SSM Freepour User manual

User Manual and Installation Guide

This guide applies to Freepour 1.0 dispenser range

Item codes: JUG2.0-CM-13, JUG2.0-CM-23, JUG2.0-CM-14, JUG2.0-CM-14

www.sixsimplemachines.com.au

D00142 A05

Freepour D00142 A05

l1

Thank you for choosing to install a Freepour self-serve beverage dispenser.

Your Freepour dispenser has been designed to eciently dispense chilled beverages in a variety of environments.

It is simple to use, clean and maintain. In order to ensure the system remains hygienic and in top working order it is

important that you read and understand this manual before connecting your Freepour station to a power outlet.

Keep this manual in a safe place for future reference.

ABOUT THIS GUIDE

This User Manual and Installation Guide contains all

the information you will require to install and use

the Freepour chilled beverage dispense station.

The manual is set out in 6 sections:

1. Product Overview

This section will introduce you to Freepour.

2. Installation Overview and Procedure

This section describes installation requirements,

dimensions and the installation procedure.

3. Operating Freepour

This section shows how to operate the machine.

4. Freepour Chiller

This section contains information about the

Freepour Juggler Chiller.

5. Maintenance

Shows how to look after the Freepour chilled

beverage dispense station.

6. Troubleshooting

Shows how to solve minor issues.

HACCP

HACCP International Pty Ltd certies Freepour as

food-safe and suitable for dispensing beverages in

facilities that operate in accordance with a HACCP

based Food Safety Programme.

This HACCP endorsement is conditional to the

following requirements:

1. Freepour must not be operated for more than

one day without performing a full clean-sanitise

using the supplied cleaning solution and

equipment;

2. Freepour must not be operated for more

than six months without deep cleaning and

sanitising, which requires dismantling the unit;

3. If Freepour is left idle for 3 or more days run the

daily cleaning routine using a double strength

solution of cleaner i.e.: 200ml of the correct

Freepour line cleaner to 2L of water.

Freepour is designed to store and dispense cold

pasteurised milk and cold pasteurised fruit juice.

Australian food laws require that the temperature

of milk and fresh fruit juice is 5ºC or colder when

it is received, displayed, transported or stored. You

should check the temperature of milk or juice when

it is delivered and reject the order if the milk is

warmer than 5ºC.

After receiving a delivery of bladders, immediately

place them into Freepour, your cold room or an

alternative refrigeration unit.

Check the temperature displayed on Freepour chiller

unit every two hours during the day. A temperature

of more than 5ºC may indicate a problem which

requires action.

You should record the temperature of the milk and

fruit juice at least once per day. Local government

health inspectors or environment ocers may

request to see these records.

If the temperature of the milk or fruit juice inside

Freepour is warmer than 5ºC you are breaking the

law and could make people sick.

Positioning the cabinet 10

Operation 10

Chiller dimensions 11

Installation Procedure 12

Step A - Place Dispenser into the hole in the bench 12

Step B - Connect drain hose 12

Step C - Mount Control Unit and connect Control to Pump cable 12

Step D - Connect uid product lines to Chiller 13

Step E - Connect uid product lines inside Chiller 13

Step F - Connect Data cables 13

Step G - Fix Dispenser in place 14

Step H - Commissioning Freepour 14

Step I - Assess Chiller drain plug 14

Before rst service 14

Optional procedures 14

Changing the Dose Time 14

Changing the Flow Rate 15

Changing the product type badges 15

3. OPERATING FREEPOUR 16

Operating Modes 16

On 16

Manual backup 16

Bladders 16

Handling bladders 16

Daily Setup Procedure 17

Operating Freepour - During Service 18

Dispensing product 18

Reloading During Service 18

Reloading a 'Connect 4' Chiller 18

Reloading a 'Connect 8' Chiller 18

Blanking 18

Operating Freepour - After Service 19

Daily Cleaning Routine 19

Leaving Freepour Overnight 19

Contents l3

TABLE OF CONTENTS

About this guide 1

HACCP 1

IMPORTANT INFORMATION 4

Safety First! 4

Cleaning 5

Refrigeration 5

Airow 5

Lifting 5

Environment 5

ALLERGEN ADVICE 5

1. PRODUCT OVERVIEW 6

System Components 6

Services required on site 6

Overview 7

Basic Dosing Functions 7

Manual dispense 7

Dose Time 7

Automatic Reverse Flow 7

2. INSTALLATION OVERVIEW & PROCEDURE 8

Planning the dispense station 8

General layout 8

Maximum permissible distances 8

Freepour Dispenser and Control Unit 9

Positioning the Dispenser 9

Dispenser dimensions 9

Bench cut-out dimensions 9

Control Unit dimensions 9

Under bench clearance 9

Freepour Chiller 10

Operating temperature range 10

Locating the cabinet 10

Contents

2l

Important Information

Product Overview l54 lContents

CLEANING

The uid product lines in Freepour must be

sanitised daily using Six Simple Machines line

cleaning chemicals that carry the Freepour logo.

Milk lines in Freepour must be sanitised with Daily

Milk Line Cleaner. Juice lines must be sanitised

with Daily Juice Line Cleaner.

NOTE: Our Daily Milk Line Cleaner (BLUE) and

Daily Juice Line Cleaner (RED) are dierent

chemical formulations. Our Daily Milk Line

Cleaner will not sanitise juice lines. Our Daily Juice

Line Cleaner will not sanitise milk lines.

IMPORTANT: If the lines are not sanitised properly

using the correct Six Simple Machines Freepour

line cleaner, the Freepour system may become

unsafe and make people sick.

Use of the correct Six Simple Machines Daily Line

Cleaners in your Freepour system is a condition of

our HACCP certication.

Failure to use the correct Six Simple Machines

Daily Line Cleaner in your Freepour system will

void the warranty on the Freepour dispensing

system.

Scan the QR codes on page 7 to see approved

varieties of milk and fruit juices and the

corresponding cleaning chemical.

REFRIGERATION

The Freepour Chiller contains R134A refrigerant

under pressure.

No part of the unit should be exposed to a naked

ame.

Maintenance of the refrigeration unit must be

carried out by an accredited service provider or

qualied refrigeration mechanic.

Always disconnect the cabinet from the mains

power supply before any cleaning or maintenance.

It is important that you follow the maintenance

procedures described on page 22.

Failure to keep the lter and condenser coil clean

will void the warranty on the Freepour Chiller.

AIRFLOW

To ensure ecient and safe operation of the

system, adequate air circulation must be provided

for the Chiller. Do not cover the Chiller grilles or

block entry or exhaust airows by placing objects

up against the Chiller.

Refer to page 10 for ventilation requirements

for the Freepour Chiller. There are no specic

ventilation requirements for the Control Unit.

LIFTING

Take care when lifting Freepour. Parts of the system

exceed safe lifting limits and require more than

one person to lift. Do not lift the Chiller by the

doors. If the Control Unit is xed to the Chiller, do

not lift the Chiller by the Control Unit.

ENVIRONMENT

This unit is intended for indoor use only and

should not be installed outdoors or exposed to the

elements of nature.

This unit should not be installed in an area that

may be cleaned by a water jet and must not be

cleaned by a water jet.

This unit can be used up to an altitude of 2000

meters above sea level.

The unit is designed to operate in ambient

temperatures between 16°C to 38°C.

If the unit is to be installed where there is risk that

water can freeze inside the hose that connects

the jug rinser to the mains water outlet, suitable

insulation should be added to the hose to

minimise this risk. If water in this hose does freeze,

it should be thawed before the hose is exed or

moved and the hose should be discarded and

replaced with a new one.

ALLERGEN ADVICE

On multi tap machines there is the risk that cross

contamination may occur between products being

dispensed. You should consider this as part of your

food allergen management program and ensure

your sta can eectively communicate this risk to

your customers.

4. FREEPOUR CHILLER 20

Freepour Chiller 20

Carel Easy electronic controller 20

Stand-by mode 20

Temperature setpoint 20

5. MAINTENANCE 22

Cleaning 22

Flush and sanitise milk lines 22

Deep clean 22

Condenser lter 22

Condenser coil 22

6. TROUBLESHOOTING 24

SAFETY FIRST!

Carefully read all instructions and ensure Freepour

is properly assembled before connecting to a power

outlet and operating.

This appliance can be used by persons (including

children aged 8 years and above) with reduced

physical, sensory or mental capabilities, or who

lack of experience or knowledge, if they have been

given supervision or instruction concerning the

safe use of the appliance by a person responsible

for their safety and they understand the hazards

involved.

Children should be supervised to ensure they do

not play with the appliance.

This appliance is only to be installed in locations

where it can be overseen by trained personnel.

Cleaning and maintenance shall not be preformed

by children without supervision.

Do not use this appliance for other than its

intended use.

Do not probe any opening.

The pumps must only be operated when

connected to the dispensing unit.

To protect against electric shock, do not immerse

cord, plug or appliance in water or any other liquid.

The power cables and power outlet must be in a

safe visible position for connection.

It is recommended to regularly inspect the

appliance. Do not use the appliance if power

supply cord, power plug, or appliance becomes

damaged in anyway.

The installation of a residual current device (safety

switch) is recommended to provide additional

safety protection when using electrical appliances.

It is advisable that a safety switch with a rated

residual operating current not exceeding 30mA

be installed in the electrical circuit supplying the

appliance. See your electrician for professional

advice. All electrical work must be performed by

authorised personnel.

Approved Milks Approved Juices

5 6

3

4

1

2

1

3

4

5

2

1 2

3

4

5

SIX

SIMPLE

MACHINES

1

2

345

6

SYSTEM COMPONENTS

Freepour Dispenser

1. Tap

2. Product type badge

3. Tap outlet

4. Sink

5. Grate

6. Activation button

Control Unit

1. Navigation Keys

2. ON-MANUAL BACKUP

Button

3. Screen

4. Adjustment Dial

5. Manual Backup Button

Bladder System

1. Connector

2. Manifold/Pump Unit

3. Cleaning Tube

4. Rack

5. Drip Tray

6. Bladder Tray (not shown)

1. Product Overview

Product Overview l76 l

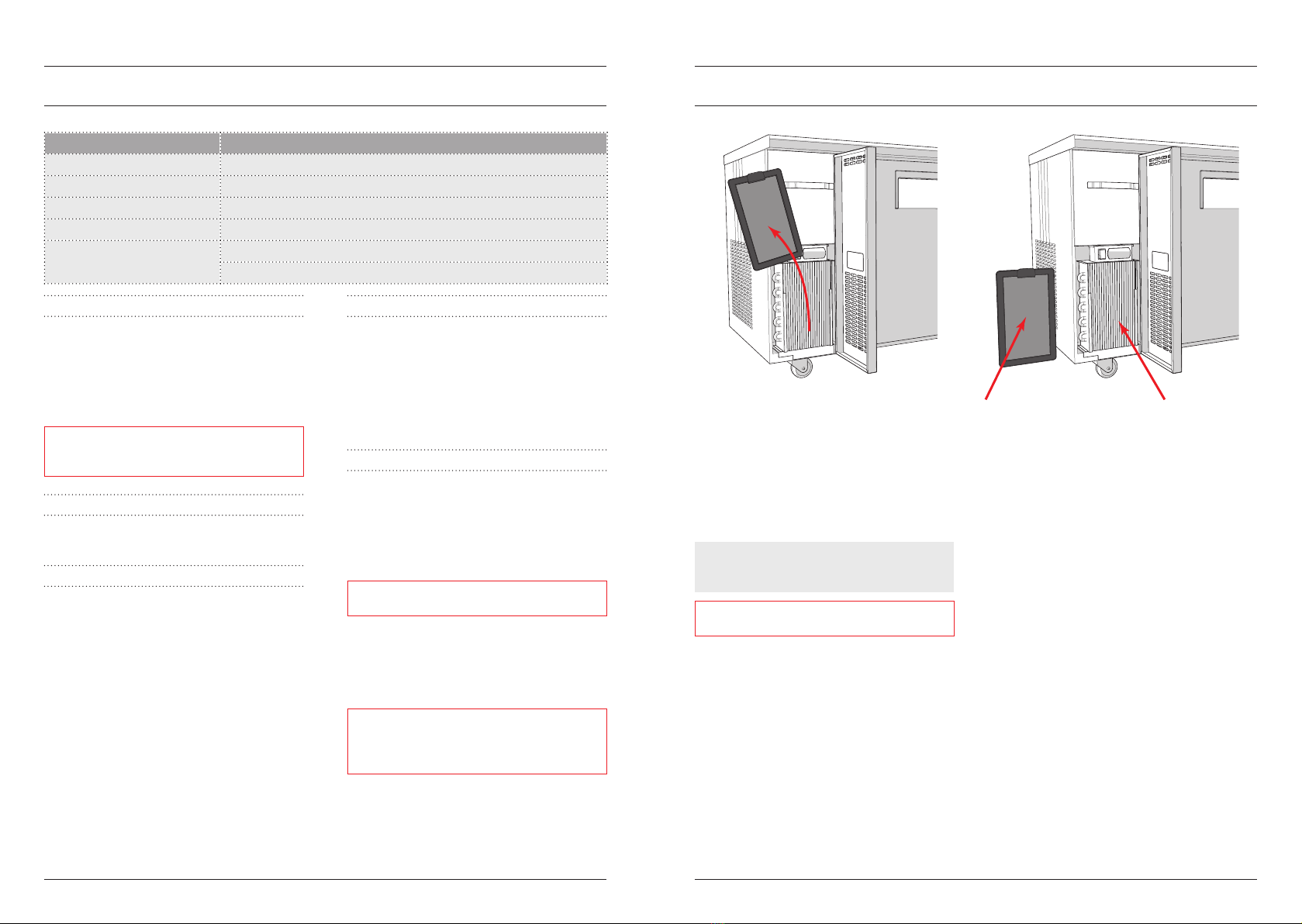

Freepour Chiller

1. Compressor

compartment door

2. Rear air vent (out)

3. Side air vent (out)

4. Front air vent (in)

5. Electronic Controller

6. Castor

OVERVIEW

Freepour self-serve beverage dispenser is a chilled

beverage dispensing system designed to satisfy a

variety of food service applications.

The system comprises 3 main units:

1. The Freepour Dispenser

The Dispenser is usually set ush into a cut-

out in your bench. The Dispenser may have a

single or multiple taps. Taps are available in

dierent heights. The Dispenser incorporates

a sink which is connected to a drain.

2. Control Unit

The Control Unit can be xed to the side of

the Chiller or in a nearby location where it

can be easily accessed by sta. The mounting

bracket used for xing the Control Unit to the

side of the Chiller can also be used to x the

Control Unit to a vertical surface; for instance

inside a cupboard.

3. Chiller

The Chiller is an undercounter style unit with

an internal compressor. Inside the Chiller is

a rack and tray system designed to accept

compatible bladder types.

Fluid products for Freepour are delivered in 10

litre compatible bladders. Freepour compatible

bladders have a special cap that automatically

connects to the dispensing system as you push

the bladder tray into the Chiller.

Each tray holds a 10 litre bladder of milk or fruit

juice. Depending on the Chiller and internal

conguration you may be able to connect all

bladders loaded or as few as one bladder at time.

IMPORTANT: Only approved varieties of milk and

fruit juice may be dispensed. Approved varieties of

milk and fruit juice can be found by scanning the

QR codes shown below.

BASIC DOSING FUNCTIONS

We have designed Freepour to be easy and

intuitive to use. Below is a basic overview of the

dosing functions.

NOTE: For step-by-step instructions on the daily

set up, use and cleaning procedures, see Section

3 - Operating Freepour on page 16.

MANUAL DISPENSE

Dispensing product is simple. Place a vessel under

the tap outlet. Press and hold the corresponding

activation button until you have the required

volume of product in the vessel. Release the

button to stop dispensing.

Dispensing will automatically stop if the button

is pressed for a time that exceeds the Dose Time

settings which are stored in the system software.

DOSE TIME

The Dose Time settings can be changed to set

the maximum volume of product that can be

dispensed during the dispense cycle.

This can be used, for example, to set a

recommended serve size or to discourage

excessive dispensing.

AUTOMATIC REVERSE FLOW

To ensure uid product is not held in the tap or in

the section of tube that is outside the Chiller, the

pumps automatically reverse between dispense

cycles drawing uid product from the tap back

inside the Chiller.

The Automatic Reverse Flow feature activates

after a timed delay stored in the system software.

The delay ensures that the user can top up their

beverage or dispense multiple beverages in

rapid succession without the dispense cycle

being interrupted by the Automatic Reverse Flow

feature.

SERVICES REQUIRED ON SITE

Power: 2 (or 3*) x 10A GPO’s

Control Unit: 1.0A

1 door Chiller: 2.8A, 2 door Chiller: 2.8A

* If a triple tap dispenser has been chosen or 2 x double tap

dispensers are running from a single chiller, an extra 10A GPO

will need to be supplied.

Drain: Access to a drain. An S or P trap is recommended

(for the drain located in Freepour dispenser sink).

Front View Side View Front View Side View

420

380352

300

380352

195

380

352

335

260227

MINIMUM 90

240

260227

195

185 230

260227230

175 240 175 360 280 360 400 360

220 240 315 240

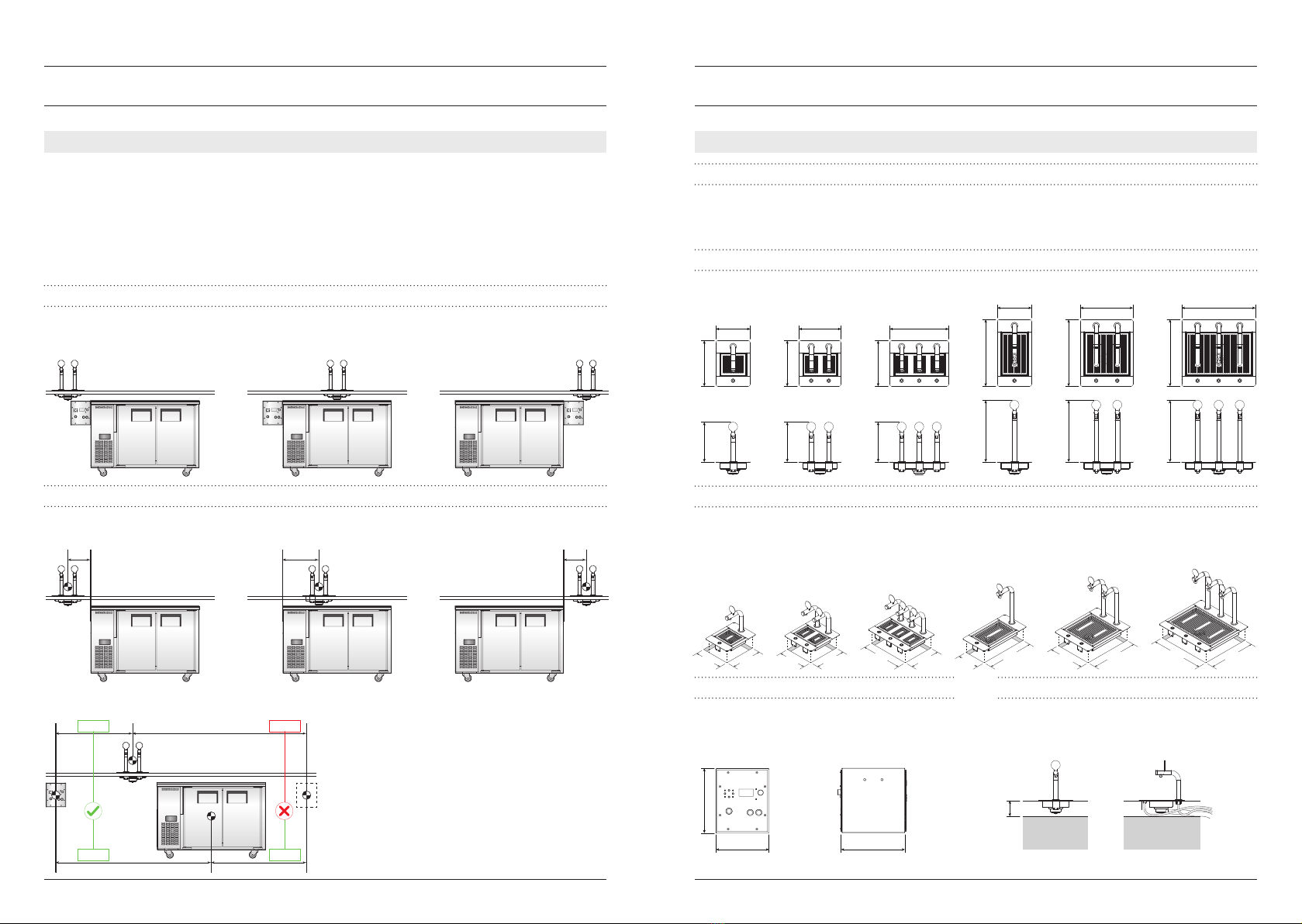

FREEPOUR DISPENSER AND CONTROL UNIT

POSITIONING THE DISPENSER

There is no set distance that the Dispenser needs to be relative to the edge of the bench. Consider that the

height of the bench and how far the Dispenser is placed in from the edge of the bench will eect access to

the Dispenser for people of dierent heights.

DISPENSER DIMENSIONS

Single Double Triple Single Tall Double Tall Triple Tall

BENCH CUTOUT DIMENSIONS

A rectangular hole in the bench is required to set the dispenser into the bench surface. A ange runs around

the perimeter of the dispenser and covers the edge of the cut-out similar to a top mount sink.

Single Double Triple Single Tall Double Tall Triple Tall

CONTROL UNIT DIMENSIONS

If a triple tap dispenser has been chosen or 2 x

double tap dispensers are running from a single

chiller, 2 x Control Units will have been supplied.

UNDER BENCH CLEARANCE

Space is required below the Dispenser to allow

room for the dispenser drain. This is measured

from the TOP surface of the bench.

max

400

<400<400

PLANNING THE DISPENSE STATION

The modular design of Freepour allows for a variety of installation congurations to suit your dispense station

layout. When deciding where each of the three units will be located, consider how the machine will be used

in service, reloaded by sta and cleaned at the end of the day.

You should also consider whether the Chiller will be set on castors and therefore will be movable allowing

sta to clean under and behind it, or whether the Chiller will be on a plinth and will not be movable. Flexible

uid product lines and data cables run between the Chiller and the dispenser. It is important that these lines

are not kinked, squashed or disconnected when moving the Chiller or accessing adjacent equipment.

GENERAL LAYOUT

The Dispenser may be placed to the left, right or directly above the Chiller. The Control Unit is most

commonly mounted on the side of the Chiller that is closest to the Dispenser. It can however be set

elsewhere so long as the maximum permissible distances and clearances are observed.

MAXIMUM PERMISSIBLE DISTANCES

The maximum distance between the Dispenser and Chiller is 400mm, measured from the centre of the

Dispenser to the closest edge of the Chiller.

The maximum distance between the Dispenser and Control Unit is 1.2 meters. The Control Unit must be no

more than 2 meters from the Chiller measured from the centre of the Control Unit to the centre of the Chiller.

<1200

<2000

>1200

<2000 Dimensions shown in mm

2. Installation Overview & Procedure

Installation Overview & Procedure l98 l

1205

400

730

A750

B

195

Floor

Drain*

205

905

750 545 195

Floor

Drain*

A

B

205

730

1800

445

730

A750

B

195

Floor

Drain*

205

Fluid product

line location

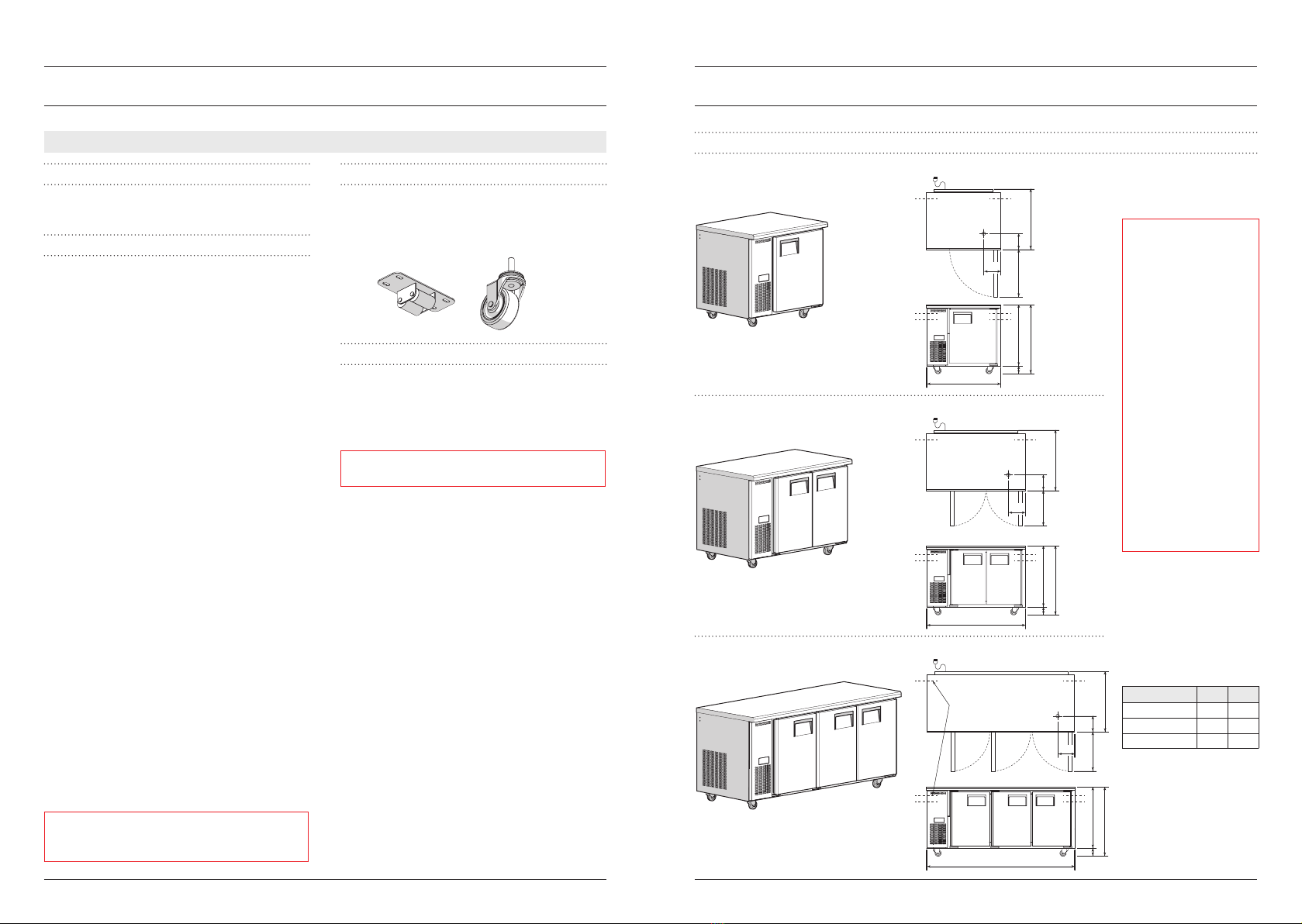

CHILLER DIMENSIONS

One Door Height Options

Two Door

Three Door

Roller Castors Standard Castors

Installation Overview & Procedure l1110 lInstallation Overview & Procedure

FREEPOUR CHILLER

OPERATING TEMPERATURE RANGE

The Chiller is designed to operate at 1°C to 4°C in

up to 38°C ambient.

LOCATING THE CABINET

Location

When positioning the cabinet, avoid direct sunlight

and warm draughts etc and areas where the

refrigeration unit could be exposed to water or

moisture. The cabinet must NOT be situated where

it is aected by warm or hot air from adjacent

equipment as this will compromise the airow and

performance of the cabinet.

The cabinet must be positioned on a level surface

for the doors to shut and seal correctly and to

prevent the condensate tray from overowing.

Allow adequate space for the doors to open fully,

including the compressor compartment door.

Ensure all packaging is removed from the cabinet.

Ventilation

Ensure there is always at least a 50mm gap around

the back and the refrigeration unit side of the

cabinet and that the hot refrigeration exhaust

air is not restricted and can easily ow out and

away from the front of the cabinet. Never store

cardboard cartons or other items in front of the

refrigeration unit. The ventilation slots on the

refrigeration unit front cover must be kept clear at

all times.

Normal operating conditions should not exceed

the operating temperature range.

Power Supply

The cabinet is supplied with a exible power

cord and plug which exits the rear of the cabinet.

Before nal positioning of the cabinet, uncoil the

power cord and connect to the power supply. For

convenience any surplus cord length may coiled

and xed to the rear of the cabinet compartment.

WARNING: Do NOT overload the power supply. See

the rating label inside the cabinet and also page 6

of this guide for power supply and current draw.

POSITIONING THE CABINET

Castors

The Chiller is usually delivered to site on standard

height castors. Short roller style castors can be

supplied by request and tted on site.

OPERATION

Automatic Start-Up

Connect the cabinet to the mains power supply

and check operation of the refrigeration unit and

electronic controller. Ensure the cabinet power

switch is turned on.

IMPORTANT: If the cabinet has been on its back,

leave for 30 minutes before running.

Power Switch

The cabinet is tted with a power switch, located

beside the electronic controller. Open the

compressor cabinet door to access the switch.

Refrigeration Unit

The compressor/condenser and evaporator

fans should all operate within two minutes from

the time the cabinet is plugged in. This may be

veried by listening for compressor switch-on and

checking for air movement inside the cabinet. The

compressor/condenser fan will switch o when the

cabinet internal air reaches a pre-set temperature.

Electronic Controller

When the cabinet is rst connected to the power

supply, the electronic controller will display the

current cabinet temperature. The compressor

symbol will come on after a few minutes, indicating

the compressor/condenser fan is operating.

To ensure ecient operation, the electronic

controller forces regular defrosts. During the

defrost cycle, the compressor/condenser fan

switches o and the evaporator fan stays on.

The Chiller can be installed on

castors or directly on a plinth.

IMPORTANT: We recommend

against plinth installations

because of the inherent

risk of uid tracking under

the Chiller and becoming

trapped between the Chiller

and plinth.

This risk is greater if a oor

pan style drain has not been

installed in the plinth.

If you install the Freepour

Chiller on a plinth we

recommend you discuss the

practicalities of installing a

oor pan style drain pan in

the plinth under the oor

drain* location with your

builder. If this is not practical

the drain plug can be

permanently xed in place.

See page 15: Step I.

*Not all Chillers are supplied

with a oor drain.

We oer two styles of

castors to accommodate

dierent bench heights. For

height options refer to the

dimensions labelled as A

and Bin the dimensioned

drawings and the table

below.

A B

Standard Castors 95 845

Roller Castors 30 780

Plinth NA 750

Dimensions are shown in

millimetres.

Note corresponding coloured labels

INSTALLATION PROCEDURE

Be aware that the system you are installing may dier from the example below. A major point of dierence is

that there may be 2 control units supplied. This is the case for example for dispensers with 3 taps, or systems

where 2 dispensers connect to a single chiller. The installation process for the second controller is the same as

shown below.

STEP A PLACE DISPENSER INTO THE HOLE IN THE BENCH

1. Uncoil the uid product lines and data cables;

2. Lower Dispenser into the hole in the bench.

NOTE: The Dispenser will be set in place with

silicone or similar sealant in Step G.

STEP B CONNECT DRAIN HOSE

1. Push the drain hose onto the barb connector

underneath the sink and attach hose clamp;

2. Route the drain hose to a drain and cut hose

to length.

IMPORTANT: For good drainage ensure adequate

fall and avoid sags in the hose. Ensure the end of

the drain hose cannot become submerged in the

drain.

STEP C MOUNT CONTROL UNIT AND CONNECT CONTROL TO PUMP CABLE

1. Mount the Control Unit on the Control Unit

mounting bracket;

2. Uncoil the Control to Pump cable from the

rear of the Chiller and connect to the rear of

the Control Unit;

IMPORTANT: To avoid malfunction ensure the

small catch on the male connector clips over the

retaining lug on the female connector.

3. Push the Chiller into place.

NOTE: Freepour generally ships with the Control

Unit mounting bracket and Control to Pump cable

set for a LHS installation. If the Control Unit is to

be set on the RHS of the Chiller or elsewhere the

Control Unit mounting bracket can be removed

from the Chiller and repositioned. The Control to

Pump cable can also be rerouted in the conduit on

the rear of the Chiller.

Installation Overview & Procedure l1312 lInstallation Overview & Procedure

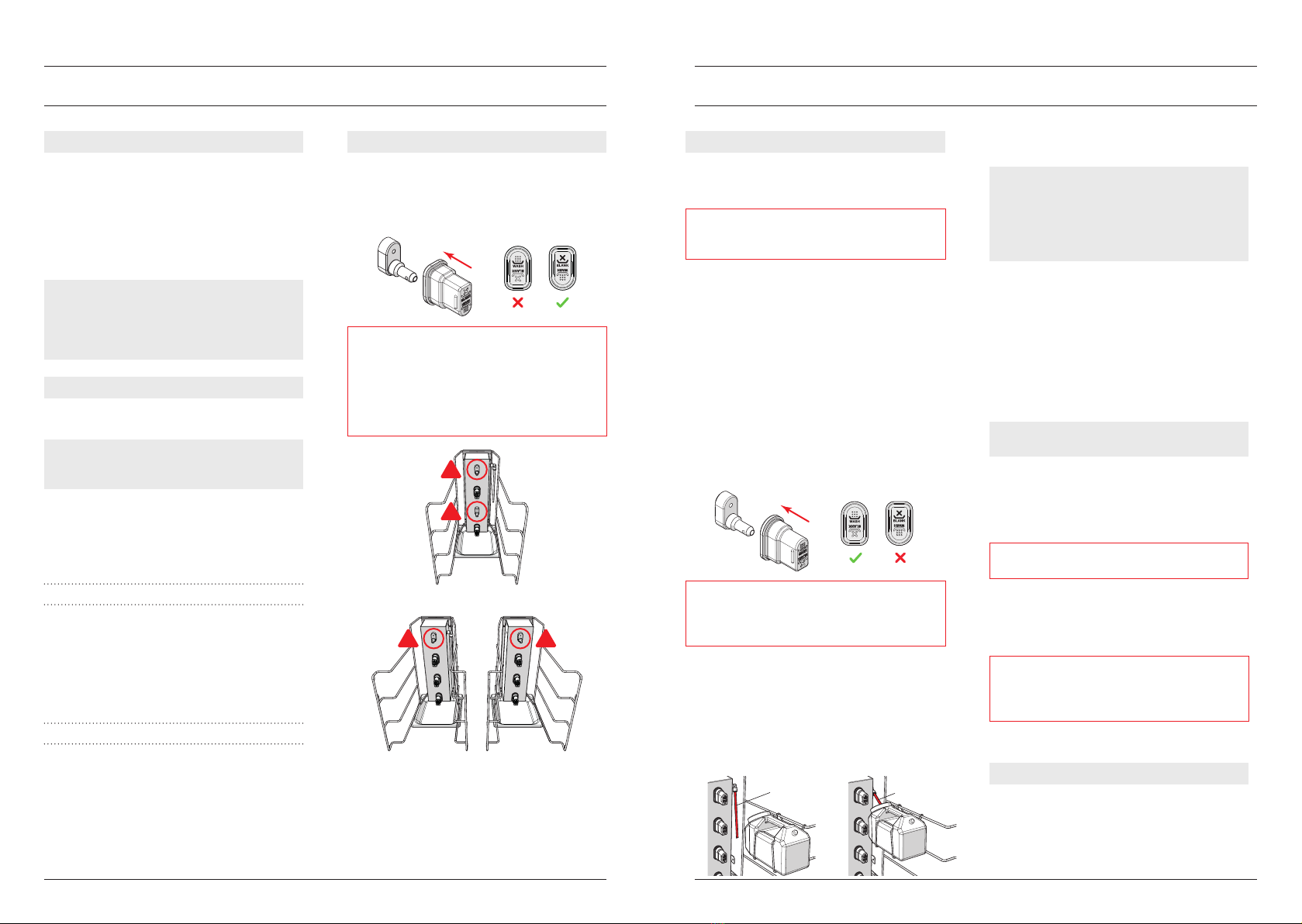

STEP D CONNECT FLUID PRODUCT LINES TO CHILLER

1. Feed the blue protective sleeves over the uid

product lines. Push the sleeves rmly up to

the tting at the base of the tap. Observe the

stickers on the protective sleeves showing the

tap and Chiller ends of the sleeve;

2. Feed insulation over the uid product lines.

Fasten in place with cable ties at both ends;

3. Punch out the centre of the rubber openings

in the side of the Chiller (inside and outside)

and push the uid product lines through

the openings until the STOP sticker on

the protective sleeve contacts the rubber

opening. It can be helpful to wet the product

lines with water and dishwashing soap before

pushing them through the openings.

STEP E CONNECT FLUID PRODUCT LINES INSIDE CHILLER

To account for all Freepour variants, uid product

lines are supplied long and need to be cut before

connecting to the manifold inside the Chiller.

1. Determine the length for the uid product

lines inside the Chiller and cut them to length;

NOTE: The length of the uid product lines inside

the Chiller is correct when they are not too long

and risk being kinked inside the Chiller and not

too short making connection dicult.

2. Plug 'A' uid product line into the top

connector on the manifold and 'B' uid

product line into the lower connector.

NOTE: Ensure that the uid product lines are

pushed FULLY into the ttings in the side of the

manifold so this connection does not leak.

STEP F CONNECT DATA CABLES

1. Connect the data cables (mentioned in STEP

A) to the rear of the Control Unit.

IMPORTANT: Ensure the small catch on the male

connector clips over the retaining lug on the

female connector. If this catch does not engage,

the connector may slowly uncouple and cause the

machine to malfunction.

Control

to Pump

cable

Mounting

bracket

Drain hose

not sagging

Drain hose

correct length

Drain hose

sagging

Drain hose

too long

Tap A

coloured label

Tap B

coloured label

Coloured labels are used to identify all fluid and data connections.

Ensure you connect fluid lines and data cables into connectors

with corresponding coloured labels.

Cable tie

Tap B

coloured label Insulation

STOP sticker

on protective

sleeve

Protective sleeve

Fluid product line

Note corresponding

coloured labels

STEP G FIX DISPENSER IN PLACE

1. Prop the Dispenser 5 to 10mm above the

bench to create a gap between the sink

ange and the bench surface;

2. Apply silicone or a similar sealant to the

bench surface under the sink ange. Follow

sealant manufacturer guidelines to ensure the

bond is strong and will not leak;

3. Remove props and carefully lower the

Dispenser into place;

4. Clean o excess sealant and allow to cure.

STEP H COMMISSIONING FREEPOUR

1. Visually inspect all connections to ensure they

are sound and in the correct place;

2. Plug the Chiller into a power supply of 220-

240 Volt AC and switch on;

3. Plug the Control unit into a power supply of

220-240 Volt AC and switch on;

NOTE: So you do not need to use bladders to test

for leaks and correct operation, set the system up

as if you are about to run the cleaning routine. Do

not add chemical to the water. See page 19 for

instructions on setting up the cleaning routine.

4. Press and hold activation button for each tap

and watch the stream of water to see that it

eventually runs clear without bubbles.

NOTE: A persistent stream of bubbles in the water

being dispensed may indicate a leak is present

somewhere in the system. You may need to top up

the cleaning bottle a few times during this test.

STEP I ASSESS CHILLER DRAIN PLUG

Some Chillers have a oor drain and plug.

IMPORTANT: If uid cannot drain away or

be easily collected, the drain plug should be

permanently sealed in place with silicone so it

cannot be removed. This is especially important

where a Chiller has been installed on a plinth.

BEFORE FIRST SERVICE

Run the Cleaning Routine and inspect for normal

operation. See page 19 for instructions on how to

run the cleaning routine.

OPTIONAL PROCEDURES

For the majority of applications the default

software settings will not need to be changed.

The two exceptions to this are:

1. Dose Time

This can be used, for example, to set a

recommended serve size or to discourage

excessive dispensing.

2. Flow Rate

This may be changed, for example, to slow

the rate of dispense into an unusual shaped

vessel to reduce the chance of overlling.

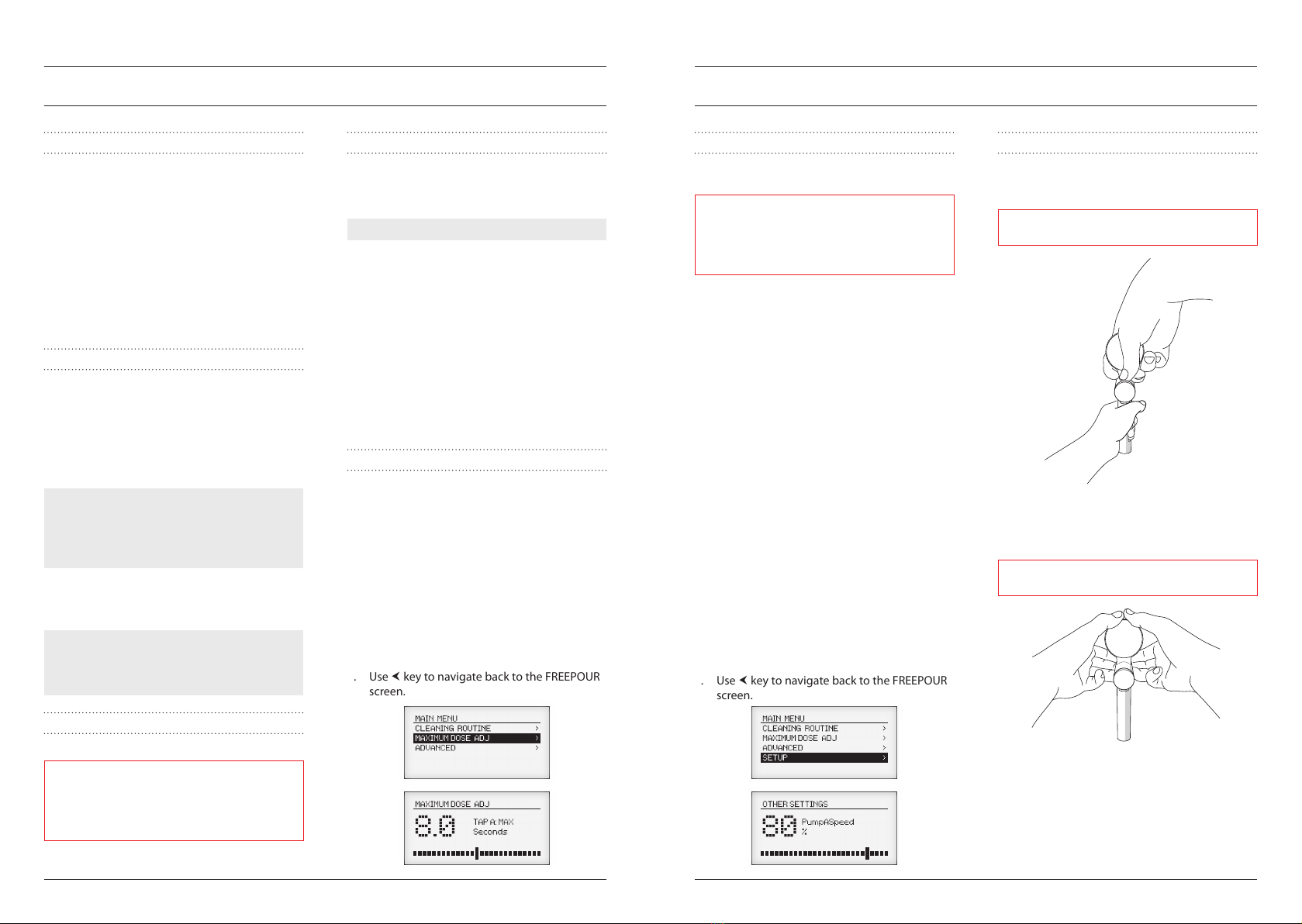

CHANGING THE DOSE TIME

Use the interface on the Control Unit to change

the Dose Time:

1. Use keys to navigate through MENU /

MAXIMUM DOSE ADJ to enter into the

MAXIMUM DOSE ADJ menu;

2. Use the adjustment dial to change the Dose

Time (in seconds) for Tap A;

3. Use key to navigate to Tap B;

4. Use the adjustment dial to change the Dose

Time (in seconds) for Tap B;

5. Use key to navigate back to the FREEPOUR

screen.

Installation Overview & Procedure l1514 lInstallation Overview & Procedure

CHANGING THE FLOW RATE

Flow Rate is in a hidden menu to help ensure it is

not changed by accident.

WARNING: The hidden SETUP menu contains

many essential system settings. We do not

recommend changing any settings in the hidden

SETUP menu unless you are sure you understand

the purpose of the setting and likely consequence.

To access the hidden SETUP menu:

1. Switch Freepour to MANUAL using the ON-

MANUAL BACKUP switch on the Control Unit;

2. Press and hold the UP and DOWN navigation

keys and switch Freepour to the ON position;

3. Wait to see DEBUG MODE appear briey on

the screen, then release the UP and DOWN

navigation keys.

To change the Flow Rate:

1. Use keys to navigate through MENU /

SETUP / OTHER SETTINGS. Press to enter

into the OTHER SETTINGS menu;

2. Use key to navigate to pump A speed

adjustment screen;

3. Use the adjustment dial to change the pump

speed (as a % between 0 and 100) for Tap A;

4. Use key to navigate to pump B speed

adjustment screen;

5. Use the adjustment dial to change the pump

speed (as a % between 0 and 100) for Tap B;

6. Use key to navigate back to the FREEPOUR

screen.

CHANGING THE PRODUCT TYPE BADGES

The badge holder can be removed from the taps

by rmly pulling the badge holder upward using

the technique shown below.

WARNING: Support the tap when removing the

badge holder otherwise the tap may be damaged.

The badge holder can be xed to the taps by

inserting the badge holder into the slot in the tap

and rmly pushing the badge holder down using

the technique shown below.

WARNING: Support the tap when replacing the

badge holder otherwise the tap may be damaged.

Cap correctly

clipped in

Cap NOT correctly

clipped in

Flip centre of

cap open

Twist to remove

centre completly

Cap face down Cap face up

Tray end past

rack end

Tray NOT past

rack end

3. Operating Freepour

16 lOperating Freepour l17

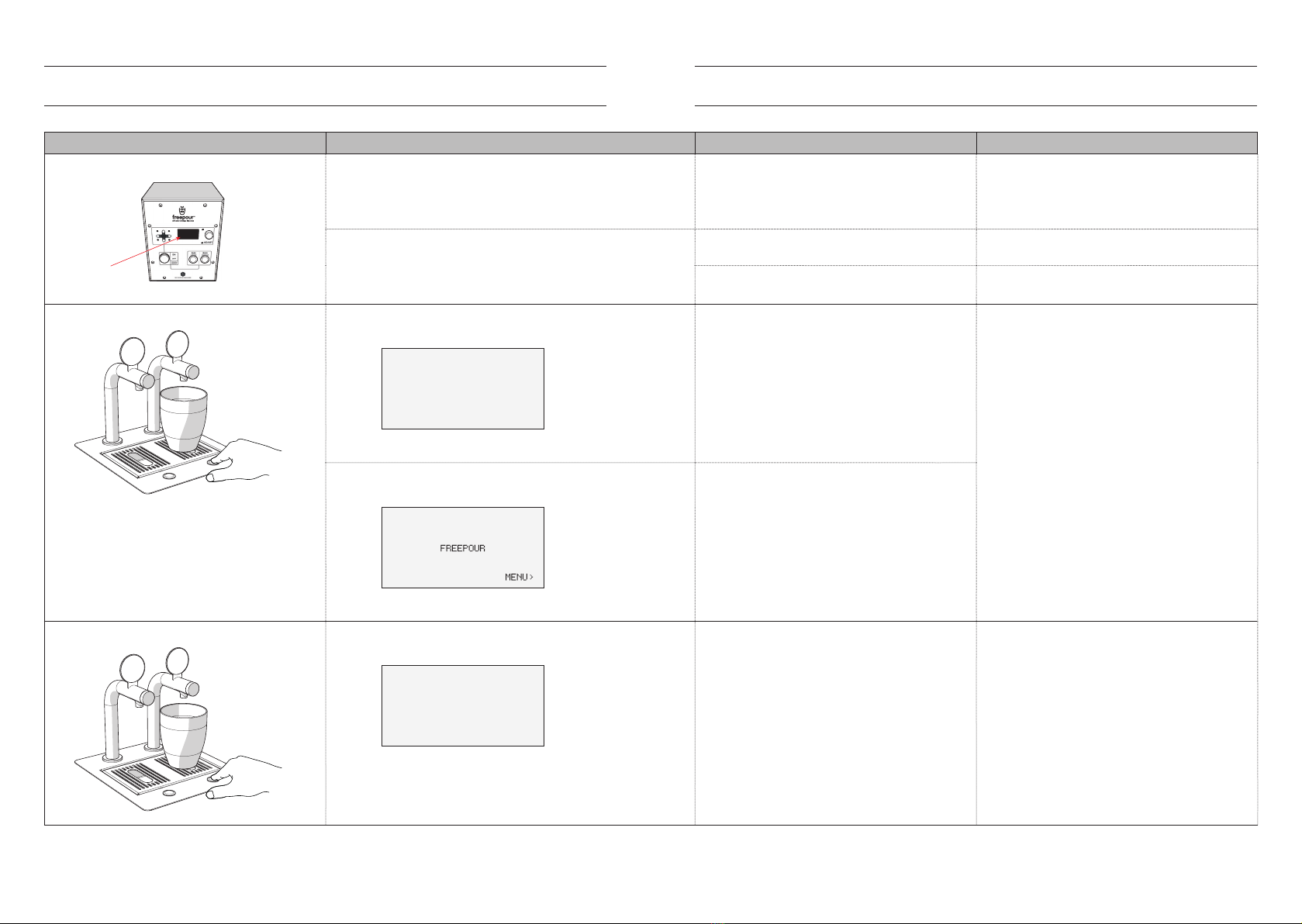

DAILY SETUP PROCEDURE

1. Remove red caps from the black connectors

inside the Chiller;

2. Remove, empty and clean the internal drip

tray(s). Replace the drip tray(s);

3. Load bladders into trays and remove the

centre of the cap;

4. Load the trays into the Chiller, starting at the

top position;

NOTE: Push the tray in quickly so milk does not

leak from the cap during connection.

IMPORTANT: Ensure the tray is rmly pushed past

the rack ends. If the tray is not pushed all the way

in, a bladder may not be connected properly and

may leak.

NOTE: If there are partially used bladders from

the day before, load these into the top positions

so they are used before full bladders loaded in the

lower positions.

5. Inspect the internal drip trays for evidence of

leaks caused by poorly connected bladders;

6. Turn Freepour ON at the Control Unit;

7. Activate a dispense cycle on all taps to prime

the system ready for use. Priming is complete

when a constant stream of uid product is

being dispensed.

OPERATING MODES

Use the ON-MANUAL BACKUP switch to select

between the following 2 operating modes:

ON

When the ON-MANUAL BACKUP switch is pressed

in the dispensing system is ON and all automatic

features, such as dispensing, automatic reverse

ow and running the cleaning routine, are active.

MANUAL BACKUP

When the ON-MANUAL BACKUP switch is not

pressed in, the unit is in STANDBY mode and all

automatic dosing and programming features are

not active.

In the event that the electronics are

malfunctioning, Freepour can still dispense milk as

long as the internal power supply and pumps are

still active. No dosing and programming features

are active in this mode.

Manual dispensing:

ON-MANUAL BACKUP switch must be in the

MANUAL BACKUP position (not pressed in).

1. Place a vessel under a tap;

2. Press and hold the RUN LEFT TAP or RUN

RIGHT TAP button on the Control Unit to

dispense product. Release the button to stop

dispensing.

IMPORTANT: Switching the ON-MANUAL

BACKUP switch to the MANUAL BACKUP position

does not cut the power o to the Control Unit. To

cut power o to the Control Unit, turn the power

o at the wall socket and remove the Control Unit

plug from the wall socket.

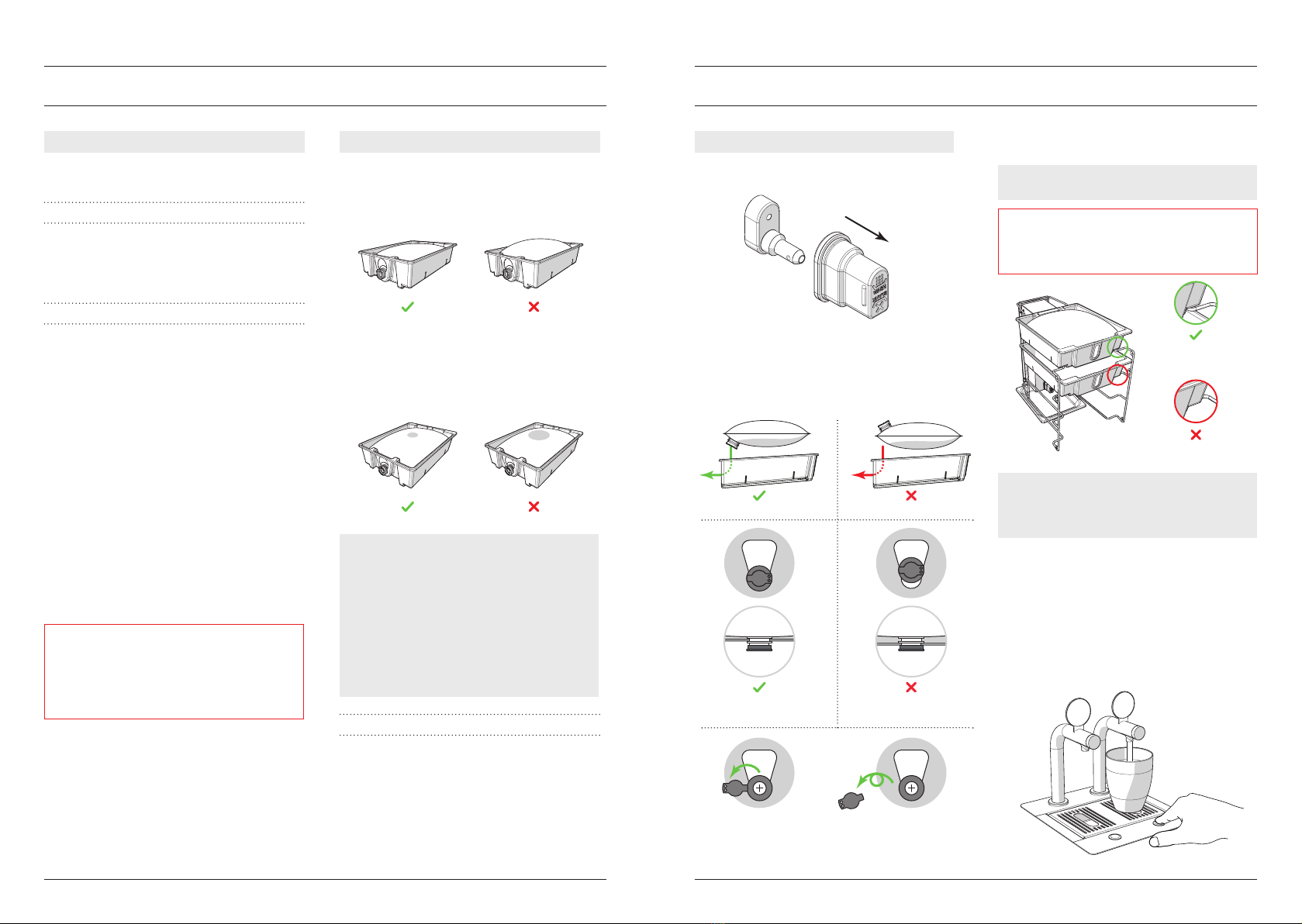

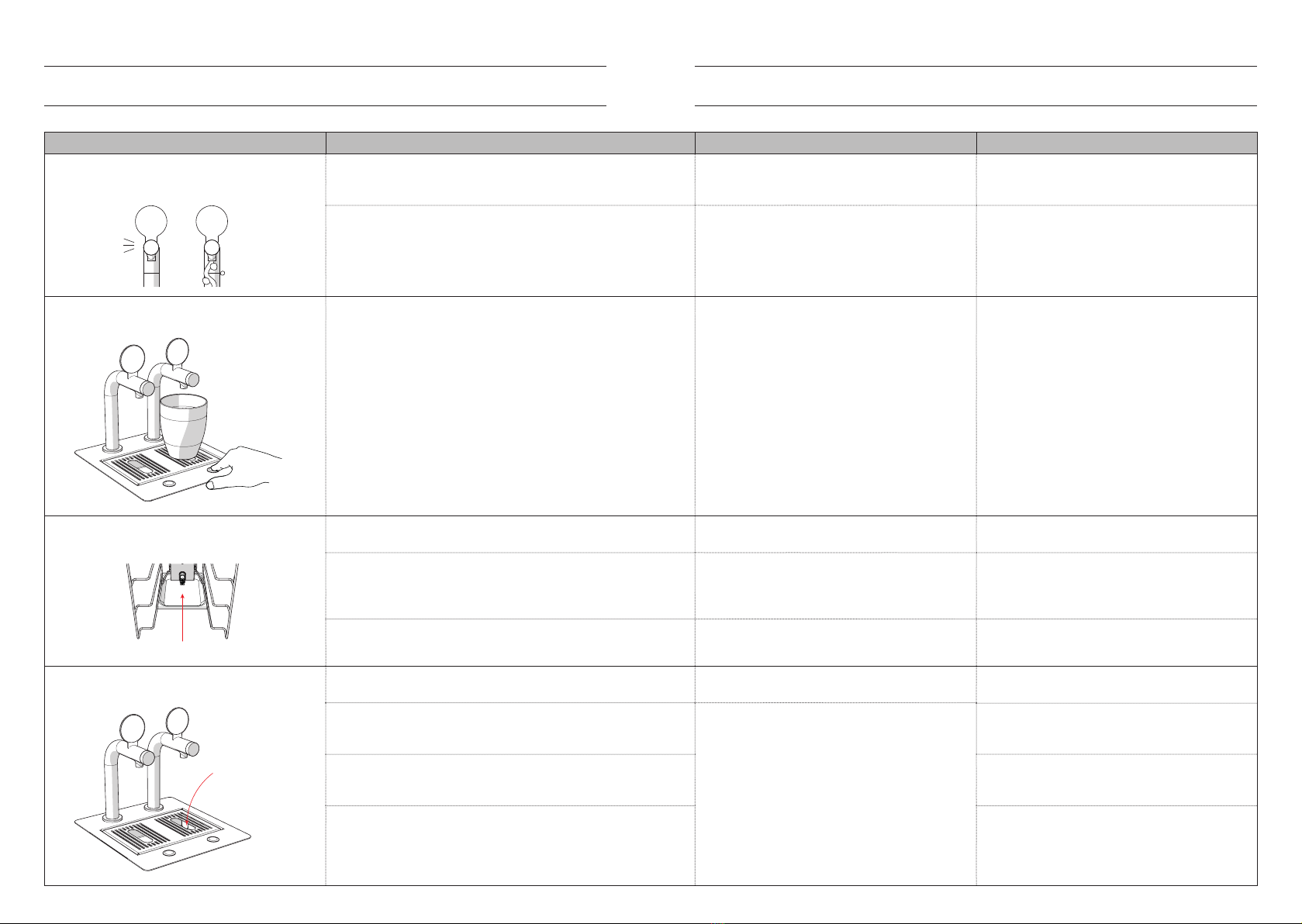

BLADDERS

To work well in Freepour, bladders must:

1. Hold exactly 10L of uid product

If overlled bladders are forced into the

Chiller, they may leak;

2. Contain as little air as possible

If a bladder contains too much air, dosing

becomes inconsistent and bubbly as each

bladder empties.

NOTE: If a bladder contains a large air bubble, it

is possible to manually bleed the air out before

loading the bladder into the Chiller.

To do this:

1. Place the bladder on a at surface with the

cap facing up and remove the centre of the

cap;

2. With the cap held higher than the bladder,

use a teaspoon to slightly open the valve as

you slowly push down on the bag.

HANDLING BLADDERS

Bladders are tougher than they appear but may

develop a leak if handled or stored incorrectly.

When handling bladders, always:

1. Carry a bladder using 2 hands;

2. Do not carry a bladder by the cap;

3. Be careful of sharp objects or edges; and

4. Be careful not to pinch bladder between tray

and racks when loading.

Small air bubble Large air bubble

Bladder fits well

in tray

Bladder bulges higher

than the top of the tray

DISPENSING PRODUCT

ON-MANUAL BACKUP switch must be in the ON

position (pressed in).

1. Place a vessel under the tap outlet;

2. Press and hold the corresponding activation

button to begin dispensing;

3. Release the button to stop dispensing.

NOTE: Dispensing will automatically stop if the

button is pressed for a time that exceeds the Dose

Time settings. The default Dose Time settings are:

• Standard height Dispenser = 8 seconds

• Tall Dispenser = 12.5 seconds

RELOADING DURING SERVICE

1. Wait for more than 10 seconds after the last

dispense cycle before removing a bladder;

NOTE: By default the Automatic Reverse Flow

feature activates 10 seconds after the last

dispense cycle.

2. Remove a tray holding an empty bladder.

Remove and discard the bladder;

3. Load a new bladder into the tray and load the

tray into the Chiller.

RELOADING A 'CONNECT 4' CHILLER

In a 'Connect 4' Chiller, the top two bladders are

usually dedicated to one uid product type and

the lower two bladders are dedicated to a second

uid bladder type.

Both bladders of a uid product type empty at

roughly the same rate.

RELOADING A 'CONNECT 8' CHILLER

In a 'Connect 8' Chiller, the four LHS bladders are

dedicated to one uid product type and the four

RHS bladders are dedicated to a second uid

bladder type.

The bladders empty from the top position to the

lowest position in an overlapping sequence.

BLANKING

Freepour can be run on as few as one bag of each

product type. A red cap must be placed over

unused connectors in the BLANK orientation

otherwise the machine will suck air in through the

uncovered connectors which disrupts dispensing.

IMPORTANT: When in dispensing mode, the

connectors highlighted below should always

have a bladder connected. Never place a red cap

on these connectors in the BLANK orientation

otherwise uid product will be sprayed into the

Chiller following each dispense cycle and during

the automatic reverse ow cycle.

Operating Freepour - After Service

Operating Freepour l19

Operating Freepour - During Service

18 lOperating Freepour

DAILY CLEANING ROUTINE

The milk and juice systems are independently

cleaned using dierent cleaning chemicals. See

page 5 for information on cleaning chemicals.

IMPORTANT: Follow the procedure below for the

milk system using Daily Milk Line Cleaner and also

for the juice system using Daily Juice Line Cleaner.

1. Enter the cleaning routine screen via the

Control Unit: MENU > CLEANING ROUTINE;

2. Remove trays with empty bladders. Discard

empty bladders and wash the trays;

3. Remove trays with partially full bladders. To

prevent bladders leaking from the cap, ip

each bladder so the caps point upward;

4. Use a soft cloth and food-safe cleaner to clean

around the base of each black connector;

5. Place a red cap on all black connectors.

Ensure the red cap is pushed rmly into place

and the rounded edge is at the top;

IMPORTANT: If you have used a red cap in the

BLANK orientation you must remove the cap and

ip it around to the CLEAN orientation to ensure

the entire dispensing system is cleaned correctly.

6. Mix 100ml of the correct Freepour Line

Cleaner with 2L of warm water (40-50) in the

corresponding Freepour cleaning bottle;

7. Hook the cleaning bottle on the rail inside

the Chiller and engage the cleaning tube in

the hole in the lid. Slide the cleaning bottle

forward as far as it will go and close the door;

8. Initiate the cleaning routine via the Control

Unit: ACTIVATE >;

NOTE: The cleaning routine runs unassisted for

around 15 minutes. During this time, the lights

in the activation buttons ash and the taps will

periodically dispense a short burst of cleaning

solution. A progress bar on the Control Unit screen

shows the progress of the cleaning routine.

9. At the 15 minute mark, the lights in the

buttons stay on and ACTIVATE WATER FLUSH?

is displayed on the Control Unit screen.

Remove the cleaning bottle and empty

remaining cleaning solution. Rinse and ll the

cleaning bottle with 2L of cold water. Load as

directed in Step 7;

10. Activate the water ush via the Control Unit:

ACTIVATE WATER FLUSH? > YES;

NOTE: The water ush runs unassisted for around

30 seconds.

11. Turn Freepour to MANUAL BACKUP on the

Control Unit;

12. Use a soft cloth and food-safe cleaner to clean

around each tap outlet;

IMPORTANT: Do not use a bottle brush to clean

inside the Freepour tap outlets.

13. Remove and rinse cleaning bottle and drip

trays. Clean internal fridge surfaces and

external surfaces of the Dispenser. Replace

drip trays.

IMPORTANT: If your Chiller has a oor drain

ensure that uid can be easily collected or can

easily drain away when the drain plug is removed.

If in doubt, do not remove the drain plug.

Cleaning is now complete!

LEAVING FREEPOUR OVERNIGHT

1. Leave red caps on connectors after the

cleaning routine is complete;

2. Ensure all partially used bladders have been

ipped on their backs to prevent them from

leaking into the Chiller overnight.

!

!

‘Connect 4’ Chiller

‘Connect 8’ Chiller

!!

Cleaning

tube

Engage

cleaning tube

4. Freepour Chiller

Freepour Chiller l2120 l

FREEPOUR CHILLER

Changing settings that relate to the operation of

the Chiller is performed through the electronic

controller.

The electronic controller is visible through a cut

out in the front panel. It controls and displays

the cabinet interior temperature and signals

temperature alarms. It uses temperature probes

around dierent areas of the refrigeration system

to collect data and to run the cabinet accordingly.

The electronic controller is pre-programmed

and requires no initial setup or additional

programming. We do not recommend that

the settings be changed unless it is absolutely

necessary.

CAREL EASY ELECTRONIC CONTROLLER

Because the electronic controller plays such an

important role, it’s helpful to know the parts of

the faceplate you may use.

1. Compressor Indicator

2. Display

3. Stand-by (up) button

4. Mute (set) button

5. Manual defrost button

NOTE: See the table on page 21 for the function of

each item above.

STANDBY MODE

Press and hold the stand-by button for three

seconds to turn stand-by mode on or o. When

stand-by mode is on, the controller display will

alternate between the cabinet temperature and

Of, and the compressor, fans and alarms are

disabled.

The interior light is still activated by the door

switch and will come on when a door is opened.

TEMPERATURE SETPOINT

The temperature setpoint is factory set and can be

adjusted if necessary.

We do not recommend that the setpoint be

changed unless it is absolutely necessary, and

then only by small increments at a time.

To view and adjust the temperature setpoint:

1. Press and hold the set button until the

controller display shows SEt followed by a

temperature value. The temperature value is

the current setpoint.

NOTE: If PS appears on the display, the set button

has been held for to long. Release it, then press the

set button twice to restart the procedure.

2. Press the up and down buttons to adjust the

value to the required setpoint.

3. Press the set button again to store the new

setpoint value.

Carel Easy - Icons and Functions

Item Icon Function

1Compressor indicator

ON when the compressor and condenser fan starts.

Flashes when activation of the compressor is temporarily delayed.

2Display

Shows the cabinet temperature.

Flashes when the door is open.

3Stand-by (up) button

Turns stand-by mode on and o.

To scroll settings up (in program mode).

Note: This is not an isolation switch.

4Mute (set) button

Mutes the audible alarm (buzzer) and deactivates the alarm relay, and used in

program mode.

5Manual defrost button

Press for more than 5 seconds to initiate manual defrost.

To scroll settings down (in program mode).

Carel Easy - Messages and Alarms

Code Alarm Action

Defrost cycle in

progress message

Cabinet is running correctly.

Message will stop displaying once the defrost cycle is complete.

Temperature sensor

fault alarm

Reset alarm by unplugging the cabinet from the power supply

for one minute, then reconnect.

If alarm persists, arrange a service call.

Product low

temperature alarm

Product high

temperature alarm

Parameter error alarm

Defrost error alarm

1 2 3

5

4

5. Maintenance

Maintenance l2322 l

Item Frequency

Surface cleaning Daily

Flush and Sanitise milk lines Daily

Deep Clean 6 monthly intervals

Clean Chiller condenser lter At least once per week

Clean Chiller condenser coil Brush clean: Once a month

Blow clean: 6 monthly intervals

CLEANING

Stainless Steel surfaces are easily scratched

by poor cleaning practices. Proper cleaning of

stainless steel requires soft cloths. Never use

scourers, steel pads, wire brushes or scrapers.

Wipe both the interior and exterior of the chiller

cabinet with a damp cloth.

IMPORTANT: Ensure the cabinet is unplugged

from the mains power supply before cleaning the

Chiller cabinet with water.

FLUSH AND SANITISE MILK LINES

Refer to page 19 for instructions on how to run

the Daily Cleaning Routine.

DEEP CLEAN

The Deep Clean procedure is performed by a

qualied service technician.

Contact Six Simple Machines to arrange for a Six

Simple Machines authorised service agent to

perform the Deep Clean.

CONDENSER FILTER

The condenser lter must be cleaned at least

once every week. Failure to do so will result

in inecient cooling performance, increased

electricity consumption and damage to the

compressor or other refrigeration components.

See page 23 for instructions on how to clean the

condenser lter.

CONDENSER COIL

Fine dust can pass through the lter and collect

on the condenser coil ns. The ns should be

inspected and cleaned once a month or more

frequently if required.

See page 23 for instructions on how to clean the

condenser coil.

IMPORTANT: Unplug the cabinet from the power

supply before cleaning the condenser coil.

Over time dust may accumulate within the

condenser coil that cannot be easily removed

with a brush. The condenser coil should be

professionally cleaned by a qualied refrigeration

technician every six months.

IMPORTANT: Failure of any refrigeration

component caused by poor cleaning of the dust

lter or condenser coil is not covered by the Chiller

warranty.

Cleaning the condenser lter

1. Open the compressor compartment door to

gain access to the condenser lter;

2. Remove the condenser lter by sliding it up.

Remove all dust and u from the lter using

a brush or a vacuum cleaner;

NOTE: If cleaning the condenser lter with a brush

or vacuum cleaner is not sucient, the lter may

be rinsed or washed with water.

IMPORTANT: If the lter has been rinsed with

water, ensure it is fully dry before retting it.

3. Ret the condenser lter, compressor

compartment door and reconnect the cabinet

to the power supply.

Cleaning the condenser coil

1. Isolate the cabinet from the power supply by

unplugging it from the wall;

2. Open the compressor compartment door to

gain access to the condenser lter and coil;

3. Remove the condenser lter by sliding it up.

Remove all dust and u from the lter;

4. Brush the condenser coil in the directions of

the ns to remove all dust and u;

5. Ret the condenser lter, compressor

compartment door and reconnect the cabinet

to the power supply.

Remove condenser filter Condenser filter Condenser coil

Troubleshooting l25

6. Troubleshooting

24 l

Problem Troubleshooting Tips Possible Cause Solution

The system does not turn on

SIX

SIMPLE

MACHINES

Blank screen

Check that the Control Unit is plugged into a power

outlet and the outlet is switched on; and

Conrm the outlet is working by plugging in another

appliance.

The Control Unit is not receiving power. Connect power cord to a functioning outlet and

turn on.

Switch to MANUAL BACKUP and press and hold RUN

LEFT TAP and RUN RIGHT TAP; and

Listen for the sound of the pumps running and/see

that the tap(s) are dispensing.

If pumps run:

• The Freepour electronics may have failed.

Run the system in MANUAL BACKUP mode and call

a service technician.

If pumps do not run:

• The Freepour power supply may have failed.

Call a service technician.

Dispensing cannot be activated on one or both taps Check Control Unit screen to see if there is the NO

CURRENT error message being shown.

NO CURRENT ON HEAD A

CHECK PUMP FUSE!

PRESS < TO CANCEL

Error shown on screen

If the NO CURRENT error is displayed on screen:

• The pump cable may have become

disconnected;

• The circuit breaker(s) may have tripped;

• A pump may be jammed; or

• The pump(s) may have failed.

Reconnect pump cable and press key on the

Control Unit to clear the error;

Reconnect data cable(s) and press key on the

Control Unit to clear the error;

Push circuit breaker in and press key on the

Control Unit to clear error; or

Call a service technician.

Check Control Unit screen to see if there is an error

message being shown.

No error shown on screen

If there are no errors displayed on screen but the

screen is on:

• The data cable(s) may have become

disconnected; or

• The pump(s) may have failed.

Dispensing cannot be activated on either tap Check Control Unit screen to see if there is the

OVERCURRENT error message being shown.

OVERCURRENT ON HEAD A

PRESS < TO CANCEL

Error shown on screen

If the OVERCURRENT error is being displayed on

screen:

• A uid product line may be kinked or blocked;

or

• A pump may be jammed.

Inspect the uid product lines for kinks and un-kink

the aected line.

If no kinks can be found or a kink has weakened the

uid product line, call a service technician.

Troubleshooting l2726 lTroubleshooting

Problem Troubleshooting Tips Possible Cause Solution

Audible 'gurgling' sound and no product is

dispensed or product being dispensed is unusually

bubbly

Gurgle Bubbly

and/or

spitting

Gurgle

Gurgle

Check to see that red caps are being used correctly

(see: BLANKING page 18 and ACTIVATING THE

CLEANING ROUTINE page 19).

The red caps may be upside down or not properly

pushed onto the black connector(s) inside the

Chiller.

Follow instructions on pages 18 and 19.

Check to see that bladders are loaded correctly. Bladders may not be connected correctly. Follow instructions on page 17.

The dispense cycle is automatically stopping before

the activation button is released

Check to see the Dose Time settings:

• Use keys to navigate through MENU /

MAXIMUM DOSE ADJ to enter into the

MAXIMUM DOSE ADJ menu; and

• Check Dose Time settings.

The Dose Time may have been set too low for the

desired application.

Follow instructions on pages 14 to change the Dose

Time(s).

There is an unusually large volume of uid product

in the drip tray or bottom of the Chiller at the end of

service

Product in drip tray

Check to see that bladders are being loaded

correctly.

If trays are pushed into the Chiller too slowly, they

will leak from the cap as they are connecting.

Push the trays in quickly when loading a new

bladder (see page 17).

Make sure that the red caps are not being used in the

BLANK orientation on the connectors where this is

not permitted.

If the red caps are being used to in the BLANK

orientation on certain connectors in the Chiller,

small amounts of milk will spray into the Chiller

after each dose and Automatic Reverse Flow cycle.

Make sure you understand where you can and

cannot use the red caps in the BLANK orientation

(see: BLANKING page 18).

Make sure you understand how the Automatic

Reverse Flow feature works.

Poor understanding of the Automatic Reverse Flow

feature may be the cause.

Read the Automatic Reverse Flow section of the

user manual (see pages 7 and 18).

The sink is not draining or is draining slowly

and/or there is uid product on the oor

Sink not draining

Check that the Dispenser drain and oor drain are

not blocked.

The drain hose running between the Dispenser

drain and oor drain may be blocked.

Check that the Dispenser drain and oor drain are

not blocked.

Ensure drain hose has been correctly attached to

the barb tting on the drain and that the drain is not

loose in the sink.

The drain hose may have been poorly installed or

may have become dislodged.

Ensure the drain hose and drain are properly

installed (see page 12 for correct installation).

Check that the drain hose is not sagging or kinked

and has adequate fall from the Dispenser sink to the

cafe drain.

Ensure the drain hose is as straight as possible and

is angled downward all the way to the cafe drain

(see page 12 for correct installation).

Check that the end of the drain hose is not

submerged in the cafe drain.

Pull the end of the drain hose up out of the drain

and cut it shorter so it cannot become submerged

(see page 12 for correct installation).

At Six Simple Machines we are always looking for ways to improve our products.

The illustrations in this guide may differ slightly from the actual product.

Made in Australia

D00142 A05 l © 2020 SIX SIMPLE MACHINES Pty Ltd

This manual suits for next models

3

Table of contents

Popular Dispenser manuals by other brands

BOWMAN

BOWMAN CL003-0111 manual

SIKA

SIKA Power Cure operating instructions

Silver King

Silver King Majestic SK12MAJ Technical manual and replacement parts list

Franke

Franke F3Dn Twin Service manual

HURAKAN

HURAKAN HKN-MT1 manual

STIEBEL ELTRON

STIEBEL ELTRON UltraHot Plus Operation and installation instructions