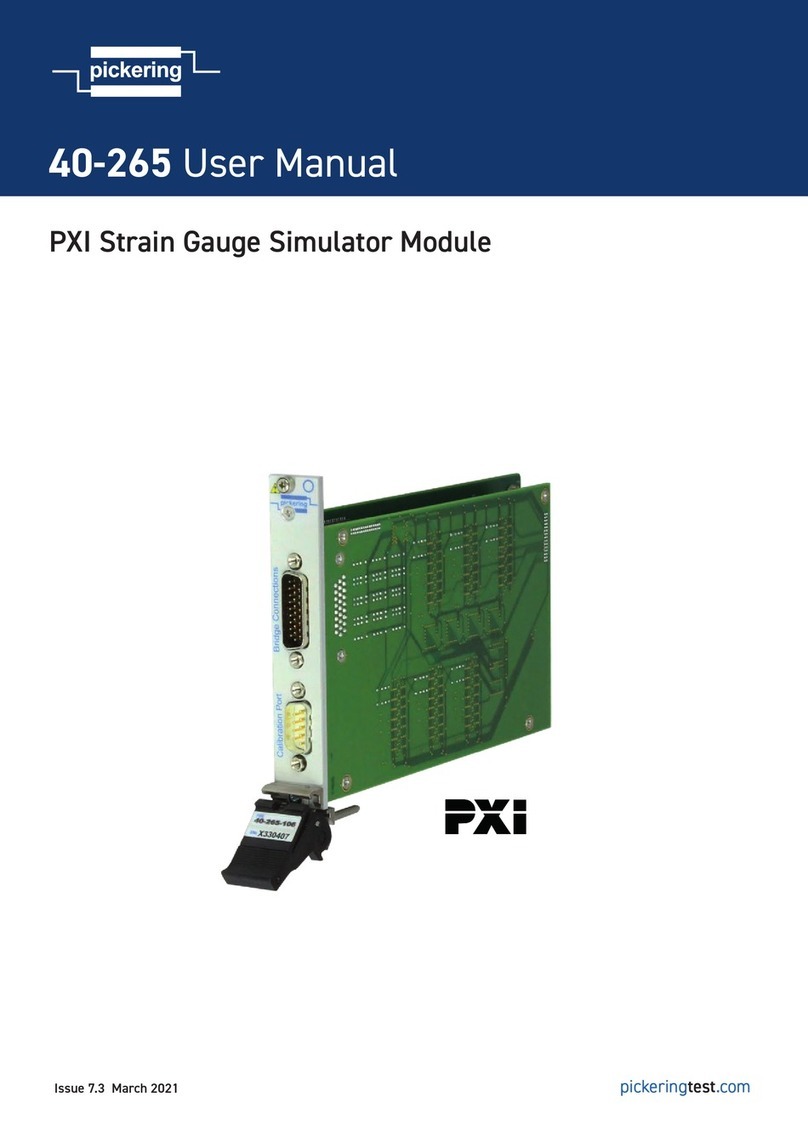

SPX APV DELTA PR2 User manual

Read and understand this manual prior to

operating or servicing this product.

Operating Manual

DELTA PR2

Sampling Valve

1

Sampling Valve

DELTA PR2

Operating Manual Rev.3

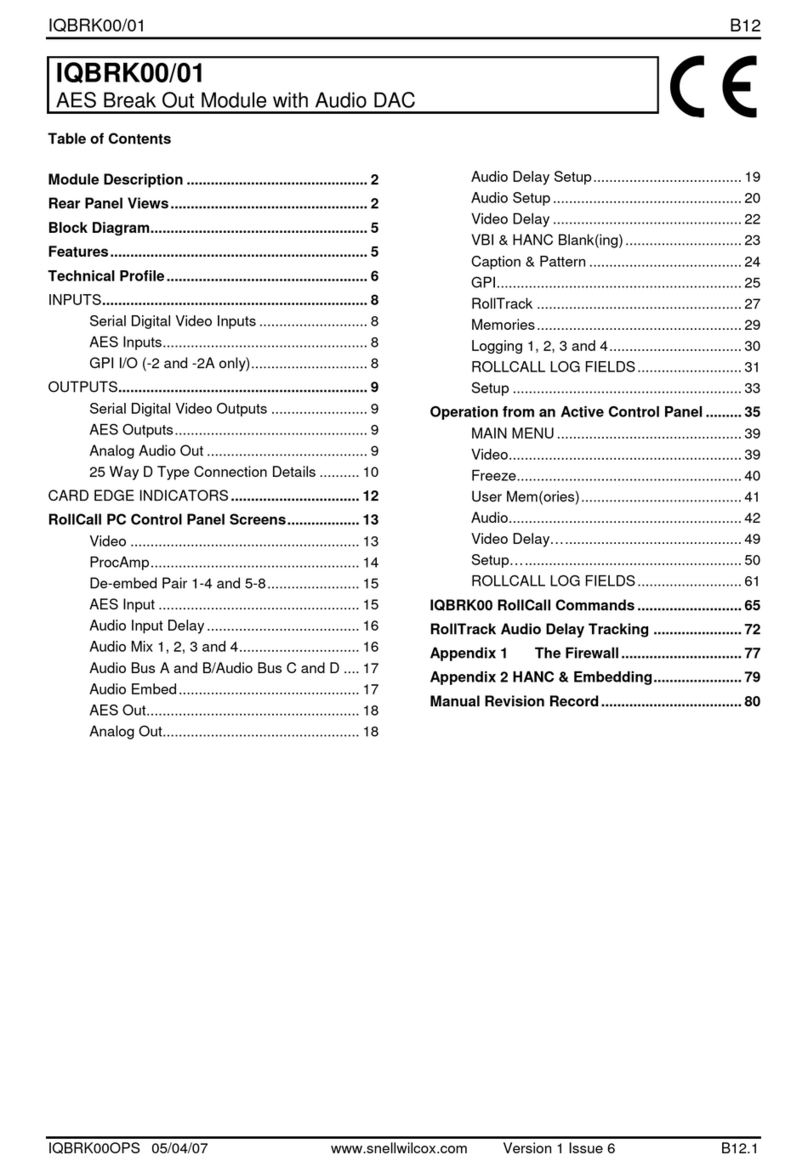

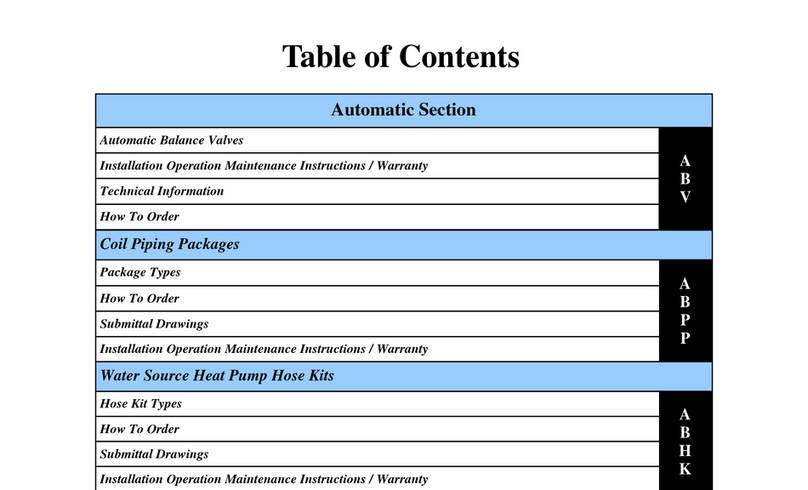

1. General Terms 2

2. Safety Instructions 2

3. Mode of Operation 2

4. Auxiliary Equipment 3

5. Cleaning 3

6. Installation 3

6.1 Welding Instructions 4

7. Maintenance 4

8. Dimensions / Weights 5

9. Materials 6

10. Technical Data 6

11. Service Instructions 7 - 9

12. Trouble Shooting 10

13. Spare Parts Lists

PR2 - HF RN 01.143.0

PR2 - FS - H RN 01.146-2

Table of Content Page

UK

This operating manual has to be read carefully and observed by

the competent operating and maintenance personnel.

We have to point out that we will not accept any liability for

damage or malfunctions resulting from the non-compliance with

this operating manual.

Descriptions and data given herein are subject to technical changes.

2. Safety Instructions

DANGER!

- Before any maintenance work, the line and cleaning system must

be depressurized.

- Observe service instructions for a safe maintenance of the valve!

3. Mode of Operation

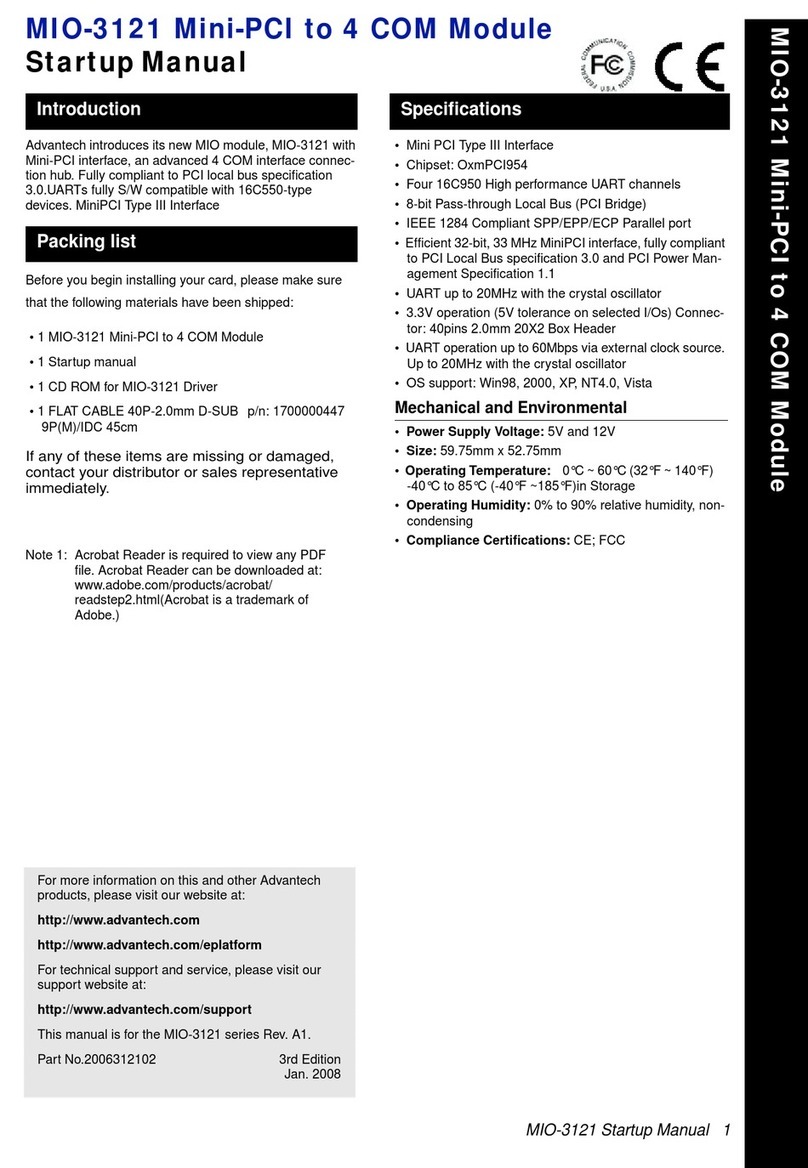

I. Manual operation (PR2-HF)

The valve is actuated by turning the handle (B).

turn left = open

turn right = closed.

II. Pneumatic operation (PR2-FS-H)

Through the compressed air supply at "A", the valve is driven into

the "open" position. Reset is done by spring force.

The valve is equipped with an emergency handle (B) which allows

opening and closing by manual operation.

turn left = open

turn right = closed.

1. General Terms

2

B

D

D

A

B

C

Sampling Valve

DELTA PR2

Operating Manual Rev.3

UK

* Valve position indication

A switch to signal the limit position of the valve shaft (On/Off) can

be mounted in the yoke area (C) if required.

* Steam-resistant housing (DN 25)

This housing is available for both valve actuations and is welded

direct to the tank or pipeline. It has connections for the steam inlet

and outlet.

5. Cleaning

- With the standard designs, the valve is cleaned during the pipe

cleaning process.

- By short-term interval-opening of the valve, the contact surface

between the valve shaft and the seat is cleaned, whereas liquid

drains off the sampling nozzle (D).

- The valve with steam connection is cleaned and sterilized through

the connecting tubes.

6. Installation

- The installation of the valve must be undertaken in such a way

that liquids can drain off the valve housing.

- The steam-resistant valve must be mounted in horizontal position.

The connecting tubes must be to the top and to the bottom.

- The standard valves can be welded into the pipelines either in

vertical position (sampling connection to the bottom) or in

horizontal position.

-Attention! Observe welding instructions.

4. Auxiliary Equipment

3

steam-resistant housing

C

Sampling Valve

DELTA PR2

Operating Manual Rev.3

UK

PR2

- Before welding of the valves, the valve insert must be dismantled

from the housing. See to a careful handling to avoid damage.

- Welding may only be carried out by certified welders (EN 287-1).

(Seam quality EN 25817 "B").

- The welding of the valve housing must be undertaken in such a

way that deformation strain cannot be transferred from the outside

to the valve body.

- The preparation of the weld seam up to 3 mm wall thickness must

be carried out in butt manner as a square butt joint without air.

(Consider shrinkage!)

- TIG orbital welding should be preferred.

- After welding of the valve housings or of the mating flanges and

after work at the pipelines, the corresponding parts of the

installation or pipelines must be cleaned from welding residues

and soiling. If these cleaning instructions are not observed, welding

residues and dirt particles can settle in the valve and cause

damage.

- Any damage resulting from the nonobservance of these welding

instructions is not subject to our guarantee.

7. Maintenance

- The maintenance intervals are different depending on the

application and are to be determined by the operator himself

carrying out temporary checks.

- Complete seal kits for the valve service are available

(see spare parts lists).

- Exchange of seals according to service instructions.

- Provide all seals with a thin layer of grease before their installation.

Recommendation:

APV food-grade grease for EPDM,HNBR and FPM

(750 g /tin - ref.-No. 000 70-01-019/93)

(60 g /tube - ref.-No. 000 70-01-018/93)

or

APV food-grade grease for VMQ

(60 g /tin - ref.-No. 000 70-01-017/93)

(60 g /tube - ref.-No. 000 70-01-016/93).

! Do not use grease containing mineral oil for EPDM seals !

! Do not use Silicone-based grease for VMQ seals !

- Assembly of the valve according to service instructions.

6.1 Welding Instructions

4

Sampling Valve

DELTA PR2

Operating Manual Rev.3

UK

8. Dimensions / Weights

5

dimensions in mm

DN A B C D E F

25 50 26 29 37 99 134

40 67 38 41 46 101 138

50 72 50 53 52 107 144

65 85 66 70 60 115 152

80 98 81 85 68 122 159

100 111 100 104 77 132 169

inch

1,5” 67 34,9 38,1 44,4 99,4 137

2” 72 47,6 50,8 51,0 107,0 144

3” 90 72,9 76,1 63,0 117,5 155

weight in Kg

DN HF - manual FS - actuated

design design

25 0,9 1,9

40 1,0 2,0

50 1,2 2,2

65 1,4 2,4

80 1,9 2,9

100 2,6 3,6

10 x 1

37,6

133

pneumatically actuated

design with steam-resistant housing

DN 25

manual design

pneumatically

actuated

design

Sampling Valve

DELTA PR2

Operating Manual Rev.3

UK

housing, housing cover 1.4571 or 1.4404

spring cylinder, yoke,

upper part of shaft,

operating cam, screws,

air connection 1.4301

seals

standard design EPDM

options HNBR ,FPM, VMQ

lower part of shaft PTFE / 25 % glass fiber

handle Hostalen

10. Technical Data

- max. line pressure 10 bar

- max. operating temperature 135 °C EPDM, HNBR

*VMQ, *FPM

- short-term load 140 °C EPDM, HNBR

*VMQ, *FPM

*(no steam)

- max. stroke 4 mm

- control pressure for

air-operated valve 10 bar max. / 6 bar min.

- air connection for hose 6 x 1

Use dry and clean pneumatic air, only.

9. Materials

6

Sampling Valve

DELTA PR2

Operating Manual Rev.3

UK

11. Service Instructions

7

Manual design - PR2 HF

The item numbers refer to the spare parts drawing RN 01.143.0.

I. Dismantling from the line system

a. Shut off line pressure in the product line.

b. Turn handle (8) to the left until the valve is in open position.

c. Remove flange screw (4) and take the complete valve insert out

of the housing (11).

d. Remove O-ring (2).

e. Insert a small screw driver through the bore in the spring housing

and into the shaft (1) to prevent the shaft from turning.

f. Remove hexagon screw (10) and washer (9) and press the shaft (1)

into the direction of the PTFE part out of the housing.

g. Pull the PTFE shaft tip (1.2) from the metal part (1.1).

The PTFE tip is destroyed during this action.

h. Remove the shaft seal (3) from the spring housing.

II. Installation of seals and assembly of valve

a. Press the slightly greased shaft seal (3) into the groove of the

spring housing.

b. Place the PTFE shaft tip (1.2) on the metal part (1.1) and lock it

into place.

c. Push the valve shaft (1) with the metal part to the front through the

shaft seal into the spring housing.

d. Insert a small screw driver into the bore of the spring housing (5)

and of the shaft (1) to prevent the shaft from turning.

e. Screw the hexagon screw (10) with washer (9) in the shaft and

tighten it.

f. Insert the slightly greased O-ring (2).

g. Press the complete valve insert into the housing (11) and fix it

with the flange screws (4).

h. Check the function of the valve by turning on and off several times.

4

11

9

3

1

2

10

8

Sampling Valve

DELTA PR2

Operating Manual Rev.3

manual design

with steam-resistant

housing DN 25

UK

Pneumatically actuated design (PR2-FS-H)

The item numbers refer to the spare parts drawing

RN 01.146-2.

III. Dismantling from the line system

a. Shut off line pressure in the product line.

b. Remove pneumatic air line.

c. Release screw of feedback support and pull off

proximity switch.

d. Turn handle (14) to the left until the valve is in

open position.

e. Remove flange screws (4) and take the complete valve

insert out of the housing (1).

f. Remove O-ring (2).

g. Insert a small screw driver through the bore in the spring

housing and into the shaft (1) to prevent the shaft from

turning.

h. Remove union (17) and washer (16) and screw off the

handle (14).

i. Turn off the cover (12). Insert two pins into the bore of the

cover to move the cover. Spring (13) and distance tube (11)

are accessible, now.

j. Remove O-ring (15).

k. Release threaded pin (6) and press the shaft (5) out to the

top. The operating ring (7) backs out during this procedure.

l. Pull the PTFE shaft tip (5.2) from the metal part (5.1).

The PTFE tip is destroyed during this action.

m.Remove the shaft seal (3) and O-rings (9, 10).

11. Service Instructions

8

14

4

1

17

12

11 10

13

15

6

9

5

3

7

2

16

Sampling Valve

DELTA PR2

Operating Manual Rev.3

pneumatically actuated

design with steam-resistant

housing DN 25

UK

Pneumatically actuated design (PR2-FS-H)

IV. Installation of seals and assembly of valve

(PR2-FS-H)

a. Slightly grease the shaft seal (3) and O-Ring (9, 19, 15)

and place them into the grooves.

b. Place the PTFE shaft tip (5.2) on the metal part (5.1)

and lock it into place.

c. Push the shaft (1) from the top through the yoke (8),

the operating ring (7) and the shaft seal (3).

d. Insert spring (13) and distance tube (11) and tighten the

cover (12) until it stops.

e. Screw on the handle (14) and secure the shaft against

turning (bore in shaft).

f. Screw the union (17) with washer (16) into the shaft.

g. Adjust the operating ring (7) on the level of the yoke bore

by tightening the threaded pin (6) and open the valve by

turning the handle to the left.

h. Insert the slightly greased O-ring (2).

i. Press the complete valve insert into the housing (1) and

fasten it by the flange screws (4).

j. Connect the pneumatic air line.

k. Push the proximity switch into the holder up to a distance

of about 2 mm from the operating ring (7).

The shift point can be adjusted by moving the operating

ring and the proximity switch if necessary.

Fix the operating ring and proximity switch holder with

the clamp screws.

l. Check the function of the valve by several opening and

closing.

11. Service Instructions

9Sampling Valve

DELTA PR2

Operating Manual Rev.3

UK

12. Trouble Shooting

10

Manual design

The item numbers refer to the spare parts drawing RN 01.143.0.

Failure removal see chapter 11.I. and II. Service Instructions.

- Leakage at the

sampling connection : - turn handle (8) into

position "OFF"

- replace valve shaft

tip (1.2)

- Leakage between housing

and yoke flange : - replace O-ring (2)

- Leakage out of the yoke bore : - replace shaft seal (3)

- Valve does not open : - check whether

screw (10) sticks

Pneumatically actuated design

The item numbers refer to the spare parts drawing RN 01.146-2.

Failure removal see chapter 11.III. and II. Service Instructions.

- Leakage at the

sampling connection : - turn handle (14) into

position "OFF"

- replace valve shaft

tip (5.2)

- shut off pneum.

air supply

- Leakage between housing

and yoke flange : - replace O-ring (2)

- Leakage at the

shaft passage : - replace shaft seal (3)

Pneumatic air does not work,

air escapes ...

- ... at the handle : - replace O-ring (10)

- ... at the valve shaft : - replace O-ring (9)

- valve position does not work

or is unprecise : - carry out fine

adjustment.

Sampling Valve

DELTA PR2

Operating Manual Rev.3

UK

Your local contact:

APV

Zechenstraße 49

D-59425 Unna

Phone: +49(0) 23 03/ 108-0 Fax: +49(0) 23 03 / 108-210

For more information about our worldwide locations, approvals, certifications, and local representatives, please visit www.apv.com.

Copyright © 2008 SPX Corporation

The information contained in this document, including any specifications and other product details, are subject to change without notice.

While we have taken care to ensure the information is accurate at the time of going to press, we assume no responsibility for errors or

omissions nor for any damages resulting from the use of the information contained herein.

UK

Translation of original manual

BA PR2 0000002

ID-No.: H170787

rev. 3

Table of contents

Other SPX Control Unit manuals

SPX

SPX APV DELTA MS4 User manual

SPX

SPX APV DELTA SV1B User manual

SPX

SPX DSV User manual

SPX

SPX Waukesha Cherry-Burrell W Series User manual

SPX

SPX 9500 Product guide

SPX

SPX APV CU4 User manual

SPX

SPX APV DELTA DKRT2 User manual

SPX

SPX Waukesha Cherry-Burrell W-Series User manual

SPX

SPX APV DELTA DE3 User manual

SPX

SPX APV DELTA SWmini4 User manual