components in up to 30 classes.

Highly sophisticated measuring programs allow a quick

and simple calibration using 1 or 2 masters.

Two numeric displays allow indicating absolute measured

values, relative deviations or the classification of compo-

nents as well as the corresponding gage number.

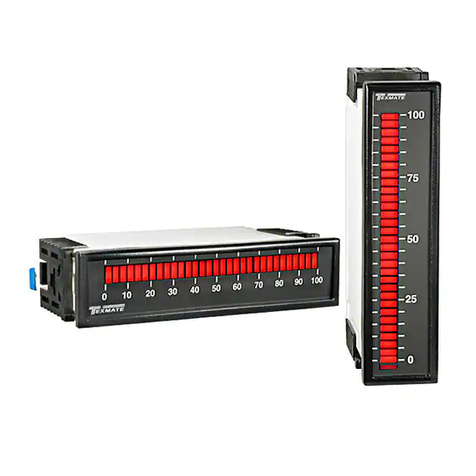

The 3-color column display with superimposable tolerance

marks gives a quick overview over the tolerance values of

the components and is an ideal tool for controlling work-

piece characteristics in mass production.

The new Bus system of the PROX200 provides solutions

for most sophisticated measuring applications, simply by

interconnecting several column gages.

5

Instruction Manual

Pro

X

200

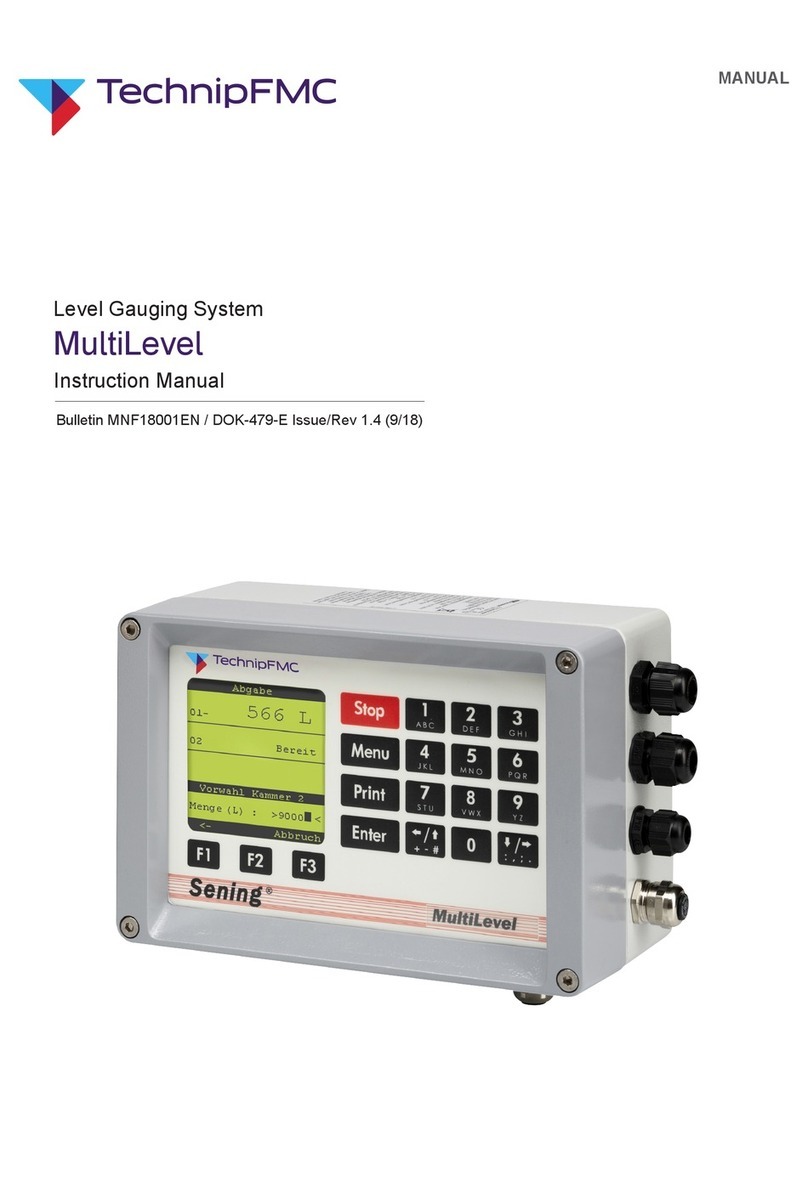

6-digit numeric display

Programming menu

Rotary encoder

2-digit numeric display

Dynamic mode display

� Column display ranges

5.0000 mm 0.50000 The 3-color column display (red, green, yellow)

1.5000 mm 0.15000 features an automatic color selection according

0.5000 mm 0.05000 to the tolerance limits adjusted.

0.1500 mm 0.01500 A maximum of 4 tolerance limits can be programmed.

0.0500 mm 0.00500 The tolerance limits are indicated as colored marks on

0.0150 mm 0.00150 the column display.

0.0050 mm 0.00050

The column display range can be set to AUTO or to a fixed range in the “BASIC SETUP” menu. In the AUTO mode

the column gage automatically selects the optimum column display range, depending on the tolerance limits adjusted.

In the measuring mode, the selected column display range is indicated on the numeric display when the Encoder but-

ton is pressed longer than 2 seconds.

1.3 Front and rear view

RS232 connector

Foot / Hand switch and

tolerance outputs

IMB modules for :

Inductive probes

Pneumatic gage heads

Incremental probes

Analog currents

Analog voltages

Digital guges

Radio receiver

Power supply:

PS2: 100 to 240 VAC

- optional -

DC1: 9 to 32 VDC

ACC: Accu pack

Tolerance marks (4)

3

-

colo

r LED

column

6

Instruction Manual

Pro

X

200

1.4 Dimensions

1.5 Hole pattern for interconnection

Picture : Column display with base

7

Instruction Manual

Pro

X

200

1.6 Technical data Mechanical characteristics

Case

Base Aluminum anodized, plastic top and bottom parts

Aluminum powder-coated

Front panel Acryl glass

Control element Rotary encoder with pushbutton function

(16 detents per rotation)

Dimensions W x H x D / Weight 56 x 418.5 x 86 mm / 1340g (incl. base)

(200 incl. base, PS2 and MC1 = 1650g)

Electrical characteristics

Power supplies: PS2

DC1

ACC

Primary switched power supply 100 to 240VAC, 45 to 60Hz

Power supply featuring DC voltage input from 9 to 32VDC

Accumulator module

Max. power consumption 2.5 VA (without measuring modules)

Display

Column display Scale with 103 plus 2 LEDs for “out-of-range” indication,

3-colors, featuring automatic color selection and

superimposable tolerance marks

Numeric display 6-digit and 2-digit LED displays: 7.62 mm, red

Mode, unit, programming menu indicators 17 LEDs, red

Connections

Interface (RS232) 9-pin SUB-D port, hardware : EIA RS232 standard,

data format corresponds to OPTO RS232

2 trigger inputs / tolerance outputs

(Ft 1 / Ft 2)

9-pin SUB-D port, trigger input for external contacts

(minimum switch-impulse duration 100 ms) and serial

output for OA-adp adapter

Measurement parameters

Measuring range / Resolution ± 99.9999 mm / 0.1 µm, ± 4.00000 / 0.00001 inches

± 999.999 mm / 1 µm, ± 40.0000 / 0.0001 inches

Resolution 16 bits (analogue), 24 bits (incremental measuring systems)

Sampling rate 50 measurements per second

For detailed specifications concerning measurement error, linearity, hysteresis and temperature drift please refer to the tech-

nical data of the particular Bus measuring module

Bus

Bus

9-pin SUB-D male (input) / female (output),

hardware : EIA RS485 Half Duplex, automatic addressing,

max. of 64 clients, max. Bus length 1200 m

Environmental conditions

Operating temperature range 0 to 50°C

Storage temperature range -20 to +60°C

Protection class Front panel IP65 (CEI / IEC 529)

Rear panel depending on the measuring modules

Electromagnetic compatibility (EMC)

Electromagnetic compatibility (EMC) Interference emission according to EN50081-2

Interference resistance according to EN50082-2

8

Instruction Manual

Pro

X

200

2. Getting started

2.1 Delivered items

Column gage, base with 4 screws (M3x8) for fixing, instruction manual, programming card, and

a 2.0 mm Allen key.

Further accessories, such as Bus measuring controllers, power supply modules, measuring

modules, foot switches or adapters according to delivery note.

Please check the shipment for completeness and keep the packaging.

2.2 Fitting the base

Use the Allen key (included in shipment)

to screw in the screws of the base and set

the column gage on a solid base.

Do not overtighten screws !

2.3 Fitting the modules

The PROX200 column gage has been developed for use of Bus modules and allows the connection of 1 to

8 probes, air plug gages, sensors and digital measuring instruments. The respective modules of the Bus

series can be fitted to the rear panel of the PROX200 in order to connect probes, sensors and gages.

See Bus Module Overview, chapter 2.12!

2.3.1 Removal of PROX200 column cover

Use the Allen key (included in

shipment) to loosen and remove both

retaining screws of the column cover.

Then remove the column cover.

4 DIN 7984 M3 x 8

2 DIN 7984

M3 x 8

9

Instruction Manual

Pro

X

200

A PROX200 column gage that comprises Bus modules is configured in a fixed order. If one single

PROX200 is to be configured, the power supply module (No. 1) always has to be fitted first, followed by the

measuring controller module (No. 2) and then subsequently (starting with No. 3) the measuring and inter-

face modules in any chosen order. The fitting order of the measuring and interface modules as a result de-

termines the address assignment (P1 to P8) of the connected sensors or measuring instruments. The

PROX200 column gage can read in a maximum of 8 connected sensors or measuring instruments.

If several PROX200 are to be connected, the adapter cable (No. 1) has to be fitted first, followed by the

power supply module (No. 2), then the measuring controller and subsequently the Bus measuring and inter-

face modules in any chosen order.

One power supply module can supply power to a maximum of 3 PROX200 column gages in this way. If

more than 3 PROX200 are interconnected, an additional power supply module has to be fitted to the fourth

PROX200 at the latest.

Extension cables can be used to place the particular modules nearby the measuring places, if necessary.

Sensitive signal leads from inductive probes, for instance, or long pneumatic hoses for pneumatic measur-

ing configurations can be avoided in this way. The total maximum length of all Bus extension cables must

not exceed 1200 m.

2.3.2 Connecting the Bus modules

(1) Push both red levers of the first module against the stop and rotate to the stop (set up).

(2) Connect modules.

(3) Rotate back both red levers to lock the modules while pressing them together.

Follow steps (1), (2) and (3) to connect the Bus modules one after the other.

The following table indicates the installation sequence of the Bus modules.

Position 1 is the bottom position later on, and is screwed to the base of the PROX200 column

gage.

Important : The bottom Bus module must be equipped with bolts to do so.

Position Bus module

1 CAS (only if interconnecting several column gages)

2 PS2, or DC1 as an alternative; ACC (power supply modules)

3 MC1 (measuring controller module)

4 Bus measuring and interface modules

5 Bus terminator (connector)

(1) (2)

(3)

10

Instruction Manual

Pro

X

200

Important :

Should an Bus module already be equipped with bolts (e.g. PS2 when using an CAS adapter ca-

ble), please replace the bolts with 2 cross-recessed screws SH-UNC / 4-40*9.5

(included in shipment) in order to enable connecting of modules.

2.3.3 Fitting of bus terminator

Prior to inserting the modules into the column profile, the bus terminator connector is attached to

the vacant port of the last module and screwed to it.

If the last module has not been fitted with bolts to fix the terminator connector, both cross-recessed

screws will have to be removed and replaced with bolts.

The bolts are included in the shipment.

About the bus terminator :

The purpose of the bus terminator is to terminate the bus lines electrically, to seal the open port,

and to provide information on the function and the power supply of the column gage.

The “VCC” LED lights up when the power supply to the column gage is secured. The “VCC” LED

will be extinguished, if the power supply module has been overloaded due to external consumers,

such as digital probes with high current consumption, or as a result of voltage drops due to long

Bus extension cables. The Bus design, however, allows adding power supply modules

between any Bus gaging and interface modules at will, to compensate voltage drops.

The “RUN” LED lights up, when the self-test of all Bus modules has finished successfully.

The “RUN” LED will not light up and will thus signal that the Bus could not be completely checked,

if more Bus modules have been fitted than can be addressed by the column gage.

Note : The “RUN” LED will not issue an error message in this case, but instead signals the

incomplete self-test of modules that cannot be addressed.

11

Instruction Manual

Pro

X

200

2.3.4 Fitting Bus modules into the PROX200 column gage

Once the Bus modules have been connected, they are slid into the PROX200 column section as a

package from the top and are then screwed to the column base using both cross-recessed screws.

Do not overtighten screws!

If modules have already been fitted into the PROX200 column and additional modules are to be in-

stalled, then all previously fitted modules must be removed first.

Loosening and removing previously fitted Bus modules:

The Bus modules are screwed to the PROX200 base by means of 2 screws. At first both cross-

recessed screws must be loosened by using a suitable screwdriver in order to remove the fitted

modules. Two lock washers keep the screws in place and they remain in the PROX200 base.

The base does not need to be removed. Once both screws have been completely loosened,

the Bus modules can be slid to the top of the column and removed from it.

After removal of the initially fitted modules, additional modules

can be added. Afterwards the complete module package can be

slid into the PROX200 column section. Finally the module package

is screwed to the column base.

2.3.5 Fitting of PROX200 column cover.

Place the column cover on top of the PROX200 and fix with two Allen screws (M3 x 8).

Do not overtighten screws !

Remove

Bus modules

Loosen screws

12

Instruction Manual

Pro

X

200

Busabschlussstecker

2.4 Measuring input addresses

The measuring inputs are referred to

as P1 to P8 for subsequent programming.

The bottom measuring input is always

P1. It is possible to connect more than 8

measuring inputs, the PROX200 column gage,

however, can only address and read in the first

8 inputs.

Note :

When connecting further column gages via

CAS adapter cables, the measuring inputs

(P1 to P8) of the first column gage are also

available at the subsequent column gages

and are referred to as the same addresses.

Therefore, there is no complex behavior to pay

attention to when programming.

When connecting several column gages, please take

into account the following facts:

A further measuring module in a series of column gages

will interrupt the connection to the previous measuring

modules, and make available its inputs for the subse-

quent column gages, including the one it is fitted into.

Note for wireless application :

The RF1 modules allow the reception of measurement

values from 1…8 RF radio modules. Therefore each RF1

module contains eight channel numbers.

Each channel can be assigned to one of the 1...120

addresses of an RF1 radio module.

When you use an RF1 module together with other IMB-

modules in one PROX200, then you must install the

RF1 module as the last module of the PROX200 (upper

position). Because the PROX200 supports only eight

channels and the RF1 has already eight channels, all

other IMB-modules behind the RF1 module are ignored

by the PROX200.

The programming of RF1 radio modules and the

address assignment of the 1…120 RF1 module

addresses to the 1…8 RF1.

P 7

P 6

P 5

P 4

P 3

P 2

P 1

P 8

MC1

measuring co

n-

troller module

PS2

power su

p

ply

module

Bus terminator conne

c

tor

P 3 ... P 8

P 2

P 1

MC1

measuring co

n-

troller module

PS2

power su

p

ply

module

13

Instruction Manual

Pro

X

200

2.5 Connecting several column gages

CAS type adapter cables are utilized to connect several column gages.

The adapter cables fulfil two tasks :

1.) Transferring the supply voltage from the first column gage to the next.

One power supply module can supply power to a maximum of 3 column gages, depending on the connected

probes, sensors and measuring instruments. The number of column gages decreases, if the current consump-

tion of the connected measuring instruments exceeds 200 mA. As shown in Example 2, power supply mod-

ules can be added at will. Each module performs the function of supplying power up to the next power supply

module.

2.) The measuring inputs P1 to P8 of the first column gage are made available for the sub-

sequent column gages.

The measuring inputs are passed on to the subsequent column gages via the CAS adapter cables. The data

flow direction within the adapter cable is always from the thinner adapter housing towards the thicker adapter

housing. A further measuring modulein a series of column gages will interrupt the connection to the previous

measuring modules, and make available its inputs for the subsequent column gages, including the one it is fit-

ted into. See also example 2 on page 14 of this manual.

Note : Foot and hand switches can be cascaded in order to synchronize several column gages (e.g. for dynamic

measuring). See chapter 2.7 for more detailed information.

Mechanical connection of column gages : The housing connector underneath the Bus column

cover serves to link together the column gages. Take

the connector out of its storage and screw it together

with the column cover.

Do not overtighten screws!

Example 1 : connecting 3 column gages

The three-column gages are linked together via

two CAS adapter cables. The adapter cables are

always fitted in the first position (bottom slot),

whereat the thinner adapter section is always

fitted to the first column gage. When using

several CAS adapter cables make sure that the

thinner adapter section is fitted in the first position,

with the thicker adapter section of the arriving

cable directly above it. The power supply module

of the first column gage supplies all three column

gages with power. The measurement inputs P1 to

P4 are available at all three column gages.

14

Instruction Manual

Pro

X

200

2.6 Power supply connection

There are three modules available from the Bus series to supply the column gage with power :

1. PS2

Switched-mode power supply (SMPS) featuring wide range

voltage input from 100 to 240 VAC, 45 to 60 Hz

2. DC1

DC to DC converter for input voltage range from 9 to 32 VDC

3. ACC

Rechargeable battery (accu-pack) module for battery-operated systems.

The module allows quick battery replacement. Rechargeable batteries

with capacities of 1850 / 4000 and 5500 mAh are available.

(Example : PROX200 with 2 inductive probes and a 4000 mAh battery pack

can operate for approx. 12 to 15 hours)

First read the sticker information on the fitted power

supply module and then check whether the module is

suitable for your mains voltage respectively DC voltage.

Use the enclosed power cable to connect the PS2

to the mains outlet.

Important ! Insert device plug into grounded

outlet only

Example 2 : connecting 5 column gages

The five column gages are linked together via

four CAS adapter cables. The cables are always

fitted in the bottom positions, as shown

in the illustration. The measurement inputs are

passed on from the thinner adapter section to-

wards the thicker adapter section. When using

several CAS adapter cables make sure that the

thinner adapter section is fitted in the first posi-

tion, with the thicker adapter section of the arriv-

ing cable directly above it. The power

supply module of column 1 supplies

columns 1, 2 and 3 with power. The power

supply module of column 4 interrupts the further

power supply from column 1 and supplies col-

umns 4 and 5 with power. The measuring mod-

ule in column 1 makes available the measure-

ment inputs (P1 to P4) for columns 1 and 2. The

measuring module in column 3 interrupts the

connection to the measurement inputs from col-

umn 1 and makes available its own measure-

ment inputs at columns 3, 4 and 5.

15

Instruction Manual

Pro

X

200

2.7 Connecting a foot or hand switch

The foot or hand switches are connected to the Sub-D ports Ft1 and Ft2 of the MC1 measuring

controller. Foot and hand switches can be cascaded in order to synchronize several column gages

(e.g. for dynamic measuring) by using a foot or hand switch connected to the Ft1 or Ft2 connector.

The Y-Adapter can then be used for cascading.

A third foot or hand switch (Ft3) can be connected directly to the Bus. An foot or hand switch

is used in order to do so. It provides an Bus connecting part and can be inserted into the Bus at any place

behind the MC1 (see illustration below).

The functions of the foot or hand switches can be configured in the “BASIC SETUP”

menu (L3 -L5).

Types of foot or hand switches : Part No.

Foot switch IP32...................................

Foot switch IP65 ..................................

Bus foot switch IP32 ............................

Bus foot switch IP65 ............................

Hand switch IP65..................................

Bus hand switch IP65 ..........................

Important !

Secure all connections by screwing them tight.

2.8 Connecting adapters for tolerance outputs

The adapters for the tolerance-controlled

outputs are connected at the rear of the

column gage to the Ft1 or Ft2 Sub-D ports

of the MC1 measuring controller.

A total of 5 tolerance-controlled outputs are available:

1. Upper tolerance limit (red) exceeded

2. Upper intervention limit (yellow) exceeded

3. Measured value OK

4. Below lower intervention limit (yellow)

5. Below lower tolerance limit (red)

Connection adapter :

High-Side Power-FET

For adapter pin assignment of ADP

see chapter 6; for more information on the adapter.

Ft1

Ft2

Ft2

Ft3

Ft1

RS232

Foot switch

16

Instruction Manual

Pro

X

200

2.9 Connecting a PC, multiplexer or statistic printer

A PC (COM 1… 8, USB), a multiplexer or a statistic printer can be connected at the rear panel of the

column gage via the RS232 Sub-D port of the MC1 measuring controller.

See chapter 6 for RS232 pin assignment!

Select connection cable or adapter according to

. .. the interface of the PC, multiplexer, statistic printer,

or other recording device.

PC-RS232 cable RS232 connection cable for PC COM1 to COM8 interfaces ..............................

PC-USB cable USB connection cable for PCs incl. driver software for emulation of ..................

COM1 to 127 interfaces

RSD Connection cable with interface converter to Mitutoyo Digimatic output .............

(cable converts RS232 output to DIGIMATIC output)

RSA adapter with digital / analogue converter to output analog .................................

voltages to a terminal block

(adapter converts RS232 output to ±10V analog output)

2.10 Connection of wireless module

RF1-232 Wireless module for stationary gages with RS232 con-

nector.

PC-RS232 cable

PC-USB cable

RSD-ADP (Mitutoyo Digimatic)

RSA-ADP (analog output of measured values, ± 10V)

RS232

RS232 The wireless

FR1

-

232

module is connected

at the rear of the column gage to the RS232

port. The wireless module enables the wire-

less transmission of measured values to PCs.

17

Instruction Manual

Pro

X

200

2.11 Connection of probes, air plug gages, sensors and measuring instruments

The modular design in conjunction with the BUS measuring and interface modules makes it possible

to connect virtually any probe, pneumatic gage head, sensor or measuring instrument to the column

gage. A maximum of 8 measuring inputs can be handled by the PROX200. It is possible to connect more

than 8 inputs, however, the additional inputs are ignored. The RUN LED on the bus terminator connector

does not light up, if the surplus Bus modules cannot be completely addressed (see page 10, Information on

Bus Terminator). The Bus measuring and interface modules can be combined in any order and allow the

simultaneous connection of different types of sensors (inductive, digital, pneumatic, etc). For an overview of

BUS measuring and interface modules see chapter 2.12.

Important ! Reliable measurements can only be guaranteed,

if the connections have been screwed tight,

so that the contact to the probe shielding is good.

Example 1 : Connection of inductive probes

Prior to connecting the probes, check whether the

probe types correspond to the type designations

listed on the Bus module (IM1 / 2 / 4 / 8). Secure the

connectors by screwing them tight.

Example 2 : Relocation of Bus measuring and interface modules

Bus extension cables can be utilized to perfectly adapt

measurement configurations with Bus modules to

spatial requirements. The extension cables can be used

to interconnect any modules and reach a maximum length

of 1200 m. Use genuine Bus extension cables and bus

terminators only !

Note :

The Bus is based on an RS485 interface and has been

developed for the demands of rough industrial use.

Bus terminator

18

Instruction Manual

Pro

X

200

Example 3 : Connection of pneumatic gage heads

Example 4 : Connection of different probes, gages, sensors and measuring instruments

Oil and dirt can destroy

the measurement system!

The example depicts a PROX200

configuration for connection of

2 inductive probes (IM2),

2 incremental probes with

1Vss output (DM2), one

pneumatic plug gage (AE1),

2 Mitutoyo dial gages (MI2)

and one calliper gage (Sylvac, Tesa,

Mahr, etc.) with Opto RS232 output

(SM1).

The column gage allows the connection

of up to 8 pneumatic measuring converters

AE1. An 8-by-6 mm hose connector

(8 mm -> outer diameter; 6 mm -> inner

diameter) is used to establish the com-

pressed air supply. A hose piece with a

length of 35 mm is required in order to

pneumatically interconnect two AE1 mod-

ules. Use dry, oil-free and filtered

(5 µm) compressed air only, ranging from

2.6 … 2.8 bars (39 … 42 psi) to connect

to the AE1 measuring converters

(recommended air pressure).

19

Instruction Manual

Pro

X

200

2.12 Power on / Self-test

Every time the column gage is switched on, a self-test will automatically be performed in order to check

all system components. If an error is detected during the self-test, the numeric display will indicate an er-

ror message.

If the display remains dark, after the PROX200 column gage was switched on, check both, the VCC and

RUN LEDs on the bus terminator connector.

Both LEDs must be lit!

VCC - LED is lit if the supplied voltage is within allowed tolerance values.

RUN - LED is lit if the internal self-test for all modules has finished successfully.

See chapter 2.3.3 for more information

A display test routine runs subsequently, during which all display elements are switched on, one after the

other. This enables the user to check the function of the display elements. Once the column test has been

completed, information on the release of the software is shown on the six-digit numeric display.

Note : The RS232 interface of the column gage is not active while the self-test is running.

20

Instruction Manual

Pro

X

200

3. Programming the column gage

The rotary encoder on the front panel is used to make all settings and carry out any programming.

During programming the user is guided through the individual menus, step by step, and prompted by the

LED and numeric displays. The programming procedure follows a logic structure and becomes self-

explanatory after studying it briefly.

Abbreviations used :

Encoder : Rotary encoder with pushbutton function

CW : Turn rotary encoder clockwise

CCW : Turn rotary encoder counterclockwise

3.1 Encoder functions

Turning the encoder By turning the encoder clockwise (CW) in the Measuring Mode, you can switch

to the Calibration Mode or the Programming Mode.

In the Calibration or Programming Mode, the flashing value or function can be

altered by turning the encoder.

CW - increases the value or moves to the next function.

CCW - reduces the value or returns to previous function.

Pushing the encoder By pushing the encoder button in the Measuring Mode, the function selected

in the Basic Setup is executed.

Programming is carried out in the “BASIC SETUP” menu, section “L2” - Encoder key

function in measuring mode.

Push the encoder button in the Calibration or Programming Mode to accept the

programmed value or the flashing setting respectively.

Push and hold The six-digit numeric display indicates the column display range in the

for > 2 sec. Measuring Mode.

The programmed value of the corresponding, flashing menu LED is displayed for

1 second in the Programming Mode.

This is only valid for the values of “NOMINAL SIZE” and “MASTER VALUE”.

Pushing and turning Switches to and from the activated gages C1 to C8 in the Measuring Mode.

The gages (C1 to C8) are activated in the “BASIC SETUP” menu, section “L0” –

Activate / deactivate gages.

3.2 Foot and hand switch functions

The column gage allows connecting up to 3 foot or hand switches. The functions of the particular

switches can be assigned in the “BASIC SETUP” menu, sections L3 to L5.

Table of contents

Other SPS Measuring Instrument manuals