SPS SD1 User manual

INSTRUCTION MANUAL

SD1

T h e D i s p l a y / I n d i c a t o r

SPS

2

Instruction Manual SD1

Contents

1. Technical Data .............................................................................................................................. : 3

2. Dimensions ................................................................................................................................... : 4

3. Connecting probes ....................................................................................................................... : 5

4. Display ........................................................................................................................................... : 6

5. Programming Menu...................................................................................................................... : 7

6. Measuring Mode ........................................................................................................................... : 13

7. Instructions for battery replacement .......................................................................................... : 14

8. PC connection .............................................................................................................................. : 15

9. Windows configuration software SD1_Win.exe ........................................................................ : 16

10. Safety Instructions ........................................................................................................................ : 17

11. Declaration of conformity ............................................................................................................ : 18

12. Guarantee ....................................................................................................................................... : 18

3

Instruction Manual SD1

1. Technical Data

Mechanical characteristics

Case

Aluminium, rubber shock protection

Front plane

Acryl glass ( scratch proof )

Dimensions / Weight

( W x H x D ) 60 x 59.5 x 21.7 mm / 95 g

Electrical characteristics

Power supply

Battery ( CR2032 )

Battery lifetime

approx. 8000 h ( SD1 with probe )

Measuring rate

adjustable, 2 … 20 values / sec

LCD display

Display type

Liquid crystal display, reflective

Numeric display

7 digits ( 10.5 mm )

Analogue display

53 segments

LEDs / Acoustical output

Tolerance display

3 LEDs : 1x red, 1x green, 1x yellow

Buzzer

Piezo

Connections

ISi interface

Bus connection for sensors, hand / foot switch,

tolerance adapter, …

Triple-I interface

Connection for IBR radio modules or cable with

USB / RS232 interface

Measuring systems

The measurands : measuring range, resolution, precision, … are defined by the

connected measuring probe or sensor.

Example : Measuring probe IMS-5S →Range 5mm, Resolution 0.01µm

Environmental conditions

Operation / Storage temp.

+41 … +113 °F / -4 … +158°F

Protection class

IP65 ( CEI / IEC 529 )

EMC according to EN50081-2 and EN50082-2

4

Instruction Manual SD1

2. Dimensions

5

Instruction Manual SD1

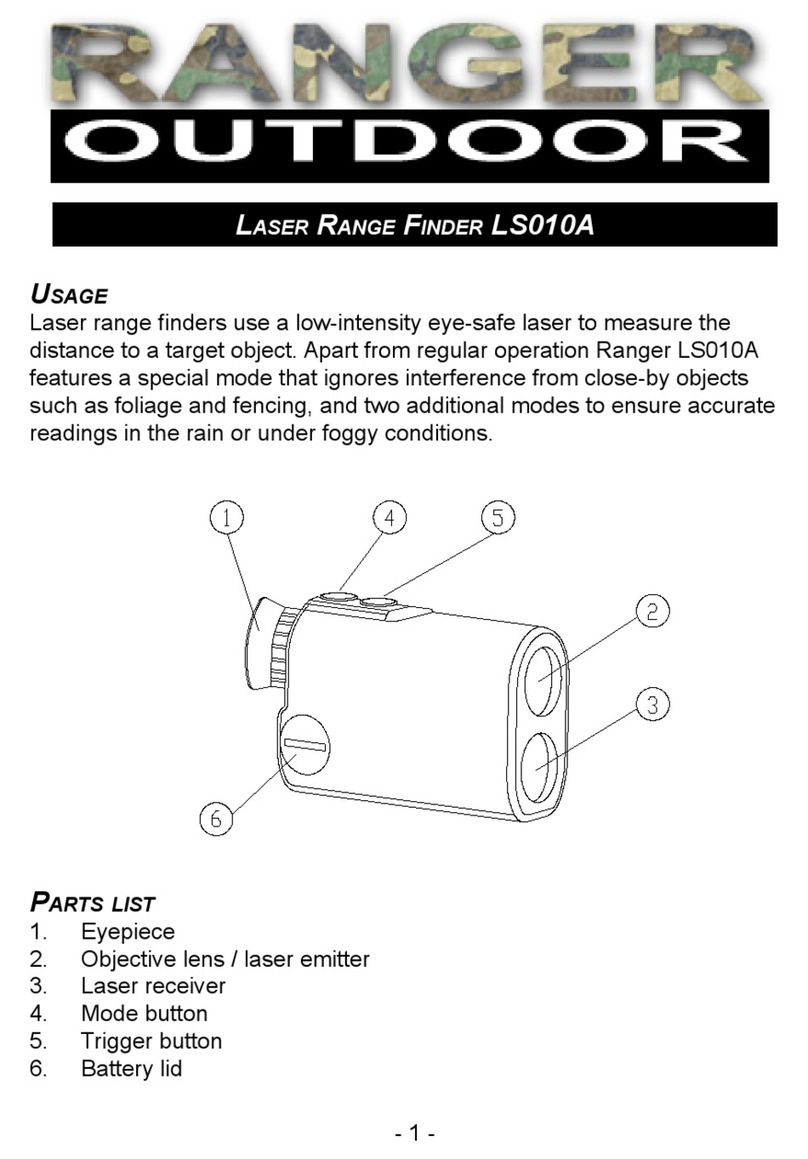

3. Connecting probes

Variant A

➔Usage as dial gauge

Variant B

➔Connection of up to 2 probes and an additional hand / foot switch

6

Instruction Manual SD1

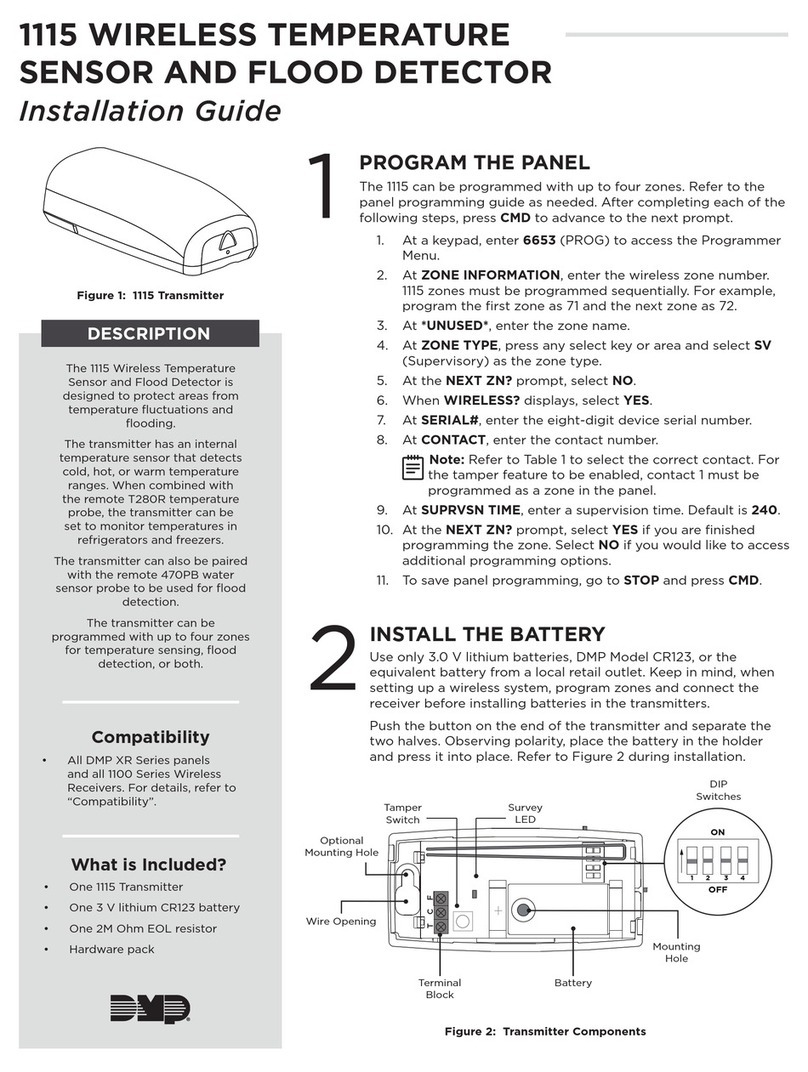

4. Display

1

2

3

4

5

6

7

8

9

10

11

12

13

1. Calibration request

2. Tolerance LEDs

3. Column display

4. Data transmission

5. Dynamic measuring mode

6. Numeric display

7. Unit

8. Battery display

9. Factor defined

10. Function „Hold“

11. Programming menu

12. Passcode set

13. Measuring probe 1 / 2

A detailed description can be found in chapter 6 “Measuring Mode”.

7

Instruction Manual SD1

5. Programming menu

Open the programming menu by pressing the PRG button.

The following settings are available :

Note : The access to the settings via the programming menu can be restricted by using

the Windows configuration software SD1_Win.exe ( ➔see chapter 9 ).

Because of this, there may not be all of the following menu options available.

Overview :

•Unit Selection of unit

•rESoL. Selection of resolution

•dir. Selection of measuring direction

•PrESEt Zeroadjustment / Preset

•2-CAL. 2 Master calibration

•dt.-CAL. Temperature forced calibration ( in steps of 0.5 °C )

•tF.-CAL. Timer forced calibration ( in steps of 30 min )

•FActor / ProbES (*) Measuring input A and B

•SEt.OP. Selection of a Measuring mode

•GrAdinG Selection of a Grading mode

•SEt.Pnt. (*) Input of the nominal value with relative tolerances

•SEt.toL. (*) Input of absolute tolerances

•toL.LED Tolerance LEDs

•CoL.diS. Analogue display

•hoLd Freezing of the display on a static measurement

•but.PRG. Assign a second function to the PRG button

•but.dAtA. Assign a second function to the DATA button

•but.CAL. Assign a second function to the >O< button

•FootS. Assign a function to a hand / foot switch

•P.C.ProG. Passcode for the programming menu ( 4 digits )

•P.C.CAL. Passcode for the calibration ( 4 digits )

•Auto.oFF Setting the Auto Power Off time

•SA.rAtE Setting the measurement rate

•BEEP Button tone

•ProG.End Leave the programming menu

Note : The selection of the active menus ( marked with (*) ) is only possible with the

Windows configuration software SD1_Win.exe ( ➔see chapter 9 ), not with the

programming menu of the SD1.

8

Instruction Manual SD1

Basic function / Selection of the unit

Basic function / Selection of the resolution

Basic function / Selection of the measuring direction

Calibration / Zeroadjustment & Preset

Calibration / 2 Master calibration

Calibration / Temperature forced calibration

Calibration / Timer forced calibration

First display variant, if only one probe was selected in the basic settings:

Note :

All digits have to be set one by one with the buttons

and . The change to the next digit is done

by pressing the button . If the button is

pressed > 2 sec., the complete number is confirmed

regardless of which digit is active at the moment.

9

Instruction Manual SD1

Second display variant, if both probes were selected in the basic settings :

Submenu for the selection of a probe

Submenu for the activation / deactivation of the probe with input of a factor

Measuring modes

(Max+Min) / 2 (Max-Min)

Grading mode / Number of grades [Off...30]

Grading mode / Display of grade on numeric display on / off

Tolerance limits / Nominal value

Note :

All digits have to be set one by one with the buttons

and . The change to the next digit is done

by pressing the button . If the button is

pressed > 2 sec., the complete number is confirmed

regardless of which digit is active at the moment.

10

Instruction Manual SD1

Tolerance limits / Tolerances

Tolerance LEDs / Exceeding upper tolerance limit and lower tolerance limit

Tolerance LEDs / Display time

Column display / Selection of the column display mode

Column display / Column starting point

Note :

All digits have to be set one by one

with the buttons

and . The change to

the next digit is done by pressing

the button . If the button

is pressed > 2 sec., the com-

plete number is confirmed

regardless of which digit is active at

the moment.

11

Instruction Manual SD1

change meas. value /

grade

execute a 2 master

calibration

send meas. value

output of the tolerance position

of the meas. value with the LEDs

execute a

calibration

Display control / Freezing the display on a static measurement

Favourite buttons / PRG button pressed > 2 seconds in measuring mode

no function change dyn.

assigned meas. mode

change temp. / change meas. value /

meas. Value diff. to nominal value

change unit on change resolution

numeric display on numeric disp.

autom. transmission turn off the delete the

on change of value on / off meas. instrument calibration

Favourite buttons / DATA button pressed > 2 seconds in measuring mode

see :

Favourite buttons / >0< button pressed > 2 seconds in measuring mode

see :

Hand / foot switch : Selection of the function

change meas. value /

battery voltage

12

Instruction Manual SD1

Passcodes / Passcode for Programming menu

Passcodes / Passcode for calibration

Special parameter / Auto Power Off time

Special parameter / Measuring rate

Special parameter / Button tone

Leave the Programming menu

Measuring mode

Note :

All digits have to be

set one by one with

the buttons

and .

The change to the

next digit is done by

pressing the button

. If the button

is pressed

> 2 sec., the complete

number is confirmed

regardless of which

digit is active at the

moment.

13

Instruction Manual SD1

6. Measuring mode

Note : During a static measurement the measuring value is transmitted by pressing

the DATA button.

During a dynamic measurement the measuring values transmitted when the

dynamic measurement is ended with the DATA button.

When and are pressed together for more than 2 seconds,

all settings are returned to Default.

The default passcode is 9837 on calling the programming menu.

Description of the display elements

1. Calibration request →blinks at temp. / time contolled calibration ( a data

transmission is not possible )

2. Tolerance LEDs →light when the DATA button is pressed

3. Column display

4. Data transmission →Standard mode : blinks shortly when DATA button is pressed

Permanent mode : is lighted permanently

5. Dynamic measuring mode →blinks while a dynamic measurement is running

6. Numeric display

7. Unit

8. Battery display →Segment off = Battery okay

on = Battery low

blinking = Battery critical

9. Factor defined

10. Function „Hold“

11. Programming menu

12. Passcode set

13. Measuring probe 1 / 2

14

Instruction Manual SD1

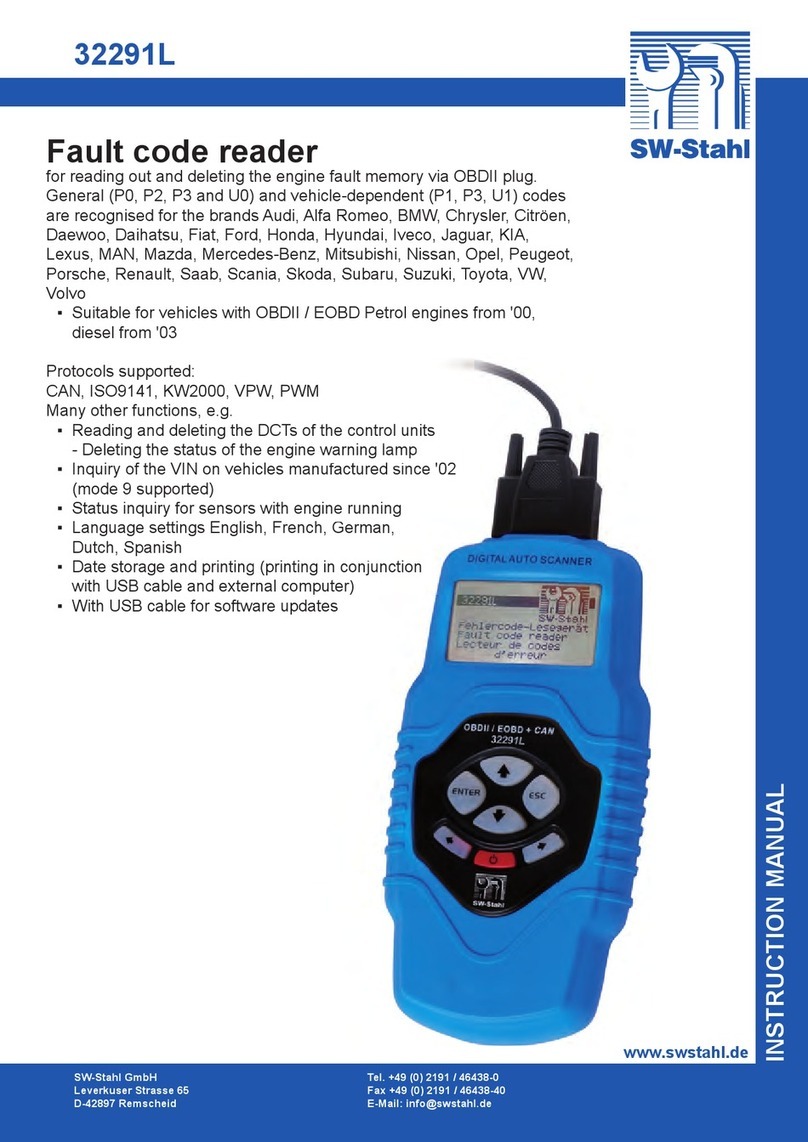

7. Instructions for battery replacement

Battery type : CR2032

15

Instruction Manual SD1

8. PC connection

16

Instruction Manual SD1

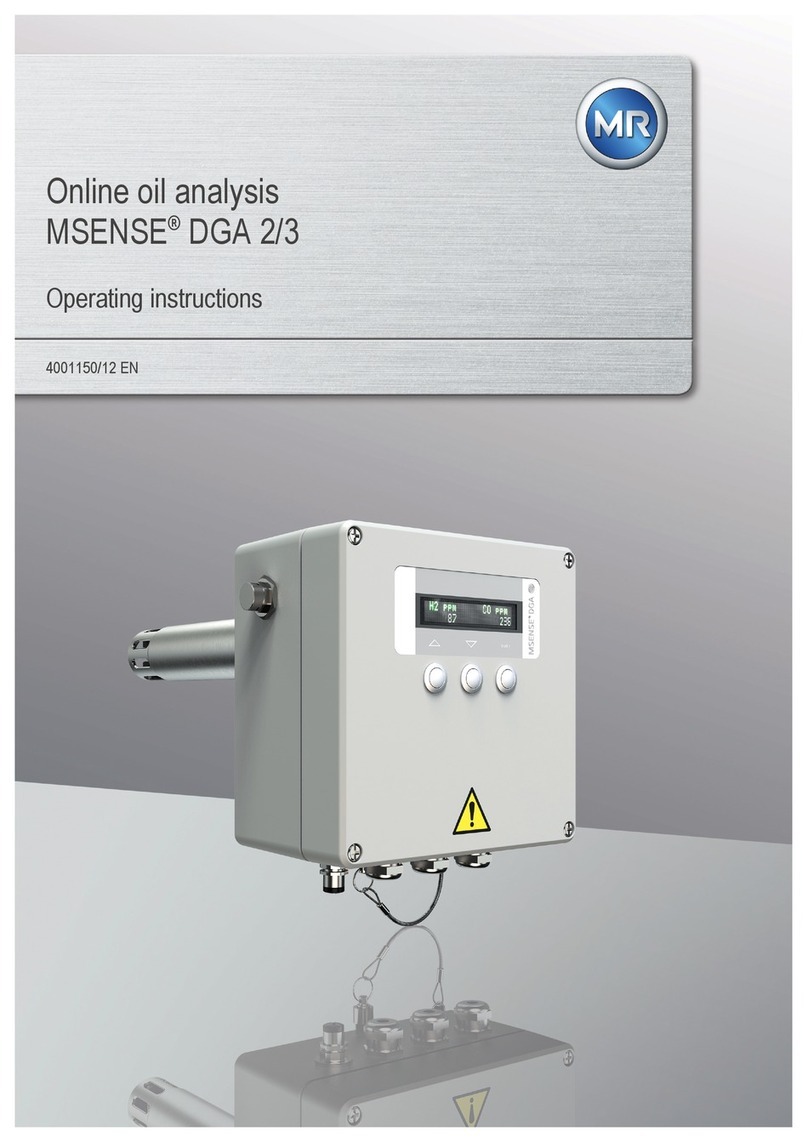

9. Windows configuration software SD1_Win.exe

The software SD1_Win.exe allows the programming of SD1 dial gauges by using a PC :

- Online programming of SD1 dial gauges

- Definition of configurations ( = test schemes )

- Saving of configurations from SD1 dial gauges to a file

- Loading of configurations from a file into SD1 dial gauges

- Menu for performing firmware updates.

Note : The SD1 has to be activated and must not be in the programming menu.

Else, no connection can be established.

By the red-marked selection boxes the programming menus inside the SD1 can be switched on / off.

By the blue-marked edit boxes the settings in SD1 can be programmed.

17

Instruction Manual SD1

10. Safety instructions

The instrument has been designed and manufactured according to the state of the art and approved technical

safety regulations. It is nevertheless mandatory to observe the following instructions in order to prevent

personal injuries or accidental death of staff members and other persons.

1. All operators must read the present instructions and this manual very carefully prior to starting

operation.

2. The instrument may be used only in proper operational condition. Malfunctions or errors that may

potentially impair the operational safety must be eliminated immediately.

3. The instrument is to be used only for its intended purpose and according to the Instruction Manual. The

Instruction Manual is to be kept near the place of operation and ready for use.

4. Prior to connecting the instrument to the power outlet, make sure that the voltage indicated on the label

corresponds to the voltage of the local mains. If this is not the case, the device should under no

circumstances be connected to the power outlet!

5. The instrument must be connected to the power supply through a properly grounded safety socket.

Extension cables, if required, must comply with VDE safety standards.

6. Any modification to or change in procedures concerning the instrument is permitted only with prior written

approval. Unauthorized opening of the instrument or tampering with the device shall void the guarantee

and exempt the manufacturer from any liability. Before opening the instrument, make sure to effectively

cut the power supply, e.g. by disconnecting the power cable.

7. Disconnect the instrument from the mains prior to cleaning.

Never let any liquids penetrate the inside of the instrument.

Do not use cleaners that dissolve plastic.

8. Replace faulty fuses only with fuses of identical amperage and current characteristics following the

instructions given in this manual.

9. Corporate guidelines and safety regulations enforced by the industrial trade associations for the

prevention of industrial accidents must be strictly observed. Make sure to consult the safety officer at

your company.

10.Do not operate the instrument in an environment containing explosive gases, because an electric spark

can cause an explosion.

We reserve the right to change the design and technical data contained in our documentation without

notifying our customers. IBR is not obliged to notify buyers of product changes.

IBRit is a registered trademark of IBR.

Windows and EXCEL are registered trademarks of Microsoft Corporation.

This document must not be reproduced, in part or in its entirety, without the prior written consent from IBR.

18

Instruction Manual SD1

11. Declaration of conformity

Thank you very much for your confidence in purchasing this product. We herewith certify that it was

manufactured and inspected in our works.

We declare under our sole responsibility that this product is in conformity with technical data as specified in

this instruction manual.

Furthermore, we certify that the measuring equipment used to check this product refers to national master

standards. The traceability of measuring values is guaranteed by our Quality Assurance System.

12. Guarantee

The quality of this instrument is guaranteed for a period of 12 months from the date of delivery. This

guarantee covers all material and manufacturing defects.

Our liability is limited to product repair services or, should we deem it necessary, replacing or crediting the

goods.

This guarantee does not include the batteries or damage due to:

◆Disregard of operating instructions

◆Incorrect handling

◆Tampering by unauthorised staff

◆Attempts by any unauthorised person to repair the instrument.

We are not to be held liable for any subsequent damage caused by, directly or indirectly, the

instrument or its use.

Table of contents

Other SPS Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

IPT

IPT ER 90 M/E A1114 Operation and maintenance manual

Kobold

Kobold DUK operating instructions

Rion

Rion VM-54 instruction manual

Fluke

Fluke DSX-600 CableAnalyzer Troubleshooting handbook

Taylor Hobson

Taylor Hobson Surtronic Duo manual

Endress+Hauser

Endress+Hauser FOUNDATION Proline 500 digital Brief operating instructions