SPX Power Team MCS Series User manual

© 2014 SPX CORPORATION 1Form No. 1000773

Rev. 0 August 12, 2014

These operating instructions must be read and thoroughly understood for the

safe commissioning, operation, and maintenance of the Motion control system. The

following procedures must be performed by qualified, trained personnel who are

familiar with this equipment. While every attempt has been made to ensure clarity, the

intent of this document is to provide basic guidance and it is the responsibility of the

end user to review each application thoroughly for suitable usage. Users should utilize

sound engineering judgment prior to, and during, product operation. Failure to comply

may result in damage, injury, or death.

Tech Services: +1 800 477 8326

Fax: +1 800 765 8326

Order Entry: +1 800 541 1418

Fax: +1 800 288 7031

SPX Hydraulic Technologies

5885 11th Street

Rockford, IL 61109-3699 USA

powerteam.com

MOTION CONTROL SYSTEM

MCS Series

Operating Instructions for:

W

ARNING

© 2014 SPX CORPORATION 2Form No. 1000773

Rev. 0 August 12, 2014

SUBJECT PAGE

GLOSSARY 4

DESCRIPTION 6

SAFETY SYMBOLS AND DEFINITIONS 8

SAFETY PRECAUTIONS 8

• PUMP 10

• ELECTRIC DRIVEN MOTOR 10

• HOSES 10

• CYLINDER 11

• ELECTRIC CONTROL UNIT 12

GENERAL OVERVIEW 13

• CYLINDER APPROACH TO LOAD 16

TRANSPORTATION 17

UNPACKING 17

OPERATING INSTRUCTIONS 19

1. Setup 19

2. Components 19

3. Documentation 19

4. Installation 19

5. Cylinders 19

6. Linear Displacement Sensors 20

7. Hydraulic Connections 20

8. Electric Connections 20

9. Important 21

SETUP AND STARTUP 21

ALARMS AND HOW TO RESET 35

GENERAL MAINTENANCE 37

1. System Evaluation 37

2. Inspection 37

3. Periodic Cleaning 37

4. Hydraulic Fluid Level 37

5. Hose Connections 38

6. Storage 38

TROUBLESHOOTING GUIDE 39

SCHEMATICS 42

TABLE OF CONTENTS

© 2014 SPX CORPORATION 3Form No. 1000773

Rev. 0 August 12, 2014

COMPONENT SPECIFIC DATA SHEETS 43

ANNEX 44

1. SPX cylinder size and square centimeter (aera) table 44

2. Motion Control System Checklist 44

3. Declaration of Conformity 46

POWER TEAM FACILITIES 47

TABLE OF CONTENTS

© 2014 SPX CORPORATION 4Form No. 1000773

Rev. 0 August 12, 2014

In the context of this Instruction sheet, the following words have the meaning as

described:

Accuracy Difference in measurement unit (usually mm or inch) be-

tween the load movement of the leading vs the lagging lifting

point.

Actuation time Time period during which the spool of the directional valve

as well as the spool of a 2-position-2-way valve to at least

one hydraulic circuit is energized.

Displacement mode Operational mode in which the PLC unit determines the

Actuation time of each 2-position-2-way valve and thus keep

the movement of the load within the preset accuracy.

Displacement sensor Device to measure the movement of the load as a result of

the

application of forces generated by hydraulic cylinders

Forced zero Starting point of the controlled load movement achieved by

pressing the "Reset" button. For Displacement mode only

Hydraulic circuit Hydraulic Cylinder connected to a 2-way-2-position valve

and the return line of the pump unit via a hydraulic hose

Lifting point The location on the load where force generated by hydraulic

cylinders is applied

Manual mode The operator is solely responsible and in

control of the movement of each cylinder while using

manual mode!

Operational mode in which the PLC unit

does NOT have any automated control function.

Measuring system Set of analog displacement sensor, sensor cable and

analog pressure sensor, one each per hydraulic circuit

Motion Control Any type of movement or translocation of a heavy load by

means of forces generated by hydraulic cylinders operated

by and under the control of a PLC-based control system

GLOSSARY

W

ARNING

© 2014 SPX CORPORATION 5Form No. 1000773

Rev. 0 August 12, 2014

PLC unit Programmable Logic Controller composed of analog input chan-

nels,

digital output channels and computing capabilities to control the

advance and retract operation of hydraulic cylinders within specic

parameters of accuracy and repeatability.

Pressure mode Operational mode in which the PLC unit controls the pressure ap-

plied to each hydraulic circuit against a maximum pressure value.

There is NO control of the actual movement of the

load in this mode.

Pressure sensor Device to measure the oil-pressure within the hydraulic circuit, one

per hydraulic circuit (motion point).

Pump unit Assembly of a hydraulic pump mounted on a reservoir with valves

and pressure sensors.

Sensor cable Shielded cable between the Displacement sensor and the PLC unit

as

carrier for the analog signal generated by the Displacement sensor.

Target Total movement of the load that shall be achieved simultaneously at

all

lifting points under the control of the PLC unit.

W

ARNING

GLOSSARY CONTINUED

© 2014 SPX CORPORATION 6Form No. 1000773

Rev. 0 August 12, 2014

Motion control is all about precision and control of a mass in motion; precision in the measure-

ment of movements and control over the energies involved.

Whether it is a bridge, a building or any other kind of heavy load; lifting, lowering, tilting or posi-

tioning of such a load can be carried out completely automatically with a high degree of accu-

racy when using the SPX® Power Team® Motion Control System.

The PLC-controlled system includes a combination of digital actuation and digital control that

provides signicant advantages including time savings, repeatability, and extremely low inter-

nal stress in the object being moved.

In the standard conguration, a state-of-the-art A/D measurement system captures the dis-

placement of the load during the movement process, in increments of less than two hundreths

of a millimeter. Those digital signals are then processed by the PLC, utilizing powerful algo-

rithms, to generate the digital output used by the hydraulic system.

With system performance being driven by extremely short duration actuation times for speci-

cally selected valves, only small units of oil are directed to the selected hydraulic cylinders at

any given moment. With this "partitioning" of the hydraulic oil, the hydraulic system becomes a

virtual digital hydraulic system with all advantages of checkability and control over the move-

ment of the load.

Subsequently, with all movement points being synchronized and under full control, no addition-

al stresses are induced into the object being moved due to bending, torsion or shifting loads.

Measurements are taken and calculations are made utilizing a Best Developed

Available Technology (BDAT) PLC. Using the BDAT-PLC allows the operator to focus on moni-

toring the movement without having to interfere or even take long-lasting manual interventions.

This creates the basis for signicant time savings compared to traditional methods of moving

heavy loads.

Improved control in applications that involve the same movement repeatedly, such as self-

climbing formworks, strand-lift or stage-lift operations, is due to the functionality of the PLC

software and the operational features provided by the HMI (Human Machine Interface).

The same factors also allow for an automated documentation of the movement including pres-

sure (force) on the various cylinders, a time signal and all operator actions taken via the HMI

(Human

Machine Interface).

DESCRIPTION

© 2014 SPX CORPORATION 7Form No. 1000773

Rev. 0 August 12, 2014

The motion control system is a PLC-based eight lift point (expandable) motion control

system which allows for accurate and reliable control of multiple hydraulic cylinders to accom-

plish the lifting / lowering / pushing / etc. of almost any size load. The PLC software controls

valves

feeding each hydraulic cylinder in a way that will keep the load-movement synchronized within

the preset tolerance range, regardless of the actual load distribution within the hydraulic circuit.

• One hydraulic setup suits both single and double-acting cylinders under different pressure -

different load – in each circuit

NOTE: When using single - acting cylinders, an overcenter, or other appropriate valve should

be used as safety in the event of hose break.

• Controlled cylinder movement in both directions: advance and retract

• Complete Motion Control System package consists of the following modules

Controller

Measuring System

Pump Unit

Valve System

Electrics/Electronics

DESCRIPTION CONTINUED

© 2014 SPX CORPORATION 8Form No. 1000773

Rev. 0 August 12, 2014

The safety signal word designates the degree or level of hazard seriousness.

[ IMPORTANT: This guide cannot cover every hazard or situation so always do the job

with SAFETY FIRST in mind.]

Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

IMPORTANT: Important is used when action or lack of action can cause equipment failure, either

immediate or over a long period of time.

W

ARNING

SAFETY SYMBOLS AND DEFINITIONS

SAFETY PRECAUTIONS

In order to take the necessary actions to avoid an accident with or any damage to the MCS

motion control system, or the load being positioned, note:

Create a lifting plan that includes:

• Who is involved and what their responsibilities are.

• What the lift objectives are and what are actions and their sequence in order to

achieve the lift.

• When the lift will take place, over what time frame .

• Where the lift takes place and where critical lift or reaction points are located.

• A comprehensive safety plan.

• Local special conditions ( legal, environmental, geographical, etc.)

Before putting the motion control system into operation, the operator shall analyze the

lift application for all foreseeable risks, their likelihood to occur, and the potential

consequences of the identied risks as per ISO 31000 and ISO/IEC 31010 in their ac-

tual

current version.

Create a lifting log documenting the lifting job as per annex XX of this manual.

© 2014 SPX CORPORATION 9Form No. 1000773

Rev. 0 August 12, 2014

SAFETY PRECAUTIONS CONTINUED

• Read and understand the Operating Manual before operating this equipment. For

the latest version of the instruction please visit the “Resources” page on our Web-

site (www.PowerTeam.com)

• IMPORTANT: For instructions specic to the various system components refer to

the related individual manufacturer’s instructions that have been included with the

MCS.

• IMPORTANT: The following procedures must be performed by qualied, trained

personnel who are familiar with this equipment. Operators must read and under-

stand all safety precautions and operating instructions included with the MCS Mo-

tion

Control System. If the operator cannot read these instructions, operating instruc-

tions and safety precautions must be read and discussed in the operator's native

language.

• The motion control system is designed for general use in normal environments.

These products are not designed for lifting and moving in special work environ-

ments such as: explosive, ammable, or corrosive. Only the user can decide the

suitability of this

system for use in these conditions or extreme environments. Power Team will

supply information necessary to help make these decisions. Consult your nearest

Power Team facility.

• Safety glasses and hearing protection must be worn at all time by the operator and

anyone within sight of the unit. Additional personal protection equipment may in-

clude: face shield, goggles, gloves, apron, hard hat, and safety shoes.

• The owner of this motion control system must ensure that safety-related decals are

installed, maintained, and replaced if they become difcult to read or understand.

• Disconnect electrical power prior to opening electrical cabinet.

To prevent operator error, perform all of the following steps to develop a

lift plan for therequirements including and especially concentrating on the controlled movement

with an assistant

operator whose sole task it is to double-check and verify any input and operational action taken

by the main operator.

IMPORTANT: All movements to be performed by the Motion Control System must be

ordered and approved by the person responsible at the job site. SPX Power Team will assist in

operating the Motion Control System, but cannot be responsible for static or strength calcula-

tions of the structure or load to be moved.

After setting up the MCS, the system needs to be tested for correct map-

ping of circuit number on the screen versus displacement sensors and correlation with the

2-way valves. Extend each displacement sensor individually for approximately 100 mm and

verify the displacement

indication on the screen to show the same change of values. Set the system into “Manual”

mode and activate each circuit one by one. Verify the function of the related 2-way valve by

checking the

movement of the spool-core.

W

ARNING

© 2014 SPX CORPORATION 10 Form No. 1000773

Rev. 0 August 12, 2014

PUMP

• Do not exceed the hydraulic pressure rating noted on the pump nameplate or tamper with

the pump's internal high pressure relief valve. Creating pressure beyond rated capacities

can result in personal injury.

• Retract all cylinders in the system before adding uid to prevent overlling the pump

reservoir. An over-ll can cause personal injury due to excess reservoir pressure created

when cylinders are retracted.

ELECTRIC-DRIVEN MOTOR

Electrical work must be performed and tested by a qualied electrician per local

directives and standards.

• Disconnect the pump from the power supply and relieve pressure before removing the

motor case cover, or performing maintenance or repair.

• Check the total amperage draw for the electrical circuit you will be using. For example: Do

not connect a pump that may draw 25 amps to a 20 amp fused electrical circuit.

• Never use an ungrounded power supply with this unit.

• Changing the voltage is an involved and, if incorrectly performed, hazardous procedure.

Consult the manufacturer for specic information before attempting rewiring.

• Wire pump motors for counterclockwise rotation when viewed from the shaft end of the

motor.

• Do not attempt to increase the power line capacity by replacing a fuse with another fuse of

higher value. Overheating the power line may result in re.

• Exposing electric pumps to rain or water could result in an electrical hazard.

• Avoid conditions that can cause damage to the power cord, such as abrasion, crushing,

sharp cutting edges, or corrosive environment. Damage to the power cord can cause an

electrical hazard.

HOSES

• Before operating the pump, tighten all hose connections using the correct tools. Do not

over-tighten. Connections should be only secure and leak-free. Over-tightening can cause

premature thread failure or high pressure ttings to split at pressures lower than their rated

maximum operating pressure.

W

ARNING

SAFETY PRECAUTIONS CONTINUED

W

ARNING

W

ARNING

© 2014 SPX CORPORATION 11 Form No. 1000773

Rev. 0 August 12, 2014

• Should a hydraulic hose rupture, burst, or need to be disconnected, immediately depress

the RED emergency E – Stop Button to shut off the pump. Never attempt to grasp a leaking

hose under pressure with your hands. The force of escaping hydraulic uid could cause

serious injury.

• Do not subject the hose to potential hazard, such as re, sharp surfaces, heavy impact,

or extreme heat or cold. Do not allow the hose to kink, twist, curl, or bend so tightly that

the uid ow within the hose is blocked or reduced. Periodically inspect the hose for wear,

because any of these conditions can damage the hose and possibly result in personal

injury.

• Do not use the hose to move attached equipment. Stress can damage the hose and

possibly cause personal injury.

• Hose material and coupler seals must be compatible with the hydraulic uid used. Hoses

also must not come in contact with corrosive material such as creosote-impregnated

objects and some paints. Consult the manufacturer before painting a hose. Never paint the

couplers. Hose deterioration due to corrosive materials may result in personal injury.

CYLINDER

• Do not exceed rated capacities of the cylinders. Excess pressure may result in personal

injury.

• Cylinders should be arranged, as much as practical, to evenly distribute the load to each

cylinder.

• Avoid off-center loads that could damage the cylinder and/or cause loss of the load.

• Read and understand all safety and warning decals and instructions for devices attached.

• Inspect each cylinder and coupler before each shift or usage to prevent unsafe conditions

from developing.

• Do not use cylinders if they are damaged, altered or in poor condition.

• Do not use cylinders with bent or damaged couplers or damaged port threads.

• With the MCS, the use of an extension with a hydraulic cylinder is prohibited.

• Avoid pinch points or crush points that can be created by the load or parts of the cylinder.

• To help prevent material fatigue if the cylinder is to be used in a continuous application, the

load should not exceed 80% of the rated capacity or stroke.

• Cylinder must be on a stable base which is able to support the load while pushing or lifting.

• To help prevent personal injury, use shims, friction material or constraints to prevent

slippage of the base or load.

• Do not set poorly-balanced or off-center loads on a cylinder. The load can tip or the cylinder

can “kick out” and cause personal injury.

• Do not use the locking collar on a threaded piston as a stop. The threads may shear

resulting in loss of the load, Dammage to equipment and personal injury.

SAFETY PRECAUTIONS CONTINUED

© 2014 SPX CORPORATION 12 Form No. 1000773

Rev. 0 August 12, 2014

• Because this system is used to lift or lower loads, be certain that the load is under operator

control at all times and that others are clear of the load.

• Never Rapidly drop the load in an uncontrolled manner.

• As the load is lifted, use mechanical blocking and cribbing to guard against a falling load.

• To help prevent personal injury, do not allow personnel to go under or work on a load before

it is properly cribbed or blocked. All personnel must be clear of the load before and during

lowering.

• Never use extreme heat to disassemble a hydraulic cylinder or ram. Metal fatigue and/or

seal damage will result and can lead to unsafe operating conditions.

IMPORTANT

• Keep the cylinders clean at all times.

• While at a job site, when the cylinder is not in use, keep it fully retracted and upside

down.

• Use an approved, high-grade pipe thread sealant to seal all hydraulic connections.

PTFE tape can be used if only one layer of tape is used and it is applied carefully

(two threads back) to prevent the tape from being pinched by the coupler and broken

off inside the pipe end. Any loose pieces of tape could travel through the system and

obstruct the ow of uid or cause jamming of precision-t parts.

• Always use protective covers on disconnected quick couplers.

• Limiting the stroke on spring return cylinders will prolong spring life.

• Limiting the stroke and pressure on all cylinders will prolong their life.

ELECTRICAL CONTROL UNIT

If the HMI( Human machine interface) touch screen becomes unreadable at any time during

operation of the MCS system, depress the RED emergency stop button IMMEDIATELY to

stop system operation until trouble shooting of malfunction can be performed.

To prevent personal injury,

Electrical work must be performed by a qualied electrican per local directives and

standards.

• Disconnect the electrical control cabinet control unit from the power supply before

removing the cover of the control unit or performing maintenance or repair on

electrical components.

• Some electronic components inside the electrical control unit are sensitive to static

charges. Always use an anti-static wrist band connected to the ground-earth bar

inside the electrical Control unit before performing any maintenance or repair work

on those electronic components.

SAFETY PRECAUTIONS CONTINUED

W

ARNING

© 2014 SPX CORPORATION 13 Form No. 1000773

Rev. 0 August 12, 2014

GENERAL OVERVIEW

(Detailed setup, start up and Operating Instructions begin on page 20)

• On the HMI touch screen, push the

“Set Zero” button to set the read-

ings of all displacement sensors to

“Forced Zero” This denes the start-

ing point of the synchronized move-

ment.

• Enter the allowed maximum differ-

ence between the leading and the

lagging lift point (Tolerance Rel.

Displ.). Make sure you observe the

unit-setting you have chosen earlier.

Enter the target stroke all lift points

shall reach simultaneously under

"Setpoint Position".

• IMPORTANT: As a background

safety-check, the system will

continuously monitor the pressure in

each cylinder and compare it to a

pre-set maximum pressure value.

Enter this max pressure value per

cylinder. This value shall be calcu-

lated based on the cylinder capacity

and the expected / predicted load at

the referring Lifting point.

• On the HMI, set the operation mode

to “Auto”.

NOTE: It is suggested that for the rst run, the duration "ON" be set at 40 ms, the duration

"OFF" be set at 20 to 30 ms, and the release quick discharge pressure be set at 50 bar.

• As you select each cylinder, you will be required to input data for each of the cylinder’s rela-

tive to pressure at 4 and 20 mAmps, and maximum load and maximum pressure.

• Back on the home screen, you must set the parameters of set point position, set point maxi-

mum load, and tolerance for relative displacement. The set point position target has to be

greater than the relative position of the cylinder’s in order to move the load up or down.

NOTE: For the rst test of lifting the platform, set the set point target at 25 mm. Before

performing lift, manually measure the platform height at each active cylinder. Record the

data for each cylinder.

© 2014 SPX CORPORATION 14 Form No. 1000773

Rev. 0 August 12, 2014

GENERAL OVERVIEW CONTINUED

• Enter the time increment value that

the 2-way valves shall be operated

within. Start with a short time value

(e.g. 50 ms). Depending on the size

and capacity of the cylinders, the

length of the hoses and the pres-

sure level needed for lifting, this

time can be too short to allow for a

reasonable lifting speed. Gradually

increase the time during the opera-

tion and monitor the resulting overall

accuracy. Too long of an Actuation

time will cause the cylinders to ad-

vance or retract in too large of steps,

subsequently exceeding the preset

tolerance. In this case the PLC soft-

ware will stop the operation, close all

valves, and display an alarm on the

screen of the HMI

• Check all data and settings. Take

notes of your settings in a Log-le as

shown in Annex 1 of this instruction

sheet.

• The PLC will perform a system integ-

rity check to avoid using settings that

are contradictory or might lead to a

dangerous situation.

• On the home screen, conrm the

cylinder selection that you will be

using in the auto operation mode.

They should be the same cylinder’s

that were originally set up in the

Manual mode.The cylinders should

be moved to a position that is not in

contact with load to be lifted.

• On the rst screen you’ll need to

establish the duration "ON" and the

duration "OFF" times, as well as the

release quick discharge pressure.

You will establish these through drop

down menus as described before.

• Touch the auto button on the home

screen. The pump will turn on.

© 2014 SPX CORPORATION 15 Form No. 1000773

Rev. 0 August 12, 2014

GENERAL OVERVIEW CONTINUED

• ON THE HOME SCREEN select

Manual mode of operation by press-

ing the Manual button on the screen.

At this point the hydraulic pump

turns on. No pressure is building in

the system as the pump ows back

to tank.

• To select a specic cylinder to raise,

touch the numbered blue box at the

top of the screen that corresponds to

the cylinder you wish to move.

• Using the up and down buttons on

the touchscreen that appear once

a cylinder is selected will indepen-

dently

manually raise and lower each active

cylinder. This movement should be

performed intermittently raising the

cylinder piston rod 1 or 2 inches at a

time until it gently touches the load

to be lifted.

(SEE NOTES ON NEXT PAGE)

© 2014 SPX CORPORATION 16 Form No. 1000773

Rev. 0 August 12, 2014

GENERAL OVERVIEW CONTINUED

• NOTES: While in Manual operation mode only one cylinder may be operated at a time.

System pressure should be low enough, there will be cylinder movement, but not high

enough to allow the load to be lifted.

• Depending upon the length of hoses and the size of the cylinder’s used as well as the

length of the initial stroke it may be necessary to add additional oil to the tank.

• In any circumstance it is recommended to use pre lled hydraulic hoses with the same oil

as the rest of the system before any lift is performed.

• While manually raising a cylinder, disconnect the connector wire from the position sensor at

that cylinder and conrm that an alarm response is received and the system stops

operating.

• Reattach the cable and touch re-set button on home page to continue testing.

CYLINDER APPROACH TO LOAD

(Set the system into Manual mode)

There is NO control of the actual movement of the load in the manual mode! Set

the maximum pressure to a setting that allows the plunger of each cylinder to move.

However, this pressure setting must be low enough such that the cylinder cannot move

the load, but only make rm contact with the load to be lifted.

During this operation the plunger of each cylinder will come into contact with the

lifting point of the load. This can cause a pinch point. Make sure all personnel

stand clear from moving plungers.

IMPORTANT: Too high of a pressure setting can cause a cylinder to start moving

the load and cause unduly stress or even damage to the structure to be moved.

Activate each circuit one by one until the plunger is in full contact with the load

and the pre-set max pressure has been reached.

W

ARNING

W

ARNING

© 2014 SPX CORPORATION 17 Form No. 1000773

Rev. 0 August 12, 2014

TRANSPORTATION

Before transporting the MCS, make sure the system is switched off and all hydraulic pres-

sure has been bled from the system. Remove all oil from the reservoir. Always disconnect all

hydraulic and electric connections before attempting to move the MCS unit. After disconnect-

ing hydraulic hoses re-install the dust covers on quick disconnects as well as hose ttings to

prevent contamination from entering the hydraulic system.

For short on-site distances, always transport the control unit in a cradle or lifting device rated

for the weight of the unit. Secure the unit against tipping over. Move the MCS unit by means of

the lifting eyes attached to the frame or a forklift type vehicle using the side or end fork loca-

tions. Always move the MCS in an upright position.

For long distance transport, use an appropriately rated forklift and slowly place the MCS into

the shipping container in which the MCS was delivered to the job site. Make certain all addi-

tional hardware and accessory items are securely stored within the shipping container prior to

shipment.

UNPACKING

When unpacking, make sure the MCS is located on a stable, at, leveled surface that will sup-

port the weight of the MCS. Carefully open the shipping container and arrange for its storage.

Save the shipping container as it is re-useable. With a forklift that is rated to safely move the

MCS, slowly remove the MCS from its shipping container. Save the shipping container as it is

re-useable

Once the MCS is removed from the shipping container, locate the MCS on a at, stable sur-

face that is sufcient to withstand the weight of the MCS system without deforming the surface

upon which it is resting.

Check the completeness of the Motion Control System:

• Pump unit

• Control unit

• Displacement sensors (contained in two small cases – NOTE: The electrical control unit

cabinet door key is included in one of these cases)

• Sensor cables (contained in one large case)

• Hoses (may not be included as part of the MCS control and may be packaged separately)

• Cylinders (may not be included as part of the MCS control and may be packaged sepa-

rately)

Check that all components are clean and without visible damage. Cable and hose connection

points should be protected from environmental humidity and dust by protective covers installed

on the unit. Conrm that the covers are in place and should remain in place until unit is ready

to use.

© 2014 SPX CORPORATION 18 Form No. 1000773

Rev. 0 August 12, 2014

UNPACKING CONTINUED

Check and conrm that the following items are undamaged and in good condition:

A. Pressure Gauges

B. Electrical Plug Outlet

C. HMI (Tough Screen)

D. External Cabinet Vents

E. Door Switch

F. Displacement Sensor Connectors

G. Hose Connection Quick Couplers

© 2014 SPX CORPORATION 19 Form No. 1000773

Rev. 0 August 12, 2014

1. SET UP

Begin by visually checking the MCS unit, cables, sensors, cylinders and connectors

(electrical with cables and hydraulic hoses) to conrm the integrity of all components

and that there is no visible signs of damage.

2. COMPONENTS

Make sure that all components such as hoses, couplers, and cylin-

ders are rated for for the maximum operating pressure provided by

the pump unit (700 bar).

3. DOCUMENTATION

IMPORTANT: To avoid operator error and to document the performance of each opera-

tional step it is recommended that the operator lls in a checklist as shown in Annex 1 of

this

instruction sheet during the Motion Control System operation.

4. INSTALLATION

Mechanicals set up

• Fill Reservoir with 40 Gallons (150L) of Power team hydraulic oil (Part Nos. 9616, 9636,

9637, 9638)

• Once the MCS has been moved into place, with no power cord attached, begin to

physically connect the cylinders to of the MCS with the appropriate hoses. Position the

magnetic bases of the position sensors by the appropriate cylinders and attach the ap-

propriate cable to each position sensor and its respective connector on the MCS face

plate.

OPERATING INSTRUCTIONS

W

ARNING

© 2014 SPX CORPORATION 20 Form No. 1000773

Rev. 0 August 12, 2014

OPERATING INSTRUCTIONS CONTINUED

6. LINEAR DISPLACEMENT SENSORS

Mounting position

• The displacement sensor must be rmly mounted as close as practical to the lift cylin-

der in a position which allows free cable movement and where damage to the sensor or

cable from foreign objects is unlikely. The sensor will operate in any orientation. Where

string cable

contamination by oil, water or particulate matter is possible, the sensor should be

mounted in the vertical plane with the cable pointing down. Where necessary a sensor

shield should be incorporated in the mounting assembly to protect the sensor from fall-

ing

solids or liquid media. It is also good practice to mount the sensor onto or close by a

rigid part of the machine or system. Never let the sensor cables snap back into the

sensor. It may damage the sensor. When mounting the position sensor make sure the

linear travel of the cable is at 90 degrees to the sensor body surface.

• IMPORTANT: Any deviation from the 90 degree angle will reduce the life of the cable

and cable outlet, and may affect the linear position readout.

• CAUTION: As a regular occurrence, moving heavy loads is typically performed

during night time with limited visibility. Make sure that each lifting point and especially

the location of the electrical control unit and pump unit has sufcient lighting. As a

general rule always protect the electrical control unit from environmental inuences such

as rain, dust, vibration , heat, the physical damage ,etc.

5. CYLINDERS

• IMPORTANT: When placing the cylinders under the load to be lifted, the cylinders

should be placed on a surface that is capable of supporting a minimum of 1.5 times the

rated cylinder capacity without surface deformation. For example, use properly sized

load-distributing steel plates in order to remain below maximum local surface loading

conditions. Failure to do so may result in surface deformation that may lead to an un-

successful lift, personal injury and damage to the structure being lifted.

• In addition to ground level surface support, make sure that the support point on the load

to be lifted is capable of withstanding and distributing the lifting forces without deforma-

tion to the lift point itself.

• A review of each lift point's estimated load should be performed, so that when selecting

and sizing cylinders for the lift, it is recommended that the load on the cylinder at each

lifting point should not exceed 80% of the rated cylinder capacity.

Table of contents

Other SPX Control System manuals

Popular Control System manuals by other brands

Favero

Favero FULL-ARM 03 Instruction and operations

Telensa

Telensa Telecell installation manual

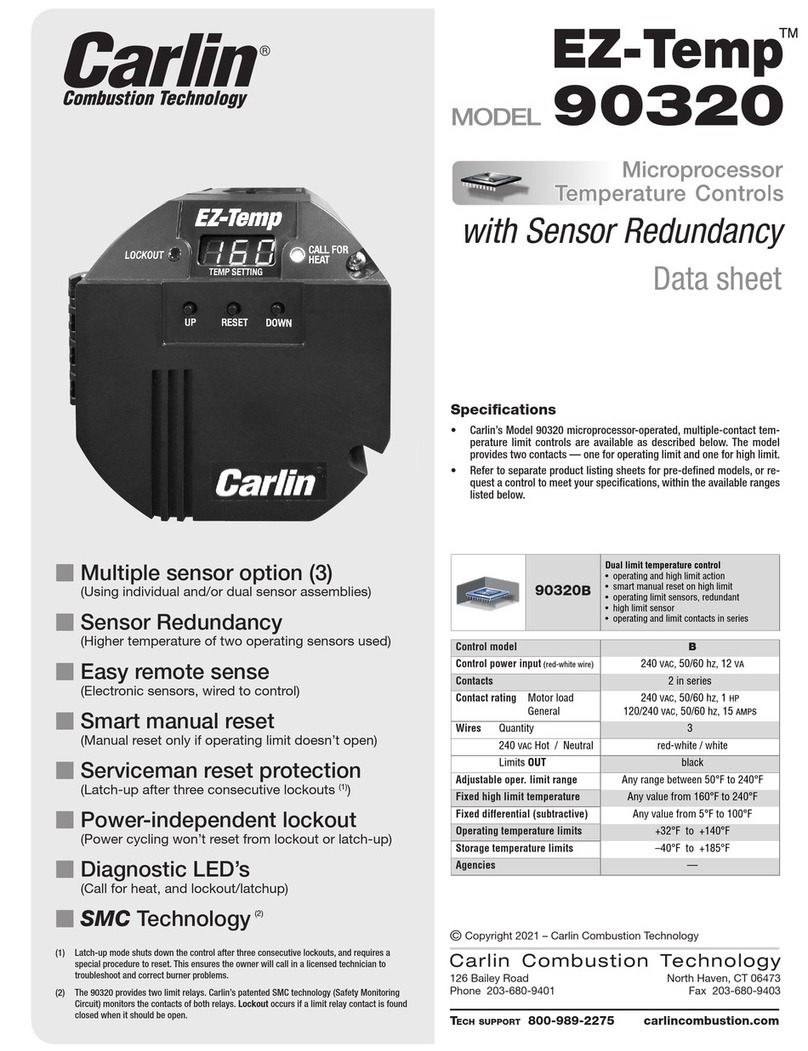

Carlin

Carlin EZ-Temp 90320 quick start guide

Allen-Bradley

Allen-Bradley Micro800 user manual

Valeo

Valeo SC600 Australien operating instructions

CANCELLI AUTOMATICI

CANCELLI AUTOMATICI WAVE WA01 installation manual