Operating Instructions

GM32 Operating Instructions V1.3 8012707 © SICK MAIHAK GmbH 5

4Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 Necessary technical knowledge for start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2 Required material (not included in the scope of delivery) . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3 Overview of assembly steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.4 Transport safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.5 Installing the device flange on the purge air fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.6 Aligning the measuring probe in flow direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.6.1 When the probe alignment has to be set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.7 For the GPP probe: Electric connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.8 SR-unit electric connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.9 Switching on the power supply of the GM32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.10 For GMP probe: Start-up of the purge air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.11 Installing the measuring probe in the gas duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4.12 Installing the SR-unit on the device flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.13 Optical fine alignment of the SR-unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1 Recognition of an unsafe operational state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.2 Operator panel (for the “Pro” variant). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2.1 Status indicators (LEDs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2.2 Assignment of buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2.3 Contrast setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2.4 Language setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.5 Menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

5.2.5.1 Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.5.2 Alignment check (automatic optical alignment) (option). . . . . . . . . . . . . . . . . . . . 41

5.2.5.3 Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.2.5.4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6 Putting Out of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1 Putting out of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1.1 Putting out of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1.2 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.2 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.3 Environmentally compatible disposal/recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.1 Maintenance plan (operator) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

7.1.1 Recommended expendable and wearing parts for 2 years operation . . . . . . . . . . . 50

7.2 Preparation work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.2.1 Swiveling out and removing the SR-unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.3 Visual inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.4 Cleaning the window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

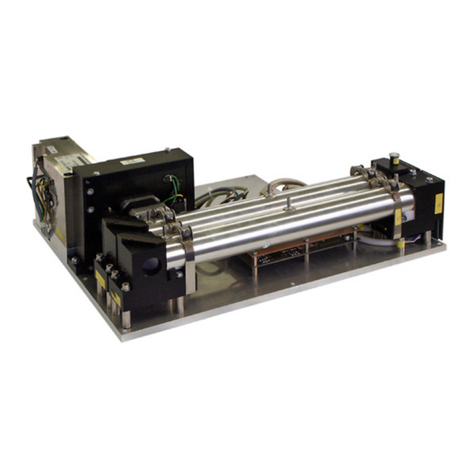

7.5 Replacing the sender lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.6 Checking and replacing the drying agent cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.7 Cleaning the purge air unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55