Table of contents

Table of contents

1 About this document ............................... 3

1.1 Target groups ................................. 3

1.2 Other applicable documents ................ 3

1.3 Warnings and symbols ....................... 3

2 Safety instructions ................................. 4

2.1 Intended use .................................. 4

2.2 General safety instructions .................. 4

2.2.1 Obligations of the operating company ...... 4

2.2.2 Obligations of personnel ..................... 4

2.3 Hazardous media ............................ 4

3 Layout and Function ............................... 5

3.1 Marking ....................................... 5

3.1.1 Name plate ................................... 5

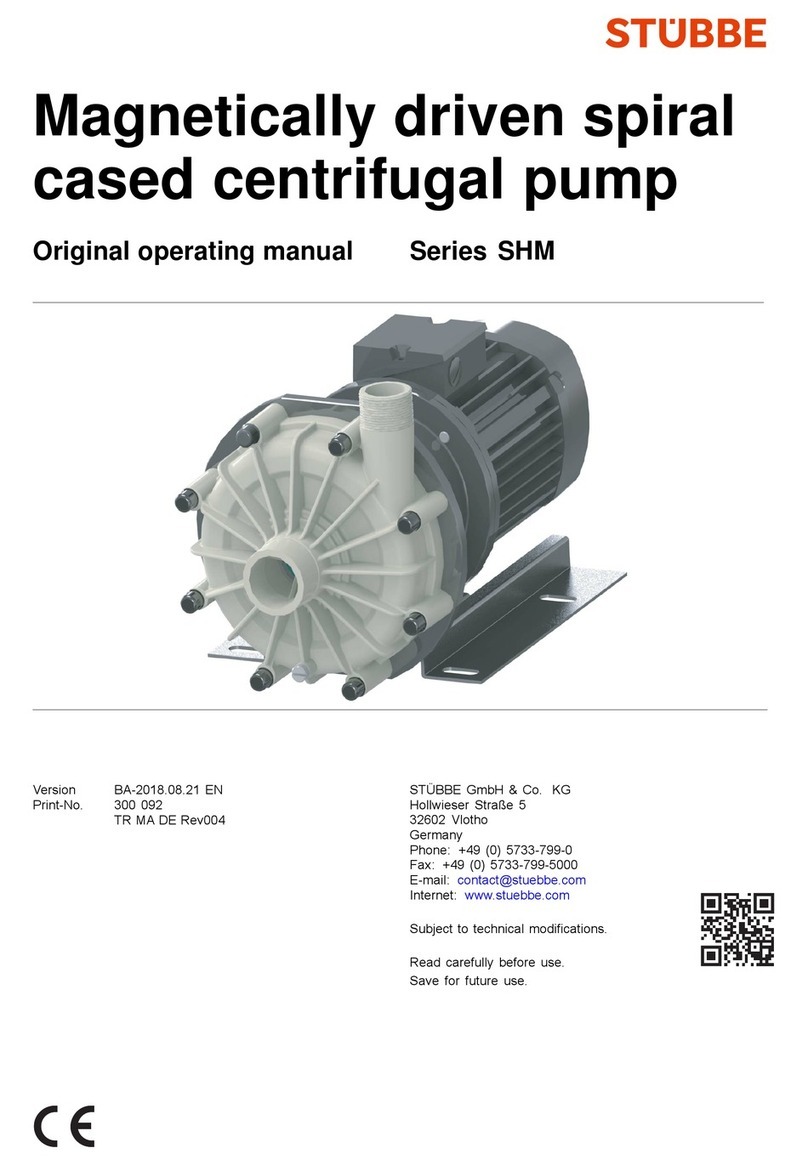

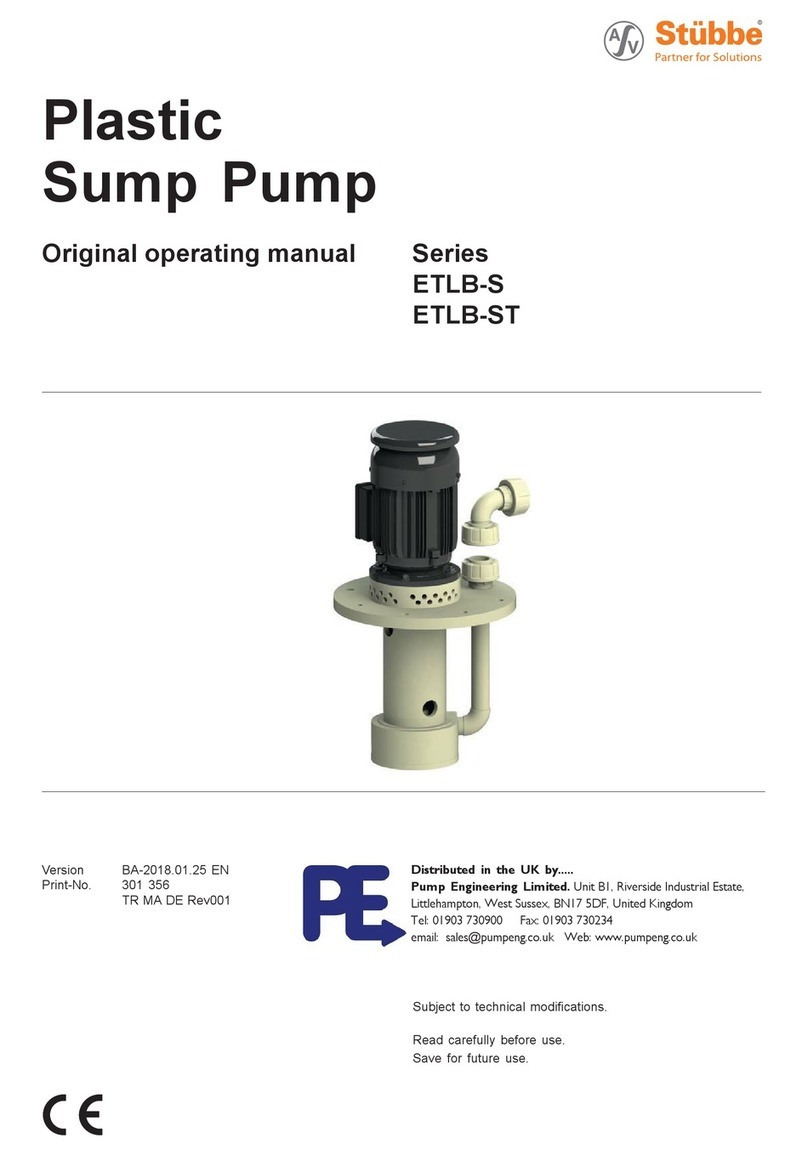

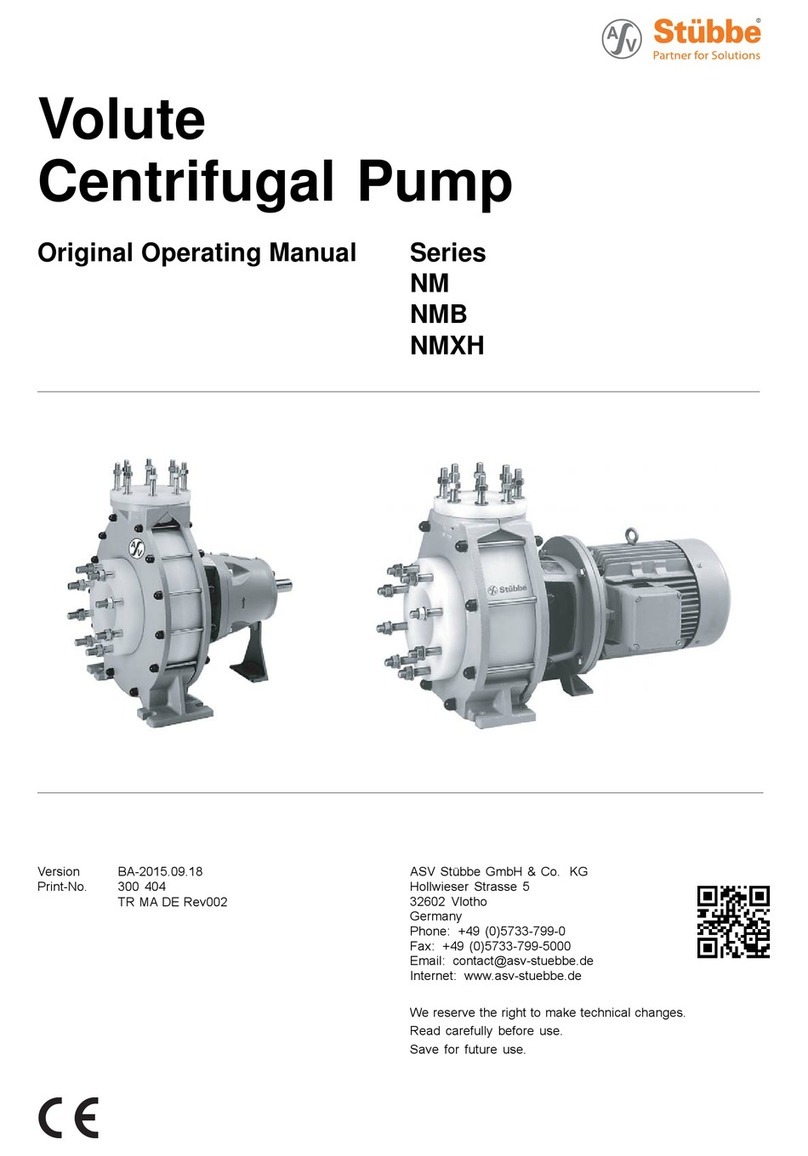

3.2 Description .................................... 5

3.2.1 Features ...................................... 5

3.2.2 Function ....................................... 5

3.3 Assembly ..................................... 5

4 Transport, Storage and Disposal ................. 6

4.1 Unpacking and inspection on delivery ...... 6

4.2 Transportation ................................ 6

4.3 Storage ....................................... 6

4.4 Disposal ....................................... 6

5 Installation and connection ....................... 7

5.1 Preparations for installation ................. 7

5.2 Planning pipelines ............................ 7

5.3 Design the layout of the fitting ............... 7

5.4 Install the fitting ............................... 7

5.4.1 Connection with flange ...................... 7

5.4.2 Connection with sockets, nozzles or female

threads ........................................ 8

5.5 Performing the hydrostatic test .............. 8

6Operation ............................................ 8

6.1 Commissioning ............................... 8

7 Maintenance ......................................... 9

7.1 Servicing ...................................... 9

7.2 Maintenance .................................. 9

7.2.1 Removing fitting .............................. 9

7.2.2 Disassemble and reassemble the

nozzle ......................................... 9

7.3 Replacement parts and return .............. 9

8 Troubleshooting .................................... 10

9 Appendix ............................................. 11

9.1 Technical specifications ...................... 11

9.2 Replacement parts ........................... 11

9.3 Flange installation ............................ 11

List of figures

Fig. 1 Name plate (example) ....................... 5

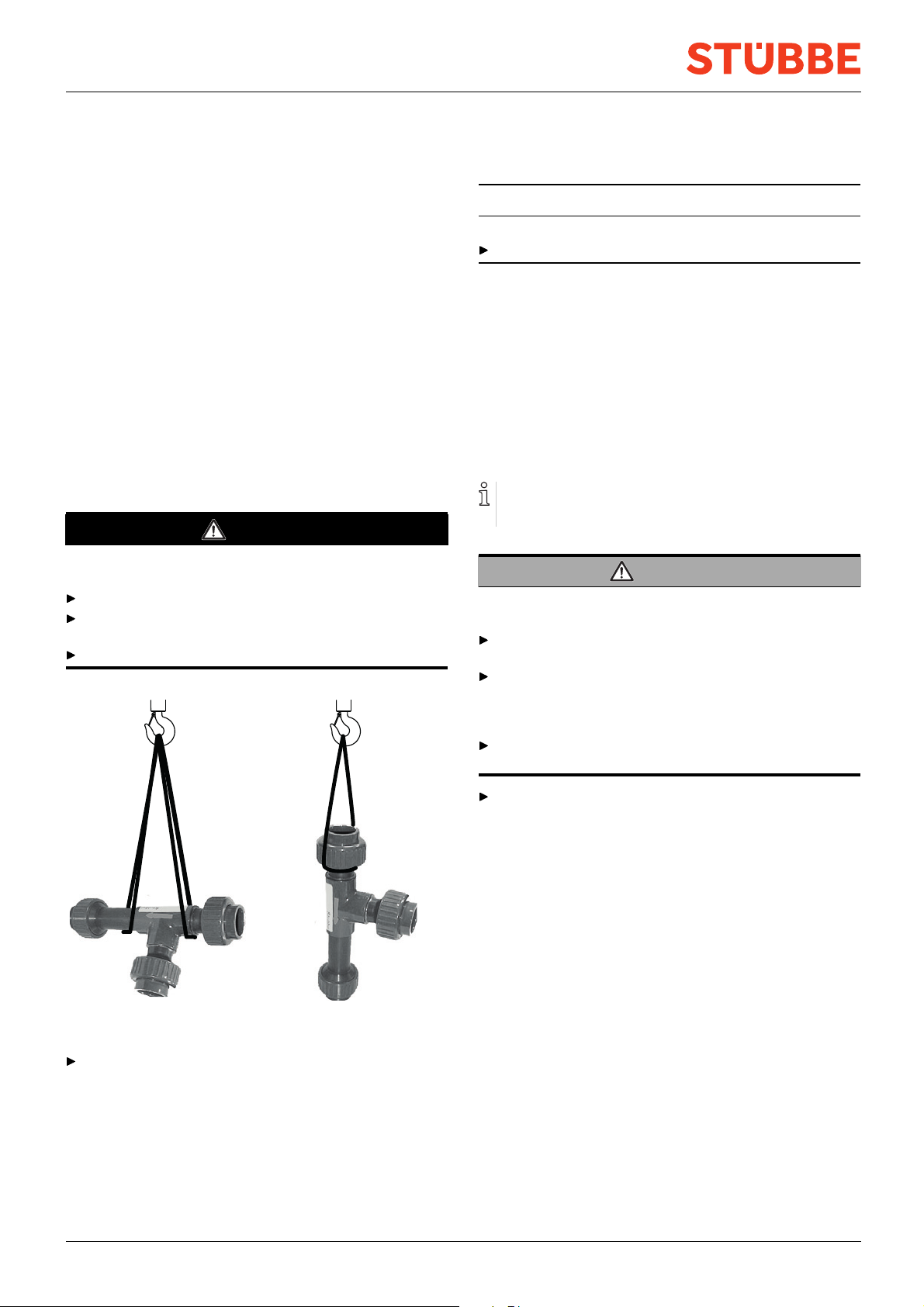

Fig. 2 Function ....................................... 5

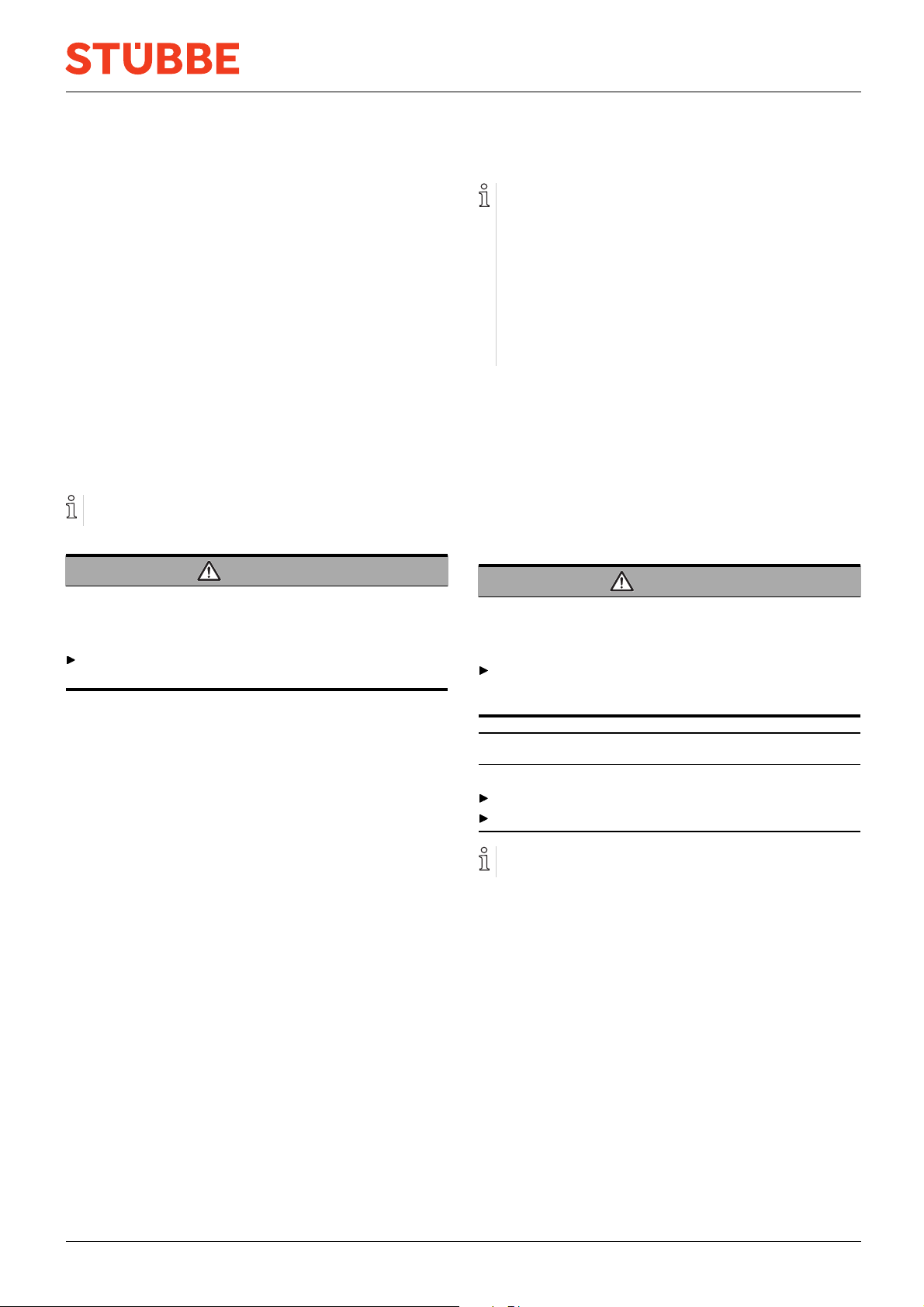

Fig. 3 Assembly ..................................... 5

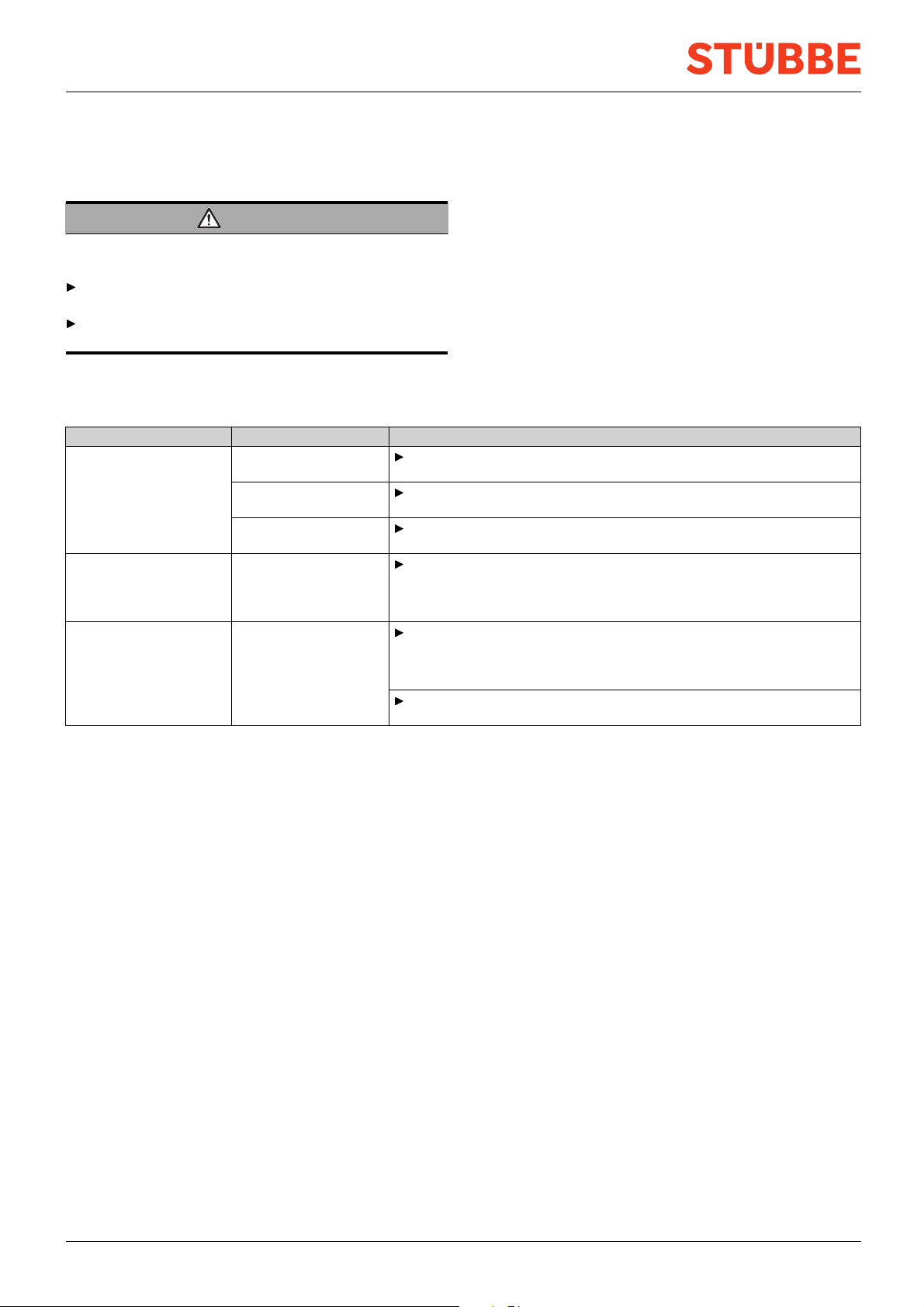

Fig. 4 Attach lifting gear (example) ................ 6

Fig. 5 Tightening torques ........................... 11

List of tables

Tab. 1 Other application documents, purpose and

where found .................................. 3

Tab. 2 Warnings and symbols ....................... 3

Tab. 3 Troubleshooting .............................. 10

Tab. 4 Tightening torques ........................... 11

2 SP 820 BA-2023.09.27 EN 302 535