Stagnoli H24 User manual

Stagnoli T.G. srl

Via Mantova, trav. I, 105A/B

+39.0309139511

+39.0309139580

www.stagnoli.com

H24

Centrale di comando per motori Hercules a 24V

I

GB

F

D

E

Control board for Hercules 24V motors

Centrale de commande pour moteurs Hercules à 24V

Steuerzentrale für Hercules-Motoren von 24V

Central de mando para motores Hercules a 24V

GB The Stagnoli H24 is the control board that has been studied for 24V Hercules

automations.

Made using only prime quality materials, it has been designed for low absorption

at rest allowing a low consumption of electricity.

Particular attention has been paid to professionals in the sector making it easier to

programme the control board by using a multi-language display.

• This manual has been created by Stagnoli for specific use by pro-

fessional and qualified staff.

• It is advisable to read the instruction manual completely before

proceeding with installation.

• During wiring the system must not be live.

• Automatic gate systems must be installed by qualified technical

staff in compliance with legal requirements.

•DOUBLE SAFETY: The control board has two safety sensors: one

with encoder and the other is amperometric.

•Before installing, check that the gate is firm, well fixed and has

measurements, dimensions and fixings that are suitable for Hercu-

les automation.

Inform the end user in detail of the method of use, residual dangers,

the need for maintenance and the need to check safety devices at least

once every six months.

18

GB

7

8

9

10

11

12

13

14

15

16

17

18

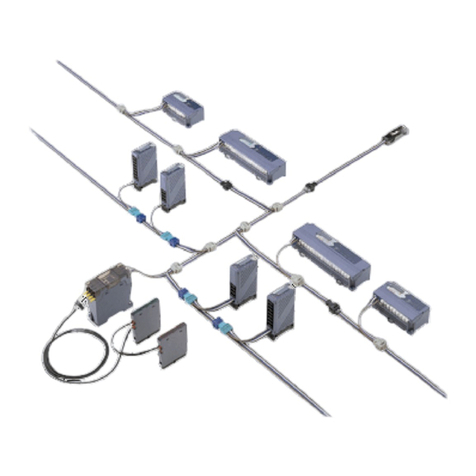

Input/Control connectors

Receiver module

System memory (removable)

24V Terminal/flasher

Flasher relay

Mosfet motor

Mosfet open gate detector exit

Motor connector

Opening relay

Rapid fuse 2,5A (card and accessories protection)

Open gate detector terminal (SCA)

Encoder connector

19 24V current card terminal

20 PTC 0,9A open gate detector exit

21 PTC 0,1A encoder exit

22 Closing relay

1

6

5

4

3

2

1

2

15

7

6a

54

3

6b

6c

14

13

12

11

10

9

8

22

21

20

19

18

17

16

Setting keys

Rib entry terminal

Display

Radio aerial terminal

Limit stop terminal

Jump resistive rib

19

GB

The current feed line (230V L,N, ) towards the automated device must be protected

by a magnetometric switch or by a pair of 5A fuses. A differential switch is recommen-

ded but not indispensable if it is already found at the top of the system.

Feed the device with a 3x1,5mm2cable (phase+neutral+earth). If the distance between

the control board and the connection to the earthing system exceeds 30m, it is necessary

to provide an earth plate near the control board.

Cabling must be done when the control board is switched off.

Input of N.C. type contacts (normally closed), if they are not used, must be bridged with

an ordinary terminal (+24V). If there are more N.C. contacts for the same input, they

must be placed in series (example: ph1 and ph2 in the diagram).

Inputs of N.O. type contacts (normally open), if not used, must be left free. If there are

more N.O. contacts for the same input, they must be placed in parallel (example: st1

and st2 in the diagram).

The rib input can be either the N.C. type or the resistive type 8k2., if it is the latter, then

bridge the jump 8k2.

24 0

T

1,25A

L N

common

0 230

stop

TRASFORMATOR

photocells

in closing

25w

5w

start

st1

st2

ph1 ph2

ph3 ph4

red

black

white

green

brown

start

photocells in

openingand

in closing

pedestrian

common

flasher

open gate

detector (SCA)

FUSE

LINE

accessory exit

20

GB Operating procedure at the first start up

•Undertake the electric wiring for the plant and

check when the card is switched off.

•Unblock the gate and check its movement (the

rack must not be supported by the motor pinion).

The stroke of the gate must not have any areas of

stiffness during movement, it must be smooth.

•Block the gate and supply current to the control

board. At this point, the electric mains detection

E

led will light up and the display will show r|-00 or r-|00 where the horizontal

line (-) indicates the opening direction of the gate. If the opening direction is not

the required one, set the opening direction function da (see later). If this does not

occur, check that the control board receives power and check the inputs activated

(see the description of the display diagnostics).

•Activate the safety devices one at a time and check that the display shows the

relative diagnostics wording. For example, activate the photocell and check that

the message pho shows on the display.

Enter the menu and select the item setup.The first two manoeuvres help to identify

the start and end of the stroke of the motor. The two that follow detect the peak

of absorption of the motors when the gate is closing and opening. In this phase,

monitor the values shown on the display.

•At the end of the learning phase, the display will show ok if programming was

done correctly, or err if errors occurred. To exit the programme press the key

ENTER.

•Correctly set the levels of anti-crushing force in opening and in closing, these

must be greater than the maximum values viewed during learning (see later for

regulating fm1a and fm1c).

WARNING: this regulation can influence the degree of safety of an automated

device.

During learning manoeuvres, the control board ignores the START and PEDE-

STRIAN commands and works with the force parameters that have been set to

maximum. Even if the safeties remain active, make sure that there are no objects

or people in the pathway of the gate.

•Carry out some test cycles checking the correct operation of the entire system.

•Measure the force of impact of the gate according to the specifications of regu-

lation EN12445.

display

LED indicator for

power supply

21

GB

r|-00

add transmitter

1ch

adjustement

ttca

rlap

function

ca

ba

rlch

fm1a

fm1c

bp

cr

2p

pl

re

en

ss

it

cf

alte

•add transmitter= me-

morisation of radio con-

trols

•1ch= memorisation of the

radio control key on the

first channel (START impul-

se)

•2ch= memorisation of

the radio control key on

the second channel (PEDE-

STRIAN impulse)

To access the menus or to undertake an opera-

tion, press ENTER (E) and release immediately.

Keeping the same button pressed, it will be pos-

sible to return to the upper menu or cancel the

operation requested (ESC).

To navigate in the menus use the up and down

arrows.

E

•r= rolling code receiver indicator

•-|= gate opening direction indicator

•00= registered transmitters

WARNING: When naviga-

ting in the menus, the con-

trol board will ignore the

START and PEDESTRIAN

commands.

Í

Î

Ï

Ï

Ï

Ï

Ï

Ï

aped

da

fcm

oc

2b

2ch

ENTER - press and

release

ESC - press for two

seconds

22

GB

00 -

delete

default parameter

erase 1 transmitter

language

italiano

english

setup

read code

erase memory transmitters

•ttca= automatic closing time

•aped= pedestrian opening

•rlap= slowed stroke in opening

•rlch= slowed stroke in closing

•fm1a= anti-crushing force of motor in opening

•fm1c= anti-crushing force of motor in closing

•da= opening direction

•ca= automatic closing

•ba= blocks impulses during opening

•bp= blocks impulses during pause

•cr= rapid closing

•2p= open/close operation

•pl= preflashing

•re= energy saving

•fcm= magnetic limit stop

•en= encoder operation

•ss= soft start

•oc= open/close operation

•it= total reversal after encountering an obstacle

•2b= two safety ribs

•cf= operation of the fixed code receiver

•al= alarm

•te= diagnostics check before each start

•default parameter= setting of factory parameters

•erase 1 transmitter= cancels one transmitter

•erase memory transmitters= cancel all registered transmitters

•setup= learning the stroke

•read code= identifying and recognising transmitters

adjustement function

•00= instant power absorbed by the motor

•-= encoder operation indicator

Î

Í

Ï

Ï

Ï

Ï

delete

23

GB Addition of radiocontrols

•Before memorising a transmitter, make sure that it is compatible with the type of

receiver that is integrated (the first time the display shows r, if the receiver is in

rolling code mode, or fif the receiver is in fixed code mode). The receiver can

memorise rolling codes type HCS300 STAGNOLI with billions of combinations or

fixed codes type HT53200 with 13 bits or the fixed part of a rolling code (28 bit

SN). It is possible to memorise up to 76 codes.

•Enter the menu add transmitter,move over the wording display 1ch or 2ch and

select the channel that is to be added. Press ENTER, the wording premi (press)

will appear.Press the key that must be memorised. At this point the display shows

the wording ok if the operation has been carried out correctly, err if there are

registration errors or full if the receiver memory is full.

•An external antenna installed far from the ground, increases the visibility betwe-

en the transmitter and the receiver. The power of the receiver can be reduced if

metal parts or reinforced concrete are placed next to it.

Regulating

•ttca (automatic closing time)= this is the time from the when the gate is fully ope-

ned to when it is closed automatically. If the photocell is engaged, the ttca viene

conteggiato dal momento in cui la fotocellula si disimpegna. time is counted from

the time when the photocell is freed. The default time set by Stagnoli is 10 secs

and it can be regulated from 1 to 240secs.

•aped (pedestrian opening)= this is the length of the stroke stated in centimetres

of the partial opening, namely the pedestrian mode. The default value set by Sta-

gnoli is 70 secs and it can be regulated from 30 to 150.

•rlap (slowed stroke in opening)= the control board slows down the stroke of the

motor in the end part of its opening phase. The default stroke set by Stagnoli is 20

cm and it can be regulated from 0 to 70 cm.

•rlch (slowed stroke in closing)= the control board slows down the stroke of the

motor in the end part of its closing phase. The default stroke set by Stagnoli is

20cm and it can be regulated from 0 to 70cm.

WARNING: before setting the slowing phase, check that the gate has been instal-

led correctly. In this phase, the motor has less power and the way this parameter is

set can influence the level of safety of the system itself. Once this phase has been

carried out, check the force of impact of the gate.

•fm1a (anti-crushing force of the motor in opening)= is the anti-crushing force of

the motor stated in percentage compared with the maximum force that the same

can generate. The default value set by Stagnoli is 50 and it can be regulated from

20 to 99.

•fm1c (anti-crushing force of the motor in closing)= is the anti-crushing force of the

motor stated in percentage compared with the maximum force that the same can

generate. The default value set by Stagnoli is 50 and it can be regulated from 20

24

GB to 99.

WARNING: the setting of these two parameters can influence the level of safety

of the system itself. Stagnoli advises setting this parameter with a safety margin

that is at least +10 compared with the maximum current consumed by the motor

respectively in the opening and closing phases. This can be read on the display

in the second main screen during the stroke of the motor.

fm1a and fm1c with a low value indicate a greater anti-crushing sensitivity. At the

end of installation, check that the forces of impact are in compliance with the

regulation EN12453.

Functions

•da (opening direction)= indicates the opening direction of the gate that is viewed

on the main screen after indicating the type of receiver (r|-00 or r-|00).

To change the gate opening direction go to da on the display and change the

parameter from 0to 1or from 1to 0depending on the desired direction.

•ca (automatic closing)= automatic closing of the gate after it has opened com-

pletely.

ca=0 function not enabled.

ca=1 function enabled.

Set the ttca regulation to customise the time that must pass from the end of ope-

ning and the start of automatic closing. N.B: If ca=1 and 2p=0, the command to

START, activated while the gate is opening, will stop the gate and the ttca auto-

matic closing time will be loaded.

•ba (impulse block during opening)= the control board ignores the START impul-

ses during the opening phase.

ba=0 function not enabled.

ba=1 function enabled.

•bp (impulse block during pause)= the control board ignores the START impulses

during the pause between opening and automatic closing (ca=1).

bp=0 function not enabled.

bp=1 function enabled.

These functions are useful when there are various passages with different inputs

through the same entry point.

•cr (rapid closing)= if there is a passage through the photocells during the ope-

ning phase or with the gate open, the regulation time ttca (if activated and more

than 3 secs) is automatically reduced to 3 secs.

cr=0 function not enabled.

cr=1 function enabled.

•2p (open/close operation)= 2p=1 function enabled: at each START impulse, the

movement of the gate changes direction (OPENING - CLOSING).

2p=0 function not enabled: the gate movement sequence becomes OPENING -

CLOSING (ttca) - CLOSING - STOP.

•pl (preflashing)= after the opening command for the gate the flasher or courtesy

25

GB light will activate for two seconds before the opening or closing phase begins.

pl=0 function not enabled.

pl=1 function enabled.

•re (energy saving)= keeps the photocells off while the system is not active per-

mitting energy saving. The photocells therefore remain active only while the gate

is in movement.

re=0 function not enabled.

re=1 function enabled.

Connect the current feed +/-24V of both the transmitter and receiver of the photo-

cells to the output set aside for the flasher.

•fcm (magnetic limit stop)= activates the operation of the magnetic limit stop.

fcm=0 function not enabled.

fcm=1 function enabled.

•en (encoder operation)= runs the operation of the motor with encoder. In the

case of encoder malfunction (the gate blocks after the start and the display shows

ENC), it is possible to disable this function and allow the motor to carry out other

manoeuvres.

en=0 encoder not enabled.

en=1 encoder enabled.

WARNING: The operation of the system without encoder is to be seen as an

emergency measure. In this mode any obstacle encountered by the motor will

command the motor to stop movement without reversing it.

•ss (soft start)= allows the motor to undertake a soft start at a reduced speed to

diminish stress of the mechanical parts of the system. Activating this function, the

motor delivers less power in its starting phase.

ss=0 function not enabled.

ss=1 function enabled.

•oc (open/close operation)= the START terminal input becomes OPEN and the

PEDESTRIAN terminal input becomes CLOSE. In this mode one control opens

the gate and another closes it without intermediate stops. The PEDESTRIAN and

START functions can be activated with the radio control on the first and second

channels respectively.

oc=0 function not enabled.

oc=1 function enabled.

•it (total reversal)= activating this function, if the motor encounters an obstacle in

the opening or closing phase, it reverses the motion and reaches the limit stop. If

the function has not been activated, when the motor encounters an obstacle in the

opening or closing phase, it reverses the motion by 50cm before it stops.

it=0 function not enabled.

it=1 function enabled.

•2b (two safety ribs)= Operates with two safety ribs 8k2 connected in parallel.

2b=0 function not enabled.

2b=1 function enabled.

26

GB •cf (operation of the fixed code integrated receiver)= cf=0 receiver functions with

rolling codes.

cf=1 receiver functions with fixed codes.

Functioning with receiver fixed codes or rolling codes can also be seen on the

initial page of the display, where r-00 indicates the rolling code functioning and

f-00 functioning with fixed code.

WARNING: The receiver can memorise rolling codes type HCS300 STAGNOLI

with billions of combinations or fixed codes type HT53200 with 13 bits or the

fixed part of a rolling code (28 bit SN).

•al (alarm)= Alarm signalling that the gate has remained open. This function

activates the SCA output after 20 seconds have passed from the end of the time

regulated by ttca and the gate is still open.

al=0 function not enabled.

al=1 function enabled.

•te (test)= A diagnostics test is carried out to check the integrity of the encoder

and amperometric sensors before each time the motors are started.

te=0 function not enabled.

te=1 function enabled.

Cancel

•default parameter= to cancel the regulation parameters and those of regula-

ted functions and reset the factory settings, enter the menu delete, go to default

parameter on the display and press ENTER. The message RESE is shown, it

flashes until the decision to reset all the parameters is confirmed or the operation

is cancelled. The default parameters are: ttca=10, aped=70, rlap=20, rlch=20,

fm1a=50, fm1c=50, da= 1, ca=1, ba=0, bp=0, cr=0, 2p=0, pl=0, re=0, fcm= 0,

en=1, ss=1, oc=0, it=0, 2b=0, cf=0, al=0, te=0.

•erase 1 transmitter= to cancel a transmitter code, enter the menu delete, then

go to the wording erase 1 transmitter on the display and press ENTER. The mes-

sage PREMI (PRESS) will apppear.Now press the key of the transmitter that must

be cancelled. If the operation has been carried out correctly, the message OK will

appear. If this has not been carried out correctly, the message ERR will appear.

•erase memory transmitters= to cancel all the recorded transmitters, enter the

menu delete, then go to the wording erase memory transmitters on the display

and press ENTER. The message PRG will appear, it flashes until the decision to

cancel all the recorded codes are confirmed by pressing ENTER or the operation

is cancelled by keeping the same key pressed for longer.

N.B: To cancel the memory of the receiver, it is neccessary to confirm twice the

cancellation (erase memory transmitters and PRG).

Language

The display is available in two languages: italiano e english. To select the chosen

language go to the menu language and press ENTER. Go to italiano or english and

confirm by pressing ENTER.

27

GB Learning

This operation allows the automation to automatically establish the start and end

of a stroke. Before proceeding with this operation, ensure that the gate has been

installed correctly and firmly and that the en function of the control board has

been activated (Stagnoli supplies the control board with this function already

activated).

When the wording setup appears on the display, press ENTER. At this point

the motor will close the gate. It will open it completely again and will repeat this

operation once more with the control board display showing maximum use of the

motors. Then set the regulation values fm1a and fm1c in so that they exceed the

detected values.

If fm1a and fm1c have a low value this indicates greater anti-crushing sensitivity.

Should consumption be shown to be excessively high, check that there are no

areas where the gate has greater friction. To do this, monitor the values showing

instant absorbed power by the motor during the stroke and presented in the se-

cond main screen of the display. If the operation has been carried out correctly,

the message OK will appear. If this has not been carried out correctly, the message

ERR will appear.

WARNING: during learning manoeuvres, the control board will ignore START and

PEDESTRIAN commands and will work with the force parameters at maximum.

Even if the safeties remain active ensure that there are no objects or people in the

area of operation of the gate.

Read code

It is possible to check if a code has already been memorised. Position yourself on

the wording read code,press ENTER, the display will show the message PREMI

(PRESS).Now press the transmitter key that must be checked, a series of screens

describing the code will be viewed:

•first screen: S r 01 or - f 01.

The first letter indicates the manufacturer of the radio control, where S means

Stagnoli and -a generic manufacturer.

The second letter indicates the type of code, where r indicates a rolling code and

fa fixed code.

The last two indicate the code of the key that was pressed.

•second screen: P_00, where Pindicates the word “position” and the number

that follows (progressive from 0 to 75), indicates the position occupied by the

transmitter in the memory. If the transmitter is not found in the memory, the display

will show ----.

•third and fourth screens: show the hexadecimal code of the transmitter.

Statistics screens

The control board has four statistics screens that are viewed by keeping the key

ENTER pressed once the display is positioned on the main menu:

•first screen: H201, where H2 indicates the motor Hercules at 24V and 01 the sof-

tware version.

•second and third screens: 0000 0000 indicates the number of complete mano-

euvres undertaken.

•fourth screen: indicates the stroke in the memory.

28

GB Diagnostics screens

The control board can recognise problems or alarms that can occur in the system

therefore it can signal some messages on the main display to allow the problem

to be identified:

•1 rf= activation of the START command on the first radio frequency channel.

•2 rf= activation of the PEDESTRIAN command on the second radio frequency

channel.

•sta= activation of the START command on the terminal board input.

•ped= activation of the PEDESTRIAN input command.

•stO= activation of the STOP command on the terminal board input.

•phO= activation of the photocells input in closing on the terminal board.

•phA= activation of photocells input in closing and in opening on the terminal

board.

•bar= activation of the safety rib input.

•swo= activation of the limit stop input in opening.

•swc= activation of the limit stop input in closing.

•am 1= activation of the amperometric sensor on the first motor.

•enc1= activation of the encoder sensor on the first motor.

•prg= programming regulations or functions underway.

•OK= successful outcome of operations.

•ERR= unsuccessful outcome of operations.

•full= radio control memory full.

•attendi= pause time.

•tout= pause time expired.

29

GB F.A.Q. - Frequently asked questions

Why choose a rolling code transmitter instead of a fixed one?

Rolling code transmitters are safer as they cannot be cloned and have over 200 mil-

lion combinations that change with each transmission. Fixed code transmitters, inste-

ad, have 1024 code combinations that do not change with each transmission.

Can the control board run the operation of the motor with emergency batteries?

Yes. To use emergency batteries use the kit supplied by Stagnoli.

The control board does not recognise the transmitter. Why?

Check that you are using the same type of control board and transmitter. It is possible

to check the type of transmitter used by the control board from the main screen and

change if necessary by setting the parameter cf.

Once the motor gets to the stop, it turns back instead of arresting. Why?

One reason that can make the control board loose its parameters is that the motor

has been working while unlocked. To be sure that the control board has found back

its parameters, shut off the supply, make sure that the motor is locked and then put the

supply back to the control board. At the first START input, the control board will find

again its parameters.

Technical data

•Automation supply: 230V - 50/60Hz.

•Primary transformer protection fuse: T1,25A/230V.

•24V Accessory output protection fuse: F2,5A.

•Integrated receiver (433Mhz): maximum capacity 76 radio codes.

•Operating temperature: -20° +55°

•Maximum rated output of the motor: 80W

•Maximum power of the flasher output: 25W

•Maximum power of the open gate detector light (SCA): 5W

•Electronic anti-crushing device: amperometric and with encoder

30

GB

31

Notes

GB

ANTENNA

CLOSING

COMMON

OPENING

LIMIT STOP

SAFETY RIB

COMMON

START

STOP

COMMON

PEDESTRIAN OPENING

+24V

-24V

FLASHER

COURTESY LIGHT

OPEN GATE DE-

TECTOR LIGHT

MOTOR

ENCODER

0

24V

MOTOR

SUPPLY

COMMANDS

32

GB

33

CLOSING

PHOTOCELLS

OPENING

PHOTOCELLS

CLOSING PHOTOCELLS

OPENING AND CLOSING PHOTOCELLS

COMMON

+24V

-24V

TX

TX RX

RX

BATTERY-CHARGER BOARD

WARNING: If a battery charger is used, the control board is

supplied by the C24 charger board, linked to a trasnsformator.

For the details of the connection, see the C24 instructions.

0 230

0 24

TRANSFORMATOR

0

24

BATTERIES

024

82

Table of contents

Other Stagnoli Control Unit manuals

Popular Control Unit manuals by other brands

Comparato

Comparato Diamant SMART PRO user manual

National Instruments

National Instruments Network Adapter NI PXIe-6672 user manual

Carel

Carel PlantWatchPRO Assembly and installation

Atlantic Technology

Atlantic Technology IWTS-8e installation instructions

BENDIX

BENDIX SS-1 SHUT OFF VALVE manual

MIX

MIX SSM250 Series Operation and instruction manual