Stagnoli D241000 User manual

0241000

ISTRUZIONI CENTRALE

DI

COMANDO PER BARRIERA

CENTRAL UNIT CONTROLLER INSTRUCTIONS FOR BARRIER .

-

„

--~

~~

-·~

~~

··.1

Q::S]

l

Moving ldeas.

OPERATING INSTRUCTIONS

FOR

INSTALLATION AND

SETIINGS

lnstructions for use only tor protessional installer. Before installing, please read carefully instructions. Uncorrect use

of

the product or a con-

nection failure could atfect

1he

correc1 working and the end user's

safe1y.

TECHNICAL

DATA

Power Supply : 230V -±10% -50Hz•;

lntegrated Receiver: 433MHz: 76 trasmettitori MAX;

Anti-crushing Electronic Device: amperometric + encoder

INTENDED USE

Working Temperature: -20°C I +60°C;

MAX Power Output External Flash:

24V-

-25W;

Accessories Supply:

24V-

-25W;

Tile Skyga1es 0241000 is the central unit controller designed to manage road barriers DAPHNE 24V and

i1s

accessories. Made only with grade

materials, it's designed to have low absorption when not working, and allows a net energy saving. Particular attention was paid to professionals

making easy the settings

of

unit controller, 1hanks to a multilanguage display.

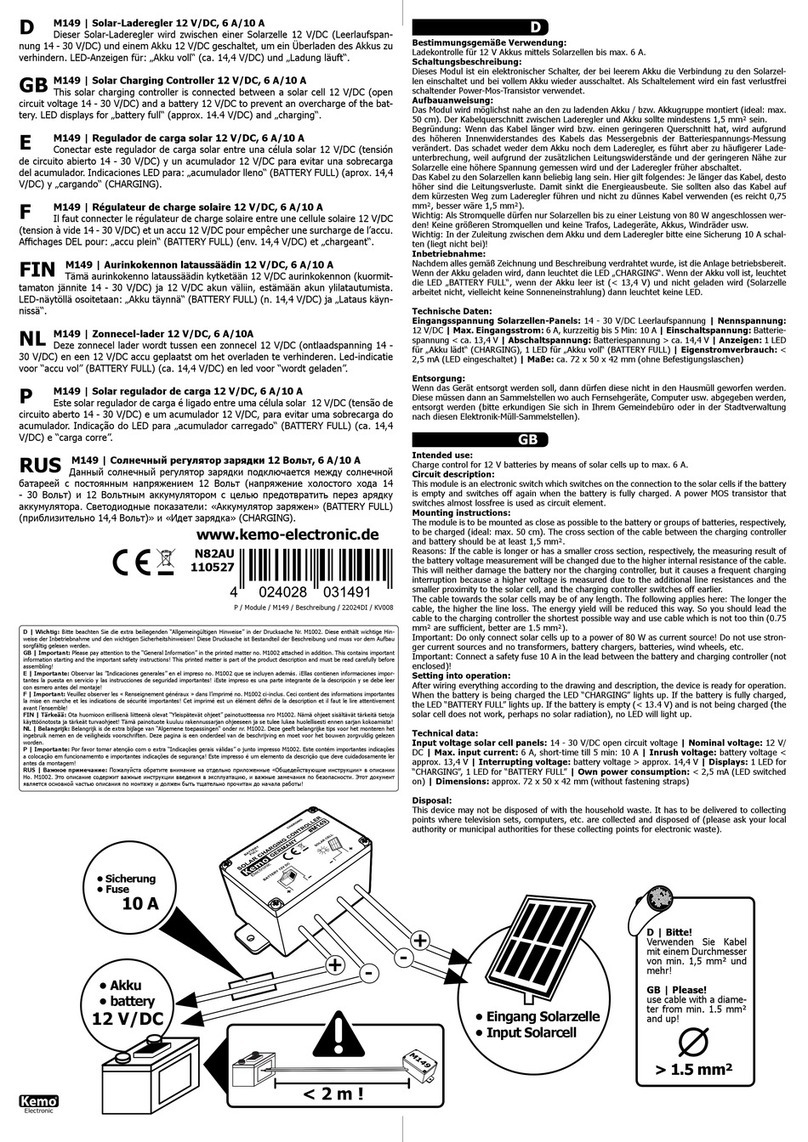

PARTS DESCRIPTlON

11

1 Line tuse: 230V (T2,5A 5x20) ·

eh

2 Terminal block for connection the line input to the transformer.

3 Primary 1ransformer: 230V, secondary

24V-,

110VA

4 Supply input:

24V-

5 - Fuses

a.

accessories output (F2A

5x20J

b. motor (F10A 5x20)

c. output flashing and LED strip (F2A 5x20)

6- Keys tor Menu navigation

7- Display LCD 4 Languages (EN,FR,ES, IT)

8- Receiving Module 433Mhz Rollingcode/Fixed Code

9- Clamp tor external antenna

10- Connection LED strip 24V

11-Terrninal for Connecting Controls and Security

12- Connection tor limit switch

13- Terminal tor connection to motor

a;

9

14-Terminal for connection external flashing (MAX 10W) and output programmable dry contact

15-Aboard flashing MAX 25W

16- lnput light sensor.

FIG 1

WIRING & CONNECTIONS

r -

&

L

Common

Op

en/Close

Stop

Phot

oc

. Close

Photoc.

Op

en

a

nd

Clo

se

Start

Waming!

The e/ectrica/connections

must

be

performedin the absence

of

power,

and

with disconnectedcharger

kit

,

where exists.

+ 2

4V

-

24

V

:o

o0

(1) o

g:

o.

s:

:::i

rrr

rn rn rn

000

•

W[ringl:

Oč

Oder

,Green= Signal

Ene

White

=-ene

,Red=

+ene

Antenna

1

J

FIG 2

www.stagnoli.com

011

e e

on

ormoz1on1

qu

1contenule sono

~ite

ne

rs

1

suscetl1

11

cii

mod111ca

m

quo

sios1

momenta e o nostro insin

aca

1e

g1u

iz10

Ali

datas

and

informat

io

n contained

th

erein must

be

regarded to change

at

any

tirne a

nd

on

Our

discretion.

MENU GUIDE

To

move within the menu it's good to

know

that:

-

if

pressed for 1sthe "E" button works as • ENTER • and

if

pressed for

3s

works

as·

ESC

·;

-When

yo

u are

in

the menu, the panel will not keep in consideration any command signal;

The starting screen as shown, reports a code where the first character signals the type ofprogrammed TX :

R=Rolling Gode ;

F=Fix Gode ;

The second character is a hyphen ( - ) . it blinks when the encoderdetects the motor

is

moving.

The next number will

be

Oat the first tirne, and it stands for the number

of

stored TX.

SETTING LANGUAGE

The Spagnoli Central Units allow you to choose between 4 different languages: English, French, Spanish, ltalian. The Default Central Unit

is

set-

ted in ltalian language,

it

you want to change language. open the menu pressing the

'E"

button, then press four times the down arrowand again

the "E" button; then choose the language with the arrows

.+t

and pressthe

'E".

SELF-LEARNING

Using this operation. the central unit will store encoder pulses and it shows on display the necessary strength to complete the race, both in

opening and closing.

To

perform a operation

of

" SELF-LEARNING • you have to:

1. Unlock the motor;

2. Set the shaft at

45

° ;

3. Lock the motor;

4. Go to the menu voice • SELF-LEARNING • and press the • E " button :

5. Wait for the barriercompleting the two operations. the first need to find the beats and the second

to

showthe necessary strength ;

6. The sel

f-

learning

ends

when the shaft returns to the closed posilion after the second operation.

7.

It

everything goeswell, the display will show"

OK

"

ot

herwise • ERA • .

8.

To

confirm the successfull self-learning, press the "E • button, which will report you to

the

ma

in screen.

During the self-learning process the control unit stores the forces required for the correct movement

of

the rod.

To

change these forces, if they don't respect the existing standard regulations, modify

the

item • AMP • in the • PARAMETERS " section

ot

the

rnenu.

:a.:

~

.-----------------------------------------------~

REMOTE CONTROL STORAGE (ONE OR MORE THAN ONE)

The Spagnoli Central Units can store 76 transmitters . both Rollingcode than fixed code , the default is enabled to store transmitters with Rollin-

gcode Skygates, for storing fixed codes you must change the • CF • parameter

in

the "FUNCTION" section of the Menu.

In

addition, tile Spagnoli Central Units provide

two

storage channels :

1-

The first channel is tor automation control: open -stop -etose (or as programmed)

2- The second channel is used to give an impulse command to the auxiliary relay. ifthe function is

OU

=1;

~-~lm

~~

I

~

Press the transmitter

_.

button

DIAGRAM MENU

Diagnostic consumption.

~

[!]

!

IJ

0

Simple press. „

Diagnostic soflware

Keep pressed „

::l

!.'!

o.

<D

a.

E

Ci5

ROD

RErlDTE

CONTROL

t

-se tor

START

ADJ

USTl'lEMTS

„

t

Trn

Automatic Cio-

lrH 1Channel 1 lmpul

'---~~

~==::::::::

sing Time [s]

V OP Opening speed

V r• Closing speed

LL.

2r" 1Channel 2 · .

- n lmpulse tor Dry

'-----'

Contact

R

flP

Motorpower

UR

Deceleration

Speed

RO Deceleration

Opening

R[ Deceleration

Closing

Motor 1power consumption ·(the 2first figures);

Shaft position, O =

Open

C =

Closed

(4 figures).

B

...

.__.,....0:2_3___.

„

Soflware version

FUN

CTI

ONS

„

•

[R

1

Automatic

....._

__

_,_

Closure

RESET

1

~::;:

ot

para-

BR

OEL

1TX

.------,

1

Lock

_of pulses

on

....._

__

......

opemng

BP

1Lock of pulses

on

....._

__

_,_

pause

1

De!ete

one

Iran-

. smitter

=~O

E

~L~

A

~L~L=I

~~~;n

tran-

.------.1

Rapid

closure

rn

2P 1Functionality

....._

__

_.

Open/Glose

PL Pre-nashing

....._

__

.....

0[

Operation Open/

....._

__

__.

Gl

ose

RP Antipanic

58

Beat

space

RE

Relax

ou

Output

re

l

ay

....._

__

.....

Enab

le light

[P

....._

__

_,

sensor

...------.

Working

PH

photocell input

in

'-----'

closing

Working

PA

photocell input

in

~----'

opening

and

closing

[F

Remote

controls

atfixed code

SR

~==:

Fire

allarm

on

the

....._

__

_,

STOP

command

„

100001

I

TALIANO

FRRNCAIS

ENG

LI

SH

ES

PRN

OL

Stored encoder

pu

l

ses

tor

race

ot

Motor

1.

www.stagnoli.com

uiti 1

dail

e le

informazi

~n1

qui contenute sono da ritenersi suscettlbi 1 i

m"Odilica

in quamas1 momento e a nostro

in~ife

""''"'

g

,..

iu

"'

ci"lz

'"

l

„

o

______

„

Ali datas and information contained therein

must

be regarded to change

al

any

tirne and on

Our

discretion.

PARAMETERS DESCRIPTION

TCR

V

OP

V[L

==i

R

rlP

B

OP

This is the tirne that elapses between the complete opening

of

the gate and

its closure that occurs automatically.

lf

the photocell

is

busy, the count

of

the tirne is reloaded.

(Opening velocity) = this is the velocity

of

the opening rod.

( Glosing velocity) = this is the velocity of the closing rod.

(Motor Power) =this is the required motor force far moving the shaft

in

the correct manner.

(Opening brake)= This is the brake used to pass from normal velocity to deceleration velocity in

the opening phase •

Default: 1

Osec

Min:

Osec

Max: 140sec

Default: 3

Min: 1

Max: 3

Default: 2

Min: 1

Max: 3

Default: 2

Min: 1

Max: 3

Default: 1

Min: O

Max: 3

8CL (Glosing Srake) = This is the brake used to pass from normal velocity to deceleration velocity

in

Default: 1

the closing phase

••

Min: O

· Max: 3

• WARNINGS:

Before

setting

the

decelerations

(slowdowns)

or

the

brakes,

check

that

the

shaft

is

correctly

lnstalled.

lndeed,

during

this

phase,

the

motor

has

less

power

and

the

setting

of

this

parameters

can

affect

the

safety

level

of

the

system

itself.

Check

the

lm-

pact

forces

after

the

adjustment

of

these

parameters.

••

WARNINGS:

The

setting

of

these

parameters

can

affect

the

safety

level

of

the

system

itself.

Skygates

recommends

to

set

these

para-

meters

with

a

safety

margin

that

is

at

least

+1O

compared

to

the

maximum

of

the

motor

current

consumption,

respectively

in

opening

and

closing

phase.

This

can

be

read

during

the

motor

race

on

the

display

in

the

second

main

screen.

A

low

value

for

the

AMP

parameter

stands

tor

a

greater

sensitlvlty

crush.

Check

after

lnstallation

that

the

lmpact

forces

respect

the

norm

EN12453.

DESCRIZIONE DELLE FUNZIONI

[R

BR

BP

2P

~--

P

_

L

_=i

RP

UR

RR

(Automatic Closure) = lf enabled, after the TTCA tirne, the gate will close automa1ically.

(Lock

of

pulses on opening) =The central unit ignores the START pulses during the opening

phase.

.(Lock.

of

pulses on pause) = The central unit ignores START"pulses during the pause phase.

Rapid closure)

=In

case of activation of opening photoce

ll

s. or the gate is open, the tirne of pause

(Break tirne) TTGA is reduced to 3 sec.

Functionality Open/Close) =

lf

enabled : at every each START pulse, the gate movement rever·

ses direction

(OPEN

·GLOSE)

. II not enabled: the movement sequence

of

the gate becomes

OPEN • STOP {

TTCA)

• CLOSE -STOP.

(Pre-flashing) = flashing

of

2 seconds before the start

of

the operation.

OC {Operation Open/Close) =

OC

=O;

The START command, which activates the automatic cycle and can be stopped

or

reversed. it can be given by remote control

or

by the clamp •START /GLOSE

•,

wtlile the •OPEN

·· clamp gives way to a single opening operation that can"t be stopped, and to etose it you have to

wait for the pause tirne set,

or

you have to give a START command.

OC =1 ; The START command, which activates the automatic cycle can be stopped

or

reversed

, it can only

be

given by remote control. The clamp

of

the • OPEN • command opens. and the

control clamp

'"

START I GLOSE • closes.

OC =2 ; function of presen! {Existent) man. the

clamp"

OPEN • opens until it reaches the limit

switch

or

the contact is kept closed, and the clamp "

STARTI

GLOSE " closes until it reaches the

limit switch or you keep the contact closed. Wilh this setting all the remote controls are ignored.

Detault: 1

AP (Antipanic) =Activating this function,

in

case of power failure, if there are backup batteries, the

barrier will stay opened accepting all commands, but it will continue to re-open.

Default: O

Off: O

On: 1

Default: O

Oft:O

On: 1

Default: O

Off: O

On

: 1

Default: o

Off: O

On

: 1

Default: O

Otf:O

On: 1

Default: o

Otf: O

On: 1

Default: 1

(Antipanic) = Activating this function, in case of power failure, if there are backup batteries. the Default: O

barrier

vJill

.stay opened accepting all commands, but it will continue to re-open. Off: O

On

: 1

(Deceleration Speed) =this is the speed

of

the deceleration phases : Overy slow , 1 slow.

(Rallentamento in apertura)= e

lo

spazio di rallentamento sulla corsa totale

in

lase di apertura,

O=minimo; 1= massimo:

Default: O

Off: O

On

: 1

Default:O

Off: O

On: 1

R'

--i

• 1

SB

[

__

RE

_,]

~

p

PH

PA

SA

(Deceleration closing) =this is the deceleration distance on the total race in the closing phase,

O= min ; 1 =maximum.

(Beat Space) =thls is.the space needed tor the central unit to recognize the beats , 0=

low

, 1 =

max . This feature results in a greater

or

lesser precision in the approach to

tile

beats.

(Relax) =if this function is enabled, for a few hundredths

of

a second. allowing the motor to turn

in the opposite direction to the just ended movement. In this way, it avoids the unlocked problems,

this feature can

be

used on assigned barriers.

(output relay) =

Auxiliary relay operation

=o

:the dry contact output switches with

open

bar;

=1

: working as second radio channel rf 2 . storing a button on

"2

eh

••

while pressing the button,

the

dry

contact relay output energizes tor 1

s.

=2:

activates the opening relay tor

1s

( for electric lock

).

(Operation light sensor) = .

Default :

O.

The light sensor is not active and the lights outputs RED and GREEN operate uninter-

ruptedly according to the logic expected : stopped

bar

-flashing RED light, opening bar -steady

RED light. open bar- flashing GREEN light, closing bar , continuously fix.ed RED lit.

1: the lights are activated as above only if the sensor detects darkness (fixed threshold for now

„.

)

(Working photocell input in closing) =(Behavior Closing photocell input ) =

O: occupying the photocell beam, the bar stops and starts.

1 : occupying the photocell

beam

, the bar stops and once the beam released, it closes.

(Working photocell input in opening and closing)

O: occupying the photocell beam , the bar stops and starts again

if

in closing, if in opening would

stop and

once

released the beam , would continue the opening .

1 : occupying the photocell beam , the

bar

stops and opens again

if

in closing, if in opening would

ignore the beam interruption.

(Remote controls at fixed cede)= ( Fixed cede ) =

lf

actlvated, the control panel is enabled tor

storing remote controls on Cede Fixed

of

type HT53200, and on fixed Rollingcode HCS.

(Fire allann on the STOP command) (Stop -Fire Alarm) =defines the STOP input behavior. you

can choose from :

O: STOP NC contact , each tirne it is opened , the panel will

show"

ALAR " and it will stop imme-

diately.

To

let it continue just make a

new

START pulse.

1 : FIRE ALARM , NC contact • each tirne you open the barrier

it

opens, it

the

contact

is

main-

tained opened , it will ignore all incoming commands.

To

make it close you will simply close the

contact and give a

new

impulse

to

.START . For situations involving the Antifire.

Detault: O

011

: 0

On: 1

Default: o

Off:O

On: 1

Default: O

011:0

On: 1

Detault: 1

Default: O

Default: O

011:0

On: 1

Default: O

011:0

On: 1

Default: o

011:

o

On: 1

Default: O

~

WARNING : BAand BP are useful In cases wbere there are severa! steps with different input through

the

same entrance.

DESCRIPTION "DELETE" MENU

The Reset menu item DELETE serves to restore to default all the parameters and

functions.

Once entering

in

DELETE

menu, move to the item RESET, pressing ENTER the display will start flashing to be confirmed , re-press ENTER if you

want to reset to factory

de

fault . Otherwise

qu

it .

lf

you press Enter on the display, It will read PAG indicating the reset in

progress.

To

delete a remote control from the Skygates Central Unit is essential

to

have the rernote control. and when accessed to

the item "DELETE

TX

1" press the button on the transmitter to

be

deleted.

lf

this button is not found the Central will return

"ERA". instead.

it

it is found and then eliminated, you will see "OK" in the display.

This item gives the option to delete all remote controls from the memory, either on channel 1 and channel 2.

ACCESSORIES DIAGNOSTIC DESCRIPTION

The

control center is able

to

recognize problems

or

alarms that

may

occur on the system, so

it

may

report on the main display some messages

to allow the detection

of

the problem:

• 1

RF

=activation

o!

the START command on the first radio frequency

channel, with transmitter.

• 2

RF

=activation

of

the second radio frequency channel, with the

transmitter.

•

1s

=activation

of

the START on the input

of

the clarnp.

•

srn

=activation of the STOP on the input

of

the clamp.

•

PHO

= activation of the entrance

of

the closing photocells on clarnp.

•

PHO

Rc input activation

of

the photocells during opening and Closing

tile

clamp.

•

R:'lP

=action

ot

the amperornetric sensor on the first motor.

•

ENC

= Action o!the encoder sensor on the first motor.

•

OPE

=open button active on the clamp.

• C

LO

=close button active on the clamp.

• IBRT= low

battery.

voltage lower then

21V

•

PRG

= programming of settings or functions in progress

•

OK

= successful operation.

•

ERR

= failure operation.

•

FUL

L= full rernote controls memory.

•

ATTE

N

DI

=wait, pause.

•

ro

ur

=waiting tirne expired.

„ www.stagnoli.com

ali e e in ormaz1oni"qui contenute sono

da

rifencrsi suscettib'iti

~

lica

m qua

sias1

momente c a nostro 1nsinda

Ccib

ile

gru

·

~liz

10

Ali

dotos

ond

information contoincd therein must

be

regarded

lo

chonge

at

ony

tirne

ond

on

Our

discretion.

J:INAL TESTING

You

should always run

afina!

test after doing all the prograrnming:

~

Unlock the motor and make sure that the rod moves freely, and finally lock it again.

Check the correct working

of

the protective devices (anti-crushing system, stop button. photocells, etc „.)

Check the operation of signaling devices

Check the operation

of

the control devices (radio control. remote control, selectors etc.).

Adjust the motor operating forces according to EN 12445, as well as to guarantee the satety ot the plant.

WARNINGS ANO STARTING UP

IMPORTANT RECOMMENDATIONS CONCERNING INSTALLATION:

The automation installation must be performed pertectly done by qualified personnel having the legal requirements and made in accordance

to the machinery directi

ve

98/37/EC and to

the

norms EN13241-1, EN 12453 and EN 12445.

Check the solidity

of

existing structures (columns, hinges. doors) in relation

to

the forces generated

by

the motor.

Check the condition

of

cables that are already presen! in the plani.

Analyse

the

risks and take the necessary safety and signaling.

lnstall the cornmands (key selector tor example) and be sure that the user is not placed in a dangerous area.

Atter installation try severa!

limes

the satety devices, signaling and release (see FINALTEST).

Ensure that the user has understood the correct automatic functioning

ofthe

manual and emergency automation.

STARTING UP

Draw up a technical dossier

ot

the plant, containing: installation design, electrical wiring diagram, risks analysis and adopted solutions,

residual risks analysis, conformity declaration of ali the products prepared

by

the manufacturer, and Declaration

of

Conformity, related to the

installation, cornpiled

by

the installer.

Apply on automating

tile

label or CE plate containing information about the hazards and idenlificalion data (number

of

series etc).

Give to the end user the operating instructions, the safety warnings, the CE declaration

ot

conformity and a copy

of

the technical dossier.

Also make sure

to

inform

the

end

user

about:

the presence

of

any unprotected residual risks and foreseeable improper

or

uncorrect use.

To

disconnectthe power supply when cleaning the automated area

or

when performing small maintenance (repainting).

To

lrequently control there are no visible damages to the automation and if any, immediately notify the installer

Not to let the ch

il

dren play closely to the automation

Prepare a plant maintenance plan (at least every 6 months tor the saf

ety)

reporting

ona

register ali the pertormed operations.

OISPOSAL

This product is made

of

various components which may contain polluting substances. Please do not litter! lnquire concerning the recycling

or product disposal according

to

the locally laws.

DISPOSAL

This protluct is made

of

various components which

may

contain polluting substances. Please do not litter! lnquire concerning the recycling or

product disposal according to the locally laws.

RECORDING PARAMETERS

AND

FUNCT/ONS

We

suggest to

mo.rk

here the porameters

you

hove

custo~ized.

NOTE:

Table of contents

Other Stagnoli Controllers manuals

Popular Controllers manuals by other brands

Delabie

Delabie TEMPOMATIC NT 441453 quick start guide

Kemo Electronic

Kemo Electronic M149 quick start guide

LubeCon

LubeCon Smart Lube 2000 manual

Plum

Plum ZAB-14 Service and assembly manual

Prolyte

Prolyte PRO LYFT AETOS PAE-C4DC-10 user manual

Xilica Audio Design

Xilica Audio Design NEUPANEL MINI Product installation guide