nekos KIMO 24V User manual

4420064 – Rev. 2010

KIMO

INSTRUCTION MANUAL

CHAIN ACTUATOR

Force 200N – Maximum stroke 210 mm

Electrical feeding 24V

NEKOS S.r.l. - Via Capitoni, 7/5 - 36064 Colceresa (VI) – ITALY

EN

2

USER INSTRUCTIONS

CAUTION. Carefully observe all the following installation

instructions to ensure personal safety.

The device is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lacking

experience and knowledge. Do not allow children to play with the

fixed controls and keep any remote-control units out of their reach.

Have installation checks performed periodically by qualified

personnel from a service centre authorised by the manufacturer. Do

not use if repair or adjustment is required.

CAUTION: if the power cable is damaged, it must be replaced by

qualified personnel from a service centre authorised by the

manufacturer.

CAUTION. Disconnect the power supply during cleaning or

maintenance operations. Do not use solvents or jets of water to

wash the appliance; the appliance should not be submerged in

water.

In the event of fault or malfunction, switch off the device at the main

switch. All repairs and adjustments (e.g. setting the stroke) must

only be performed by qualified personnel from a service centre

authorised by the manufacturer.

Always request exclusive use of original spare parts. Failure to

respect this condition could compromise safety and invalidate the

benefits contained in the warranty for the appliance. In the event of

any problems or queries, consult your agent or contact the

manufacturer directly.

The A-weighted sound pressure level is less than 70dB(A).

Carefully preserve these instructions after installation.

INSTALLER

nekos

products have been manufactured in accordance with safety standards and

conforms to the stipulations of current standards in force.

When correctly assembled, installed and used according to the present instructions, they

will not generate any danger

for persons, animals or items.

Symbols used in the manual

DANGER

Contents

1. Security rules

................................

2.

Formulas and recommendations for installation

2.1.

Calculation of opening / closure force

2.2.

Maximum opening based on sash height

3.

Technical operating information

4.

Construction and regulatory references

5. Technical data

................................

6. Id plate and marking data

................................

7. Electric power supply

................................

7.1. Selecting the cross

-

8. Electrical connection

................................

9. Instructions for assembly

................................

9.1.

Preparation for mounting the actuator

9.2.

Recessed mounting

9.3.

Surface mounting on top

windows

................................

10. Programming the actuator

10.1. Opening stroke-

end

10.2. Closure stroke-end

................................

10.3. Operation with BK-

LOCK

11.

Actuator kit with electromechanical lock

11.1.

Electrical connection and operating logic

11.2.

Sound diagnostics in case of anomaly

12.

Checking for correct assembly

13.

Emergency manoeuvres, maintenance or cleaning

14. Troubleshooting

................................

15. Environmental protection

................................

16. Certificate of guarantee

................................

17.

Declaration of incorporation (for a partly completed machine) and EC Declaration of

Conformity

................................

3

INSTALLER

INSTRU

CTIONS

products have been manufactured in accordance with safety standards and

conforms to the stipulations of current standards in force.

When correctly assembled, installed and used according to the present instructions, they

for persons, animals or items.

Symbols used in the manual

This indication draw the attention about potential dangers for safety and

health of peoples and animals.

................................

................................

................................

Formulas and recommendations for installation

................................

Calculation of opening / closure force

................................

................................

Maximum opening based on sash height

................................

Technical operating information

................................

................................

Construction and regulatory references

................................

................................

................................

................................

................................

................................

................................

................................

................................

................................

-

section of the power supply cables

................................

................................

................................

................................

................................

................................

Preparation for mounting the actuator

................................

................................

Recessed mounting

................................

................................

Surface mounting on top

-hung windows

opening outwards or bottom

................................

................................

................................

................................

................................

end

................................

................................

................................

................................

LOCK

electromechanical lock

................................

Actuator kit with electromechanical lock

................................

................................

Electrical connection and operating logic

................................

Sound diagnostics in case of anomaly

................................

Checking for correct assembly

................................

................................

Emergency manoeuvres, maintenance or cleaning

................................

................................

................................

................................

................................

................................

................................

................................

Declaration of incorporation (for a partly completed machine) and EC Declaration of

................................

................................

................................

CTIONS

products have been manufactured in accordance with safety standards and

When correctly assembled, installed and used according to the present instructions, they

This indication draw the attention about potential dangers for safety and

................................

................ 4

................................

............................ 5

................................

.. 5

................................

............................. 5

................................

..................... 6

................................

......... 6

................................

............... 7

................................

.............................. 7

................................

.... 8

................................

........ 8

................................

..... 8

................................

............................... 9

................................

10

................................

.......................... 10

opening outwards or bottom

-hung

................................

.................. 10

................................

........................... 11

................................

........................... 11

................................

............................ 11

................................

.............. 12

................................

....... 12

................................

........................... 12

................................

............................... 13

................................

.................... 13

................................

...................... 13

................................

.......... 14

................................

............................. 14

................................

............................... 14

Declaration of incorporation (for a partly completed machine) and EC Declaration of

................................

.................. 15

1. Security rules

C

AREFULLY OBSERVE ALL

ENSURE PERSONAL SAFE

SAFETY

.

MANDATORY RISK ANALY

The Nekos electrical actuators comply with the Machinery Directive (2006/42/EC),

Standard IEC 60335-2-

103 (Particular requirements for drives for gates, doors and

windows) and other directives and regulations indicated in the attached Declarations of

Incor

poration and CE Conformity (at the end of the manual). According to the Machinery

Directive, actuators are “partly completed machinery” intended for incorporation into doors

and windows. The manufacturer/supplier of the window is required, with exclusive

r

esponsibility, to ensure the compliance of the entire system with the applicable standards

and to issue CE certification. We strongly discourage any use of the actuators other than

that specified and therefore, in any case, the supplier of the complete sys

liability.

For systems installed at a height of less than 2.5 m above floor level or other levels

accessible to users, the manufacturer/supplier of the window must conduct

regarding potential harm (violent blows, crushing, w

use or possible malfunction or accidental breakage of the automated windows, and to

implement suitable

protective measures

recommended by the specified standard:

- controlling th

e actuators via a “deadman’s button” placed near the system and within

the operator’s field of view, to ensure that people are out of the way during operation.

The button must be placed at a height of 1.5 m and operated by key if accessible to

the public; or:

-

use of contact safety systems (also included in the actuators) that ensure a maximum

closing force of 400/150/25 N, measured in accordance with paragraph BB.20.107.2

of IEC 60335-2-103; or:

- use of non-

contact safety systems (lasers, light grids); or:

-

use of fixed safety barriers that prevent access to moving parts.

Automated windows are deemed adequately protected if they:

-

are installed at a height of >2.5 m; or:

- have a leading-

edge opening of <200 mm and a closing speed of <15 mm/s; or:

- are pa

rt of a smoke and heat evacuation system for emergency use only.

In any case, moving parts of windows that could fall below 2.5 m following breakage of a

system component need to be fixed or

falling or collapsing

: e.g. the use of safety arms on bottom

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge. Do

not allow children to play

out of their reach.

The actuator is destined exclusively for installation indoors. For any special

application we recommend you consult the manufacturer beforehand.

After removing packaging, check f

4

AREFULLY OBSERVE ALL

THE FOLLOWING INSTAL

LATION INSTRUCTIONS

ENSURE PERSONAL SAFE

TY

.

I

MPROPER INSTALLATION

CAN SERIOUSLY ENDANG

MANDATORY RISK ANALY

SIS AND PROTECTION MEASURES

.

The Nekos electrical actuators comply with the Machinery Directive (2006/42/EC),

103 (Particular requirements for drives for gates, doors and

windows) and other directives and regulations indicated in the attached Declarations of

poration and CE Conformity (at the end of the manual). According to the Machinery

Directive, actuators are “partly completed machinery” intended for incorporation into doors

and windows. The manufacturer/supplier of the window is required, with exclusive

esponsibility, to ensure the compliance of the entire system with the applicable standards

and to issue CE certification. We strongly discourage any use of the actuators other than

that specified and therefore, in any case, the supplier of the complete sys

For systems installed at a height of less than 2.5 m above floor level or other levels

accessible to users, the manufacturer/supplier of the window must conduct

regarding potential harm (violent blows, crushing, w

ounds) caused to people by normal

use or possible malfunction or accidental breakage of the automated windows, and to

protective measures

in view of these. Such measures include those

recommended by the specified standard:

e actuators via a “deadman’s button” placed near the system and within

the operator’s field of view, to ensure that people are out of the way during operation.

The button must be placed at a height of 1.5 m and operated by key if accessible to

use of contact safety systems (also included in the actuators) that ensure a maximum

closing force of 400/150/25 N, measured in accordance with paragraph BB.20.107.2

contact safety systems (lasers, light grids); or:

use of fixed safety barriers that prevent access to moving parts.

Automated windows are deemed adequately protected if they:

are installed at a height of >2.5 m; or:

edge opening of <200 mm and a closing speed of <15 mm/s; or:

rt of a smoke and heat evacuation system for emergency use only.

In any case, moving parts of windows that could fall below 2.5 m following breakage of a

system component need to be fixed or

secured in order to prevent them from suddenly

: e.g. the use of safety arms on bottom

-

hung windows.

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge. Do

not allow children to play

with the fixed controls and keep any remote

The actuator is destined exclusively for installation indoors. For any special

application we recommend you consult the manufacturer beforehand.

After removing packaging, check f

or any damage on the appliance.

LATION INSTRUCTIONS

TO

CAN SERIOUSLY ENDANG

ER

The Nekos electrical actuators comply with the Machinery Directive (2006/42/EC),

103 (Particular requirements for drives for gates, doors and

windows) and other directives and regulations indicated in the attached Declarations of

poration and CE Conformity (at the end of the manual). According to the Machinery

Directive, actuators are “partly completed machinery” intended for incorporation into doors

and windows. The manufacturer/supplier of the window is required, with exclusive

esponsibility, to ensure the compliance of the entire system with the applicable standards

and to issue CE certification. We strongly discourage any use of the actuators other than

that specified and therefore, in any case, the supplier of the complete sys

tem retains full

For systems installed at a height of less than 2.5 m above floor level or other levels

accessible to users, the manufacturer/supplier of the window must conduct

risk analysis

ounds) caused to people by normal

use or possible malfunction or accidental breakage of the automated windows, and to

in view of these. Such measures include those

e actuators via a “deadman’s button” placed near the system and within

the operator’s field of view, to ensure that people are out of the way during operation.

The button must be placed at a height of 1.5 m and operated by key if accessible to

use of contact safety systems (also included in the actuators) that ensure a maximum

closing force of 400/150/25 N, measured in accordance with paragraph BB.20.107.2

use of fixed safety barriers that prevent access to moving parts.

edge opening of <200 mm and a closing speed of <15 mm/s; or:

rt of a smoke and heat evacuation system for emergency use only.

In any case, moving parts of windows that could fall below 2.5 m following breakage of a

secured in order to prevent them from suddenly

hung windows.

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge. Do

with the fixed controls and keep any remote

-control units

The actuator is destined exclusively for installation indoors. For any special

application we recommend you consult the manufacturer beforehand.

or any damage on the appliance.

Always request exclusive use of original spare parts. Failure to respect this

condition could compromise safety and invalidate the benefits contained in the

warranty for the appliance.

In the event of any problems or querie

manufacturer directly.

2.

Formulas and recommendations for installation

2.1.

Calculation of opening / closure force

Using the formulas on this page, approximate calculations can be made for the force

required to open or close the window considering all the factors that determine the

calculation.

Symbols used for the calculation

F (Kg) = Force for opening or closing

C (cm) = Opening stroke (actuator stroke)

For horizontal light domes or

skylights

F = 0,54 x P

(Eventual weight of snow or wind on the

cupola should be

calculated separately)

2.2.

Maximum opening based on sash

The selection of the actuator stroke should be made based on the height of the sash

and its application. As a general rule, never select a stroke greater than the height of

the window frame; select the stroke directly below it.

W

ARNING

.

The actuator is designed to be recess mounted on the window frame.

Check that during the stroke the chain does not touch the profile of the sash, there

are no obstacles to opening the window and the chain does not push against the

window frame.

5

Always request exclusive use of original spare parts. Failure to respect this

condition could compromise safety and invalidate the benefits contained in the

warranty for the appliance.

In the event of any problems or querie

s, consult your agent or contact the

manufacturer directly.

Formulas and recommendations for installation

Calculation of opening / closure force

Using the formulas on this page, approximate calculations can be made for the force

required to open or close the window considering all the factors that determine the

Symbols used for the calculation

F (Kg) = Force for opening or closing

P (Kg) =

Weight of the window (mobile sash only)

C (cm) = Opening stroke (actuator stroke)

H (cm) = Height of the mobile sash

For horizontal light domes or

(Eventual weight of snow or wind on the

calculated separately)

.

For vertical windows

TOP HUNG WINDOWS

,

OUTWARD OPENING

BOTTOM HUNG WINDOWS

F = 0,54 x P x C : H

(Eventual load of favourable or unfavourable wind

on the sash should be calculated separately).

Maximum opening based on sash

height

The selection of the actuator stroke should be made based on the height of the sash

and its application. As a general rule, never select a stroke greater than the height of

the window frame; select the stroke directly below it.

The actuator is designed to be recess mounted on the window frame.

Check that during the stroke the chain does not touch the profile of the sash, there

are no obstacles to opening the window and the chain does not push against the

Always request exclusive use of original spare parts. Failure to respect this

condition could compromise safety and invalidate the benefits contained in the

s, consult your agent or contact the

Using the formulas on this page, approximate calculations can be made for the force

required to open or close the window considering all the factors that determine the

Weight of the window (mobile sash only)

H (cm) = Height of the mobile sash

For vertical windows

OUTWARD OPENING

(A)

BOTTOM HUNG WINDOWS

(B)

F = 0,54 x P x C : H

(Eventual load of favourable or unfavourable wind

on the sash should be calculated separately).

The selection of the actuator stroke should be made based on the height of the sash

and its application. As a general rule, never select a stroke greater than the height of

The actuator is designed to be recess mounted on the window frame.

Check that during the stroke the chain does not touch the profile of the sash, there

are no obstacles to opening the window and the chain does not push against the

3. Technical

operating information

The chain actuator is used to open and close the window by means of a three

steel chain (Nekos Patent)

. The movement is achieved with

SELV

) electricity that powers a gear motor controlled by a functional el

device. Window opening can be programmed, and the device allows excursion of

the chain to strokes of 70, 125, 170 and 210 mm. For the return stroke, i.e., the

closing of the window, the stroke

automa

tically calculates the required power absorption to produce the movement of

the window, and therefore no settings are required. The actuator can also be

installed without the immediate availability of electricity for window movement; in this

case the actua

tor will simply hold the window closed after assembly. The structure of

the actuator is entirely metal and it is used for room ventilation. The coupling

between the actuator and support brackets fixed to the window frame is a quick

connect coupling that al

lows the actuator to rotate in order to adapt to the stroke of

the chain, even on windows with reduced height. The brackets are fixed to the frame

during actuator assembly with just two screws. Combined with the

product and perimeter fittings, it constitutes the security lock that keeps the window

closed tight and guarantees a high thermal K.

4.

Construction and regulatory references

INTENDED USE

The KIMO chain actuator is designed and built to open

and close top-

hung windows opening outwards, bottom

up-and-

over roof windows. Its use is specifically intended for ventilation, air

conditioning of rooms and, if used in combination with the BK

lock, also as a building security system; it is

actuator not be used for any other purpose unless approved

manufacturer beforehand, with the supplier of the entire system in any case

retaining sole liability.

The actuator is manufactured in accordance with the EC Directives and

Regulations listed in the attached Declaration of Incorporation and

Conformity .

Electrical connections must conform to regulations in force for the design

an

d set up of electrical equipment.

To ensure efficient separation from the grid, an approved type of bipolar

“dead-

man” switch should be used. An omnipolar general power switch with

minimum distance of 3 mm between contacts should be installed upstream of

the control line.

The actuator is individually packaged in a cardboard container and each pack contains:

24V

electrical actuator complete of connector for feeding cable wiring.

2 support brackets

2 half-

brackets for attach to the frame, complete with

Instruction manual

6

operating information

The chain actuator is used to open and close the window by means of a three

. The movement is achieved with

very

) electricity that powers a gear motor controlled by a functional el

device. Window opening can be programmed, and the device allows excursion of

the chain to strokes of 70, 125, 170 and 210 mm. For the return stroke, i.e., the

closing of the window, the stroke

-

end is determined by an electronic process that

tically calculates the required power absorption to produce the movement of

the window, and therefore no settings are required. The actuator can also be

installed without the immediate availability of electricity for window movement; in this

tor will simply hold the window closed after assembly. The structure of

the actuator is entirely metal and it is used for room ventilation. The coupling

between the actuator and support brackets fixed to the window frame is a quick

lows the actuator to rotate in order to adapt to the stroke of

the chain, even on windows with reduced height. The brackets are fixed to the frame

during actuator assembly with just two screws. Combined with the

product and perimeter fittings, it constitutes the security lock that keeps the window

closed tight and guarantees a high thermal K.

Construction and regulatory references

The KIMO chain actuator is designed and built to open

hung windows opening outwards, bottom

over roof windows. Its use is specifically intended for ventilation, air

conditioning of rooms and, if used in combination with the BK

lock, also as a building security system; it is

highly recommended that the

actuator not be used for any other purpose unless approved

manufacturer beforehand, with the supplier of the entire system in any case

retaining sole liability.

The actuator is manufactured in accordance with the EC Directives and

Regulations listed in the attached Declaration of Incorporation and

Electrical connections must conform to regulations in force for the design

d set up of electrical equipment.

To ensure efficient separation from the grid, an approved type of bipolar

man” switch should be used. An omnipolar general power switch with

minimum distance of 3 mm between contacts should be installed upstream of

The actuator is individually packaged in a cardboard container and each pack contains:

electrical actuator complete of connector for feeding cable wiring.

brackets for attach to the frame, complete with

pin

The chain actuator is used to open and close the window by means of a three

-link

very

low-voltage (24V

) electricity that powers a gear motor controlled by a functional el

ectronic

device. Window opening can be programmed, and the device allows excursion of

the chain to strokes of 70, 125, 170 and 210 mm. For the return stroke, i.e., the

end is determined by an electronic process that

tically calculates the required power absorption to produce the movement of

the window, and therefore no settings are required. The actuator can also be

installed without the immediate availability of electricity for window movement; in this

tor will simply hold the window closed after assembly. The structure of

the actuator is entirely metal and it is used for room ventilation. The coupling

between the actuator and support brackets fixed to the window frame is a quick

-

lows the actuator to rotate in order to adapt to the stroke of

the chain, even on windows with reduced height. The brackets are fixed to the frame

during actuator assembly with just two screws. Combined with the

BK-LOCK

product and perimeter fittings, it constitutes the security lock that keeps the window

The KIMO chain actuator is designed and built to open

hung windows opening outwards, bottom

-hung windows or

over roof windows. Its use is specifically intended for ventilation, air

conditioning of rooms and, if used in combination with the BK

-LOCK window

highly recommended that the

actuator not be used for any other purpose unless approved

by the

manufacturer beforehand, with the supplier of the entire system in any case

The actuator is manufactured in accordance with the EC Directives and

Regulations listed in the attached Declaration of Incorporation and

Electrical connections must conform to regulations in force for the design

To ensure efficient separation from the grid, an approved type of bipolar

man” switch should be used. An omnipolar general power switch with

minimum distance of 3 mm between contacts should be installed upstream of

The actuator is individually packaged in a cardboard container and each pack contains:

electrical actuator complete of connector for feeding cable wiring.

7

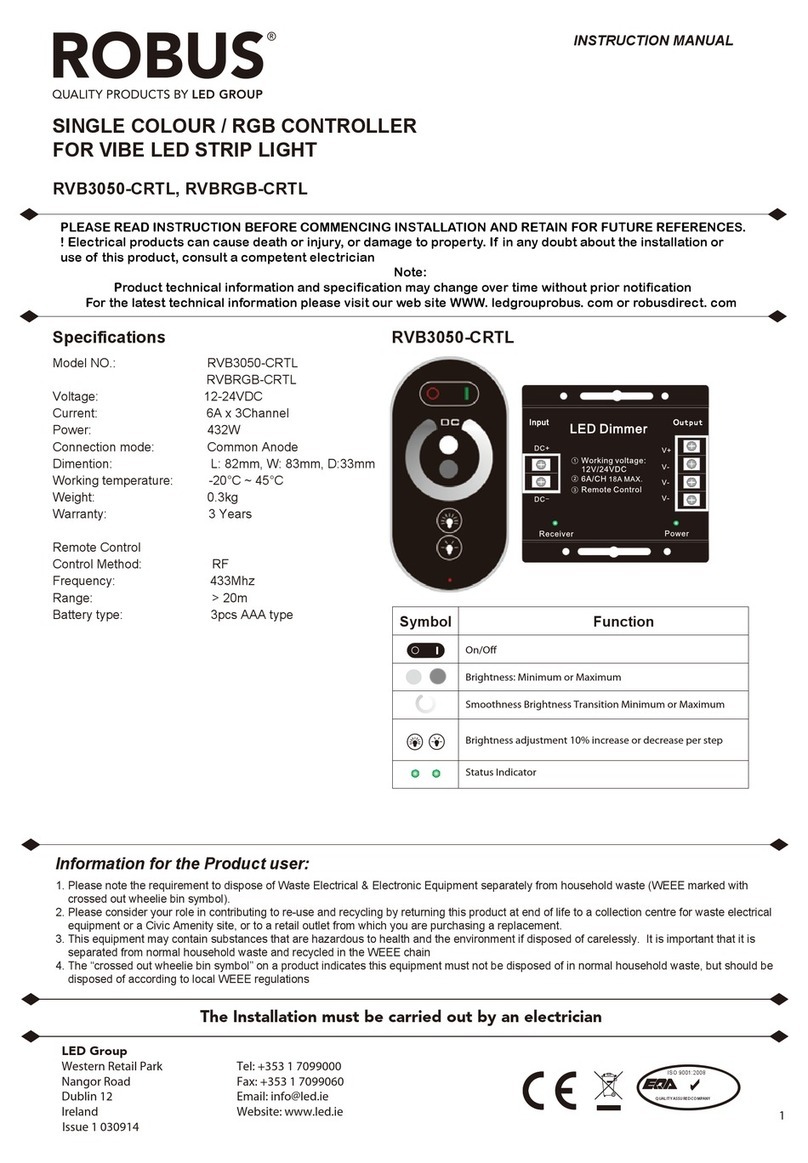

5. Technical data

Model

K

IMO

24V

Force exerted by thrust (F

N

) 100N

Force exerted by traction (F

N

) 200N

Strokes (S

V

) 70, 125, 170, 210 mm

Power supply voltage (U

N

) 24 V SELV

Rated absorbed current (I

N

) 0,36A

Power absorbed at nominal load (P

N

) 8,6W

Electrical insulation Class III

No load speed 5,5 mm/s

Duration of no load stroke (210 mm) 38 s

Type of service (D

R

) 5 cycles

Operating temperature - 5 + 65 ºC

Protection index for electrical devices IP32

Adjustment of connection to window frame Automatic definition of position

Parallel powering of two or more motors YES (max 20 actuators)

Operation with BK-LOCK electromechanical

lock

Yes

Synchronised function Not foreseen

Holding nominal force (it can vary according to

the chosen brackets)

1.700N

Stroke-end at opening Electronic by dip-switch

Stroke-end at closing At absorption of power

Chain exit Central

Length of power cable 2 m

Dimensions 29x29x310 mm

Weight 0,720 Kg

The data indicated in these figures is not binding and is subject to variation without notification.

6. Id plate and marking data

The KIMO actuators have CE marking and comply with the Standards listed in the

Declaration of Conformity. They also come with a Declaration of Incorporation, due

to their classification by the Machinery Directive as “partly completed machines”.

Both declarations are included in the final pages of this manual.

The plate data is displayed on an adhesive label placed on the outside of the casing,

which must remain intact and visible.

The main information it displays includes: manufacturer's address, product name -

model number, technical characteristics, production date and serial number.

In the event of a complaint, please indicate the serial number (SN) displayed on the

label.

An explanation of the symbols used on the label to abbreviate the technical

characteristics is given in the table in the chapter on “TECHNICAL DATA”.

8

7. Electric power supply

The KIMO actuator is powered with a voltage of 24V SELV. The power supply

cable has three conductors: the first conductor RED “1” that should be connected to

the + (positive) CLOSES the window; the second conductor BLACK “2” that should be

connected to the + (positive) OPENS the window; the third conductor GREEN “3” is

the conductor used for the BK-LOCK control communication signal.

The 24V low-voltage actuators can be powered using a station with emergency

batteries or a security power supply unit with an output voltage of 24V (min. 20.4V,

max. 28,8V), that is to say, sized based on the number of actuators connected.

7.1. Selecting the cross-section of the power supply cables

It is necessary to check the cross-section of the cable, which should be calculated

based on the length of the cable itself. The table below specifies the maximum length

of the cables for connection of a motor.

CABLE SECTION

Actuator fed at

24V

0.50 mmq ~40 m

0.75 mmq ~60 m

1.00 mmq ~80 m

1.50 mmq ~120 m

2.50 mmq ~200 m

4.00 mmq ~320 m

6.00 mmq ~480m

8. Electrical connection

The machines are equipped with a power supply cable constructed in compliance

with safety standards and restrictions on radio-frequency interference.

The power supply cable - with conductors having a cross-section of 0.5 mm² - is 2

meters long with different colored conductors, as follows

1 – RED-coloured conductor;

2 – BLACK-coloured conductor;

3 – GREEN-coloured conductor:

For harness, please follow this diagram:

9

-+

24V

3

1

2

1 2 3

24V

Note: the first conductor RED “1” that should be connected to the + (positive) CLOSES

the window; the second conductor BLACK “2” that should be connected to the +

(positive) OPENS the window; the third conductor GREEN “3” is the conductor used for

the BK-LOCK control communication signal.

9. Instructions for assembly

These indications are for specialised technical personnel and basic work and

safety techniques are not indicated.

All preparatory, assembly and electrical connection operations must be performed

by specialised technical personnel to guarantee optimal function and service of the

actuator. Check that the following fundamental conditions have been met:

Before installing the actuator, check that the moving parts of the window on

which it is to be installed are in perfect working condition and that they

open and close properly and are well balanced (where applicable).

Actuator specifications must be sufficient for movement of the window

without encountering any obstacle. The limits indicated in the technical data

table must not be superseded (page 7) and the most appropriate stroke

should be selected. Calculations should be checked using the formula

indicated on page 5.

Attention. Check that the electrical power supply corresponds to that

indicated on the TECHNICAL DATA label on the machine.

Ensure that the actuator has not been damaged during transport, first

visually and then by powering in both directions.

Check that the width of the inside of the window (where the actuator is to

be assembled) is over 360 mm, otherwise the actuator should not be

installed.

Check that once the actuator has been installed, chain completely in, the

window is perfectly closed. If this is not the case the actuator will not

function correctly as the window will not close correctly.

10

9.1. Preparation for mounting the actuator

Before beginning to mount the actuator, depending on the type of application, the

window frame must be prepared by carrying out the following operations.

9.2. Recessed mounting

For recessed mounting, the window frame must be prepared by milling and making

two holes as indicated in the diagram below. The depth of the milling must be at

least 30 mm.

Then make two Ø4.5 holes on the sash for the attachment bracket. The

measurements are specified in the diagram below.

9.3. Surface mounting on top-hung windows opening outwards or

bottom-hung windows

The actuator can also be surface mounted on top-hung windows opening outwards or

dormer windows and on bottom-hung windows, however for these specific applications

special support brackets are required for the actuator which must be supplied

separately.

The two half-brackets attaching the actuator to the sash, however, are the same

standard brackets supplied with the actuator and included in the package.

Warning. In order to prevent unpleasant mishaps with the machine and

possible safety hazards, carefully choose the length of the clamping screws

in order to avoid damaging the power supply cables during the mounting

procedure.

In order to carry out a cost-effective and precise up-to-standard work, it is best if you

prepare the following complementary material: small parts, equipment and tools.

Fastening on metal window frames: M4 threaded inserts (2 pieces for recessed

mounting and 4 pieces for surface mounting), M4x12 flat head metric screws (2

pieces (4 pieces for surface mounting)).

11

Fastening on wooden window frames: Ø4 self-threading wood screws (2 pieces

for recessed mounting and 4 pieces for surface mounting), with an appropriate

length for the type of window frame.

Fastening on PVC window frames: Ø3.9x13 self-threading metal screws (2

pieces for recessed mounting and 4 pieces for surface mounting), with an

appropriate length for the type of window frame.

Equipment and tools: tape-measure, pencil, drill/electric screwdriver, set of drill

bits for metal, insert for screwing in, electrician's scissors, screwdrivers.

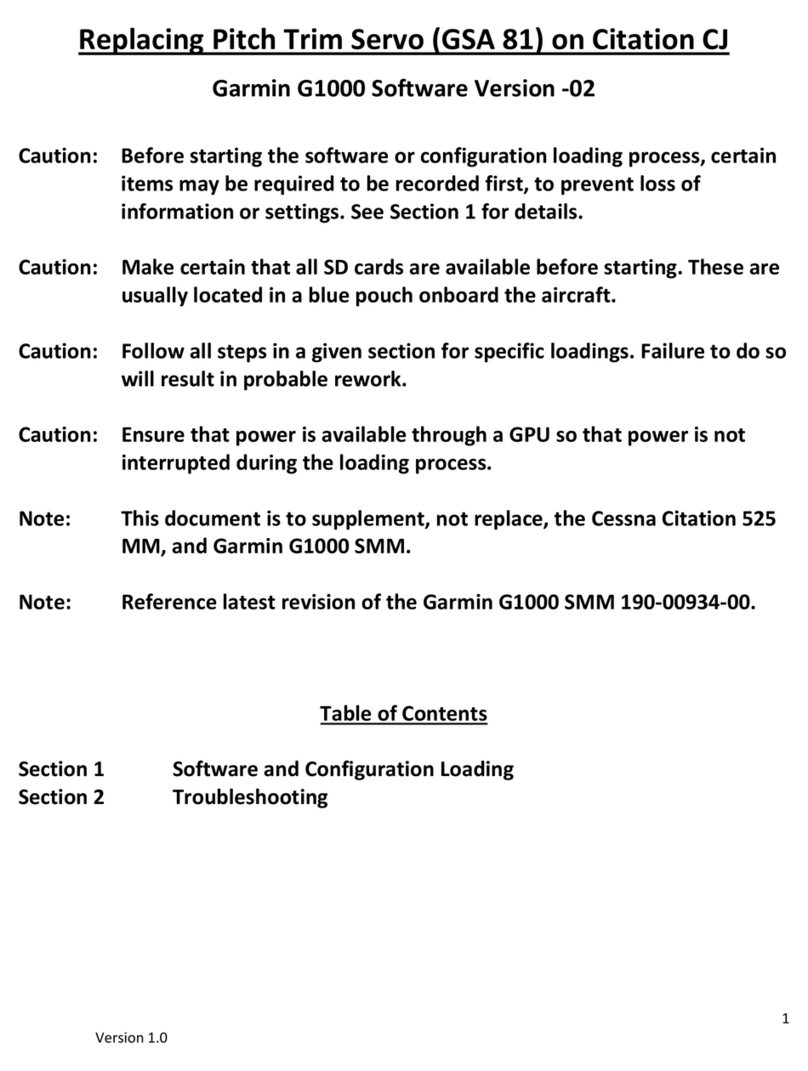

10. Programming the actuator

10.1. Opening stroke-end

The opening stroke-end of the actuator can be adjusted by selecting the dip-

switches located inside the actuator underneath the black rubber plug (T) (see fig.

below), near the label that indicates the state of the dip-switches.

The setting can be made very easily by selecting the dip-switches as specified in the

table below.

STROKE

(mm)

DIP-SWITCH WITHOUT

BK-LOCK

WITH

BK-LOCK

1 2 3 4 4

70 ON OFF OFF

OFF ON

125 OFF ON OFF

170 OFF OFF ON

210 OFF OFF OFF

The actuator is factory-set with the longest stroke (210 mm).

10.2. Closure stroke-end

The stroke-end at closure is automatic and cannot be programmed.

The actuator stops when the charge is absorbed when the window is completely

closed and the weather stripping is completely depressed.

After each closure or intervention of electronic protection devices, the chain will

move about 1 mm in the opposite direction to give correct compression to the seals

and release the mechanical parts.

10.3. Operation with

The actuator can also work in combination with the

lock; this operating mode can be selected using dip

set on ON without the lock being connected, the actuator will not move.

11.

Actuator kit with electromechanical lock

Warning

. Always comply with the corr

the two machines; an incorrect connection may damage the machines and

create a hazardous situation.

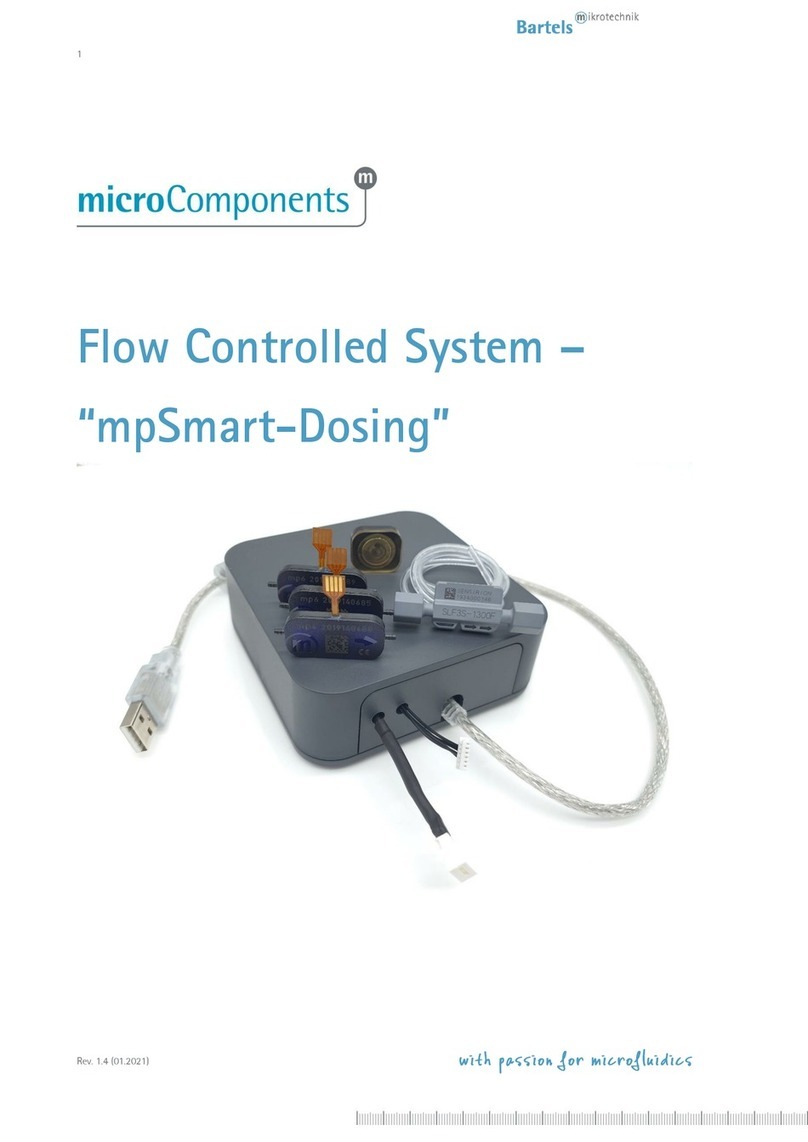

11.1.

Electrical connection and operating logic

In order for the two machines to work in combination with one another, the

connection must be made by connecting the wires according to the following

diagram.

-

In the BK-LOCK

electromechanical lock select, using dip

stroke and set, using dip-

switch No. 2, the “

instructions in the BK-

LOCK

Power the two machines with a voltage of 24V

inverting the polarity to open and close the system.

Powering Black wire

with +24V

effects:

the lock moves in the opening direction;

the lock arrives at stroke

the chain actuator begins opening, opening the movable sash;

the KIMO chain actuator reaches stroke

Powering Red wi

re with +24V

effects:

the chain actuator moves in the closing direction;

the actuator reaches stroke

12

Operation with

BK-LOCK

electromechanical lock

The actuator can also work in combination with the

BK-

LOCK

lock; this operating mode can be selected using dip

-

switch No.4. If the dip

set on ON without the lock being connected, the actuator will not move.

Actuator kit with electromechanical lock

. Always comply with the corr

ect electrical connections between

the two machines; an incorrect connection may damage the machines and

create a hazardous situation.

Electrical connection and operating logic

In order for the two machines to work in combination with one another, the

connection must be made by connecting the wires according to the following

-+

24V

3

1

2

1 2 3

24V

electromechanical lock select, using dip

-

switch No. 1, the desired

switch No. 2, the “

OPER

ATION WITH ACTUATOR

LOCK

manual also).

Power the two machines with a voltage of 24V

(Red

wire and

inverting the polarity to open and close the system.

with +24V

and Red wire with -24V

produces the following

the lock moves in the opening direction;

the lock arrives at stroke

-end, stop;

the chain actuator begins opening, opening the movable sash;

the KIMO chain actuator reaches stroke

-end.

re with +24V

and Black wire with -24V

produces the following

the chain actuator moves in the closing direction;

the actuator reaches stroke

-

end and stops with a short relax;

electromechanical lock

LOCK

electromechanical

switch No.4. If the dip

-switch is

set on ON without the lock being connected, the actuator will not move.

ect electrical connections between

the two machines; an incorrect connection may damage the machines and

In order for the two machines to work in combination with one another, the

required

connection must be made by connecting the wires according to the following

switch No. 1, the desired

ATION WITH ACTUATOR

” mode (see

wire and

Black wire),

produces the following

the chain actuator begins opening, opening the movable sash;

produces the following

end and stops with a short relax;

the lock moves in the closing direction;

the lock arrives at stroke

Important note

. If, during the closing movement, the chain actuator stops

suddenly due to an overload or mechanical sticking, this state is

interpreted as a "closing

closure, even if the sash is not effectively closed.

11.2.

Sound diagnostics in case of anomaly

1 Beep

The lock is set in "with actuator" mode but does not receive any

commands from the actuator.

-

The lock does not move because it didn't receive the command.

-

Check the contact of wire "3" of the lock and that

actuator is on ON.

4 Beeps

The actuator (or actuators) are in error.

-

The lock is ready for the command but the connected actuators are in error.

-

Check the diagnostics of the actuators connected to the electromechanical

lock.

12. Che

cking for correct assembly

Check that the window is perfectly closed at corners and that there are no

obstacles caused by incorrect positioning during assembly.

Check that when the window frame is closed the chain terminal is at least a few

millimetres

away from the actuator body. This will ensure the window is properly

closed and seals are correctly compressed. In the event that this should not be

the case there is no guarantee that the window is closed correctly.

Check that hinges and support brackets

fixed against the window frame with screws fixed correctly into position.

Check that the window reaches the desired position according to the stroke

selected.

13.

Emergency manoeuvres, maintenance or cleaning

In the ev

ent that the window frame should require manual opening due to power

failure or problem with the mechanism or for normal maintenance or external cleaning

of the window frame, in built

-

1. Unscrew the tw

o screws that fix the sash to the attachment bracket.

2.

Take care during this operation since the bracket, which is in two pieces after

removing the screws, may fall as it is no longer secured.

3.

Manually open the window frame.

13

the lock moves in the closing direction;

the lock arrives at stroke

-end.

. If, during the closing movement, the chain actuator stops

suddenly due to an overload or mechanical sticking, this state is

interpreted as a "closing

stroke-end

" and thus the lock motor performs a

closure, even if the sash is not effectively closed.

Sound diagnostics in case of anomaly

The lock is set in "with actuator" mode but does not receive any

commands from the actuator.

The lock does not move because it didn't receive the command.

Check the contact of wire "3" of the lock and that

dip

The actuator (or actuators) are in error.

The lock is ready for the command but the connected actuators are in error.

Check the diagnostics of the actuators connected to the electromechanical

cking for correct assembly

Check that the window is perfectly closed at corners and that there are no

obstacles caused by incorrect positioning during assembly.

Check that when the window frame is closed the chain terminal is at least a few

away from the actuator body. This will ensure the window is properly

closed and seals are correctly compressed. In the event that this should not be

the case there is no guarantee that the window is closed correctly.

Check that hinges and support brackets

are aligned to each other and tightly

fixed against the window frame with screws fixed correctly into position.

Check that the window reaches the desired position according to the stroke

Emergency manoeuvres, maintenance or cleaning

ent that the window frame should require manual opening due to power

failure or problem with the mechanism or for normal maintenance or external cleaning

-

in actuators it’s necessary to perform these operations:

o screws that fix the sash to the attachment bracket.

Take care during this operation since the bracket, which is in two pieces after

removing the screws, may fall as it is no longer secured.

Manually open the window frame.

. If, during the closing movement, the chain actuator stops

suddenly due to an overload or mechanical sticking, this state is

" and thus the lock motor performs a

The lock is set in "with actuator" mode but does not receive any

The lock does not move because it didn't receive the command.

dip

-switch No. 2 of the

The lock is ready for the command but the connected actuators are in error.

Check the diagnostics of the actuators connected to the electromechanical

Check that the window is perfectly closed at corners and that there are no

Check that when the window frame is closed the chain terminal is at least a few

away from the actuator body. This will ensure the window is properly

closed and seals are correctly compressed. In the event that this should not be

the case there is no guarantee that the window is closed correctly.

are aligned to each other and tightly

fixed against the window frame with screws fixed correctly into position.

Check that the window reaches the desired position according to the stroke

-end

Emergency manoeuvres, maintenance or cleaning

ent that the window frame should require manual opening due to power

failure or problem with the mechanism or for normal maintenance or external cleaning

in actuators it’s necessary to perform these operations:

o screws that fix the sash to the attachment bracket.

Take care during this operation since the bracket, which is in two pieces after

A

TTENTION

:

DANGER

held in position by the chain.

4.

After maintenance and/or cleaning repeat points 1 and 2 in reverse order.

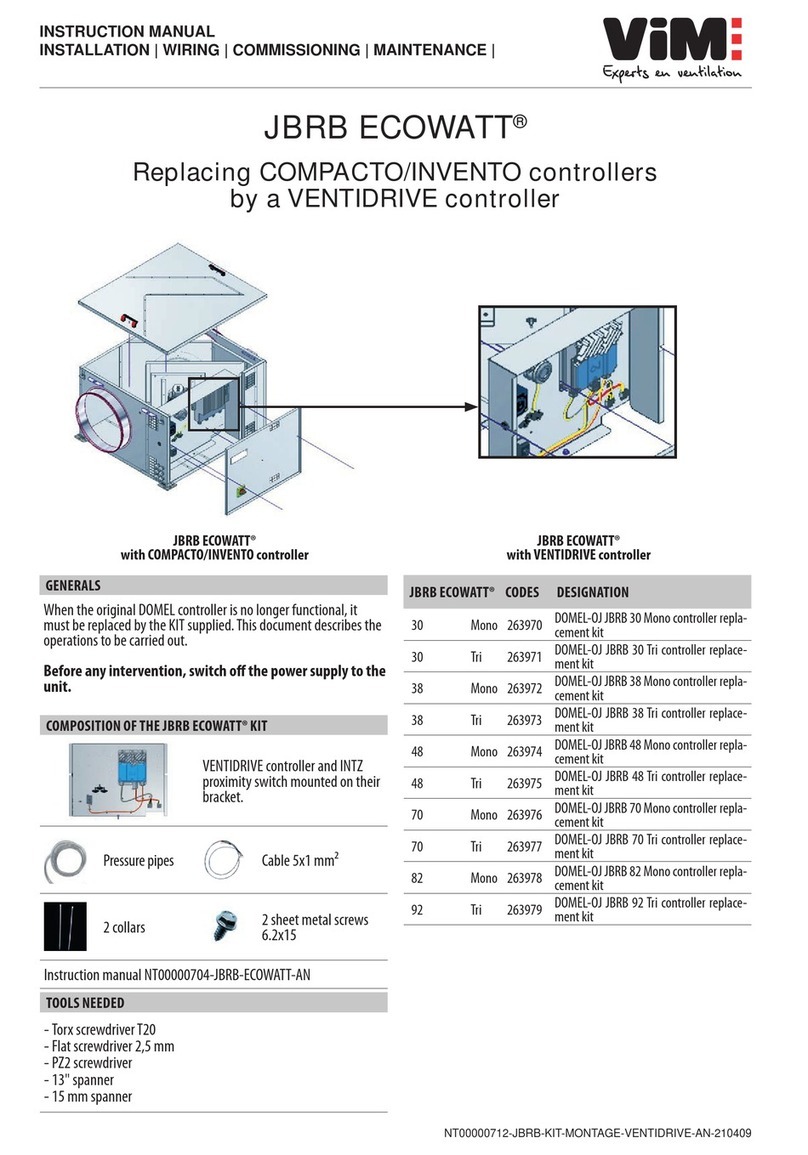

14. Troubleshooting

Possible causes of malfunction during installation or use.

Problem

Actuator does not work

15.

ENVIRONMENTAL PROTECTION

All materials used in the manufacture of this appliance are recyclable.

We recommend that the device itself, and any accessories, packaging, etc. be sent

to a centre for ecological recycling as established from laws in force on recycling.

The device is ma

inly made from the following materials: aluminium, zinc, iron, plastic

of various type, cuprum. Dispose materials in conformity with local regulations about

removal.

16.

CERTIFICATE OF GUARANTEE

The manufacturer will guarantee good function of the appliance. T

shall undertake to replace defective parts due to poor quality materials or

manufacturing defects in accordance with article 1490 of the Civil Code.

The guarantee covers products and individual parts for

purchase. The latter is valid as long as the purchaser possesses proof of purchase

and completion of all agreed conditions of payment.

Guarantee of good function of appliances agreed by the manufacturer implies that

the latter undertakes

to repair or replace free of charge and in the shortest period

possible any parts that break while under warranty.

The purchaser is not entitled to any reimbursement for eventual direct or indirect

damage or other expenses incurred. Attempt to repair by pe

the manufacture shall render the warranty null and invalid.

The warranty does not cover fragile parts or parts subject to natural wear and tear or

corrosion, overload, however temporary etc. The manufacturer will accept no

responsi

bility for eventual damage incurred by erroneous assembly, manoeuvre or

insertion, excessive stress or inexpert use.

Repairs performed under guarantee are always "

Respective transport expenses (out/back) are the responsibil

14

DANGER

– the window

could fall as the sash is no longer

held in position by the chain.

After maintenance and/or cleaning repeat points 1 and 2 in reverse order.

Possible causes of malfunction during installation or use.

Possible cause

No electricity at feeder

Check status of circuit

breaker or safety switch

Cable not connected

or wire disconnected.

Check electrical

connections at reduction

motor

ENVIRONMENTAL PROTECTION

All materials used in the manufacture of this appliance are recyclable.

We recommend that the device itself, and any accessories, packaging, etc. be sent

to a centre for ecological recycling as established from laws in force on recycling.

inly made from the following materials: aluminium, zinc, iron, plastic

of various type, cuprum. Dispose materials in conformity with local regulations about

CERTIFICATE OF GUARANTEE

The manufacturer will guarantee good function of the appliance. T

shall undertake to replace defective parts due to poor quality materials or

manufacturing defects in accordance with article 1490 of the Civil Code.

The guarantee covers products and individual parts for

2 years

purchase. The latter is valid as long as the purchaser possesses proof of purchase

and completion of all agreed conditions of payment.

Guarantee of good function of appliances agreed by the manufacturer implies that

to repair or replace free of charge and in the shortest period

possible any parts that break while under warranty.

The purchaser is not entitled to any reimbursement for eventual direct or indirect

damage or other expenses incurred. Attempt to repair by pe

rsonnel unauthorised by

the manufacture shall render the warranty null and invalid.

The warranty does not cover fragile parts or parts subject to natural wear and tear or

corrosion, overload, however temporary etc. The manufacturer will accept no

bility for eventual damage incurred by erroneous assembly, manoeuvre or

insertion, excessive stress or inexpert use.

Repairs performed under guarantee are always "

ex factory of the manufacturer

Respective transport expenses (out/back) are the responsibil

ity of the purchaser.

could fall as the sash is no longer

After maintenance and/or cleaning repeat points 1 and 2 in reverse order.

Solution

Check status of circuit

breaker or safety switch

Check electrical

connections at reduction

All materials used in the manufacture of this appliance are recyclable.

We recommend that the device itself, and any accessories, packaging, etc. be sent

to a centre for ecological recycling as established from laws in force on recycling.

inly made from the following materials: aluminium, zinc, iron, plastic

of various type, cuprum. Dispose materials in conformity with local regulations about

The manufacturer will guarantee good function of the appliance. T

he manufacturer

shall undertake to replace defective parts due to poor quality materials or

manufacturing defects in accordance with article 1490 of the Civil Code.

2 years

from the date of

purchase. The latter is valid as long as the purchaser possesses proof of purchase

Guarantee of good function of appliances agreed by the manufacturer implies that

to repair or replace free of charge and in the shortest period

The purchaser is not entitled to any reimbursement for eventual direct or indirect

rsonnel unauthorised by

The warranty does not cover fragile parts or parts subject to natural wear and tear or

corrosion, overload, however temporary etc. The manufacturer will accept no

bility for eventual damage incurred by erroneous assembly, manoeuvre or

ex factory of the manufacturer

".

ity of the purchaser.

15

17. Dichiarazione di Incorporazione (per una quasi macchina) e Dichiarazione CE di

Conformità / Declaration of incorporation (for a partly completed machine) and EC

Declaration of Conformity.

Con la presente il / Hereby the

Costruttore:

Manufacturer:

Nekos Srl

Via Capitoni 7/5- 36064 Colceresa (Vicenza) - Italy

Tel +39 0424 411011 – Email info@nekos.it

dichiara sotto la propria responsabilità che i seguenti prodotti:

declare under its own responsibility that the following products:

Descrizione prodotto :

Product Designation:

Attuatore a catena per finestre

Window chain drive

Modello:

Type :

230 V : KATO 253

-

KATO

-

KATO 305

KATO SYNCRO3 - KATO 305 SYNCRO3

INKA 356 - INKA 356 SYNCRO3

24 V : KATO 253 - KATO - KIMO - KATO 305

KATO SYNCRO3 - KATO 305 SYNCRO3

INKA 356 - INKA 356 SYNCRO3

Anno di costruzione dal / Year of manufacturing from: 2017

Soddisfano gli applicabili requisiti essenziali della

Direttiva Macchine 2006/42/EC, Allegato I

Fulfil the essential requirements of the Machinery Directive 2006/42/EC, Annex I, Art. 1.1.2, 1.1.3, 1.1.5,

1.2.1,1.2.3, 1.2.6; 1.3.2, 1.3.4, 1.3.9, 1.5.1, 1.5.2, 1.5.6, 1.5.7, 1.5.8, 1.5.9, 1.5.10, 1.5.11, 1.7.1, 1.7.1.1, 1.7.3,

1.7.4.2, 1.7.4.3

La documentazione tecnica pertinente è compilata secondo l’Allegato VII, sezione B

The relevant technical documentation is compiled in accordance with Annex VII, Part B

La persona autorizzata a costituire la documentazione tecnica pertinente è:

The person authorised to compile the relevant technical documentation is: ing. Matteo Stefani – Nekos S.r.l.

Su richiesta adeguatamente motivata delle autorità nazionali, la documentazione tecnica dei citati prodotti sarà resa

disponibile, via e-mail, entro un tempo compatibile con la sua importanza.

In response to a reasoned request by the national authorities, we will provide, via e-mail, the relevant information on

the product listed above within an adequate period proportional to its importance.

Inoltre i succitati prodotti sono conformi alle disposizioni pertinenti delle seguenti Direttive:

Furthermore the products listed above complies with the provisions of followings Directives :

2014/30/EU Direttiva Compatibilità Elettromagnetica / ElectroMagnetic Compatibility Directive (EMCD)

2014/35/EU Direttiva Bassa Tensione / Low Voltage Directive (LVD)

2011/65/EU Direttiva sulla restrizione dell’uso di determinate sostanze pericolose nelle apparecchiature

elettriche ed elettroniche (Direttiva RoHS) / Restriction of the use of certain hazardous substances Directive

(RoHS Directive)

2015/863/EU Direttiva Delegata recante modifica dell’allegato II della Direttiva 2011/65/EU del Parlamento Europeo e

del Consiglio per quanto riguarda l’elenco delle sostanze con restrizioni d’uso. / Delegated Directive amending Annex II

of Directive 2011/65/EU of the European Parliament and of the Council regarding the list of substances with usage

restrictions

e delle seguenti norme armonizzate e/o specifiche tecniche:

and of the following harmonised standards and/or technical specifications:

EN 60335-2-103; EN 61000-6-3:2007 + A1:2011 + AC:2012; EN IEC 61000-6-2:2019;

EN 60335-1:2012 + AC:2014 + A11:2014; EN 50581:2012

La messa in moto di una macchina completa che includa la quasi macchina sopra menzionata, da noi fornita, non è

permessa finché non sia accertato che l’installazione sia stata fatta secondo le specifiche e le indicazioni di

installazione contenute nel “Manuale d’istruzioni” fornito con la quasi-macchina e che sia stata espletata e

documentata, in apposito protocollo, una procedura di accettazione da parte di un tecnico abilitato.

Commissioning of the complete machinery including the above mentioned drives delivered by us is not allowed until it

is ascertained that the installation of the complete machinery was performed in accordance with the specifications and

the operating and installation advice given in our Mounting Instructions, and that the acceptance procedure was duly

carried out and documented in an acceptance protocol by a specialist.

Questa dichiarazione è fatta dal costruttore / This is declared by the manufacturer:

NEKOS SRL - Via Capitoni 7/5 - 36064 Colceresa (Vicenza) - Italy

Rappresentato da / Represented by : Giuliano Galliazzo – A.D. Presidente / President CEO

Luogo e data / Place and date : Colceresa 04/03/2020 Firma / Valid signature

16

NEKOS S.r.l. - Via Capitoni, 7/5

36064 Colceresa (VI) – ITALY

+39 0424 411011 – +39 0424 411013

www.nekos.it info@nekos.it

This manual suits for next models

1

Table of contents

Other nekos Controllers manuals

nekos

nekos KATO RADIO 230V User manual

nekos

nekos ROCK 230 V User manual

nekos

nekos KATO 253 User manual

nekos

nekos SKYRO 650 User manual

nekos

nekos INKA 356 Series User manual

nekos

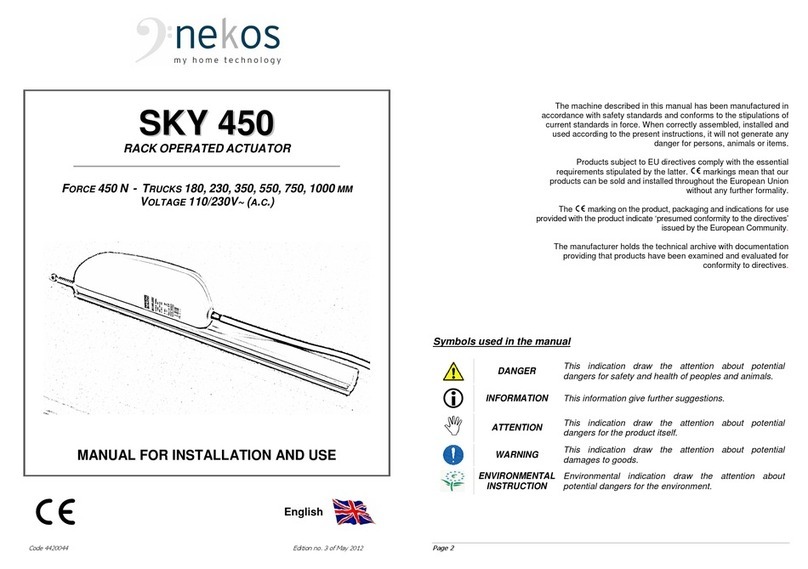

nekos SKY 450 User manual

nekos

nekos SKY 450 Quick start guide

nekos

nekos KIMO User manual

nekos

nekos SKY 650 User manual

nekos

nekos KIMO 202 User manual