6

Control Unit CU4 Direct Connect U -3 / 20.04.2011

Control Unit

CU4 Direct Connect

Instruction Manual: U -3

UK

APV

3. General Terms

3.3. Function of the individual components

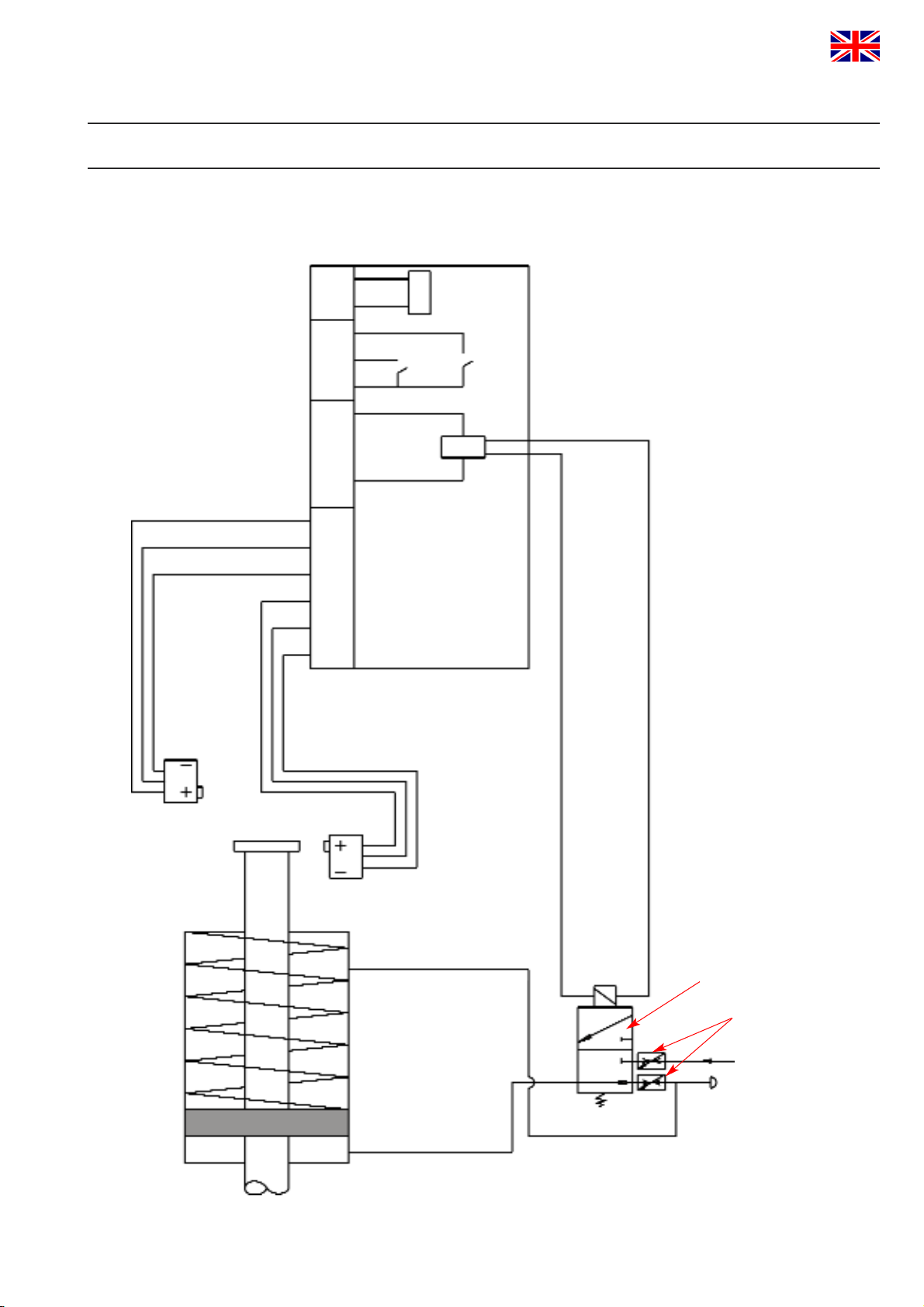

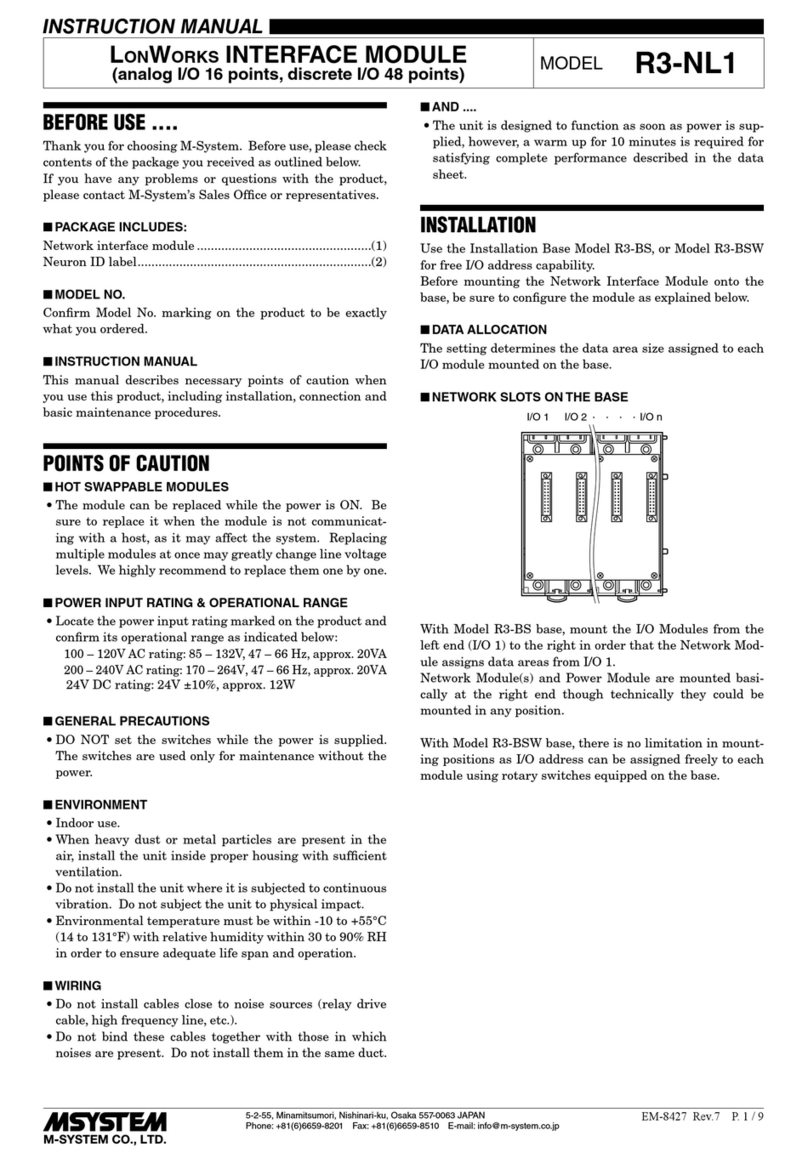

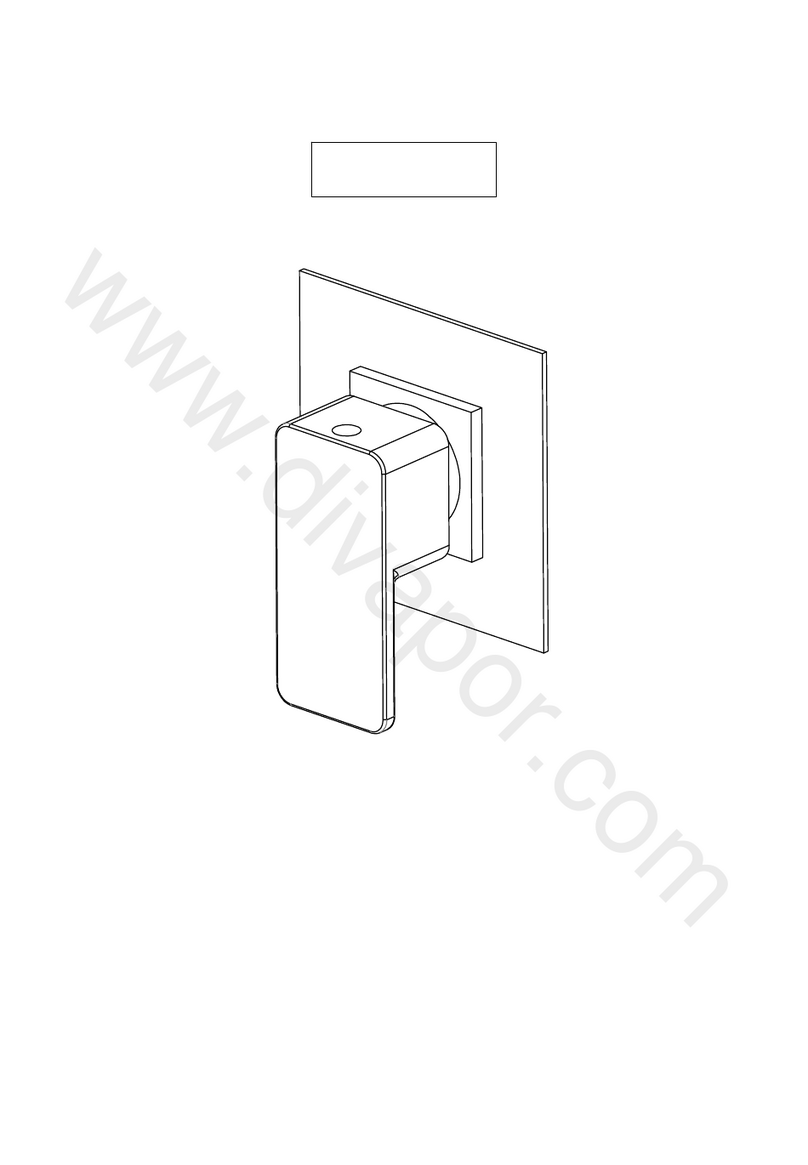

The installation of the control unit is undertaken by special

adapters which are available for the different valves types,

see chapter 5. Adapter. The snap connectors for supply air and

pneumatic air to the individual cylinders at the valves are located

at the outside of the control unit. At the control units for valves

with turning actuator, the pneumatic air is transferred internally to

the actuator. The air supply of the control unit is equipped with an

exchangeable air filter. Observance of the required compressed air

quality is imperative. Please also see chapter 4.5.

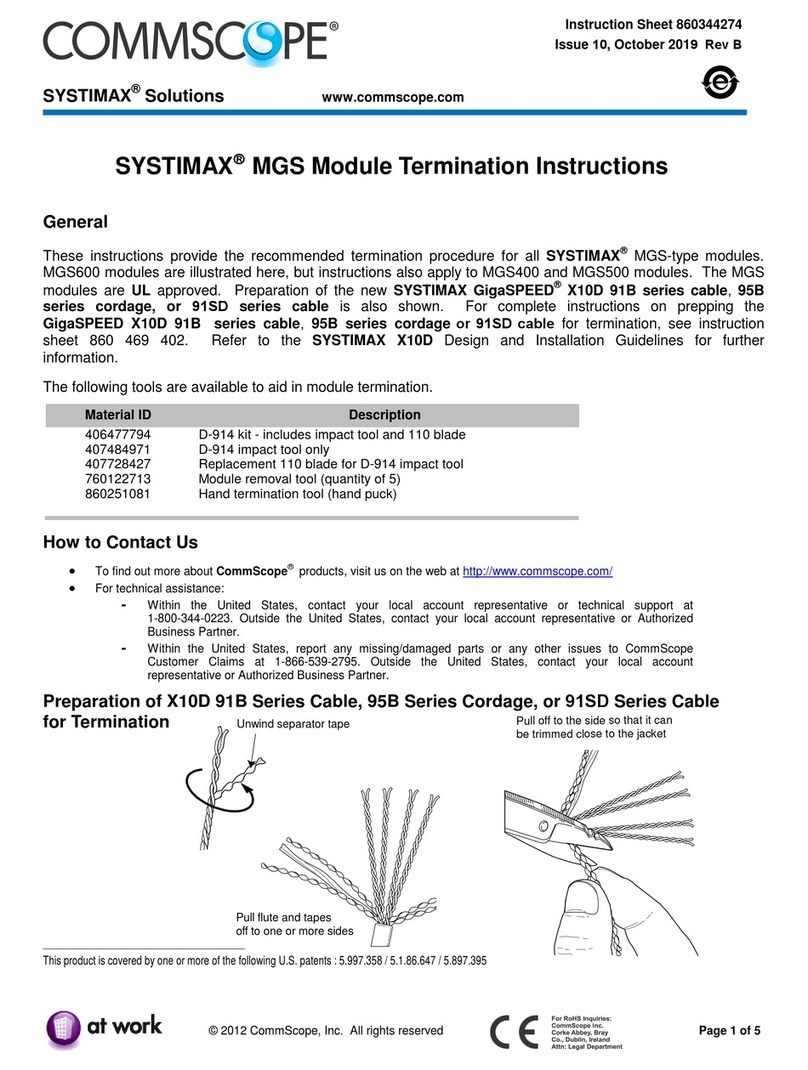

The number of the solenoid valves installed in the CU4 depends

on the valve actuators to be controlled. Single seat and butterfly

valves and double seat valves without seat lift function require 1

solenoid valve. Control units for double seat valves equipped

with 3 solenoid valves. For the manual actuation, the solenoid

valves are provided with a safe handle which is easy to operate.

The electronic module installed in the control unit fulfils the task

to process the electric signals from the control, to control the

solenoid valves and to evaluate the feedback signals from the

feedback unit. Moreover, the signalling and indication of the valve

positions as well as additional diagnostic functions are undertaken

via the electronic module.

The electronic module is the interface between control actuators or

sensors. Depending on the control type, different modules are

available, e.g. Direct Connect, AS-Interface, Profibus and

DeviceNet. The CU4 Direct Connect module described

here provides for the direct parallel wiring of the control.

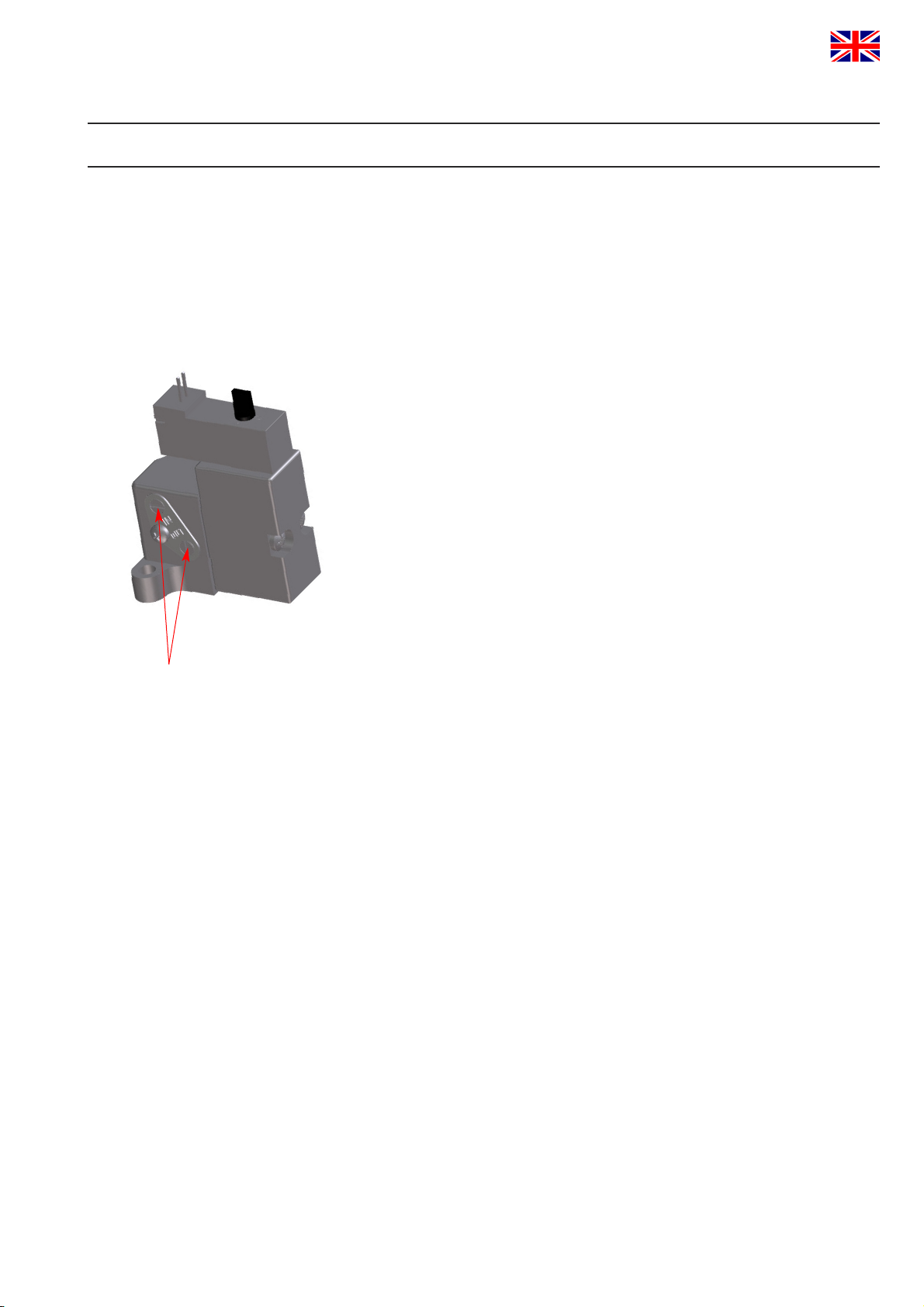

A feedback unit is required to detect the valve position.

The CU4 Direct Connect is equipped with 2 adjustable Hall

effect sensors.

These are activated by a valve control rod installed on the

operating cam. In this way, the open and closed valve position

can be detected.

The 2 Hall effect sensors are continuously adjustable over an

additional range. Thus, feedback messages for different valves

with different stroke lengths can be adjusted properly. As an

alternative, external proximity switches can be connected instead

of the integrated Hall effect sensors when the valve position

indication is undertaken direct at the process valve.