ST STM32F20 Series Installation and operating instructions

Other ST Microcontroller manuals

ST

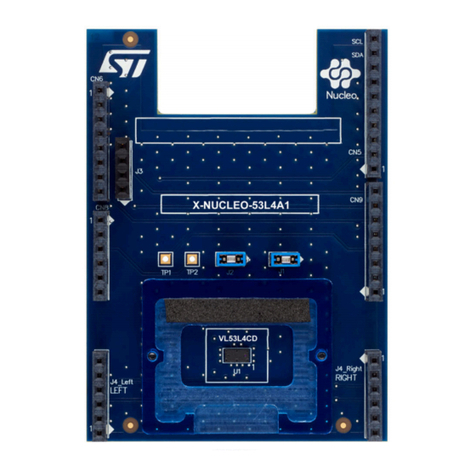

ST X-NUCLEO-53L4A1 User manual

ST

ST STLINK-V3MINIE User manual

ST

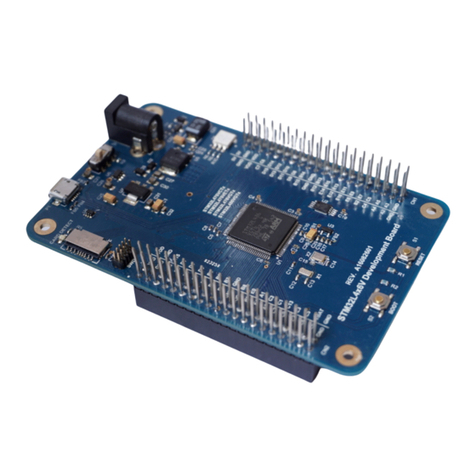

ST STM32 Nucleo User manual

ST

ST STM8S Installation and operating instructions

ST

ST STM32L4x6 User manual

ST

ST STM32F423 Series User manual

ST

ST STM32Cube User manual

ST

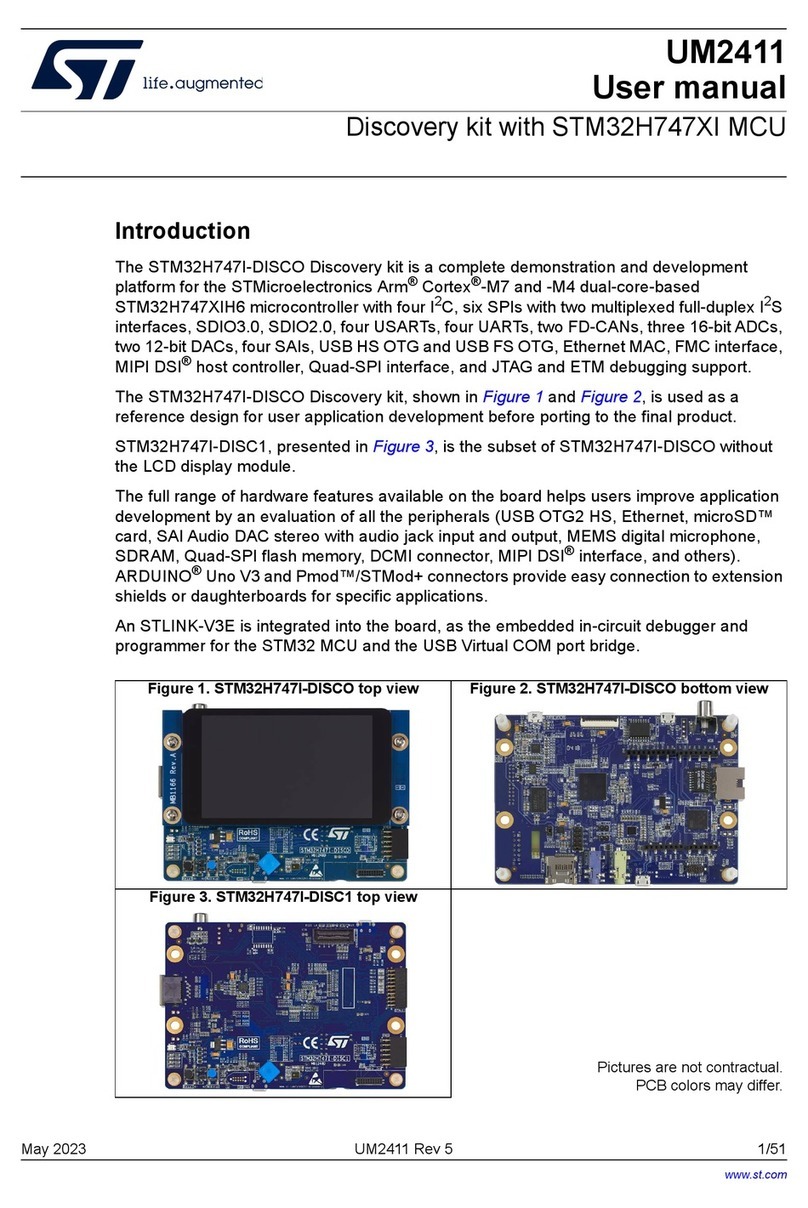

ST STM32H747I-DISCO User manual

ST

ST STM32F7 Series Supplement

ST

ST ST10F276E User manual

ST

ST STM32F429I-DISCO User manual

ST

ST SPC574S-DISP Sphaero Discovery+ User manual

ST

ST ST7LITE1 B Series User manual

ST

ST STM32L0 Series Installation and operating instructions

ST

ST STM32F413 Series User manual

ST

ST STM32CubeL5 User manual

ST

ST STM32MP135F-DK User manual

ST

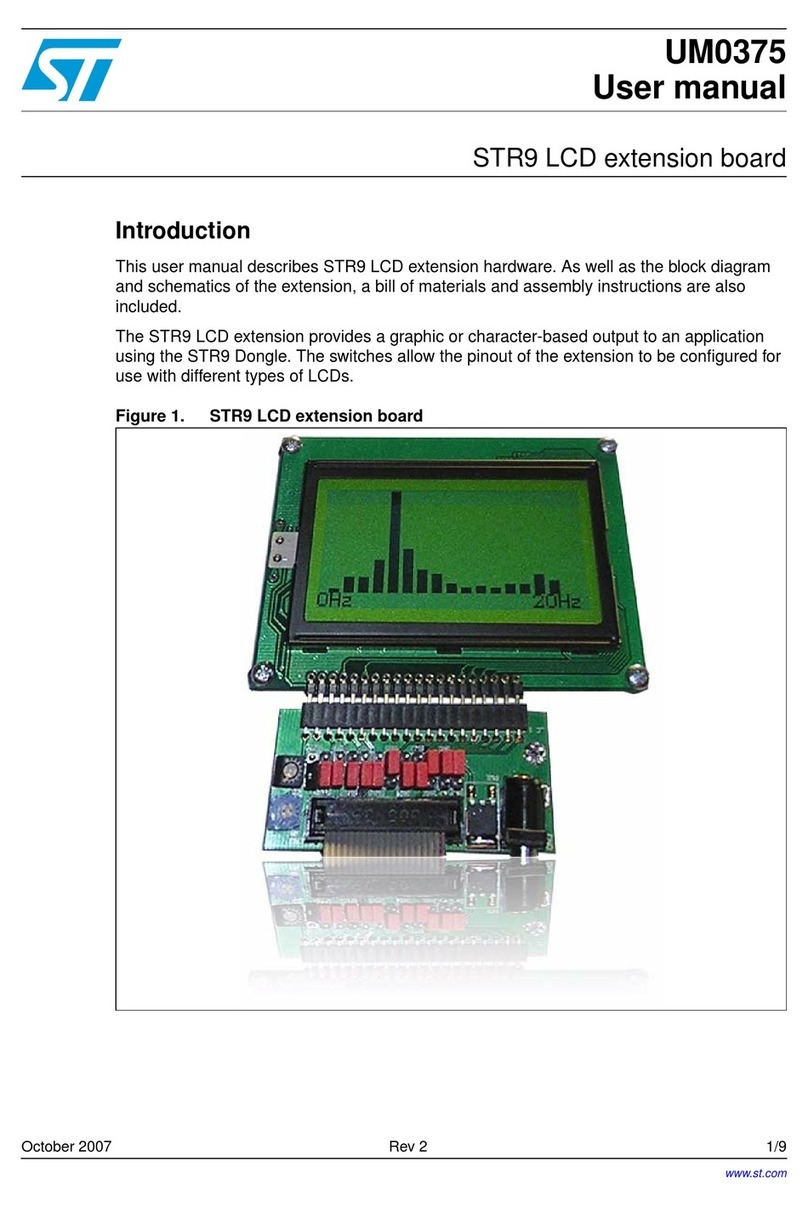

ST STR9 User manual

ST

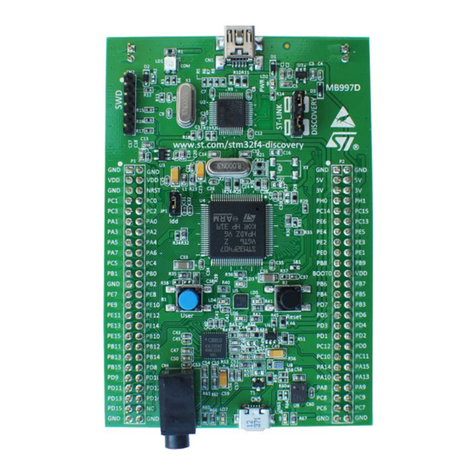

ST STM32F4DISCOVERY User manual

ST

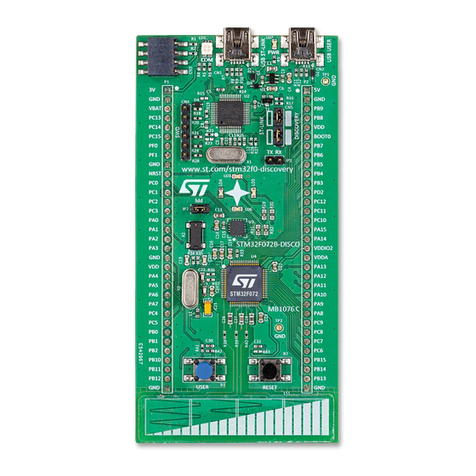

ST STM32F072 User manual

Popular Microcontroller manuals by other brands

Novatek

Novatek NT6861 manual

Espressif Systems

Espressif Systems ESP8266 SDK AT Instruction Set

Nuvoton

Nuvoton ISD61S00 ChipCorder Design guide

STMicrolectronics

STMicrolectronics ST7 Assembler Linker user manual

Texas Instruments

Texas Instruments Chipcon CC2420DK user manual

Lantronix

Lantronix Intrinsyc Open-Q 865XR SOM user guide