COMPARATO NELLO SRL

2

Notices ___________________________________________________________________________

Technical features ________________________________________________________________________

Installation ______________________________________________________________________________________________

Connection to the ball valve _______________________________________________________________________________________________

Electrical connections __________________________________________________________________________

Reference positions __________________________________________________________________________

Emergency manual opening __________________________________________________________________________

Auxiliary microswitch signals __________________________________________________________________________

Position feedback __________________________________________________________________________

Operation __________________________________________________________________________

Fail Safe (optional) __________________________________________________________________________

Motor anti-overheating (optional upon request) __________________________________________________________________________

Monitoring __________________________________________________________________________

Wi-Fi communication (optional) __________________________________________________________________________

Serial RS458 communication - Modbus (optional) __________________________________________________________________________

Operating anomalies __________________________________________________________________________

General warranty conditions __________________________________________________________________________

NOTICES

Read the warnings contained in the manual carefully, since they provide important information about safe installation, use and maintenance. Installation and maintenance shall be performed in accordance with the

relevant regulations and the manufacturer's instructions. In case of failure and/or malfunctioning of the appliance, do not attempt any repair or direct servicing. Always contact qualified personnel, as provided by

law. Only qualified technicians are allowed to carry out any repair operation. Failure to comply with the provisions listed above may compromise the safety of the appliance.

TECHNICAL FEATURES

TABLE OF CONTENTS

2

2

3

4

4

6

6

7

7

7

12

13

13

14

16

18

18

DANGER:

DANGER:

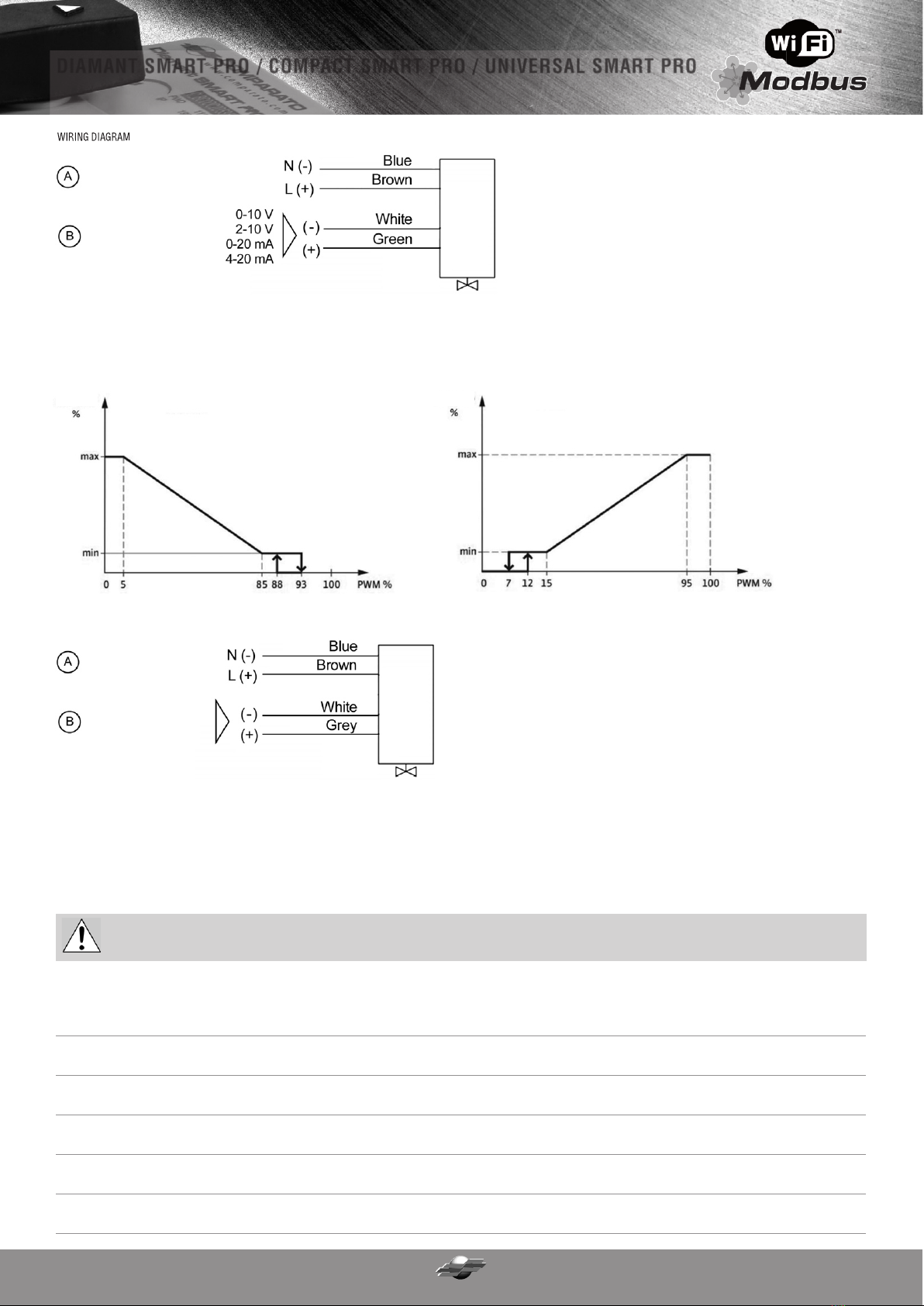

12Vdc • 24Vdc • 24V 50/60 Hz • 100...240V 50/60 Hz

10W 25W 25W

2W 3W 3W

3W 5W 5W

11Nm 22Nm 40Nm

Diamant

SMART PRO Compact

SMART PRO Universal

SMART PRO

Power supply

Maximum power consumption during operation

Power consumption during standby

Heating resistance power

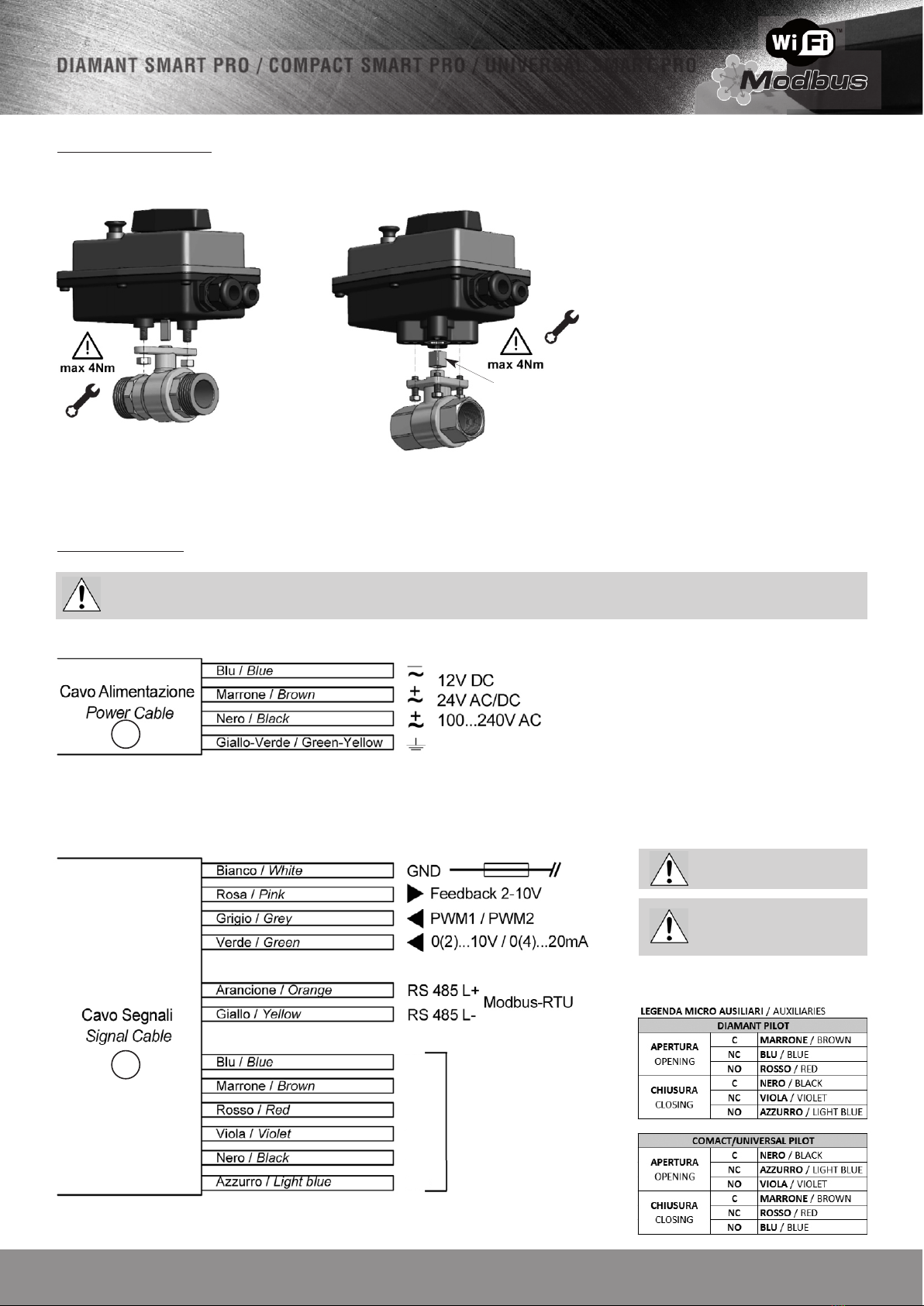

Supply cable

Signal cable

Auxiliary micro output

Rated torque

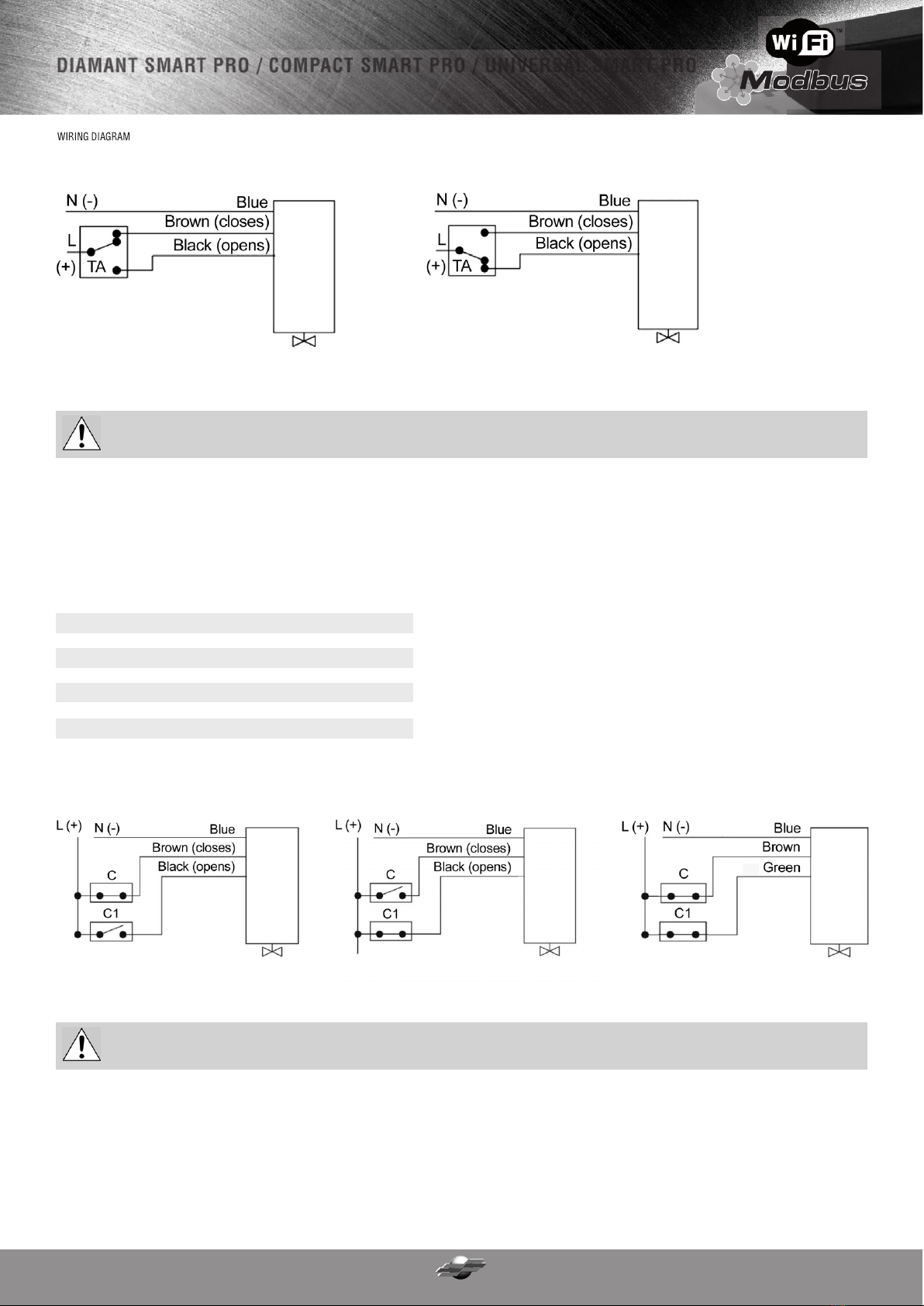

Control type ON/FF

Proportional positioning signal

Position signal dead band

Position signal impedance

Positioning feedback

Maximum position feedback current

Positioning accuracy

Motor rotation direction

Manual override

Rotation angle

Angular positioning correction

Operating time ( 90°)

Maximum noise

Protection degree

Connection to the valve

Accumulator

Emergency position

Fail safe operating time ( 90°)

Minimum charging time

Maximum power consumption

4 x 0,5 mm^2 (AWG 20) - Length 1m

12 x 0,2 mm^2 (AWG 24) - Length 1m

max 30Vdc - 0,1 A

2-point • 3-point • 0°- 45° - 90° • 0°- 90° - 180°

0-10V • 2-10V • 0-20 mA • 4-20 mA • PWM1 • PWM2

Adjustable: 1% • 3% • 5%

100kΩ(0-10V / 2-10V) • 500kΩ(0-20 mA / 4-20 mA) • 133kΩ(PWM)

2-10Vdc

40 mA

+/- 5%

Reversible

Release lever and button

90° • 180°

With Modbus or Wi-Fi interface

DIAMANT SMART PRO / COMPACT SMART PRO / UNIVERSAL SMART PRO

ELECTRICAL DATA

ELECTRICAL DATA

FAIL SAFE

15s* • 30s • 60s • 120s 15s* • 30s • 60s • 120s 30s • 60s • 120s

45 dB (A) 60 dB (A)

Supercapacitors

Programmable opening / closing / intermediate

IP67

65 dB (A)

0,6 W 3 W 3 W

20s 26s 30s **

15 min (90°) • 60 min (180°) 9 min (90°) • 18 min (180°) 50 min (90°)

Comparato • ISO 5211 F03/F05 ISO 5211 F03/F05 ISO 5211 F05/F07

* time not available with 12Vdc power supply.

** for the 180° rotation angle fail safe operation, please contact our technical office.

Electrical hazard! The unit contains high-voltage equipment.

Scalding hazard! Even in normal operation conditions, the unit can reach very high temperatures which may cause scalds.