Features

Higher Energy Savings

The compressor in McQuay DC Multi Split Inverter is programmed to run at the optimum speed. The

compressor speed is controlled by input frequency that varies according to the indoor load requirements.

Once the indoor set temperature is achieved, the input frequency supply to the compressor will be reduced.

Hence, less energy is required to maintain the unit operation and this will consume less energy.

Fast Cooling

During the unit start up, the inverter air-conditioner system takes a shorter period to achieve the set room

temperature than conventional air-conditioner systems. Thus, the inverter system offers fast cooling features.

Low Starting Current

Taking advantage of the ability to modulate the compressor speed, inverter models are designed with “soft

starter” feature. The compressor motor will not draw high current during start up.

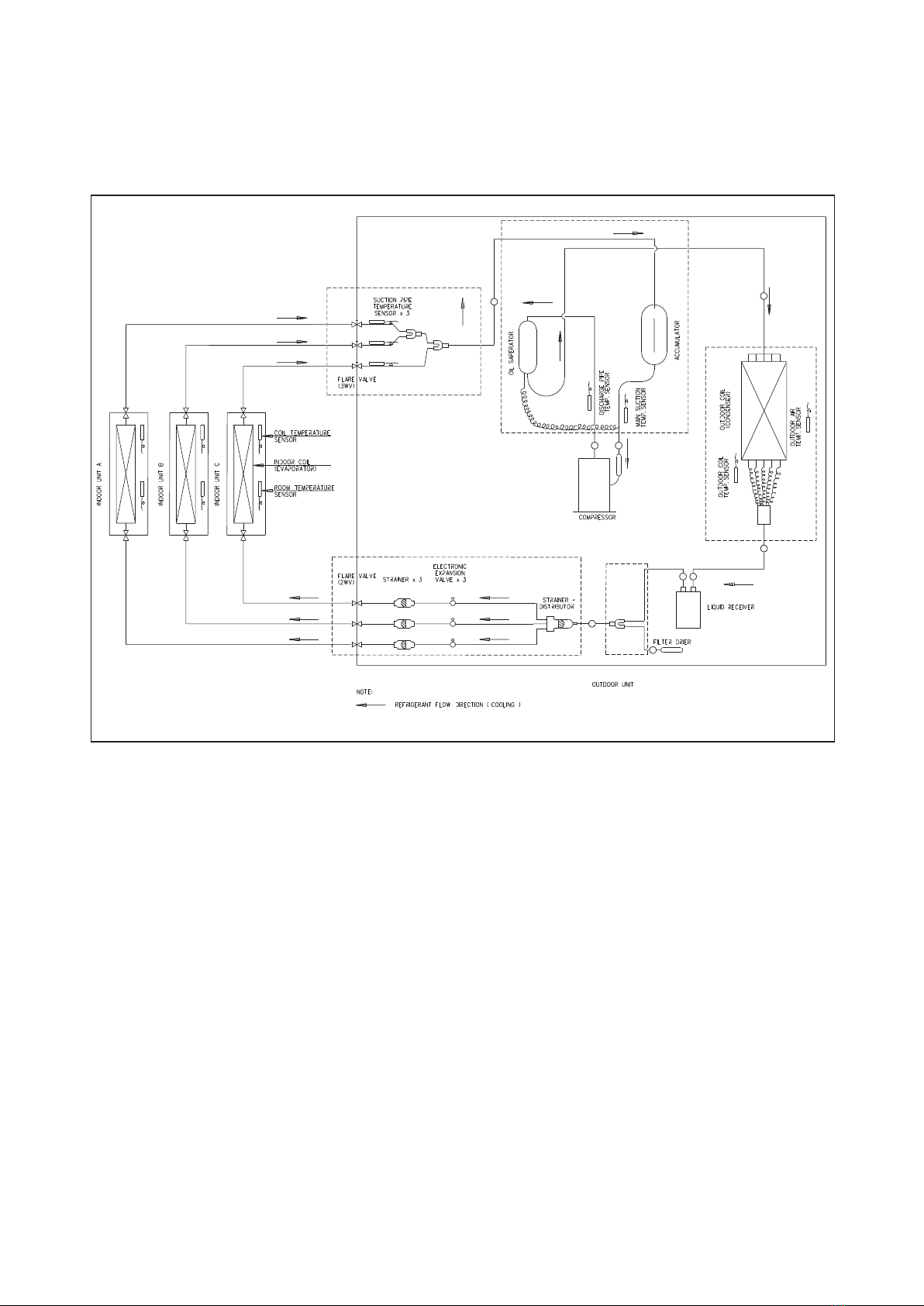

Zero-Ozone Depleting Potential Refrigerant

Introducing the new type of refrigerant – R410A which is environmental friendly with Zero Ozone Depletion

Potential (ODP = 0). R410A also provides the higher volumetric capacity and better refrigerating effect per

unit of volume.

Advance Technology

The traditional conventional air conditioners repeat “the start” and “the stop” during the thermostat cycle off

and causes the room temperature to be unstable. Incorporating fuzzy logic control into the McQuay DC Multi

Split Inverter design enables greater flexibility in handling the system control.

This result in:

•Powerful, efficient and economical operation.

•Even room temperature control.

•Constant and quiet compressor operation.

•Enhanced system reliability and reduced maintenance costs.

Low Noise Operation

McQuay DC Multi Split Inverter System has been designed to use the state-of-the-art, twin rotary compressor.

In this compressor, the roller phases are staggered 180° apart from each other. With this design, the centrifugal

forces of one roller is counterbalanced by the force of the other roller, whereby reducing the vibration of the

compressor. This makes the unit quieter and less vibration.

To further reduce the noise level, brushless DC motor is used. This further reduces noise generated by the

fan motor. Additionally, by using a bigger sized fan blade, a lower rpm is possible while maintaining ample

airflow.

Improved Compressor Life Span

For the McQuay DC Multi Split Inverter system, once the unit is started, the compressor rotation speed is

steadily ramp up or down based on load requirement throughout the operation. This control method gives

the compressor motor a smooth operation. It helps to reduce the wear and tear of the compressor motor. In

the long run, the life span of compressor is increased.

4