SPX PEARPOINT P350 User manual

P350 flexitrax

Pearpoint’s advanced crawler-

based video inspection system

90/P350-OPMAN-ENG/05

Operation Manual lIssue 5 lJuly 2011

P350 flexitrax system

™

P350 exitrax Operation Manual i

Preface

Before you begin

Please read this operation manual before attempting to

use the P350 exitrax system. Note that this manual and

all its contents are subject to change. Pearpoint products

are under continuous development.

Pearpoint reserves the right to modify any product, including

this manual, without notice and some product changes may

have taken place after this user manual was published.

Contact your local Pearpoint dealer or visit

www.radiodetection.com for the latest information

about the P350 exitrax product family, including all

accessories, documentation and software updates.

Important safety notices

Please observe all safety notices and warnings in this manual

before operating any Radiodetection or Pearpoint product.

Warnings, Cautions and Notes

WARNING!: Warnings alert you to possible personal

injury.

CAUTION: Cautions alert you to possible equipment

damage.

NOTE: Notes contain useful information.

Key to symbols used

General Warning: Refer to Manual for specic

instruction or advice.

Electrical Hazard: Observe safe practices and

exercise extreme caution.

Heavy object: Additional care must be taken when lifting.

Biohazard: Disinfect after use. Wear appropriate

personal protective equipment (PPE).

Hot Surface: Allow to cool or use appropriate

protection when handling.

Pinch point: Keep ngers or loose clothing clear.

General

Pearpoint has taken care to provide the necessary

information in this manual for the safe installation,

operation, maintenance and disposal of this equipment.

However, a risk assessment should be performed prior

to commencing work as it may highlight additional safety

issues specic to the application.

Installation

The P350 exitrax, including its component parts is heavy.

If available, use the wheels to assist transport. Observe

heavy-lifting safety practices when lifting any component

of this system. Refer to the specications in Appendix 9.9

for a description of the system’s dimensions and weights.

If mains operated equipment is connected to the

system then the external equipment must be earthed in

accordance with the manufacturer’s instructions. Failure

to comply with this may cause the unit to become live and

a LETHAL HAZARD.

Generator Selection

Pearpoint strongly recommends the use of generator

equipment with Inverter type outputs. This results in the

best possible quality of supply voltage to the P350 system

over varying load conditions. To power the P350 system

in isolation (in all congurations) requires an inverter output

rated at 1.2kVA, additional electrical loads connected to

the same generator will increase the overall required rating

accordingly.

Generator equipment with AVR type outputs may be

suitable for use if the minimum requirements of generator

loading for AVR operation are met under all operational

circumstances; this is one reason why inverter output

equipment is highly recommended. The minimum load

the P350 system provides can be as low as 75VA. AVR

equipment operated below its minimum loading can lead

to loss of voltage regulation that could cause damage to

the P350 system. Additional high power loads (such as a

water heater or air-conditioner) on an AVR generator can

also lead to voltage uctuations that could exceed the

maximum ratings of the P350 system.

Generator equipment that does not employ voltage

regulation techniques outlined above (e.g. condenser

output or synchro-converter output) must not be used with

the P350 system as damage to the P350 system from

unregulated voltages is likely.

If in doubt regarding generator output selection, voltage

stability or installation of the generator into a vehicle, consult

a qualied electrician and/or your generator supplier.

ii P350 exitrax Operation Manual

Operation guidelines

Please observe your company, region or country’s

Standard Code of Practice for surveying underground

utilities with CCTV equipment, if applicable, when using

this equipment.

Always carry out a risk assessment of the site to be

inspected. This equipment is NOT approved for use in

areas where hazardous gasses may be present.

Foul water systems can be a source of serious

biological hazards. Wear appropriate protection when

handling the P350 exitrax.

The camera will get hot during use. This is normal.

Exercise care when handling the camera at all times.

System components must NOT be connected/

disconnected when the power is on.

Take care to ensure that video and power cables do not

get entangled in the drum. Cables ties are recommended

and will not impede system performance.

Always store the P350 exitrax system in a clean and dry

environment.

Safety precautions

Ensure that standard safety precautions for working in

hostile environments are followed.

The exitrax Power Supply Unit (PSU) is designed to

reduce hazards from electric shock provided that proper

operating procedures are followed. The P350 exitrax

system requires connection to a protective earth; if in

doubt, consult a qualied electrician.

Electrical equipment is factory tested for electrical safety.

Routine inspection is recommended (and may be required

by law) to maintain this level of protection. If you are

unsure, contact your local safety authority for advice.

The exitrax Power Supply Unit has a number of

ventilation slots around the casing that are designed

to maximize air circulation and reduce heat. There is a

potential re risk if the build-up of heat is prevented from

escaping. Under no circumstances are these ventilation

slots to be covered or blocked.

If using a generator follow the manufacturer’s instructions

on load connection and sequencing. In the absence of

these instructions the following guidelines should be used:

When starting the generator; ensure that all electrical

loads, including the P350 are switched off before

starting the generator. Allow the generator to

stabilise before connecting any electrical loads or

switching on the P350.

•

When stopping the generator; ensure all electrical

loads, including the P350 are switched off before

stopping the generator.

Starting or stopping a generator whilst the P350

system is connected and the main switch is in the

On position could lead to damage to the P350

system or the generator.

Always use heavy duty industrial gloves when handling

cable which is being withdrawn from a sewer.

Always ensure that cabling is properly connected.

A portable generator can be a hazard if not properly

operated. Always follow the manufacturer’s instructions.

Always transport a generator with the minimum amount of

fuel in the tank.

Always switch the system on and off using the main

system switch.

Never lower crawlers or other heavy equipment into

manholes while personnel are working in the manhole.

To avoid risk of burns do not touch cameras/

lightheads when they are switched on or immediately

after switch off. Leave ample time for them to cool before

handling.

The camera’s LEDs are very powerful. Do not look

directly at the LEDs or point them at other people.

Maintenance

Clean and sanitize the P350 exitrax system at regular

intervals and after conducting an inspection.

Always keep all connectors covered with their protective

caps when the equipment is not in use.

Do not dismantle any component of this system

unless directed by this operation manual. Dismantling

components not specied by this manual may void the

product warranty.

Pearpoint recommends that only authorized service

centers carry out service of this product. Service

elsewhere will void the warranty.

For information regarding any service needs, please

visit www.radiodetection.com or contact your local

Radiodetection or Pearpoint representative or dealer.

Disposal

Do not dispose of this product in municipal waste

facilities. Please check local regulations for disposal of

electronic products.

Radiodetection complies with the requirements of

2002/96/EC Waste Electrical and Electronic Equipment.

•

•

P350 exitrax Operation Manual iii

iv P350 exitrax Operation Manual

Compliance

EU Compliance

This equipment complies with the following EU Directives.

Low Voltage Directive: 2006/95/EC

Machinery Directive: 98/37/EC

EMC Directive: 2004/108/EC

R&TTE Directive: 99/5/EC

FCC Compliance Statement

This equipment complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

The equipment may not cause harmful interference.

The equipment must accept any interference

received, including interference that may cause

undesired operation.

Note: This equipment has been tested and found

to comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against

harmful interference when the equipment is operated in

a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the

manufacturer’s instruction manual, may cause harmful

interference with radio communications. Operation of

this equipment in a residential area is likely to cause

harmful interference, in which case you will be required

to correct the interference at your own expense.

Modications: Any modications made to this equipment

that are not approved by Pearpoint may void the authority

granted to the user by the FCC to operate this equipment.

Industry Canada compliance

statements

ICES-003 Class A Notice:

This Class A digital apparatus complies with Canadian

ICES-003.

Avis NMB-003, Classe A:

Cet appareil numérique de la classe A est conforme à la

norme NMB-003 du Canada.

Bluetooth transmitter

Contains Transmitter Module FCC ID: PI409B / IC:

1931B-BISMPA33.

•

•

•

•

•

•

Trademarks

exitrax, exiprobe, FlexiSight and RD7000DL are

trademarks of Radiodetection Ltd, all rights reserved.

Pearpoint is a trademark owned by Radiodetection Ltd

- SPX Corporation.

The Bluetooth word, mark and logo are registered

trademarks of Bluetooth SIG, Inc. and any use of such

trademarks by Radiodetection is under license.

Windows, Windows XP, Windows Vista, Windows

Media Player, Windows Movie Maker, Microsoft Word

and Microsoft Ofce 97 are trademarks of Microsoft

Corporation, all rights reserved.

QuickTime, Mac, Mac OS, Finder, iMovie and Final Cut

Pro are trademarks of Apple Inc., registered in the U.S

and other countries.

Other trademarks or registered trademarks mentioned in

this document belong to their respective owners.

Disclaimer

Any third-party products (including hardware, software

and services) mentioned in this manual are for

instructional purposes only and is not an endorsement by

Radiodetection Ltd, Pearpoint and SPX Corporation.

Radiodetection Ltd does not accept any liability for loss of

data or damage to equipment when using any third-party

products.

Copyright statement

Copyright 2011 Pearpoint Ltd. / Radiodetection Ltd

– SPX Corporation. All rights reserved.

Radiodetection is a subsidiary of SPX Corporation.

SPX, Radiodetection and exitrax are trademarks of

Radiodetection Ltd. and SPX Corporation. Due to a policy

of continued development, we reserve the right to alter or

amend any published specication without notice.

This document may not be copied, reproduced,

transmitted, modied or used, in whole or in part, without

the prior written consent of Radiodetection Ltd.

Training

Pearpoint provides training services for most Pearpoint

products. Our qualied instructors will train equipment

operators or other personnel at your preferred location

or at Pearpoint headquarters.

For more information go to www.radiodetection.com

or contact your local Pearpoint representative.

P350 exitrax Operation Manual v

Table of contents

Preface i

Before you begin i

Important safety notices i

Warnings, Cautions and Notes i

Key to symbols used i

General i

Installation i

Operation guidelines i

Safety precautions i

Maintenance ii

Disposal ii

Compliance iv

EU Compliance iv

FCC Compliance Statement iv

Industry Canada compliance statements iv

Bluetooth transmitter iv

Trademarks iv

Disclaimer iv

Copyright statement iv

Training iv

Section 1 – Introduction 1

1.1 About this manual 1

1.2 Overview 1

1.3 Safety notices 1

1.4 Latest updates and information 1

Section 2 – System overview 2

2.1 Command module 2

2.1.1 Keypad 2

2.2 Cable drums 4

2.2.1 Powered drum 4

2.2.2 Manual drum 4

2.2.3 External PSU (manual system only) 4

2.2.4 Link cables 4

2.3 Crawlers and Crawler cameras 6

2.4 Pushrod reels and cameras 6

2.5 Accessories 6

Section 3 – System assembly 7

3.1 Crawler and accessories 7

3.1.1 Crawler weight (P354 Only) 7

3.1.2 Wheels and tires 8

3.1.3 Cameras 10

3.1.4 Elevator 10

3.1.5 Auxiliary Lighthead 11

3.1.6 Crawler connection 12

3.2 Crawler deployment tools 12

3.3 Manual drum and external PSU 13

3.4 Powered drum 13

3.5 Command module 13

3.5.1 Mounting 13

3.5.2 Power, data and video 13

3.5.3 Compact Flash card 13

3.5.4 Keyboard 13

3.5.5 Headset 13

3.6 External video equipment 13

Section 4 – Command module

and system setup 14

4.1 Overview 14

4.2 Powering up 14

4.3 Getting help 14

4.4 Welcome screen 14

4.5 On-screen display (OSD) 15

4.5.1 Customizing the OSD 15

4.5.2 OSD layouts 15

4.5.3 System menu timeout 16

4.5.4 Text appearance 17

4.6 System Menu 17

4.6.1 General navigation and text entry 17

4.6.2 SETUP menu 18

4.6.3 CARD menu 20

4.6.4 DVR menu 20

4.6.5 SCRN menu 22

4.6.6 DRIVE 22

4.6.7 TEXT and Report menu 23

4.7 Command module settings 24

4.8 Drum and reel settings 24

4.8.1 Drum type and cable length 24

4.9 Crawler and camera settings 24

4.9.1 Crawler wheel size 24

4.9.2 Numeric inclinometer 24

4.9.3 Camera settings 25

4.10 Company details 25

4.11 Splash and video title screens 26

4.11.1 Splash screens 26

4.11.2 Video title screen 26

4.12 Ethernet conguration 26

4.13 Restoring factory settings 27

vi P350 exitrax Operation Manual

Section 5 – System operation 28

5.1 Emergency stop 28

5.2 Deployment 28

5.2.1 Before deployment 28

5.2.2 Using the crawler deployment tool 28

5.2.3 Cable and manhole rollers 30

5.2.4 Distance counter and Auto Stop point 31

5.2.5 Sonde 31

5.3 Driving crawlers 31

5.3.1 System stop 31

5.3.2 Drive mode and OSD 31

5.3.3 Mimic 33

5.3.4 Navigating with advanced mimic 34

5.3.5 Pitch proler 34

5.3.6 Manual system 36

5.3.7 Powered drum 36

5.3.8 Steering (P356 crawler only) 37

5.3.9 Tractor power 38

5.4 Video recording 38

5.5 Still pictures 38

5.6 Camera controls 38

5.6.1 Lights 38

5.6.2 Auxiliary lighthead 38

5.6.3 Focus 39

5.6.4 Pan 39

5.6.5 Tilt or rotate. 39

5.6.6 Center 39

5.6.7 Zoom 39

5.7 Digital image controls 39

5.7.1 Pan 39

5.7.2 Rotate 39

5.7.3 Zoom 39

5.8 Pendant controller 40

5.9 Retrieving the crawler 43

Section 6 – File management and Transfer 44

6.1 CARD menu 44

6.1.1 Destination folder 44

6.1.2 Reports 45

6.1.3 Card status 45

6.1.4 Formatting the card 45

6.2 Supported card types 45

6.3 File browser 46

6.3.1 Organizing your work 46

6.3.2 Filename structure 46

6.3.3 Copying les 46

6.3.4 Moving les and folders 47

6.3.5 Renaming les and folders 47

6.3.6 Deleting les and folders 47

6.3.7 Creating folders 47

6.3.8 Sending a le with Bluetooth®: 47

6.3.9 Information 47

6.4 Viewing Pitch Log 47

6.5 Viewing JPEG pictures 48

6.6 Playing videos 48

6.6.1 Screen captures 49

6.7 USB connections 49

6.6.1 Disconnecting 49

6.8 Bluetooth®50

6.8.1 Pairing 50

6.8.2 Transferring les 50

Section 7 – Inspection reports

and text pages 52

7.1 About reports and pages 52

7.2 Defect Codes 52

7.3 Video text pages 52

7.3.1 Browsing text pages 52

7.3.2 Overlay selected page 52

7.3.3 Remove text page 52

7.3.4 Editing text pages 52

7.3.5 Changing text appearance 53

7.4 Reports 53

7.4.1 Creating a new report 54

7.4.2 Client 54

7.4.3 Company 54

7.4.4 Freetext 55

7.4.5 Observations 55

7.4.6 Photos 55

7.4.7 Site page 56

7.4.8 Survey 56

7.5 Editing reports 56

7.6 Deleting reports 57

7.7 Viewing and printing reports 57

7.7.1 Folder structure 57

7.7.2 Browsing and printing 57

7.8 Exporting reports to Word 58

7.8.1 Conversion requirements 58

7.8.2 Conversion overview 58

7.8.3 Conversion troubleshooting 59

7.8.4 Customizing the Word template 59

Section 8 – Digital Video 60

8.1 Video Specication 60

8.2 Video quality Settings 60

8.2.1 Custom quality settings 61

8.3 Advanced video options 61

P350 exitrax Operation Manual vii

8.3.1 INPUT 61

8.3.2 DESTN 62

8.3.3 FNAME 62

8.4 Video playback 62

8.4.1 Command module playback 62

8.4.2 Computer playback 62

8.5 Distributing your recordings 63

8.5.1 Producing a DVD video 64

8.5.2 Supported digital video les 64

8.5.3 Unsupported digital video les 65

8.5.4 Using data CDs, DVDs and USB ash drives 65

8.6 Converting digital videos 66

8.6.1 System requirements 66

8.6.2 Conversion software for Windows 66

8.6.3 Conversion software for Mac OS X 66

8.7 Advanced video editing 67

8.7.1 FlexiSight 67

8.7.2 DV 67

Section 9 – Appendix 68

9.1 Shortcuts 68

9.2 Care and maintenance 69

9.2.1 Terminals 69

9.2.2 Cleaning the system 69

9.2.3 Storing the system 69

9.3 Upgrading software 69

9.4 Crawler cable re-termination 71

9.5 Cable drum replacement 72

9.5.1 Disassembly 72

9.5.2 Assembly 73

9.5.3 Replacing cable 73

9.6 AVC Video licence 74

9.7 Defect codes text le 74

9.7.1 Text encoding 74

9.8 Specications 75

9.8.1 Environmental specications 75

9.8.2 Command module 75

9.8.3 Cable Drums 76

9.8.4 Crawlers 76

9.8.5 Cameras 76

9.8.6 Auxiliary lighthead 77

9.8.7 Elevators 77

9.8.8 Pendant Controller 77

9.8.9 Approvals 77

List of figures and tables

Figure 2.1: Command module 3

Figure 2.2: Command module rear view 3

Figure 2.3: Command module I/O panel 3

Figure 2.4: Command module keypad 3

Figure 2.5: Powered drum with command module

installed 5

Figure 2.6: Manual drum 5

Figure 2.7: Front and rear connection panels

(Common to powered drum and external PSU) 5

Figure 2.8: External PSU 5

Figure 2.9: Link cables 5

Figure 2.10: P354 crawler with P350-CAM-FW

camera installed 6

Figure 2.11: P356 crawler with P350-CAM-PTZ

camera installed 6

Figure 3.1: P356 crawler assembly 7

Figure 3.2: Connecting various tires 8

Figure 3.3: Crawler congurations (opposite) 8

Figure 3.4: Connecting a xed view camera 10

Figure 3.5: Fixed view camera 10

Figure 3.6: Pan and tilt camera 10

Figure 3.7: Pan, tilt and zoom camera 10

Figure 3.8: P350 camera elevators 11

Figure 3.9: Adjustable elevator 11

Figure 3.10: Installing the large adjustable elevator 11

Figure 3.11: Adjusting the large adjustable elevator 11

Figure 3.12: Auxiliary lighthead 11

Figure 3.13: Strain relief clamp and spring guard 12

Figure 4.1: Welcome Screen 14

Figure 4.2 System onscreen display (OSD) 15

Figure 4.3: Normal OSD layout 16

Figure 4.4: TV OSD layout 16

Figure 4.5: Custom OSD layout 16

Figure 4.6: Main screen showing top-level

system menu 17

Table 4.1: Setup menu schema. 18

Table 4.2: CARD menu schema 20

Table 4.3: DVR menu schema 21

Table 4.4 Screen menu schema 22

Table 4.5: Drive menu schema 22

Table 4.6: TEXT menu schema 23

Figure 4.7 Company information menu 25

Figure 4.8: Video title page 26

Figure 4.9: Ethernet conguration 27

Figure 5.1: Downhole cable rollers 28

Figure 5.2: Crawler grab kit 28

viii P350 exitrax Operation Manual

Figure 5.3: Crawler grab setup 29

Figure 5.4: Crawler grab and crawler 29

Figure 5.5: Crawler grab and crawler

with attached elevator 30

Figure 5.6: Crawler grab in the closed position 30

Figure 5.7: Lowering the crawler into a manhole 30

Figure 5.8: Using cable rollers 30

Figure 5.9: Driving mode OSD 32

Figure 5.10: Basic mimic 33

Figure 5.11: Steering mimic 33

Figure 5.12: Pan and tilt mimic with steering bar 33

Table 5.1: Advanced mimic controls 34

Figure 5.13: Advanced mimic controls 35

Figure 5.14: Crank handle for powered drum 37

Figure 5.15: Pendant controller 40

Figure 6.1 Compact Flash card warning page 44

Figure 6.2: CARD menu 44

Figure 6.3: Compact Flash card status page 45

Figure 6.4: Compact Flash browser 46

Figure 6.5: File browser delete and show screen 47

Figure 6.6: Windows USB hub manager 49

Figure 6.7: Bluetooth® menu 50

Figure 6.8: Bluetooth® device selection page 51

Figure 6.9: Mac OS X Sharing preferences 51

Figure 7.1: Text and Report menu 52

Figure 7.2 Video text editing page 53

Figure 7.3: Report menu 53

Figure 7.4: Report pages 54

Figure 7.5: Viewing reports in Internet Explorer 57

Figure 7.6: Report Navigation 58

Figure 7.7: FlexiSight Report select box 58

Table 8.1: Video Quality proles 60

Figure 8.1: DVR Record settings menu 60

Figure 8.2: Advanced video settings menu 60

Figure 8.3: Video playback on Windows XP

using VLC media player 63

Figure 8.4: 4:3 aspect ratio video space usage 63

Table 9.1: Miscellaneous commands and shortcuts 68

Table 9.2: Crawler commands and shortcuts 68

Table 9.3: Camera commands and shortcuts 68

Table 9.4: Video commands and shortcuts 69

Figure 9.1: Software Versions info page 69

Figure 9.2: Camera info page 70

Figure 9.3: Crawler info page 70

Figure 9.4: Drum info page 71

Figure 9.5: Command module info page 71

Figure 9.6: Drum cassette replacement (exploded) 72

Figure 9.7: Powered drum with slave side panel

and drum support channel removed 72

Figure 9.8: Adjusting the drive train 73

Figure 9.9: Cable layering sprocket and follower 73

Figure 9.10: Cable layering mechanism 73

Figure 9.11: Cable drum cassette 73

Table 9.6: Defect_codes.txt structure 74

P350 exitrax Operation Manual 1

Section 1 – Introduction

1.1 About this manual

This manual provides comprehensive operating

instructions for the P350 exitrax™ pipeline video

inspection system. Before attempting to operate the

P350 exitrax system it is very important that you read

this manual, noting all safety warnings and procedures

in the Preface, Section 1.3 and throughout the rest of

the manual.

Once you have read this manual, it is recommended that

you retain it for reference purposes. A printed version of

this manual is available on request. Please contact your

local Pearpoint representative for more information. The

rest of the manual is detailed as follows.

Section 2 includes annotated illustrations of the command

module, powered and manual drums and selected

accessories.

Section 3 provides a detailed guide to assembling the

system ready for conducting inspections.

Section 4 provides a comprehensive introduction to using

and conguring the command module.

Section 5 introduces the basics of pipeline inspections

and describes how to deploy and drive the crawler,

create video recordings and control the camera during

an inspection. Section 5 also details retrieving the crawler

safely once the inspection is concluded.

Section 6 introduces the Compact Flash card browser and

provides a detailed guide to managing your survey les.

Section 7 introduces the report writing function and

shows you how to view reports or convert them to

Microsoft Word format. Section 7 also details the ability to

edit and display system text pages.

Section 8 provides a comprehensive guide to digital video

options and settings. Section 8 also includes a guide

to converting and distributing videos for playback on

computers and other video equipment.

Section 9 is an appendix that includes reference and

other important information as well as instructions on

caring for and maintaining your P350 system.

1.2 Overview

The P350 exitrax is an advanced pipeline video

inspection system that is ideal for a broad range of

applications. This system allows operators to identify and

document pipeline faults using the latest in digital video

recording technology.

The P350 exitrax is a fully modular system; the

command module can drive any combination of drums,

cameras and crawlers and is also compatible with the

P330+ and P340 exiprobe™ range of pushrod reels and

cameras.

1.3 Safety notices

Caution must be taken when conducting any pipeline

or draining system inspection. Please observe all safety

warnings located in the Preface and throughout this

operation manual.

Before you attempt to operate the P350 exitrax

system, it is recommended that you familiarize yourself

with any additional health and safety requirements that

may be dened by company policy and any applicable

local or national laws. Contact your company’s or

local government’s health and safety ofcer for further

information.

1.4 Latest updates and information

Pearpoint may have released new system software, user

documentation or other information after you purchased

your system.

You can download the latest software, documentation

and application notes from www.radiodetection.com.

For more information about checking and upgrading your

system’s software, please refer to Appendix 9.3.

2 P350 exitrax Operation Manual

Section 2 – System overview

RJ-45 socket: Connects to a PC running

compatible reporting software.

Optional Vehicle wall mount kit: to mount the

command module to the side of your van

(not shown).

2.1.1 Keypad

Function keys: Use to select menu items or

activate shortcuts.

Camera key: Press to take screen captures.

Text key: Press to access the Text and Report

menu.

Play: Enters the card browser menu. Starts video

playback of selected le.

Pause: Press to pause video playback or

recording.

Record: Press to begin a new video recording.

Stop: Press to stop video playback or recording.

Crawler stop: Stops the crawler moving.

Arrow keys: Use for navigation and to select

system parameters.

OK: Press to select or conrm choices in the

menu system.

LED Brightness/Camera Focus keys: Adjust LED

brightness and camera focus. Fn + brightness key

to adjust camera focus.

Rotate/Pan keys: Press to rotate the camera view.

Fn + Rotate to pan left or right. Simultaneous

press will re-center the view.

Zoom/Iris keys: Press to zoom in or out of the

camera’s subject. Fn + Zoom to modify the Iris.

Simultaneous press will reset the zoom to unity,

Fn + simultaneous press will reset to automatic

iris.

Function key (Fn): Press and hold to activate

different functions.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

2.1 Command module

The command module acts as the controller and digital

video recorder and playback device. Video is displayed

on an 8” industrial LCD. Video, pictures and inspection

reports are stored on a compatible high-speed Compact

Flash card.

On/Off Switch: This switch only works when the

unit is powered by a DC source connected to the

power socket.

Keypad and function keys: Allows the operator to

control the system, select functions and edit text

entries.

Keyboard: Provides enhanced text entry

capabilities and shortcuts to access system

functions.

Display: LCD Screen shows video, images and

various on-screen system information.

Link Cable Socket: To connect the pushrod reel,

powered drum or manual external PSU to the

command module with a link cable.

Command module support clamp: To mount the

command module to the powered or manual

drum support stand or to the optional vehicle wall

mounting kit.

Fuse holder: 5x20mm T3.15A 250V cartridge

fuse.

RCA Video Jacks: Provide secondary input and

output options for external composite video

equipment.

Power Socket: DC power input from vehicle

supply, battery box or mains adapter. For use with

pushrod reels or as a standalone unit.

Compact Flash card slot: The command module

uses a Compact Flash card to store video

recordings, reports and pictures. Most stored

les can be viewed or played on the command

module or transferred to PC. Also used to store

and upload software upgrades.

Keyboard Socket: Connects the keyboard.

Audio Socket: Connects the optional headset to

record audio over videos.

USB-A socket: Reserved for future use.

USB-B socket. USB connection to transfer les to

computers.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

P350 exitrax Operation Manual 3

2

4

1

12

11

7

8

15

9

10

13

14

Figure 2.1: Command module Figure 2.3: Command module I/O panel

Figure 2.4: Command module keypad

5

Figure 2.2: Command module rear view

17

18

20

22

23 24

26

25

30

27

28

29

19

21

6

3

4 P350 exitrax Operation Manual

2.2 Cable drums

The system supports either a powered or manual drum

that can accommodate cable lengths of 100m (330’),

150m (495’) or 250m (820’). The powered drum contains

an integral power supply whilst the manual drum requires

an external power supply unit.

The cable drum cassette in the powered drum is

user-replaceable. Please refer to Appendix 9.5 for

instructions on how to remove and install the cable

drum cassette.

Optional lengths of cable are also available for both the

powered and manual drums. Please refer to Appendix 9.5

for instructions on how to remove and install the cable.

Please visit www.radiodetection.com for a complete list

of spares and accessories.

2.2.1 Powered drum

Command module support stand.

On/Off switch. Switches the system on or off.

Command module.

Reel compartment: Houses up to 250m (820’) of

cable wound onto the drum cassette.

Removable handle, handle bars and wheels:

Allow you to manoeuvre the system easily into

position.

Emergency stop: Instantly shuts off system

power. When initiated, the system must be reset.

Pendant connector: For connecting the optional

pendant controller.

Command module connector: To connect the

command module link cable.

BNC Video Jacks: Provide secondary input and

output options for external composite video

equipment.

Power supply socket: To connect mains power.

Fuse holder: 5x20mm T12A 250V cartridge fuse.

Crank handle: Will allow the manual retrieval of

the deployed cable. (Not shown).

Optional vehicle mounting rails: To secure the

system in your van. (Not shown).

Cable rollers.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

2.2.2 Manual drum

Cable drum: Houses up to 250m (820’) of cable.

Cable brake.

Crawler connection terminal (Not shown).

Crank handle socket.

Command module support clamp.

PSU link cable socket.

Manual layering handle: To assist with laying cable

evenly on the drum.

Cable rollers.

2.2.3 External PSU (manual system only)

On/Off switch. Switches the system on or off.

Emergency stop: Instantly shuts down the system

power. When initiated, the system must be reset.

Pendant connector: To connect the optional

pendant controller.

Command module connector: To connect the

command module link cable.

BNC Video Jacks: Provide secondary input and

output options for external composite video

equipment.

Power supply socket: To connect mains power.

Fuse holder: 5x20mm T12A 250V cartridge fuse.

Link cable connection for manual drum.

2.2.4 Link cables

Command module link cable.

Manual drum link cable.

15.

16.

17.

18.

19.

20.

21.

22.

2.

6.

7.

8.

9.

10.

11.

23.

24.

25.

P350 exitrax Operation Manual 5

Figure 2.5: Powered drum with command module installed

1

4

5

3

Figure 2.7: Front and rear connection panels (Common to powered

drum and external PSU)

8

9

10

2

11

7

6

Figure 2.8: External PSU

23

Figure 2.6: Manual drum

20

16

15

19

18

Figure 2.9: Link cables

24

25

22 22

14

21

6 P350 exitrax Operation Manual

2.3 Crawlers and Crawler cameras

The system offers two different crawlers: the P354

(100mm/4”) and P356 (150mm/6”). Both crawlers are

fully compatible with three interchangeable cameras.

The P350-CAM-FW is a xed, forward view camera. The

P350-CAM-PT offers pan and tilt capabilities and the

P350-CAM-PTZ offers pan, tilt and 10x optical zoom.

2.4 Pushrod reels and cameras

The command module is compatible with the full range

of P330+ and P340 exiprobe pushrod reels, cameras

and accessories. When used with a pushrod system,

the command module must be connected directly to

the pushrod coiler. Power is supplied by mains or a

vehicle adapter, which connects to the DC socket in the

command module’s I/O panel. When a pushrod system is

connected, the command module’s power switch will turn

the system on and off.

Refer to 4.8.1 for information on how to congure the

command module to drive a pushrod system

For information on assembling and using a pushrod

system, refer to the P330+ and P340 exiprobe user

documentation available on the FlexiSight installation CD

or at www.radiodetection.com.

2.5 Accessories

The P350 exitrax system features a range of accessories

that expand its functionality and range of applications.

Please visit www.radiodetection.com, for a complete list

of available accessories.

Figure 2.10: P354 crawler with P350-CAM-FW camera installed

Figure 2.11: P356 crawler with P350-CAM-PTZ camera installed

P350 exitrax Operation Manual 7

Section 3 – System assembly

The P350 exitrax allows you to congure the

system in a large number of ways, depending on the

components you have chosen for your survey. This

section provides details on assembling and setting up

a system using either the powered or manual drum

and external PSU.

WARNING! Before attempting to assemble the

system, ensure that the powered drum or the manual

PSU is switched off.

3.1 Crawler and accessories

You can congure the P354 and P356 crawlers with a

variety of wheels, tires, cameras and accessories to suit a

wide range of pipes and conduits.

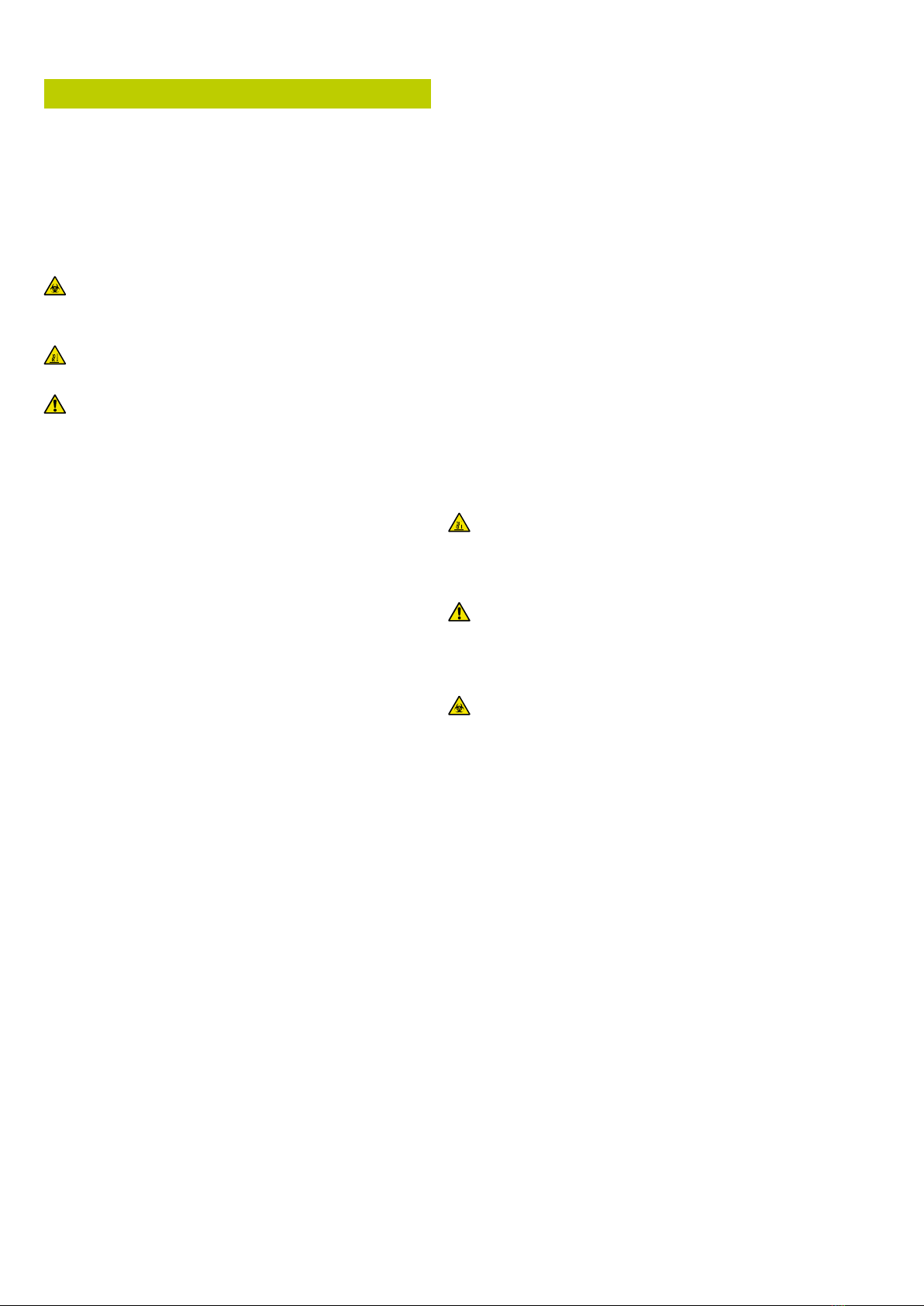

Figure 3.1 demonstrates the modularity of the crawlers.

It shows an exploded view of some of the many

congurations available.

3.1.1 Crawler weight (P354 Only)

The crawler weight is a metal plate designed to increase

traction on the P354 crawler by adding more weight to

the crawler’s body.

To x this to the body, place the weight on the crawler’s

body before adding any other components or accessories

and x in place using the supplied screws.

Figure 3.1: P356 crawler assembly

8 P350 exitrax Operation Manual

3.1.2 Wheels and tires

The P354 is compatible with the 62mm (2.5”) and 110mm

(4.3”) wheel sets, which can be connected in singular

or twin congurations. This conguration allows you to

deploy the P354 in pipes from 110mm (4”) up to 380mm

(15”) in diameter.

The P356 is compatible with the 62mm (2.5”), 110mm

(4.3”) and 170mm (6.7”) wheels, which can be connected

in singular or tandem congurations. This conguration

allows you to deploy the P356 in pipes from 150mm (6”)

to 610mm (24”) in diameter.

The 62 and 110mm wheel sets are compatible with a

hard or soft tire set to suit most traction requirements.

Figure 3.2: Connecting various tires

Figure 3.3: Crawler configurations (opposite)

For a complete list of compatible wheels and tires, please

visit www.radiodetection.com.

Figure 3.3 (opposite) shows a range of recommended

wheel and elevator congurations to suit a variety of

pipe diameters and to position the chosen camera in the

center of the pipe.

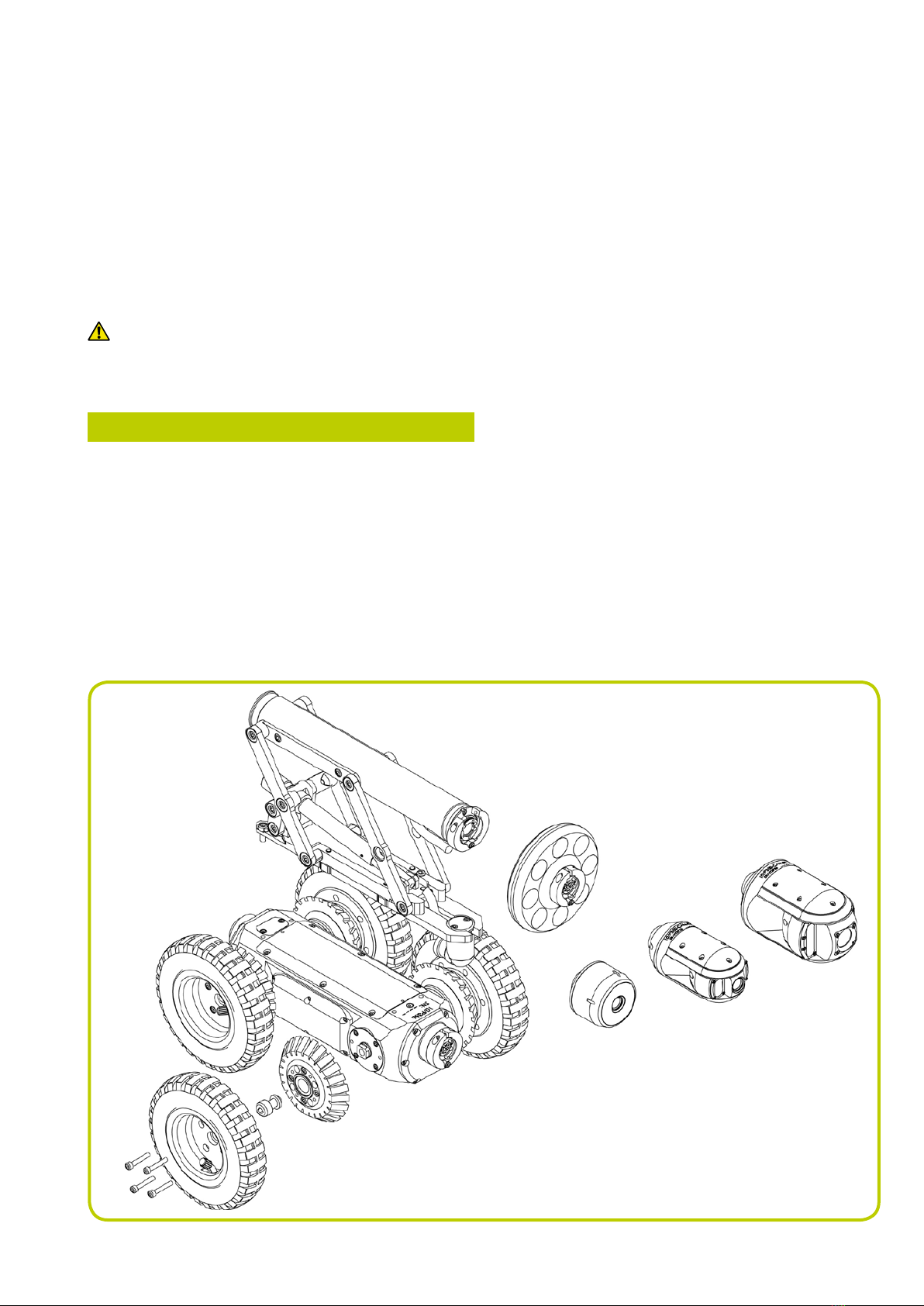

Connecting wheels and tires

Figure 3.2 demonstrates how to attach wheels and tires

to the P354 and P356 crawlers (62mm and 110mm only).

The inner hub is located on the crawler’s body. Place the

wheel on the inner hub and secure in place using the

outer hub clamp.

NOTE: Make sure you afx the wheel screws rmly to

the crawler body.

5

1 Inner hub

2 Wheel or tire

3 Outer hub clamp

4 Fasteners

5 Washer

3

2

1

4

P350 exitrax Operation Manual 9

10 P350 exitrax Operation Manual

3.1.3 Cameras

The P354 and P356 are compatible with three high-

resolution cameras that support PAL or NTSC video

standards.

All cameras offer remote focus capabilities and use the

latest generation of ultra bright LEDs for optimum light

performance.

Cameras can be tted direct to the crawler’s body or to

an elevator or lighthead if used. The cameras are simple

to attach as they can only be tted in one way. A single

3mm Allen-head screw is used to secure the camera’s

collar to the crawler’s body, lighthead or elevator.

Connecting cameras

Figure 3.4 illustrates the connection of cameras using the

C-clamp connection. Note that the procedure is the same

for all supported cameras.

Figure 3.4: Connecting a fixed view camera

Supported cameras:

Fixed View camera

P350-CAM-FW (Figure 3.5): this robust and compact

camera offers a focal range from 10mm to innity and a

120 lm light source.

Figure 3.5: Fixed view camera

Pan and Tilt cameras

P350-CAM-PT (Figure 3.6): the pan and tilt capabilities

provides the crawler with almost 360° vision. The pan

and tilt camera’s focal range is from 10mm to innity; it

features a 210 lm light source.

Figure 3.6: Pan and tilt camera

P350-CAM-PTZ (Figure 3.7): this camera has the same

pan and tilt features as the P350-CAM-PT camera. The

PTZ camera also features auto focus, 10x optical zoom

with a focal range of 10mm (WIDE) to innity and a 420 lm

light source.

Figure 3.7: Pan, tilt and zoom camera

3.1.4 Elevator

The P350 elevators are used to elevate the camera and

help center it in pipes 254mm (10”) in diameter or larger,

see Figure 3.3. The elevator is installed between the

crawler and camera.

The P350 system offers a choice of 3 elevators:

P350-ELV-F xed elevator (Figure 3.8 left). The xed

elevator will deploy the P354 in pipes up to 300mm

(12") and the P356 in pipes up to 380mm (15”).

P350-ELV-A adjustable elevator (Figure 3.8 center).

The adjustable elevator will deploy the P354 in pipes

up to 350mm (15") and the P356 in pipes up to

458mm (18").

•

•

Other manuals for PEARPOINT P350

1

Table of contents