2

Table 1 – Minimum Mounting Dimensions and Bolt Torque

Minimum Required Shaft Length

Reducer Size

Tapered Bore Straight Bore

Standard

Length Shaft

Short Length

Shaft Two Collars One Collar

TA0107LM 173 110 150 131

TA1107HM 177 113 148 129

TA 2 115 HM 198 122 165 146

TA3203HM 219 139 193 167

TA4207HM 227 144 204 172

TA5215HM 263 162 228 196

TA6307HM 275 171 239 207

TA7315HM 301 194 270 232

TA8407HM 326 206 294 256

TA9415HM 325 217 311 270

TA10507HM 393 246 355 299

TA12608HM 465 295 425 346

Bushing Screw Information and Minimum Clearance for Removal

Reducer Size Fastener Size Torque in N-m A

TA0107LM M8x1.25 23 - 27 30

TA1107HM M8x1.25 23 - 27 30

TA 2 115 HM M10x1.5 23 - 27 36

TA3203HM M10x1.5 23 - 27 36

TA4207HM M10x1.5 31 – 35 36

TA5215HM M12x1.75 90 - 105 48

TA6307HM M12x1.75 90 - 105 48

TA7315HM M12x1.75 90 - 105 53

TA8407HM M12x1.75 90 - 105 53

TA9415HM M16x2 100 – 115 60

TA10507HM M16x2 100 - 115 60

TA12608HM M16x2 100 - 115 60

2. Install one bushing backup plate on the end of the hub and

secure with the supplied retaining ring. Repeat procedure

for other side.

3. Place one bushing, ange end rst, onto the driven shaft

and position per dimension “A”, as shown in Table 1. This

will allow the bolts to be threaded into the bushing for

future bushing and reducer removal.

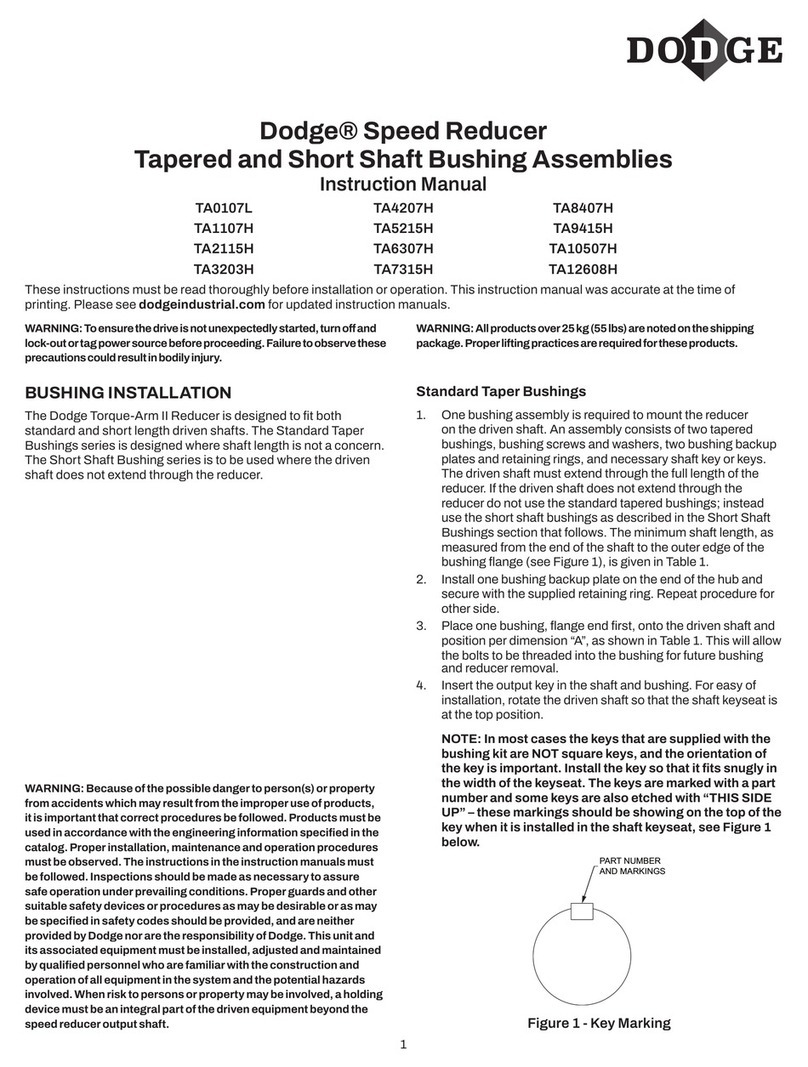

4. Insert the output key in the shaft and bushing. For ease of

installation, rotate the driven shaft so that the shaft keyseat

is at the top position.

5. Mount the reducer on the driven shaft and align the

shaft key with the reducer hub keyway. Maintain the

recommended minimum distance “A” from the shaft

bearing.

6. Insert the screws, with washers installed, in the unthreaded

holes in the bushing ange and align with the threaded holes

in the bushing backup plate. If necessary, rotate the bushing

backup plate to align with the bushing screws. Tighten the

screws lightly. If the reducer must be positioned closer than

dimension “A”, place the screws with washers installed,

in the unthreaded holes in the bushing before positioning

reducer making sure to maintain at least 3mm between the

screw heads and the bearing.

7. Place the second tapered bushing in position on the shaft

and align the bushing keyway with the shaft key. Align the

unthreaded holes in the bushing with the threaded holes in

the bushing backup plate. If necessary, rotate the bushing

backup plate to align with the bushing holes. Insert bushing

screws, with washers installed in the unthreaded holes in the

bushing. Tighten screws lightly.

8. Alternately and evenly tighten the screws in the bushing

nearest the equipment to the recommended torque given in

Table 1. Repeat procedure on outer bushing.

Short Shaft Bushings

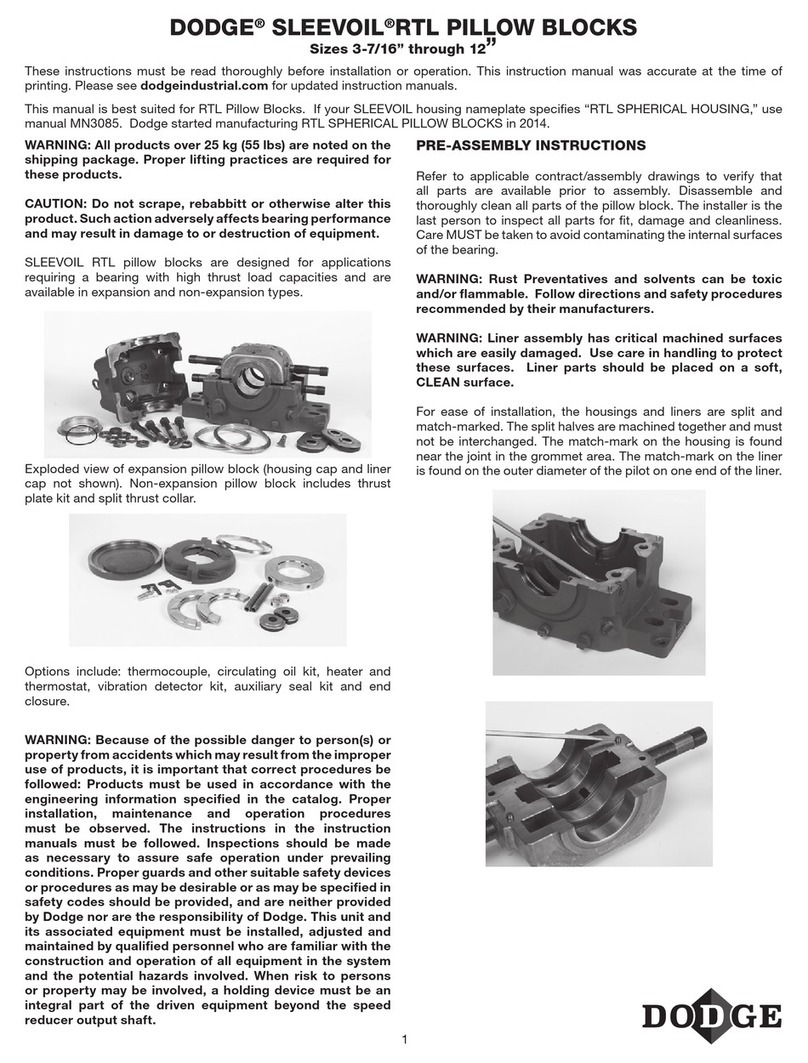

1. One bushing assembly is required to mount the reducer

on the driven shaft. An assembly consists of one long

tapered bushing, one short tapered bushing, one tapered

bushing wedge, bushing screws and washers, two bushing

backup plates and retaining rings, and necessary shaft key

or keys. The driven shaft does not need to extend through

the reducer for the short shaft bushing to operate properly.

The minimum shaft length, as measured from the end of the

shaft to the outer edge of the bushing ange (see Figure 1),

is given in Table 1.

2. The long bushing is designed to be installed from the side

of the reducer opposite the driven equipment as shown

in Figure 2. The long bushing when properly installed is

designed to capture the end of the customer shaft that does

not extend through the reducer. Normally the reducer would

be mounted such that the input shaft extends from the

side of the reducer opposite the driven equipment however

the reducer design allows installation of the reducer to be

mounted in the opposite direction.

3. Install the tapered bushing wedge into the hollow bore of

the reducer from the same side as the long bushing will be

installed. When installing the tapered bushing wedge into

the reducer hub, install the ange end rst so that the thin

taper is pointing outwards towards the long bushing as

shown in Figure 2. The wedge is properly installed when it

snaps into place in the reducer hub.

Tapered Bushing Wedge

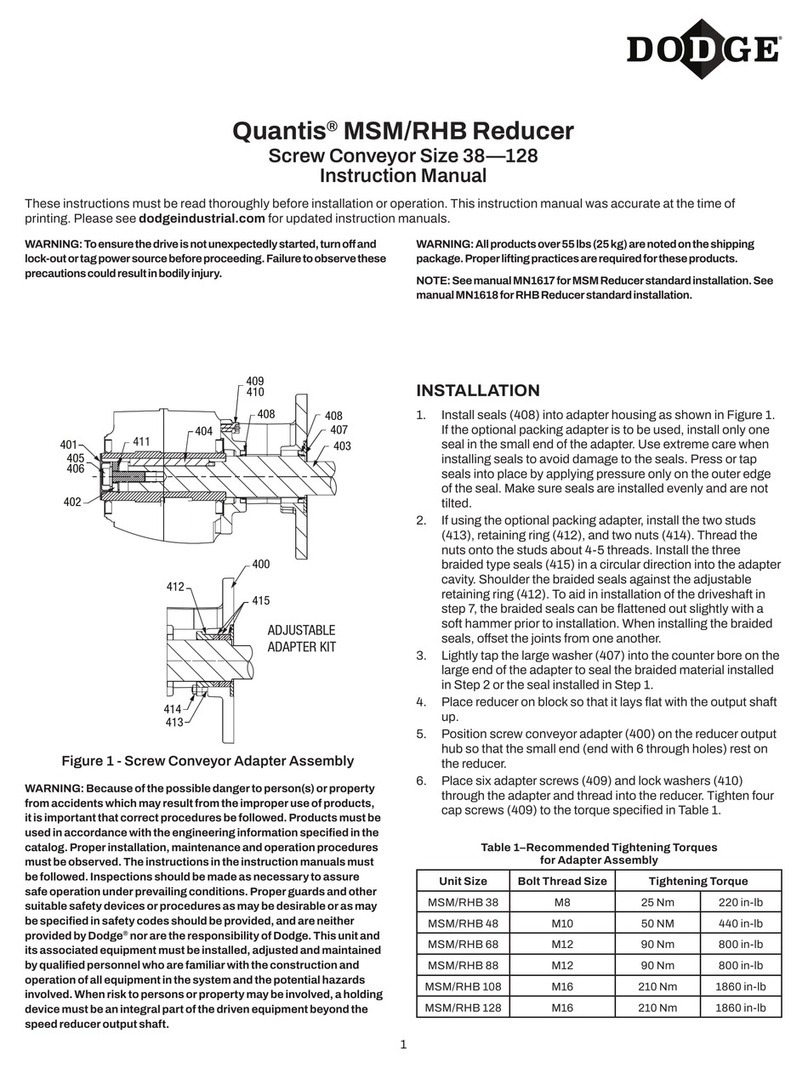

Figure 2 - Short Shaft Bushing and Output Assembly

4. Align the tapered bushing wedge keyway with the reducer

hub keyway. The keyway in the wedge is slightly wider than

the keyway in the reducer hub allowing for easier installation.

5. Install one bushing backup plate on the end of the hub and

secure with the supplied retaining ring. Repeat procedure

for other side.

6. Install the short bushing; ange rst, on the driven shaft and

position per dimension “A”, as shown in Table 1. This will

allow the bolts to be threaded into the bushing for future

bushing and reducer removal.

7. Insert the output key in the shaft and bushing. For ease of

installation, rotate the driven shaft so that the shaft keyseat

is at the top position.