9.2 Adjusting the end position – on the spring package

The end position is adjusted using the adjusting screw on the spring package:

Type Valve position

DFPD-HD-...-RS Valve open

DFPD-HD-...-LS Valve closed

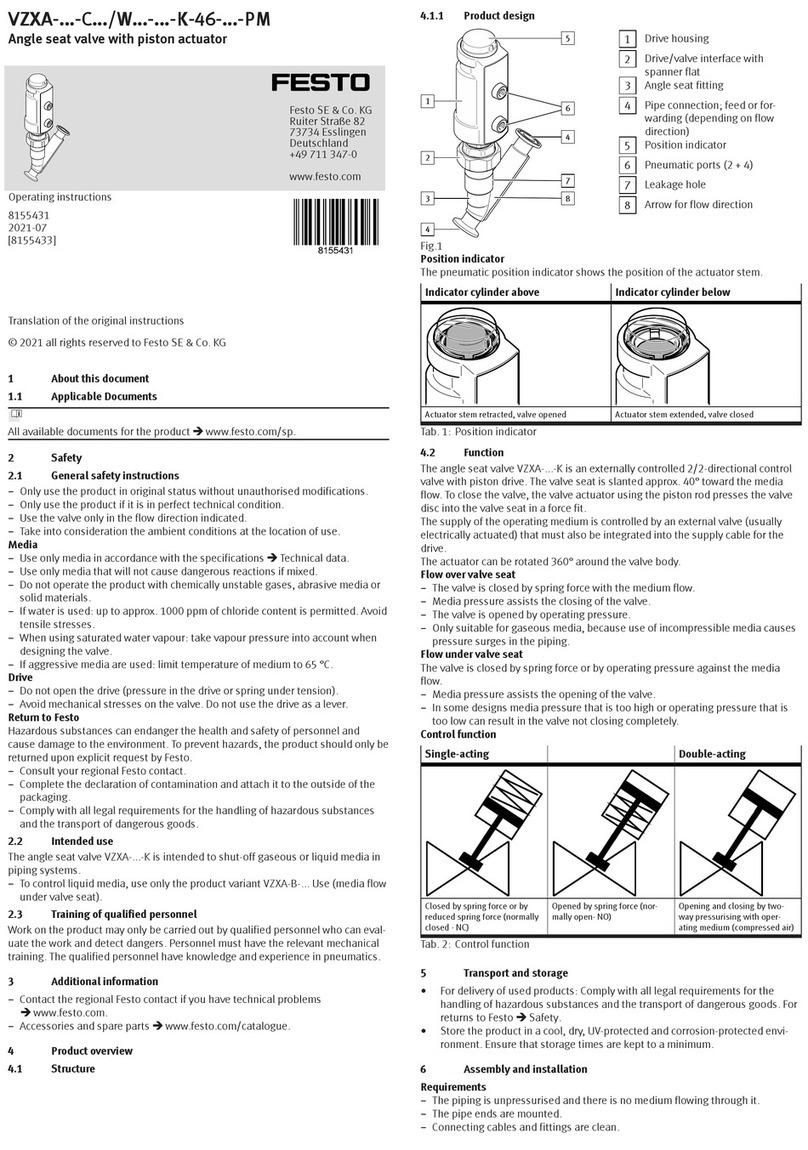

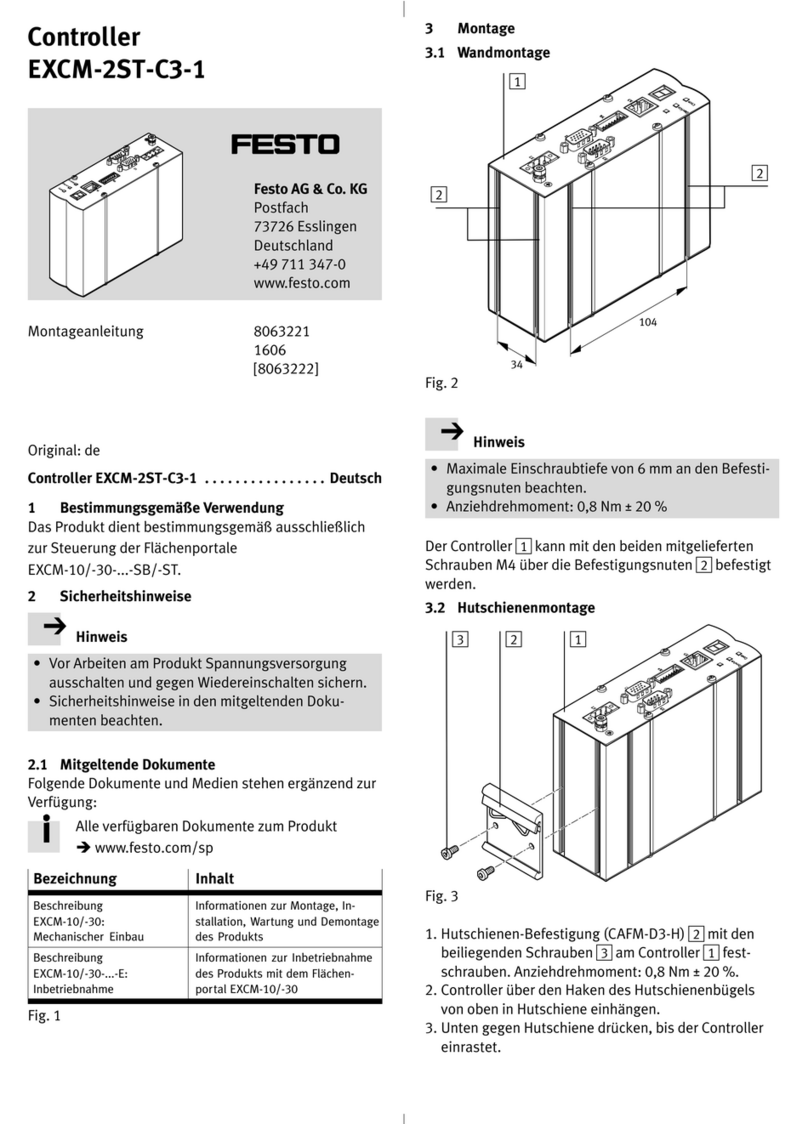

Fig. 8

1

2

3

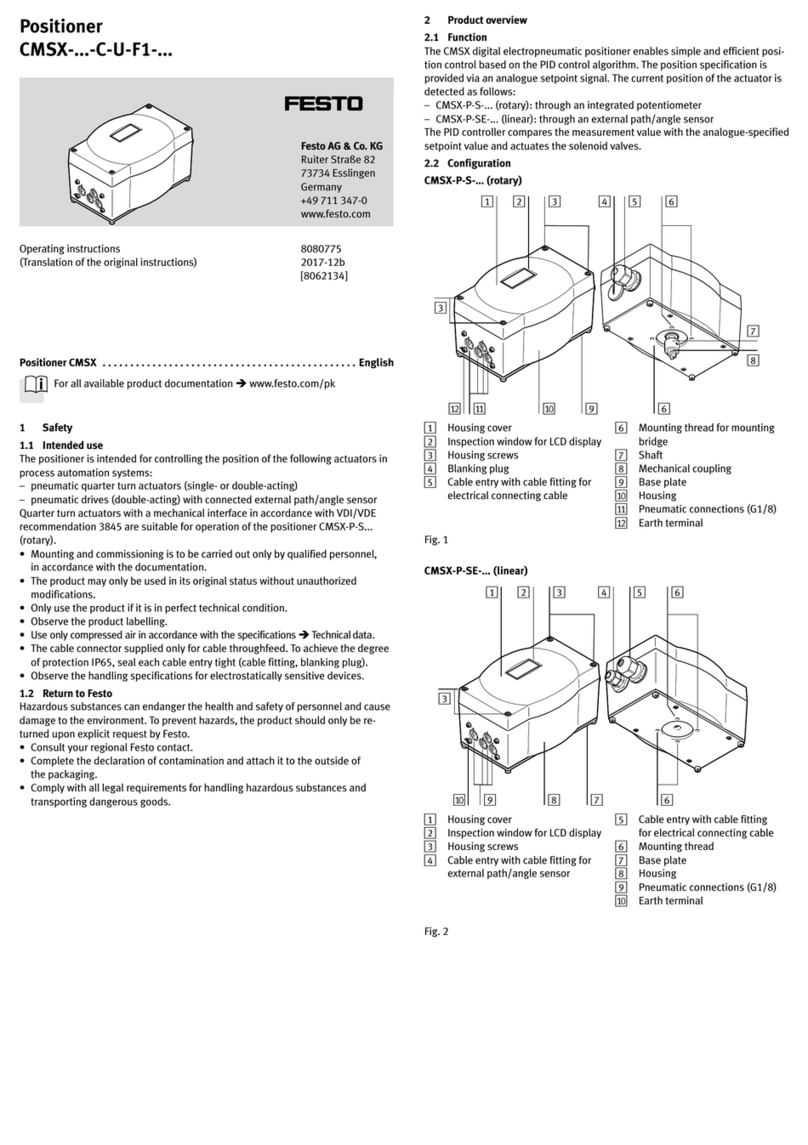

Fig. 9

1. To relieve the spring, switch off the compressed air supply.

2. Remove the stop cap 1and sealing disc 2.

3. To reduce the rotation angle, screw in the stop adjusting screw 3.

To increase the rotation angle, unscrew the stop adjusting screw 3.

4. Switch on the compressed air supply.

5. To check the adjustment, run through a complete cycle.

6. Reinsert the stop cap 1and sealing disc 2.

10 Operation

Comply with operating conditions.

Observe the permitted limit values.

Note

Use lubricated compressed air for continuous operation under extreme

conditions. The oil must be chemically inert and must not carbonise. After the

initial use of lubricated compressed air, it is required in continued operation.

11 Fault clearance

In case of malfunctions, consult your regional Festo contact.

12 Service

When used as intended, the product is maintenance-free.

Festo recommends the following periodic inspections:

Interval Inspection

Annually Correct function of the quarter turn actuator by

repeatedly opening and closing the valve

(rotation angle = 90°)

Every six months Visual inspection (during operation)

Quarterly Correct function of the quarter turn actuator during

operation

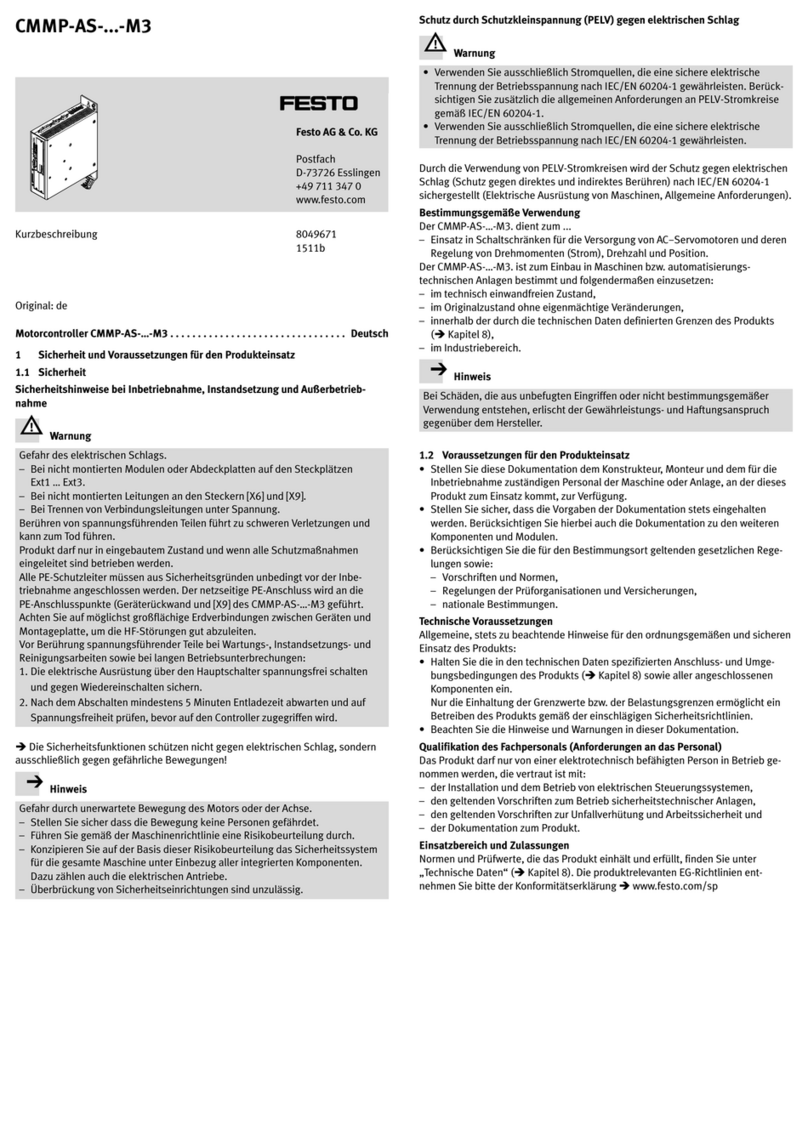

Fig. 10

13 Dismantling

Note

Disassembly only by qualified specialized personnel.

Warning

Danger of crushing!

The product without accessories weighs up to about 1500 kg, depending on the

product version.

Body parts can be crushed if the product falls.

Use appropriate load handling equipment.

Use the 3 transport lugs to life the quarter turn actuator (Fig. 3, 8).

Loosen the quarter turn actuator before dismantling the process valve.

Warning

Risk of injury due to uncontrolled movements.

Depressurise the pipeline before dismantling the quarter turn actuator.

1. Disconnect the quarter turn actuator from the compressed air supply.

2. Loosen the pneumatic connections.

3. Loosen the mounting screws of the quarter turn actuator.

4. Lift the quarter turn actuator off the process valve.

14 Disposal

Observe the local regulations for environmentally friendly disposal.

Dispose of the product in an environmentally friendly manner. When doing this,

also take residual media into account (potential recycling of hazardous waste).

15 Technical data

DFPD

Operating medium Compressed air in accordance with

ISO8573-1:2010 [7:4:4] 1)

Note on the operating medium Lubricated operation possible

(required in further operation)

Ambient temperature [°C] –20…+80

Rotation angle [°] 0…90

Mounting position Parallel to line axis

(DFPD-HD-...-HW horizontal only)

Pneumatic port G½, G1

Standard connection to the process valve ISO 5211

CE marking (see declaration of conformity

èwww.festo.com/sp)

As per EU Explosion Protection Directive

(ATEX)

To EC Machinery Directive

Operating conditions

Operating pressure 2) [bar] 3…8.5

Nominal operating pressure [bar] 5.0

End position adjustment range 0° [°] ± 5

End position adjustment range 90° [°] ± 5

Degree of protection IP66M, IP67M

Materials

Housing Steel

Cap Steel

Pneumatic cylinder Steel (nickel-plated)

Piston rod Steel (chrome-plated)

Piston Steel

Tie rod Steel

Stop cap Steel

Stop adjusting screw Steel

Seal NBR, polyurethane

Ceiling paintjob Polyurethane

1) Note: Pressure dew point at least 10 °C below the outside temperature.

2) Dependent on the spring force, see product labelling

Fig. 11