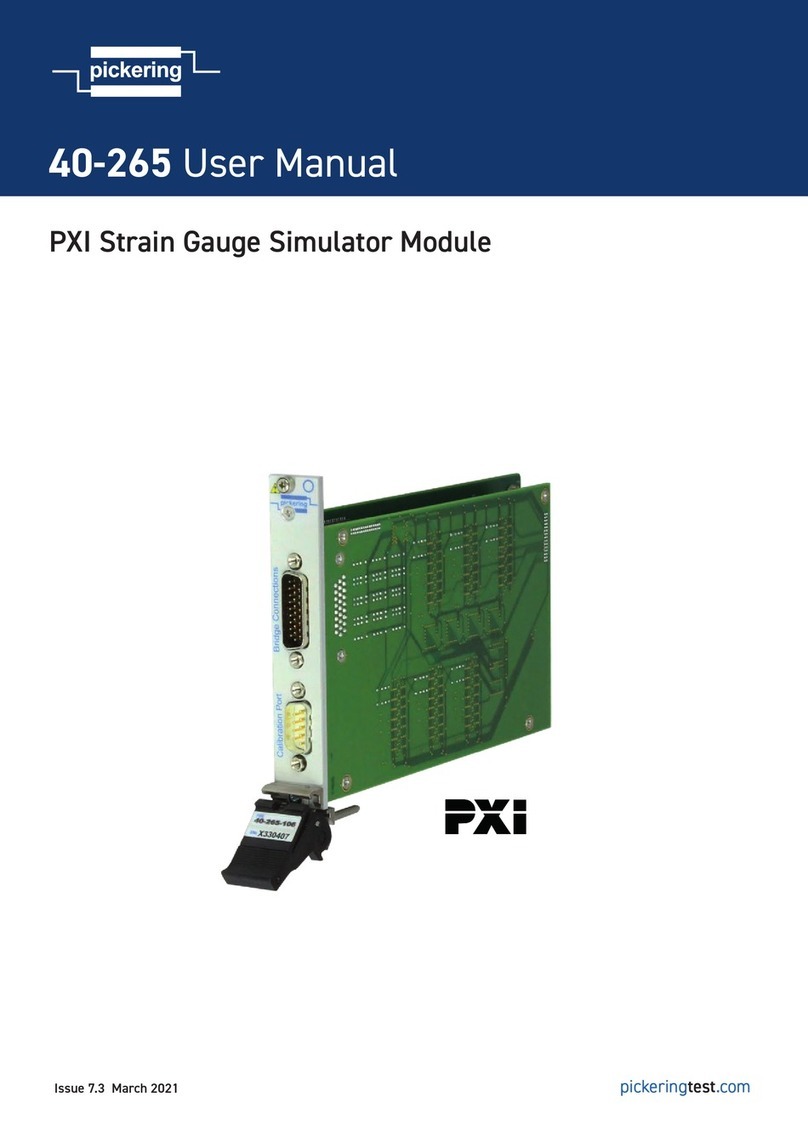

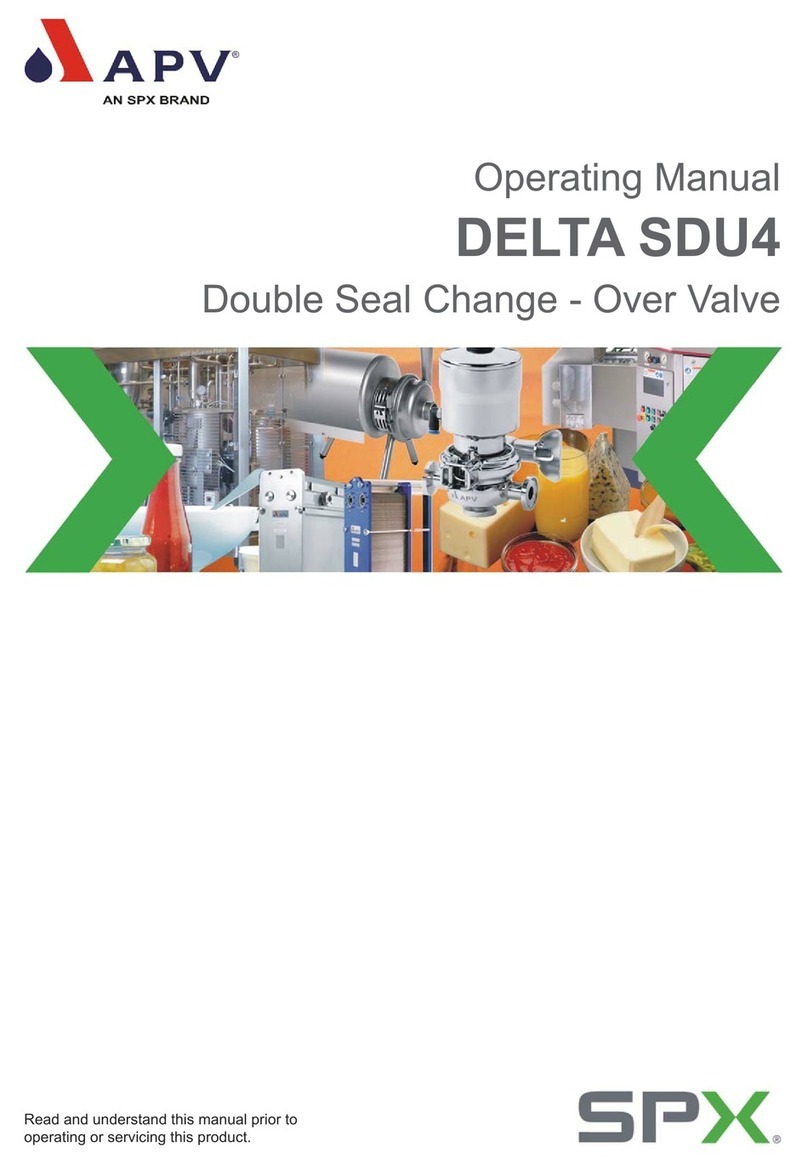

SPX APV DELTA UF3 User manual

Operating Manual

DELTA UF3(A)/UFR3(A)

Relief Valve

Read and understand this manual prior to

operating or servicing this product.

www.sks-online.com

www.sks-webshop.com

www.sks-online.com

www.sks-webshop.com

Declaration of Conformity

for Valves and Valve Manifolds

SPX Flow Technology Rosista GmbH, Zechenstr. 49, D-59425 Unna-Königsborn

herewith declares that the

double seat valves of the series D2, SD4, SDT4, SDM4, SWcip4, DSV,

DA3, DE3, DEU3, DET3, DKR2, DKRT2, DKRH2

in the nominal diameters DN 25 - 150, 1“ – 6“ and 1 Sh5 - 6 Sh5

butterfly valves of the series SV1 and SVS 1 F

in the nominal diameters DN 25 - 100, DN 125 - 250 and 1“ – 4“

ball cocks of the series KH, KHV

in the nominal diameters DN 15 - 100

single seat, diaphragm and spring loaded valves of the series

S2, SW4, SWmini4, SWT4, M3, MF3, M4, MF4, MP4, MS4, AP1, APT1, CPV, RG4, RGM4,

RGE4, RGEM4, PR2, PR3, PR4, SI2, UF3, VRA,VRAH

in the nominal diameters DN 10 - 150, 1/2“ – 4“ and 1 Sh5 - 6 Sh5

and the valve manifolds installed thereof

meet the requirements of the Directives 2006/42/EC (superseding 89/392/EEC

and 98/37/EC) and GPSG - 9.GPSGV.

For official inspections, SPX Flow Technology Rosista GmbH presents

a technical documentation according to Appendix VII of the Machinery Directive,

this documentation consisting of documents of the development and construction,

description of measures taken to meet the conformity and to correspond with

the basic requirements on safety and health, incl. an analysis of the risks,

as well as an operating manual with safety instructions.

The conformity of the valves and valve manifolds is guaranteed.

Authorised person for the documentation:

SPX Flow Technology Rosista GmbH, Frank Baumbach, Zechenstr. 49, D-59425 Unna

November 30, 2010

Manager Research and Development

UK

www.sks-online.com

www.sks-webshop.com

www.sks-online.com

www.sks-webshop.com

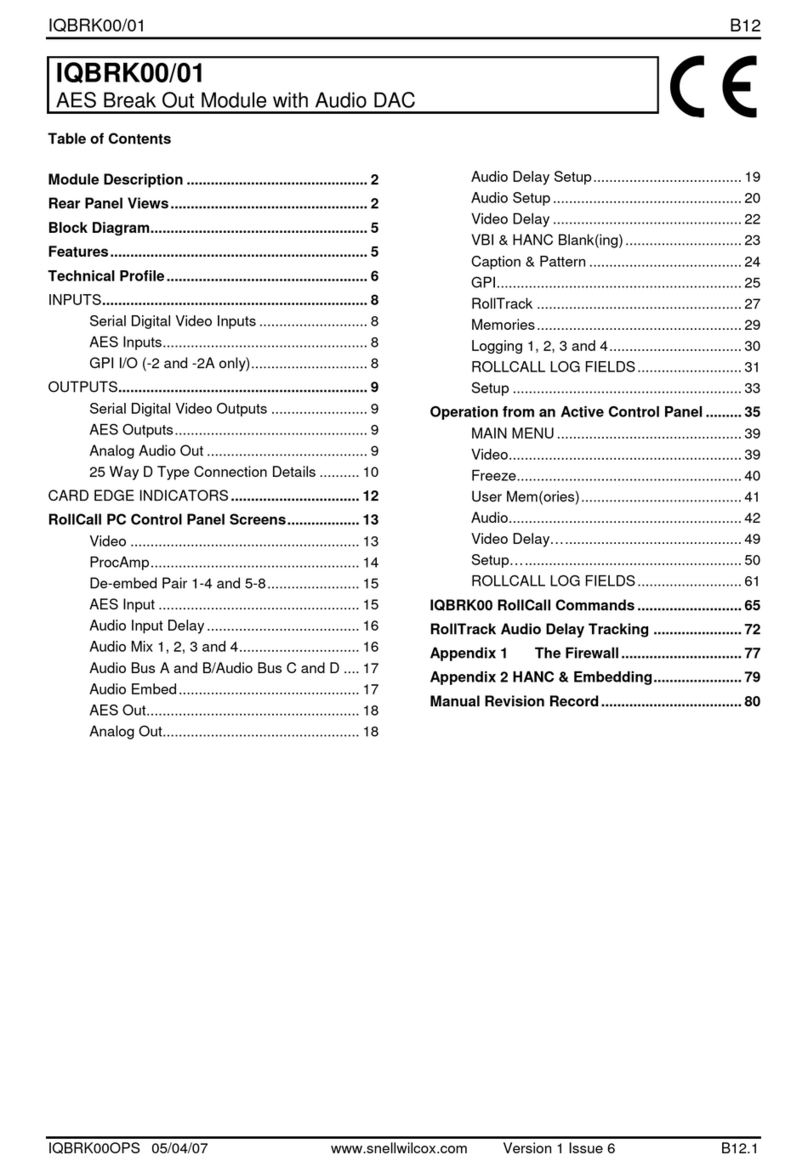

Content Page

DELTA UF3-UK5.qxp / 06.2008

U

1. General Terms 2

2. Safety Instructions 2

3. Mode of Operation 3

4. Auxiliary Equipment 4

5. Cleaning 5

6. Installation 5 - 6

6.1. Welding Instructions

7. Dimensions / Weights 7

8. Technical Data 8

8.1. General

8.2. Specification of compressed air

9. Maintenance 9

9.1. Assembly Tool

10. Service Instructions 10 - 13

10.1. Dismantling from the line system

10.2. Dismantling of wear parts

10.3. Assembly of spring cylinder

10.4. Installation of seals and assembly of valve

10.5. Installation of valve

11. Service Instructions 14

11.1. Installation of seat seal in valve shaft

12. Trouble Shooting 15

13. Spare Parts Lists 15

UF3 - DN design - RN 01.054.53

Inch design - RN 01.054.570

UF3-A - DN design - RN 01.054.54

Inch design - RN 01.054.571

UFR3 - DN design - RN 01.054.55

Inch design - RN 01.054.573

UFR3-A - DN design - RN 01.054.56

Inch design - RN 01.054.572

UF3 - Inch 3A-design - RN 01.054.574

UF3-A - Inch 3A-design - RN 01.054.575

UFR3 - Inch 3A-design - RN 01.054.576

UFR3-A - Inch 3A-design - RN 01.054.577

1

Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

www.sks-online.com

www.sks-webshop.com

www.sks-online.com

www.sks-webshop.com

1. General Terms

2

Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

DELTA UF3-UK5.qxp / 06.2008

U

This operating manual has to be read carefully and observed by

the competent operating and maintenance personnel.

We have to point out that we will not accept any liability for

damage or malfunctions resulting from the non-compliance

with this operating manual.

Descriptions and data given herein are subject to technical

changes.

2. Safety Instructions

Danger!

- The technical safety symbol draws your attention to important

directions of operating safety. You will find it wherever the activities

described are bearing risks of personal injury.

- Disconnect electrical and pneumatic connections.

- Depressurize the line and cleaning system and discharge the lines,

if possible, before any maintenance work.

-Risk of injury by sudden valve actuation!

- Observe service instructions for a safe maintenance of the valve.

- The valve must only be assembled, disassembled and

reassembled by persons who have been trained in APV valves

or by APV service team members. If necessary, contact your local

APV representative.

- The spring cylinders are preloaded by spring force.

Opening of the actuators is strictly forbidden.

Danger to life!

Actuators which are no longer used and / or defective

must be disposed in professional manner.

Defective actuators must be returned to your

APV Solutions & Services company

for their professional disposal and

free of charge for you.

Please address to your local APV representative.

!

!

!

www.sks-online.com

www.sks-webshop.com

3. Mode of Operation

3Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

DELTA UF3-UK5.qxp / 06.2008

U

The valve has been developed for use in the brewing and

beverage industries, in the dairy and food production as well as

in chemical and pharmaceutical applications.

It deals with an universally applicable valve design featuring high

mechanical reliability and simple servicing.

The UF3/UFR3 relief valve is applied to hold a product pressure or

to discharge a product quantity, as the process requires.

If the preset opening pressure is exceeded, the valve is

opened automatically by the imminent line pressure in the

supply line (A) under the valve seat.

The liquid is drained via the discharge line (B). If the set value

adjusted falls short, the valve is closed by spring force.

The flow direction is always from A B.

Attention:

As defined by the Pressure Equipment Directive 97/23/EC,

the relief valve DELTA UF3/UFR3 is a "pressure accessory"

and not a "safet accessor ",

i.e. it must not be used as safety valve.

A

B

UF 31-A

www.sks-online.com

www.sks-webshop.com

* Seat lift actuator

The UF3 valve can be equipped with a seat lift actuator if required

for cleaning technical reasons.

(see chapter 5.)

* Valve position indication (fig. 4.1)

To indicate the valve position, proximity switches can be mounted

in the yoke area at (C).

We recommend to use our APV standard types.

Operating distance : 5mm / diameter :11mm.

If the customer decides to use a valve position indication other

than APV type, we cannot take over any guarantee for a faultless

function.

* Valve seat variants

Valve seats in flat and conical design, for special applications,

are available. Through the use of a valve seat with regulating

cone (D), the flow behaviour at low through put quantities is

improved and a “softer” valve closing is achieved.

This valve variant is called “UFR3“ (fig. 4.2).

* Housing shapes

Different housing shapes can be applied to reduce dead spaces

to a minimum.

*The spring cylinder is available with scale and hand wheel

to allow for a simple adjustment of the response pressure (fig. 4.3).

* As a special version, the pressure relief valves are available

in aseptic design (with flat diaphragm or metal bellow).

- Deviations from the standard spare parts lists result. These

special drawings and spare parts lists will be supplied separately.

4. Auxiliary Equipment

4

Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

DELTA UF3-UK5.qxp / 06.2008

U

C

scale

hand wheel

0,2

0,6

1,0

1,4

(bar)

regulating cone (D)

fig. 4.1

fig. 4.2

fig. 4.3

www.sks-online.com

www.sks-webshop.com

5Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

DELTA UF3-UK5.qxp / 06.2008

U

Optimum cleaning is given if the seat lift actuator (E) drives

the valve seat into the position “on” during the cleaning process.

During this process, the cleaning liquid can flush the seal

surfaces.

After termination of the cleaning step, the seat lift actuator is

vented and the valve seat is driven into the position “off” by

spring force.

5. Cleaning

6. Installation

- Installation has to be done in such a way that liquids can drain off

the valve housing. Vertical position is preferred.

- Valves can be welded direct into the pipeline.

(valve insert completely dismantable)

- After the installation, the set value must be adjusted by a pressure

gauge.

Adjustment: turn right = pressure increase

turn left = pressure reduction

If required, the value can be corrected during production

by turning the adjusting screw at the spring cylinder.

-Attention: Observe welding instructions.

seat lift actuator (E)

valve seat

fig. 5.1

www.sks-online.com

www.sks-webshop.com

6. Installation

6

Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

DELTA UF3-UK5.qxp / 06.2008

U

6.1 Welding Instructions

UF3

- Before welding of the valve, dismantle the valve insert from the

housing. Proceed carefully to avoid damage.

- Welding may only be carried out by certified welders (EN 287 - 1).

(seam quality EN 25817 ,,B”)

- The welding of the valve housings must be undertaken in such a

way that deformation strain cannot be transferred to the valve body.

- The preparation of the weld seam up to 3 mm thickness must be

carried out in butt manner as a square butt joint without air.

(Consider shrinkage!)

- TIG orbital welding is best!

- After welding of the valve housing or of the mating flanges and after

work at the pipelines, the corresponding parts of the installation or

pipelines must be cleaned from welding residues and soiling.

If these welding instructions are not observed, welding residues

and dirt particles can settle in the valve and cause damage.

- Any damage resulting from the nonobservance of these welding

instructions is not subject to our guarantee.

www.sks-online.com

www.sks-webshop.com

7Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

DELTA UF3-UK5.qxp / 06.2008

U

7. Dimensions / Weights

* without / with regulating cone

** weight without / with seat lift actuator

*** dimensions without / with seat lift actuator

F

* *** *** **

pressure range

(bar)

A1 A2 Ø D F L1 L2 Ø G1

in g

G2

in g

DN Inch flat cone without with DN Inch without with without with

25 1” 0-6,8 0-5,4 310 395 26 22,2 50 360 445 53 2,4 4,9

25 1” 0-10,0 0-10,0 353 438 26 22,2 50 403 488 53 2,6 5,1

40 1,5” 0-3,5 0-2,9 316 401 38 34,9 67 383 468 53 3,3 5,8

40 1,5” 0-7,5 0-6,3 359 444 38 34,9 67 426 511 53 3,5 6,0

40 1,5” 0-10,0 0-10,0 389 474 38 34,9 67 456 541 85 5,6 8,1

50 2” 0-2,1 0-1,8 322 407 50 47,6 72 394 479 53 3,8 6,3

50 2” 0-4,5 0-4,0 365 450 50 47,6 72 437 522 53 4,0 6,5

50 2” 0-10,0 0-10,0 395 480 50 47,6 72 467 552 85 6,1 8,6

65 2,5” 0-1,2 0-1,1 330 415 66 60,3 85 415 500 53 5,2 7,7

65 2,5” 0-2,7 0-2,4 373 458 66 60,3 85 458 543 53 5,4 7,9

65 2,5” 0-7,6 0-7,0 403 488 66 60,3 85 488 573 85 7,5 10,0

65 2,5” 0-10,0 0-10,0 451 536 66 60,3 85 536 621 85 8,0 10,5

3” 0-1,1 0-1,0 333 418 72,9 90 423 508 53 6,6 9,1

3” 0-2,3 0-2,1 376 461 72,9 90 466 551 53 6,8 9,3

3” 0-6,5 0-6,0 406 491 72,9 90 496 581 85 8,8 11,3

3” 0-10,0 0-10,0 454 539 72,9 90 544 629 85 9,3 11,8

80 0-0,9 0-0,8 338 423 81 98 436 521 53 6,7 9,2

80 0-1,8 0-1,7 381 466 81 98 479 564 53 6,9 9,4

80 0-5,2 0-4,8 411 496 81 98 509 594 85 9,0 11,5

80 0-10,0 0-10,0 459 544 81 98 557 642 85 9,5 12,6

100 4” 0-0,6 0-0,5 347 432 100 97,6 111 458 543 53 8,5 11,0

100 4” 0-1,2 0- 1,1 390 475 100 97,6 111 501 586 53 8,7 11,2

100 4” 0-3,5 0-3,2 420 505 100 97,6 111 531 616 85 10,8 13,3

100 4” 0-8,3 0-7,7 468 553 100 97,6 111 579 664 85 11,3 13,8

F A1 (A2)

L1 (L2)

D

Ø

Ø

UF31-A

spring cylinder

with seat lift actautor

www.sks-online.com

www.sks-webshop.com

8

Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

DELTA UF3-UK5.qxp / 06.2008

U

8. Technical Data

8.1 General

housing, housing cover

shafts: 1.4571, 1.4404

spring cylinder, yoke,

intermediate piece, operating cam

screws: 1.4301

seals

standard design: EPDM / PTFE

option: FPM, VMQ, HNBR

max. line pressure: 10 bar

max. operating temperature: 135O C EPDM, HNBR

* VMQ, FPM

short-term load: 140O C EPDM, HNBR

* VMQ, FPM

* (no steam)

air connection: 6 bar

air connection for hose: 6x1

Control pressure of seat lift actuator: 10 bar max. / 6 bar min.

Depending on the size of the spring cylinder, the response

pressure can be adjusted variably or up to max. 10 bar.

! The minimum response pressure can be > 0 bar depending on

the valve mounting position and the friction of the shaft seal.

8.2 Specification of compressed air

compressed air quality: quality class according to

DIN/ISO 8573-1

content of solid particles: qualit class 3

max. size of solid particles per m³

10000 of 0,5µm <d<1,0µm

500 of 1,0µm <d<5,0µm

content of water: qualit class 4

max. dew point temperature + 3°C

For installations at lower

temperatures or at higher altitudes,

additional measures must be

considered to reduce the pressure

dew point accordingly.

content of oil: qualit class 1

max. 0,01mg/m³

(The oil applied must be compatible with Polyurethane

elastomer materials.)

www.sks-online.com

www.sks-webshop.com

9Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

DELTA UF3-UK5.qxp / 06.2008

U

- The maintenance intervals depend on the different applications

and have to be determined by the operator carrying out regular

checks.

- Replacement of seals according to Service Instructions.

Customer stock keeping of spare seals is recommended.

For valve service we supply complete seal kits including

seal grease (see spare parts lists).

-Slightly grease all seals before their installation !!!!!

Recommendation:

APV food-grade grease for EPDM, HNBR and FPM

(0,75 kg/ tin - ref.-No. 000 70-01-019/93)

(60 g/ tube - ref.-No. 000 70-01-018/93)

or

APV food-grade grease for VMQ

(0,60 kg/ tin - ref.-No. 000 70-01-017/93)

(60 g/ tube - ref.-No. 000 70-01-016/93)

!Do not use grease on mineral oil basis for EPDM seals.

!Do not use Silicone-based grease for VMQ seals.

- Assembly of the valve according to Service Instructions.

9. Maintenance

9.1 Assembly tool

To simplify the installation of the seat seal, the following

assembly tools are available:

Assembly tool for seat seal

DN Inch ref.-No.:

25 1” 000 51 - 13 - 110/17

40 1,5” 000 51 - 13 - 111/17

50 2” 000 51 - 13 - 112/17

2,5” 000 51 - 13 - 120/17

65 000 51 - 13 - 113/17

3” 000 51 - 13 - 121/17

80 000 51 - 13 - 114/17

100 4” 000 51 - 13 - 115/17

125 000 51 - 13 - 116/17

150 000 51 - 13 - 117/17

www.sks-online.com

www.sks-webshop.com

The item numbers refer to the spare parts drawings,

drawing-No. see page 1.

10.1. Dismantling from the line system

1. Shut off line pressure in the product line.

2. Remove pneumatic air lines (seat lift actuator).

3. Release screw at the feedback support and extract proximity

switches. (If valve is not equipped with feedback, omit 10.1.3.).

4. Remove flange screws (10).

5. Screw two flange screws into the threaded bores of the valve yoke,

slightly lifting the complete valve insert.

6. Remove the flange screws and carefully lift the valve insert

vertically out of the valve housing.

10

Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

DELTA UF3-UK5.qxp / 06.2008

U

10. Service Instructions

www.sks-online.com

www.sks-webshop.com

11 Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

DELTA UF3-UK5.qxp / 06.2008

U

10. Service Instructions

10.2. Dismantling of wear parts

1. Remove housing screws (7) from housing cover (6).

2. Release screw of coupling (13) and dismantle.

3. Take the valve shaft (3) from the housing cover,

simultaneously removing the operating cam (12) and

the intermediate piece (14) of the UF valve without seat lift actuator.

4. Prick into the seat seal (2) with a peak object and carefully take it

out of the groove.

5. Release screw (11). This is to position the housing cover.

Remove the housing cover (6) and take out the two

seal parts (4, 5).

6. Press the guide ring (8) out of the yoke flange.

7. Take the guide bush (9) out of the guide ring.

8. Remove the screws (16) and separate the complete spring cylinder

(18) from the yoke (15).

9. Remove the O-ring (21) - UF3 with seat lift actuator or the guide

band (17) - UF3 without seat lift actuator.

10.3. Assembly of spring cylinder

1. Insert the O - ring (21) - UF3 with seat lift actuator or guide

band (17) - UF3 without seat lift actuator.

www.sks-online.com

www.sks-webshop.com

12

Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

DELTA UF3-UK5.qxp / 06.2008

U

10.4. Installation of seals and assembly of valve

1. Fasten the spring cylinder (18) at the yoke (15) by the screws (16).

2. Insert the guide bush (9) in the guide ring (8) and press the

complete unit into the yoke flange.

3. Insert the greased seal parts (4, 5) into the groove of the

housing cover.

4. Screw the housing cover (6) to the yoke (15) by the hexagon

screws (11).

5. Before installing the valve shaft, insert the seat seal (2).

* UF3 valve without regulating cone - use assembly tool for

seat seal.

* UF3 valve with regulating cone - install seal as follows:

Press the slightly greased seal at four spots, the wide side to the

front and the graduation to the top, into the groove.

Introduce the seal, at the four protuding loops, e.g. by a thin, dull

screwdriver into the groove and insert it by strong thumb pressure.

Proceed alternately at the four loops to get an even fit of the seal.

Finally, flatten the seal by strong pressure, e.g. by the handle of a

screwdriver and prick the blade of a small screwdriver between the

groove edge and the inner side of the seal down to the groove

ground to vent the groove.

Check the even fit of the seal after the installation.

6. UF3 valve without seat lift actuator - press the intermediate piece

(14) from the bottom into the spring cylinder (18).

7. Push the shaft (3) carefully through the housing cover (6).

8. Attach the operating cam (12) on the valve shaft (3).

9. Push the valve shaft against the intermediate piece and

connect both shaft ends with the coupling clamp (13).

Attention: The distance tube must be between the two

coupling halves when tightening the screws.

The coupling screw must not slew into the

feedback area.

10. Check the firm fit of the adjusting screw (11).

11. Insert the slightly greased housing seal (7) into the groove of the

housing cover (6).

10. Service Instructions

regulating cone

www.sks-online.com

www.sks-webshop.com

13 Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

DELTA UF3-UK5.qxp / 06.2008

U

10.5. Installation of valve

1. Place the complete valve insert carefully into the valve housing (1).

2. Enter the screws (10) and tighten them crosswise.

3. UF3 valve with seat lift actuator - mount the pneumatic air lines.

4. Installation of valve feedback.

basic adjustment: Push the proximity switch into the holder

with a 2 mm distance to the operating cam

(12).

fine adjustment: By slightly displacing the switch, the shift

point can be adjusted more precisely

if necessary. Observe the luminous

diode at the switch during this adjustment.

Fix the switch by the clamp screw.

10. Service Instructions

www.sks-online.com

www.sks-webshop.com

Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

DELTA UF3-UK5.qxp / 06.2008

U

14

11. Service Instructions

11.1. Installation of the seat seal in the valve shaft

The assembly tool consists of:

- nut

- thrust ring

- ring with venting plug

- housing

- threaded bolt.

1. Insert the valve shaft into the housing in such a manner that

the seal groove is in the valve housing.

2. Clamp the shaft in the housing by the threaded bolt.

Clamp the housing in a vice.

3. Slightly grease the seat seal with APV food-grade grease.

Then pull the seal onto the ring until stop by means of the

venting plug.

4. Introduce the ring with the seat seal into the housing and

press it down until it stops.

5. Insert the thrust ring into the housing. Screw on the nut and

tighten it until stop by means of a hook spanner.

6. Release the nut. Pull the ring and thrust ring out of the housing.

7. Take the housing out of the vice, unscrew the threaded bolts.

Take the valve shaft out of the housing.

Check the correct fit of the seat seal.

Attention:

The tool is not suited for the installation of seals in valve shafts

of UFR valves with regulating cone.

nut

thrust ring

ring

seat seal

valve shaft

housing

threaded bolt

www.sks-online.com

www.sks-webshop.com

15 Relief Valve

DELTA UF 3 (A) / UFR3 (A)

Operating Manual: Rev.5

DELTA UF3-UK5.qxp / 06.2008

U

12. Trouble Shooting

13. Spare parts lists

(see annex)

The reference numbers of the spare parts for the different valve

designs and sizes are included in the attached spare parts

drawings with corresponding lists.

Please indicate the following data to place an order

for spare parts:

- required number of parts

- reference number

- designation.

Data are subject to change.

Failure Remed

Operating position closed

Leakage at discharge side Replace seat seal (2).

Check line pressure (max. 10bar).

Check control of seat lift actuator

Leakage between housing and yoke flange Check housing seal (7) and shaft seal (4,5),

replace damaged seal.

Leakage at valve shaft Replace shaft seal (4,5).

Spring c linder

Correction at spring cylinder is not possible. Replace complete spring cylinder (18).

Seat lift actuator

Seat lift actuator does not work

(air escapes permanently from the shaft rod). Replace O-ring (21).

Seat lift actuator does not work

(air escapes permanently from the vent bore)

Replace complete spring cylinder

Do not open cylinder by force.

Spring force!

Valve feedback

Valve feedback does not work or is unprecise. Carry out fine adjustment.

www.sks-online.com

www.sks-webshop.com

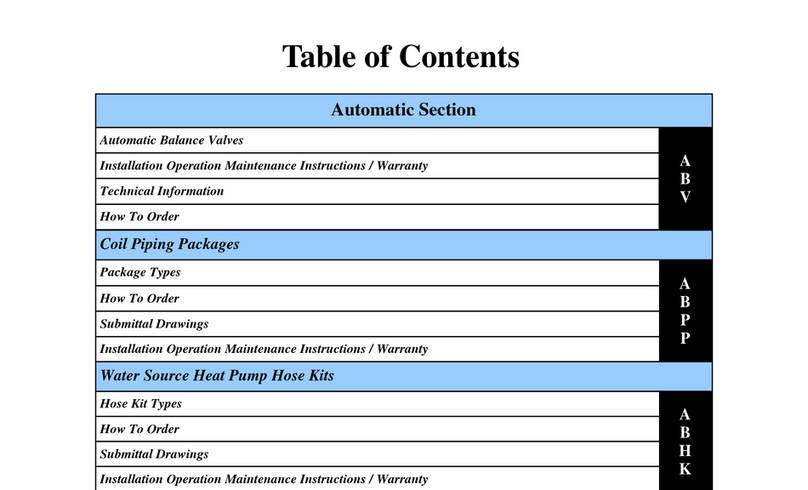

This manual suits for next models

3

Table of contents

Other SPX Control Unit manuals

SPX

SPX APV DELTA MF4 User manual

SPX

SPX APV DELTA SDU4 User manual

SPX

SPX APV DELTA DF plus 2 User manual

SPX

SPX DELTA SW4 User manual

SPX

SPX APV DELTA DE3 User manual

SPX

SPX APV DELTA SVS1F DN 125 User manual

SPX

SPX Waukesha Cherry-Burrell W Series User manual

SPX

SPX APV DELTA PR2 User manual

SPX

SPX APV DELTA M4 User manual

SPX

SPX APV DELTA MS4 User manual