Srne HESP4860S100-H User manual

Solar Hybrid Inverter V1.0

1

Solar Hybrid Inverter

User Manual

Product models:

HESP4860S100-H

Solar Hybrid Inverter V1.0

2

Important safety instructions

Please keep this manual for future use.

This manual contains all safety, installation and operating instructions for the HESP Series all-in-one

solar charge inverter.

Please read all instructions and precautions in the manual carefully before installation and use.

Non-safety voltage exists inside the all-in-one solar charge inverter. To avoid personal injury, users

shall not disassemble the all-in-one solar charge inverter themselves. Contact our professional

maintenance personnel if there is a need for repair.

Do not place the all-in-one solar charge inverter within the reach of children.

Do not install the all-in-one solar charge inverter in harsh environments such as moist, oily,

flammable or explosive, or heavily dusty areas.

The mains input and AC output are high voltage, so please do not touch the wiring terminals.

The housing of the all-in-one solar charge inverter is hot when it is working. Do not touch it.

Do not open the terminal protective cover when the all-in-one solar charge inverter is working.

It is recommended to attach proper fuse or circuit breaker to the outside of the all-in-one solar

charge inverter.

Always disconnect the fuse or circuit breaker near the terminals of PV array, mains and battery

before installing and adjusting the wiring of the all-in-one solar charge inverter.

After installation, check that all wire connections are tight to avoid heat accumulation due to poor

connection, which is dangerous.

The all-in-one solar charge inverter is off-grid. It is necessary to confirm that it is the only input

device for load, and it is forbidden to use it in parallel with other input AC power to avoid damage.

Solar Hybrid Inverter V1.0

3

CONTENTS

1. GENERAL INFORMATION ..................................................................... 4

1.1 PRODUCT OVERVIEW AND FEATURES .................................................... 4

1.2 BASIC SYSTEM INTRODUCTION ............................................................. 4

1.3 APPEARANCE ......................................................................................5

1.4 DIMENSION DRAWING .......................................................................... 6

2. INSTALLATION INSTRUCTIONS ......................................................... 8

2.1 INSTALLATION PRECAUTIONS ................................................................8

2.2 WIRING SPECIFICATIONS AND CIRCUIT BREAKER SELECTION ................... 8

2.3 INSTALLATION AND WIRING .................................................................10

2.4 PARALLEL MACHINE WIRE CONNECTION .............................................. 17

2.4.1 Introduction ........................................................................................17

2.4.2 Precautions for connecting the parallel connecting lines .................. 17

2.4.3 Schematic diagram of parallel connection in single phase ............... 19

2.4.5 Schematic diagram of parallel connection in three phase .................22

3. OPERATING MODES .......................................................................... 28

3.1 CHARGING MODE ..............................................................................28

3.2 OUTPUT MODE ................................................................................. 29

4. LCD SCREEN OPERATING INSTRUCTIONS ................................... 30

4.1 OPERATION AND DISPLAY PANEL ........................................................30

4.2 SETUP PARAMETERS DESCRIPTION .....................................................35

4.3 BATTERY TYPE PARAMETERS ............................................................. 44

5. OTHER FUNCTIONS ...........................................................................46

5.1 DRY CONTACT .................................................................................. 46

5.2 RS485 COMMUNICATION PORT ..........................................................46

5.3 CAN COMMUNICATION FUNCTION ....................................................... 46

5.4 USB COMMUNICATION PORT ............................................................. 46

5.5 PARALLEL COMMUNICATION FUNCTION (PARALLEL OPERATION ONLY) ... 47

6. PROTECTION ...................................................................................... 47

6.1 PROTECTIONS PROVIDED ................................................................... 47

6.2 FAULT CODE ..................................................................................... 50

6.3 HANDLING MEASURES FOR PART OF FAULTS ....................................... 54

7.TROUBLESHOOTING .......................................................................... 55

8. TECHNICAL PARAMETERS ...............................................................56

Solar Hybrid Inverter V1.0

4

1. General information

1.1 Product overview and features

HESP series is a new all-in-one hybrid solar charge inverter, which integrates solar energy storage &

means charging energy storage and AC sine wave output. Thanks to DSP control and advanced control

algorithm, it has high response speed, high reliability and high industrial standard. Four charging modes

are optional, i.e. Only Solar, Mains Priority, Solar Priority and Mains & Solar hybrid charging; and two

output modes are available, i.e. Inverter and Mains, to meet different application requirements.

The solar charging module applies the latest optimized MPPT technology to quickly track the maximum

power point of the PV array in any environment and obtain the maximum energy of the solar panel in

real time.

Through a state of the art control algorithm, the AC-DC charging module realizes fully digital voltage

and current double closed loop control, with high control precision in a small volume. Wide AC voltage

input range and complete input/output protections are designed for stable and reliable battery charging

and protection.

Based on full-digital intelligent design, the DC-AC inverter module employs advanced SPWM

technology and outputs pure sine wave to convert DC into AC. It is ideal for AC loads such as

household appliances, power tools, industrial equipment, and electronic audio and video equipment.

The product comes with a segment LCD design which allows real-time display of the operating data

and status of the system. Comprehensive electronic protections keep the entire system safer and more

stable.

Features:

1. Anti-backflow grid connection function, support for inverter and mains power hybrid output,

support for use without battery, can be set up for on-grid power generation.

2. Two output modes: mains bypass and inverter output; uninterrupted power supply.

3. Available in 4 charging modes: Only Solar, Mains Priority, Solar Priority and Mains & Solar

hybrid charging.

4. Advanced MPPT technology with an efficiency of 99.9%.

5. Designed with a LCD screen and 3 LED indicators for dynamic display of system data and

operating status.

6. With time slot control, you can set the priority of using the mains and battery according to

the time slot in conjunction with the local peak and valley tariffs.

7. Power saving mode available to reduce no-load loss.

8. Intelligent variable speed fan efficiently dissipate heat and extend system life.

9. Lithium battery activation by PV solar or mains, allowing access of lead-acid battery and

lithium battery.

10. 360 ° all-around protection with a number of protection functions.

11. Complete protections, including short circuit protection, over voltage and under voltage

protection, overload protection, reverse protection, etc.

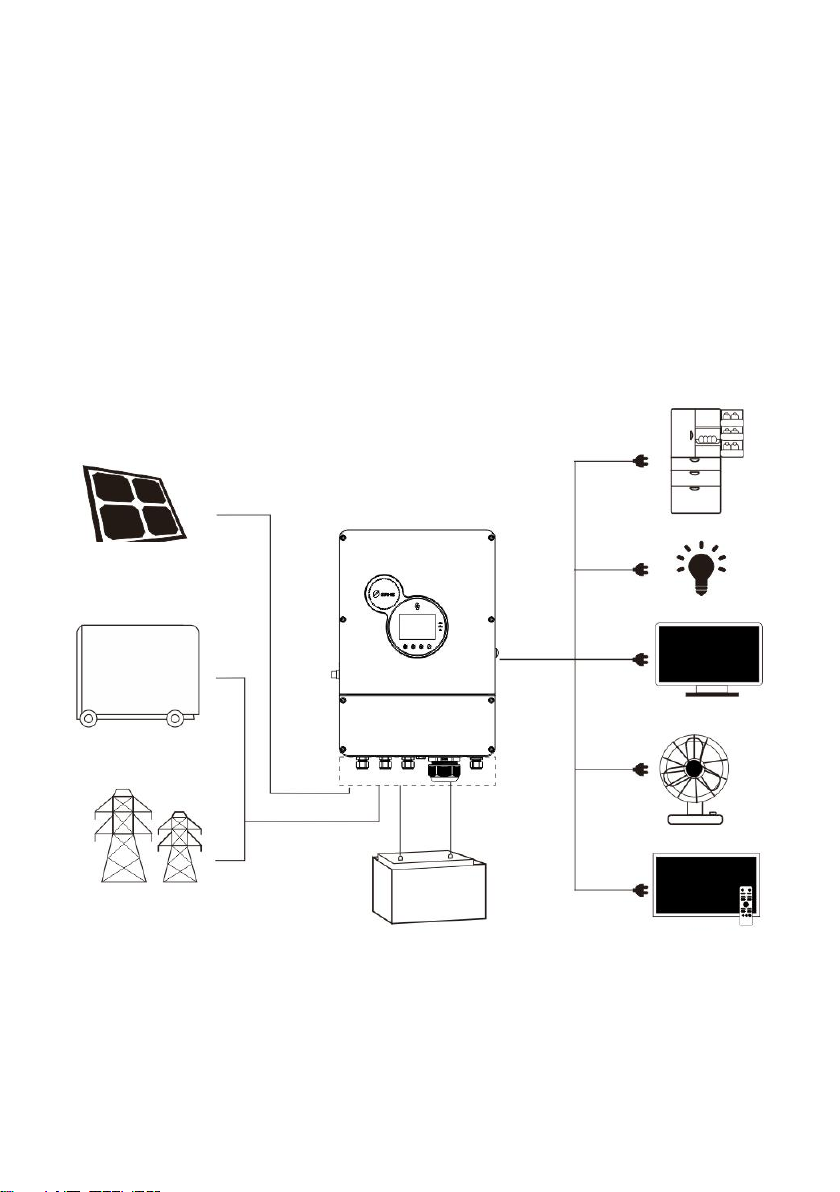

1.2 Basic system introduction

Solar Hybrid Inverter V1.0

5

The figure below shows the system application scenario of this product. A complete system consists of

the following parts:

1. PV module: Convert light energy into DC power, and charge the battery through the all-in-one

solar charge inverter, or directly invert into AC power to drive the load.

2. Mains or generator: Connected at the AC input, to power the load while charging the battery. If

the mains or generator is not connected, the system can also operate normally, and the load is

powered by the battery and PV module.

3. Battery: Provided to ensure normal power supply to the system loads when solar energy is

insufficient and the Mains is not connected.

4. Household load: Allow connection of various household and office loads, including refrigerators,

lamps, TVs, fans and air conditioners.

5. All-in-one solar charge inverter: The energy conversion unit of the whole system.

Specific system wiring method depends on the actual application scenario.

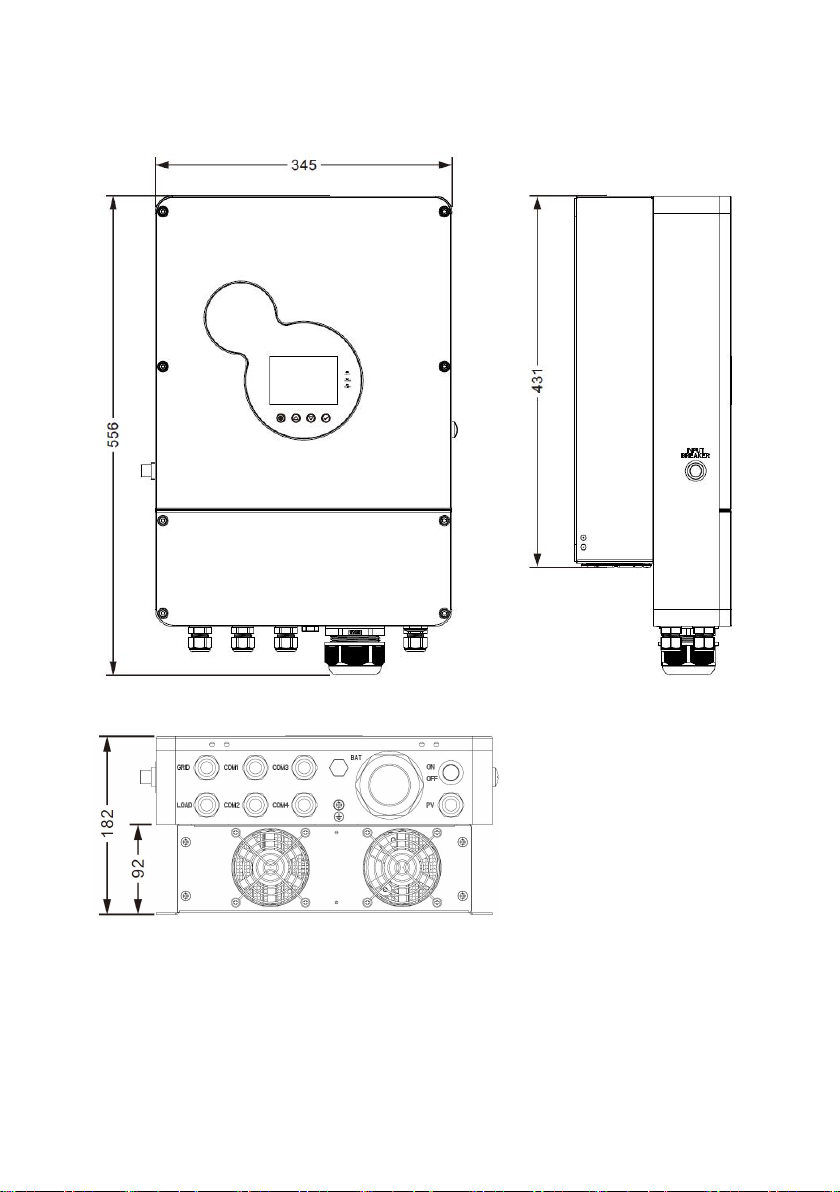

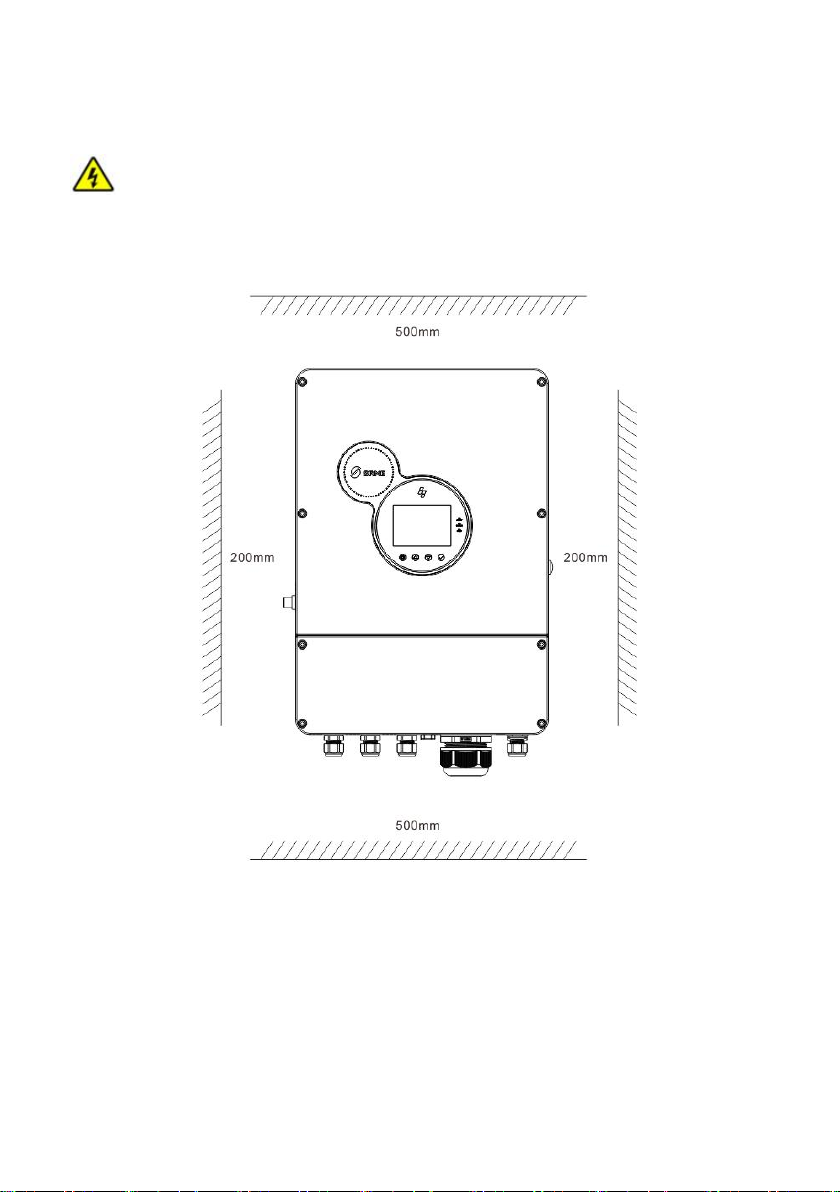

1.3 Appearance

PV array

Home Appliances

External Battery packs

Utility

Generator

or

Solar Hybrid Inverter V1.0

6

①

Indicator light

⑨

AC input

②

LCD screen

⑩

RS485-2 Communication Port

③

Touch button

⑪

USB communication port

④

PV terminal

⑫

RS485-1 Communication Port

⑤

Battery terminal

⑬

Dry-contact port

⑥

Parallel communication A port

⑭

Overload protector

⑦

Parallel communication B port

⑮

CAN communication port

⑧

AC output

1.4 Dimension drawing

Solar Hybrid Inverter V1.0

7

Solar Hybrid Inverter V1.0

8

2. Installation instructions

2.1 Installation precautions

Please read this manual carefully prior to installation to familiarize yourself with the installation

steps.

Be very careful when installing the battery. Wear safety goggles when installing a lead-acid

liquid battery. Once coming into contact with the battery acid, rinse with clean water timely.

Do not place metal objects near the battery to prevent short-circuit of the battery.

Acid gas may be generated when the battery is charged. So, please ensure good ventilation.

When installing the cabinet, be sure to leave enough space around the all-in-one solar

charge inverter for heat dissipation. Do not install the all-in-one solar charge inverter and

lead-acid battery in the same cabinet to avoid corrosion by acid gas generated during

battery operation.

Only the battery that meets the requirements of the all-in-one unit can be charged.

Poorly connected connections and corroded wires may cause great heat which will melt the

wire insulation, burn the surrounding materials, and even cause fires. So, make sure the

connectors have been tightened, and the wires are secured with ties to avoid looseness of

connections caused by shaking of wires during mobile application.

The system connection wires are selected according to a current density of not more than 5

A/mm2.

Avoid direct sunlight and rainwater infiltration for outdoor installation.

Even after the power is turned off, there is still high voltage inside the unit. Do not open or

touch the internal components, and avoid related operations until the capacitor completely

discharges.

Do not install the all-in-one solar charge inverter in harsh environments such as moist, oily,

flammable or explosive, or heavily dusty areas.

Polarity at the battery input end of this product shall not be reversed, otherwise it may

damage the device or cause unpredictable danger.

The mains input and AC output are high voltage, so please do not touch the wiring terminals.

When the fan is working, do not touch it to prevent injury.

Load equipment input power needs to confirm that this all-in-one solar charge inverter is the

only input device, and it is forbidden to use in parallel with other input AC power to avoid

damage. It is necessary to confirm that the solar charge inverter is the only input device for

load equipment, and it is forbidden to use it in parallel with other input AC power to avoid

damage.

2.2 Wiring specifications and circuit breaker selection

Solar Hybrid Inverter V1.0

9

Wiring and installation must comply with national and local electrical codes.

Recommended PV array wiring specifications and circuit breaker selection: Since the output current of

the PV array is affected by the type, connection method and illumination angle of the PV module, the

minimum wire diameter of the PV array is calculated according to its short-circuit current; refer to the

short-circuit current value in the PV module specification (the short-circuit current is constant when the

PV modules are connected in series; the short-circuit current is the sum of the short-circuit currents of

all PV modules connected in parallel); the short-circuit current of the PV array shall not exceed the

maximum input current.

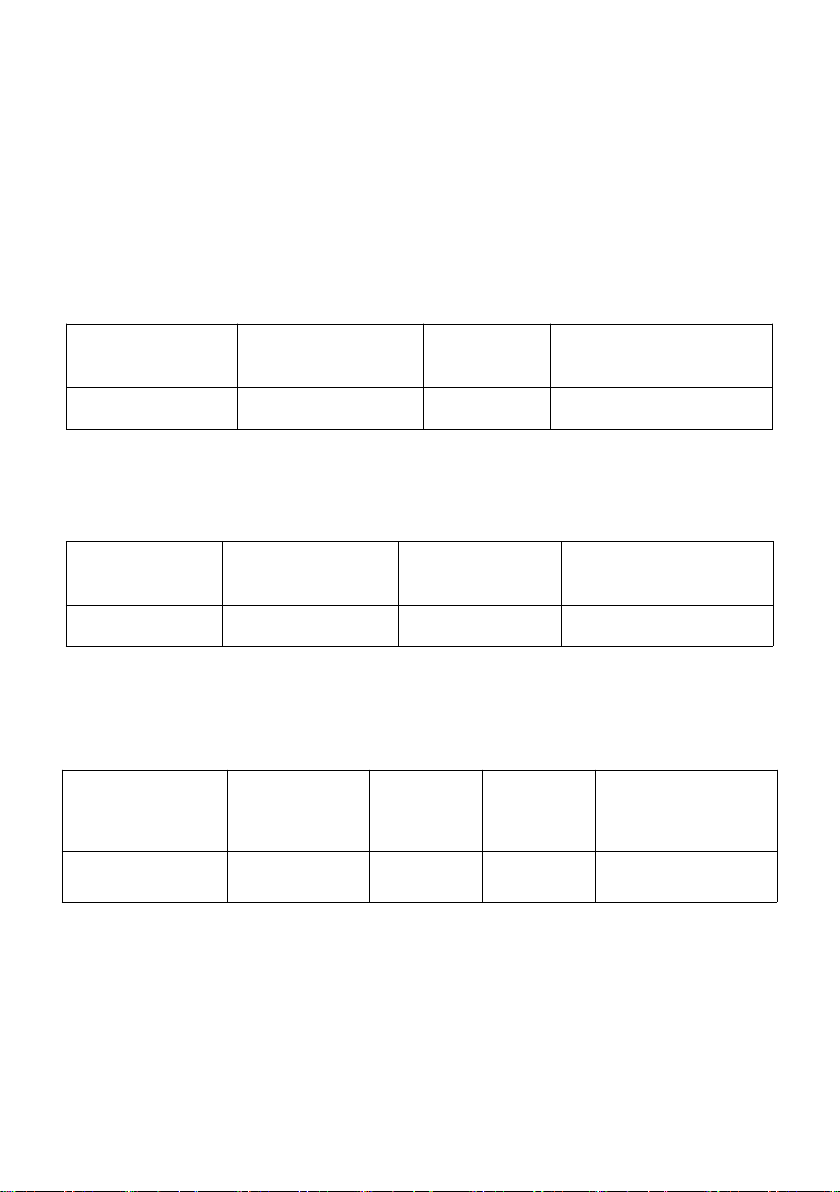

Refer to the table below for PV input wire diameter and switch:

Models

Recommended PV

wiring diameter

Maximum PV

input current

Recommended circuit

breaker type

HESP4860S100-H

6mm2/10AWG

22A

2P—25A

Note: The voltage in series shall not exceed the maximum PV input open circuit voltage.

Refer to the table below for recommended AC input wire diameter and switch:

Models

Recommended AC

input wiring diameter

Maximum bypass

input current

Recommended circuit

breaker type

HESP4860S100-H

10mm2/7AWG

40A

2P—40A

Note: There is already an appropriate circuit breaker at the Mains input wiring terminal, so it is not

necessary to add one more.

Recommended battery input wire diameter and switch selection

Models

Recommended

battery wiring

diameter

Rated battery

discharge

current

Maximum

charge

current

Recommended

circuit breaker type

HESP4860S100-H

30mm2/2AWG

135A

100A

2P—160A

Recommended AC output wiring specifications and circuit breaker selection

Solar Hybrid Inverter V1.0

10

Models

Recommended

AC output wiring

diameter

Rated inverter

AC output

current

Maximum

bypass output

current

Recommended

circuit breaker type

HESP4860S100-

H

10mm2/7AWG

26A

40A

2P—40A

Note: The wiring diameter is for reference only. If the distance between the PV array and the all-in-one

solar charge inverter or the distance between the all-in-one solar charge inverter and the battery is

relatively long, using a thicker wire can reduce the voltage drop to improve system performance.

Note: The above are only recommended wiring diameter and circuit breaker. Please select the

appropriate wiring diameter and circuit breaker according to actual situations.

2.3 Installation and wiring

Installation steps::

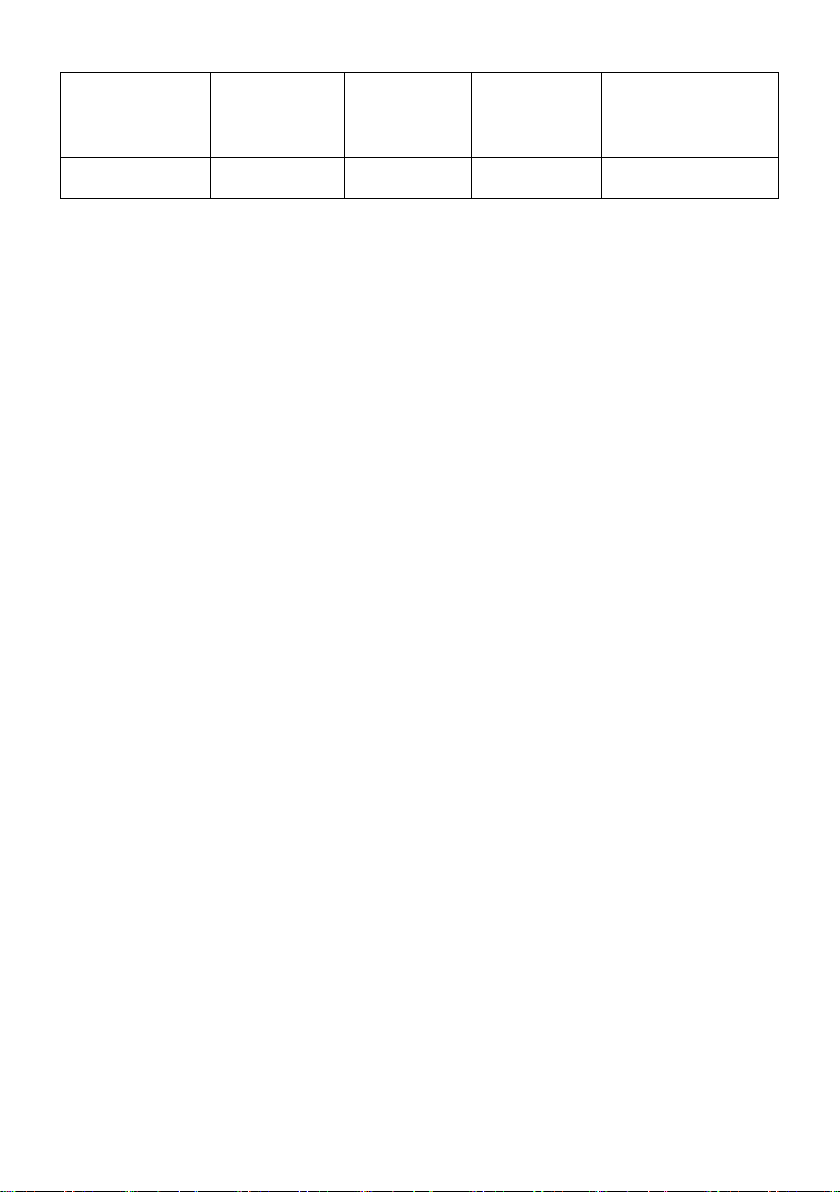

Step 1: Determine the installation position and the space for heat dissipation. Determine the installation

position of the all-in-one solar charge inverter, such as wall surface; when installing the all-in-one solar

Solar Hybrid Inverter V1.0

11

charge inverter, ensure that there is enough air flowing through the heat sink, and space of at least

200m m to the left and right air outlets of the inverter shall be left to ensure natural convection heat

dissipation. Refer to the installation diagram of the whole machine as above.

Warning: Danger of explosion! Never install the all-in-one solar charge inverter and lead-acid

battery in the same confined space! Also do not install in a confined place where battery gas may

collect.

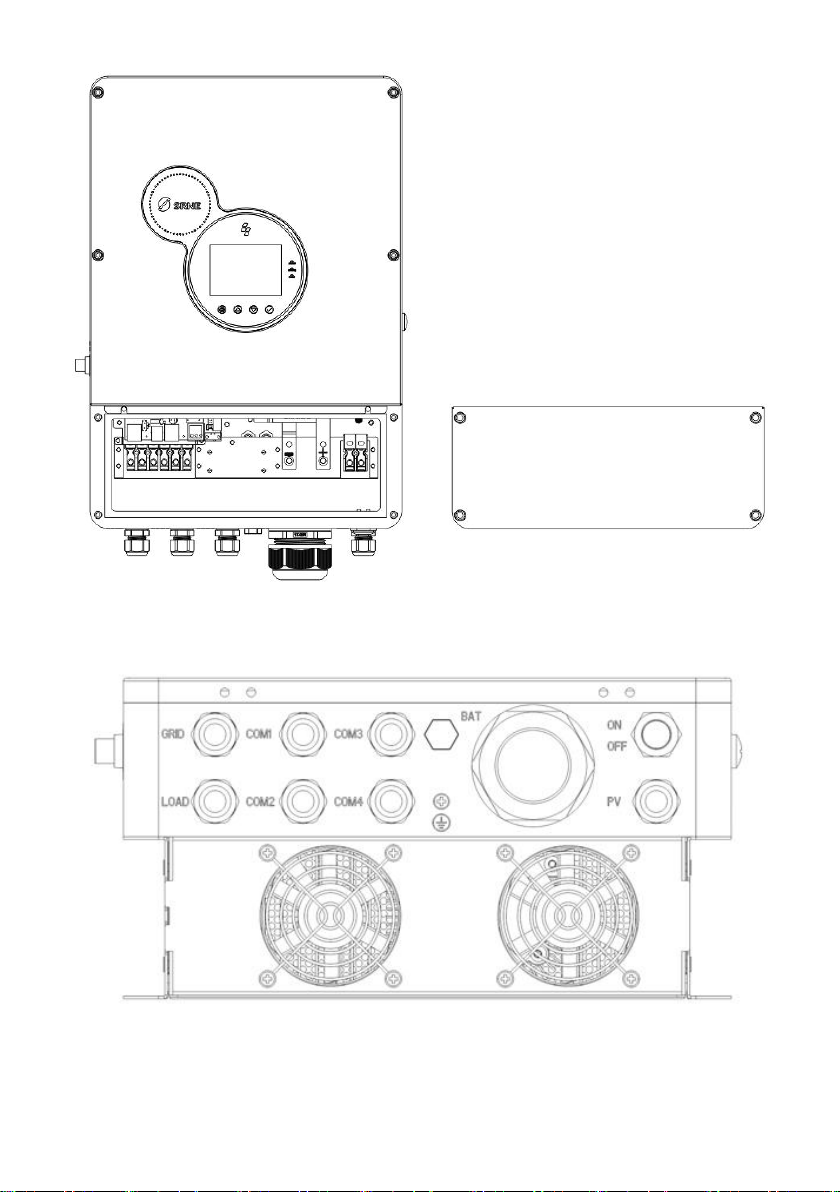

Step 2: Open 4 holes in the wall according to the following dimensions, and knock in expansion

screws, as shown in the following figure:

Solar Hybrid Inverter V1.0

12

Step 3: Hang up the machine and tighten the screws.

Step 4: Remove the terminal cover

Solar Hybrid Inverter V1.0

13

Step5: Connect the Wire. (Note: The wire shall penetrate into the corresponding joint before

crimping the terminal.)

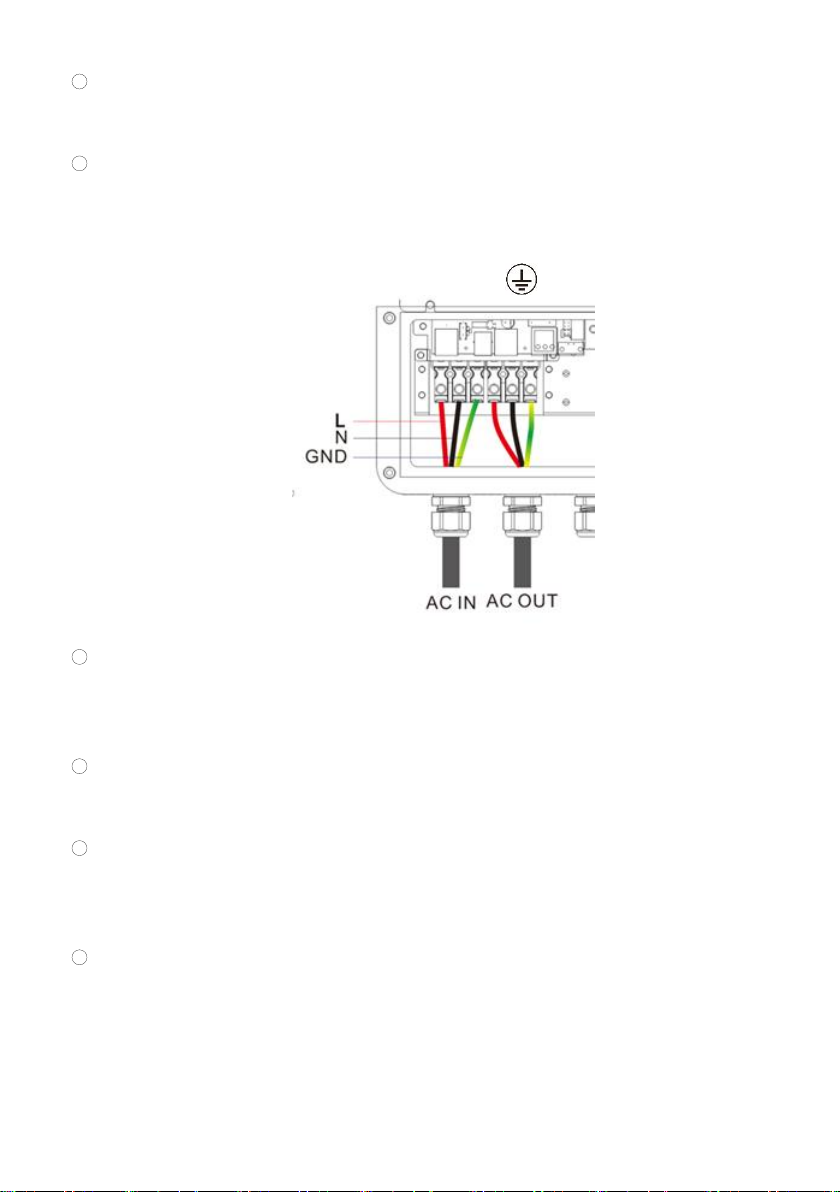

Connection method of AC I/O:

Solar Hybrid Inverter V1.0

14

1Prior to AC I/O wiring, disconnect the external circuit breaker and confirm whether the

cable used is thick enough. Please refer to Chapter "2.2 Wiring Specification and Circuit

Breaker Selection";

2According to the cable sequence and terminal position shown in the following figure,

connect the AC input line properly, please connect the grounding wire first, then connect

the live wire and the neutral wire;

L: Live Wire N: Neutral Wire : Ground Wire

3Connect the AC output line properly according to the cable sequence and terminal position

shown in the above figure. Please connect the ground wire first, then the live wire and the

neutral wire.

Wiring Method of PV Input:

1Prior to wiring, disconnect the external circuit breaker and confirm whether the cable used

is thick enough. Please refer to Chapter "2.2 Wiring Specification and Circuit Breaker

Selection";

2According to the cable sequence and terminal position shown in the following figure,

connect the PV input line properly.

BAT Wiring Method:

1Prior to wiring, disconnect the external circuit breaker and confirm whether the cable used

is thick enough. Please refer to Chapter "2.2 Wiring Specification and Circuit Breaker

Selection". BAT wire shall be connected with the machine through O-terminal. It is

recommended to use O-terminal with inner diameter of 7MM. The O-terminal must firmly

compress BAT wire to prevent excessive heating caused by excessive contact impedance;

Solar Hybrid Inverter V1.0

15

2According to the cable sequence and terminal position shown in the following figure,

connect the BAT wire properly.

Ground Wire of the Entire Machine:

As shown in the following figure, it is located on the bottom of the chassis and shall be be

connected by O-terminal. It is recommended to use O-terminal with inner diameter of 6MM.

Note: As far as possible, the ground cable should be much thicker as possible (the sectional

area of wire should not be less than 4mm2), and the grounding point should be kept close to the

Inverter as possible. The ground wire shall be shorter as possible.

Warning:

1Please be sure to disconnect the circuit breaker or fuse prior to wiring, since the mains

input, AC output and PV array will generate high voltage;

2Pay attention to safety in the process of wiring; Do Not close the circuit breaker or fuse,

and ensure the "+" and "-"pole leads of each component be connected properly in the

process of wiring; the circuit breaker must be installed at the battery end. Please refer to

Solar Hybrid Inverter V1.0

16

Chapter 2.2 “Wiring Specification and Circuit Breaker Selection” for their selection;

prior to wiring, please be sure to disconnect the circuit breaker to prevent strong electric

spark in the process of wiring and avoid short-circuiting the battery in the process of wiring; if

the inverter is applied in any area with frequent lightning, it is recommended to install an external

surge protection device at PV input.

Step 6: Check whether wires are connected properly and firmly, especially check whether

the positive and negative of the battery input are reversely connected, whether the positive and

negative of PV input are reversely connected and whether the AC input is improperly connected

to the AC output.

Step 7: Tighten the waterproof joint cover and close the machine cover back.

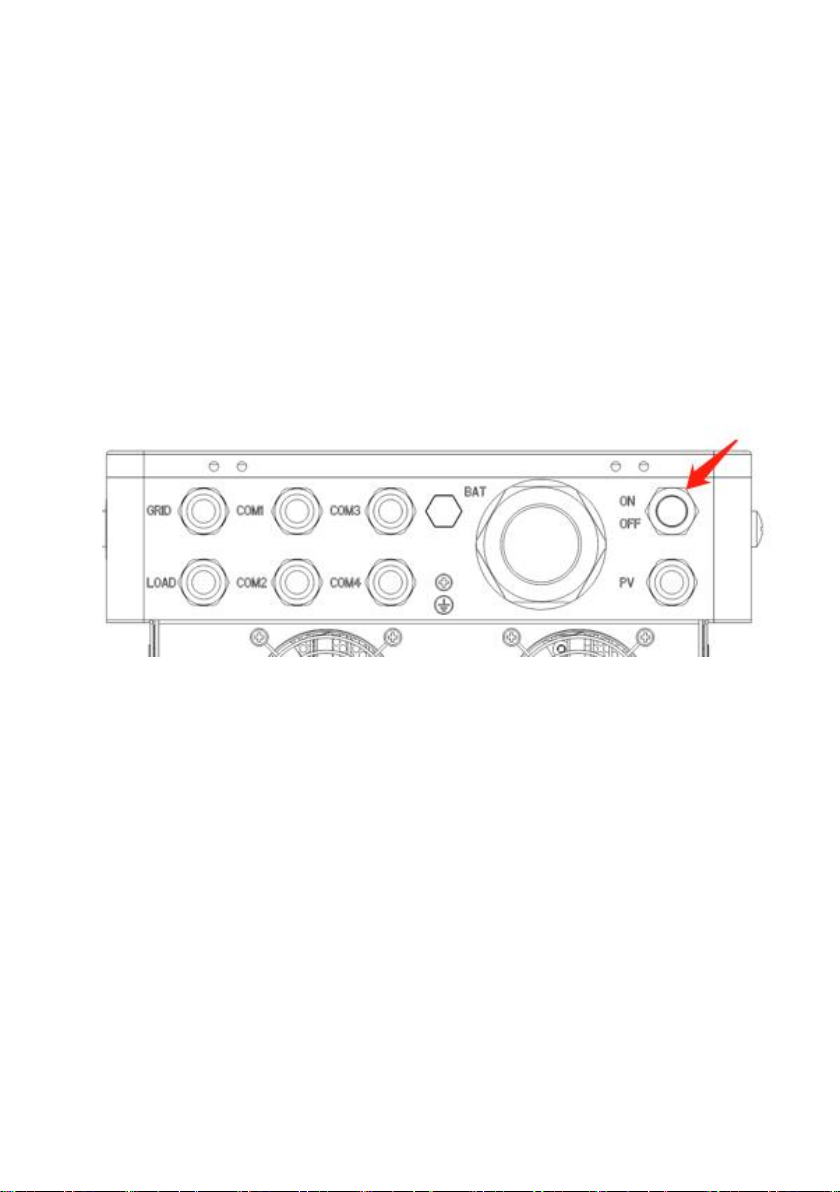

Step 8: Start the inverter

First close the circuit breaker at the battery end, then press the circular ON/OFF switch on

the right of the machine.

The flashing of "AC/INV" indicator lamp indicates that the inverter works normally. Close the

circuit breaker of PV array and Mains Power again. Finally, open the AC load one by one after

the AC output is normal so as to avoid protection action caused by major instantaneous impact

caused by opening the load at the same time and ensure that the inverter work normally in the

preset mode.

Note: If power is supplied to different AC loads, it is recommended to turn on the load with

high impulse current first, and then turn on the load with small impulse current till the load can

work stably.

Note: If the inverter is not working properly or the LCD or indicator light displays abnormally,

please refer to Chapter 6 for troubleshooting.

Solar Hybrid Inverter V1.0

17

2.4 Parallel machine wire connection

2.4.1 Introduction

1. Up to six units connected in parallel.

2. When using the parallel operation function, the following connecting lines (package

accessories) shall be firmly and reliably connected:

Parallel communication line*1:

2.4.2 Precautions for connecting the parallel connecting lines

Warning:

1. PV connection:

When used in parallel connection, different machines need to be connected to different PV

arrays or PV sources.

2. Battery wiring:

Parallel connection in single or three-phase: Ensure that all all-in-one solar charger inverters

are connected to the same battery, with BAT + connected to BAT + , BAT - connected to

BAT -, and that the connection is correct with the same wiring length and line diameter

before power on and start-up, so as to avoid the abnormal operation of parallel system

output caused by wrong connection.

3. AC OUT wiring:

Parallel connection in single phase: Ensure L-to-L, N-to-N and PE-to-PE connection for all

all-in-one solar charger inverters, and that the connection is correct with the same wiring

length and line diameter before power on and start-up, so as to avoid the abnormal operation

of parallel system output caused by wrong connection. For specific wiring, please refer to

2.4.3 Wiring Diagram

Parallel connection in three-phase: Ensure N-to-N and PE-to-PE connection for all all-in-one

Solar Hybrid Inverter V1.0

18

solar charger inverters. The Llines of all inverters connected to the same phase need to be

connected together. But Llines of different phases cannot be joined together. Other

connection precautions are the same as parallel connection in single phase. For specific

wiring, please refer to 2.4.4Wiring Diagram

4. AC IN wiring:

Parallel connection in single phase: Ensure L-to-L, N-to-N and PE-to-PE connection for all

all-in-one solar charger inverters, and that the connection is correct with the same wiring

length and line diameter before power on and start-up, so as to avoid the abnormal operation

of parallel system output caused by wrong connection. Meanwhile, it is not allowed to have

multiple different AC source inputs to avoid damage to the external equipment of the inverter.

The consistency and uniqueness of AC source input shall be ensured. For specific wiring,

please refer to 2.4.3 Wiring Diagram.

Parallel connection in three-phase: Ensure N-to-N and PE-to-PE connection for all all-in-one

solar charger inverters. The Llines of all inverters connected to the same phase need to be

connected together. But Llines of different phases cannot be joined together. Other

connection precautions are the same as parallel connection in single phase. For specific

wiring, please refer to 2.4.4 Wiring Diagram.

5. Wiring of parallel communication line:

Parallel connection in single or three-phase: Our company's parallel communication line is a

DB15 standard computer cable with shielding function. Ensure the "one-in-one-out" rule

when connecting each inverter, that is, connect the male connector (out) of this inverter with

the female connector (in) of the inverter to be paralleled. Do not connect the male connector

of the inverter to its female connector. In addition, make sure to tighten the parallel

communication line of each inverter with self-contained end screws of DB15 to avoid the

abnormal operation or damage of the system output caused by the falling off or poor contact

of the parallel communication line.

6. Wiring of current sharing detection line:

Parallel connection in single phase: Our company's current sharing detection line is a twisted

connection line. Ensure the "one-in-one-out" rule when connecting each inverter, that is,

connect the current sharing line of the inverter with the current sharing green port of the

inverter to be paralleled (choose one port from the two, and there is no mandatory sequence

requirement). The current sharing ports of the inverter cannot be connected to each other. In

addition, make sure that the red and black current sharing connection lines of each inverter

Solar Hybrid Inverter V1.0

19

are not manually exchanged, and make sure to tighten the lines with self-contained screws to

avoid the abnormal operation or damage of the system output caused by abnormal parallel

current sharing detection. For specific wiring, please refer to 2.4.3 Wiring Diagram.

Parallel connection in three-phase: The current sharing detection lines of all inverters

connected to the same phase need to be connected together. But the current sharing

detection lines of different phases cannot be joined together. Other connection precautions

are the same as parallel connection in single phase. For specific wiring, please refer to 2.4.4

Wiring Diagram.

7. Before or after connecting the system, please carefully refer to the following system wiring

diagram to ensure that all wiring is correct and reliable before power on.

8. After the system is wired, powered on and in normal operation, if a new inverter needs to be

connected, make sure to disconnect the battery input, PV input, AC input and AC output, and

that all all-in-one solar charger inverters are powered off before reconnecting into the system.

2.4.3 Schematic diagram of parallel connection in single phase

1. The parallel communication line and current sharing detection line of the all-in-one solar

charger inverter need to be locked with screws after connecting. The schematic diagram is

as follows:

2. In case of parallel operation with multiple inverters, the schematic diagram of parallel

connection is as follows:

a)Two all-in-one solar charger inverters of the system connected in parallel:

Solar Hybrid Inverter V1.0

20

b)Three all-in-one solar charger inverters of the system connected in parallel:

Table of contents

Other Srne Inverter manuals

Srne

Srne HFP4850S80-H User manual

Srne

Srne HT4830S80-145 User manual

Srne

Srne ASF4880U180-H User manual

Srne

Srne IU Series User manual

Srne

Srne ASF4880SH3 User manual

Srne

Srne HFP4850S80-145 User manual

Srne

Srne HES4855S100-H User manual

Srne

Srne HES4840S100-H User manual

Srne

Srne BP Series User manual

Srne

Srne HF2420S40-75 User manual

Srne

Srne HT4825U80 -145 User manual

Srne

Srne MC Series User manual

Srne

Srne HF4830S80-145 User manual

Srne

Srne HES4880S200-H User manual

Srne

Srne HYP4850S100-H User manual

Srne

Srne ASF4880S180-H User manual

Srne

Srne HF4825U80-145 User manual

Srne

Srne HESP Series User manual

Srne

Srne HF2430S80-H User manual

Srne

Srne HF2420U60-100 User manual