BA_ST_EN.FM

3

Table of contents

1 Safety instructions 1.1 Symbols ........................................................................................................................... 5

1.2 Operating instructions .................................................................................................. 6

1.3 Use for intended purpose............................................................................................. 6

1.4 Inappropriate use .......................................................................................................... 6

1.5 Safety-conscious operation......................................................................................... 7

1.6 Attaching load ................................................................................................................ 7

1.7 Organisational safety precautions.............................................................................. 8

1.8 General regulations....................................................................................................... 8

1.9 Electrical equipment ..................................................................................................... 8

1.10 Transport and storage................................................................................................... 8

1.11 Weight.............................................................................................................................. 8

1.12 Installation, commissioning, maintenance and repairs .......................................... 9

1.13 Warranty.......................................................................................................................... 9

1.14 Periodic tests.................................................................................................................. 9

1.15 After sales service.........................................................................................................9

1.16 Declaration of conformity/declaration of incorporation ......................................... 9

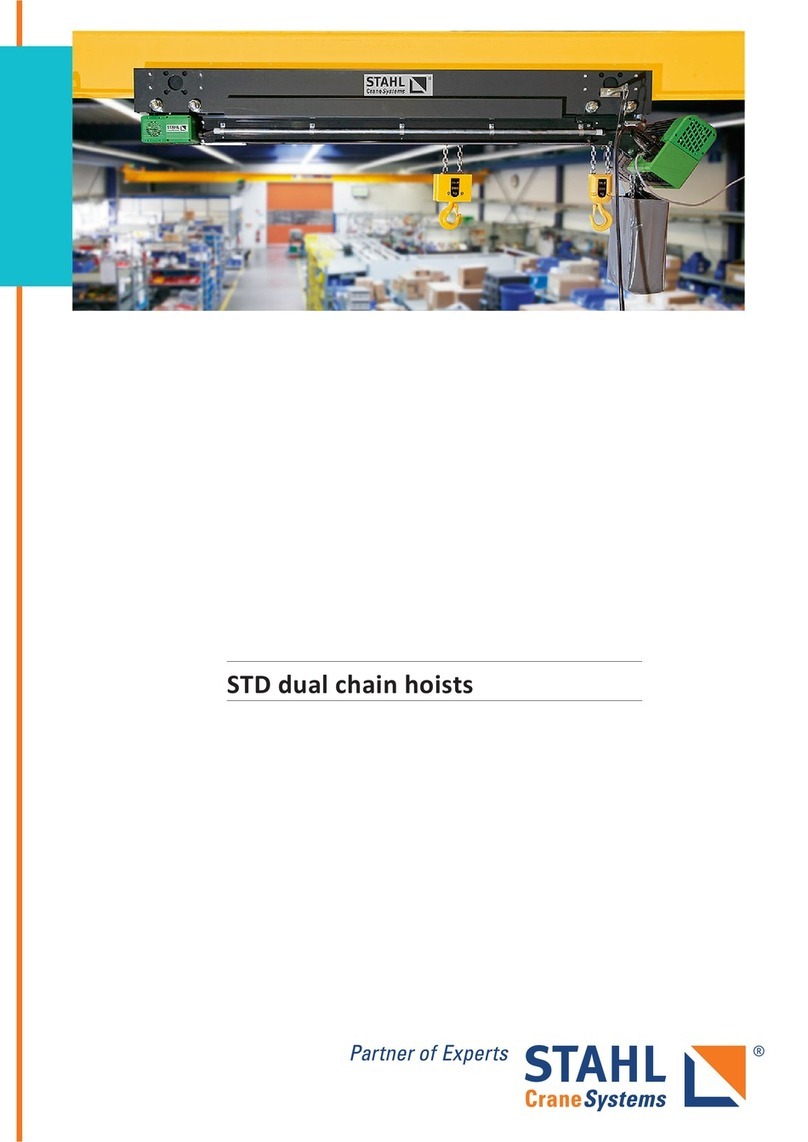

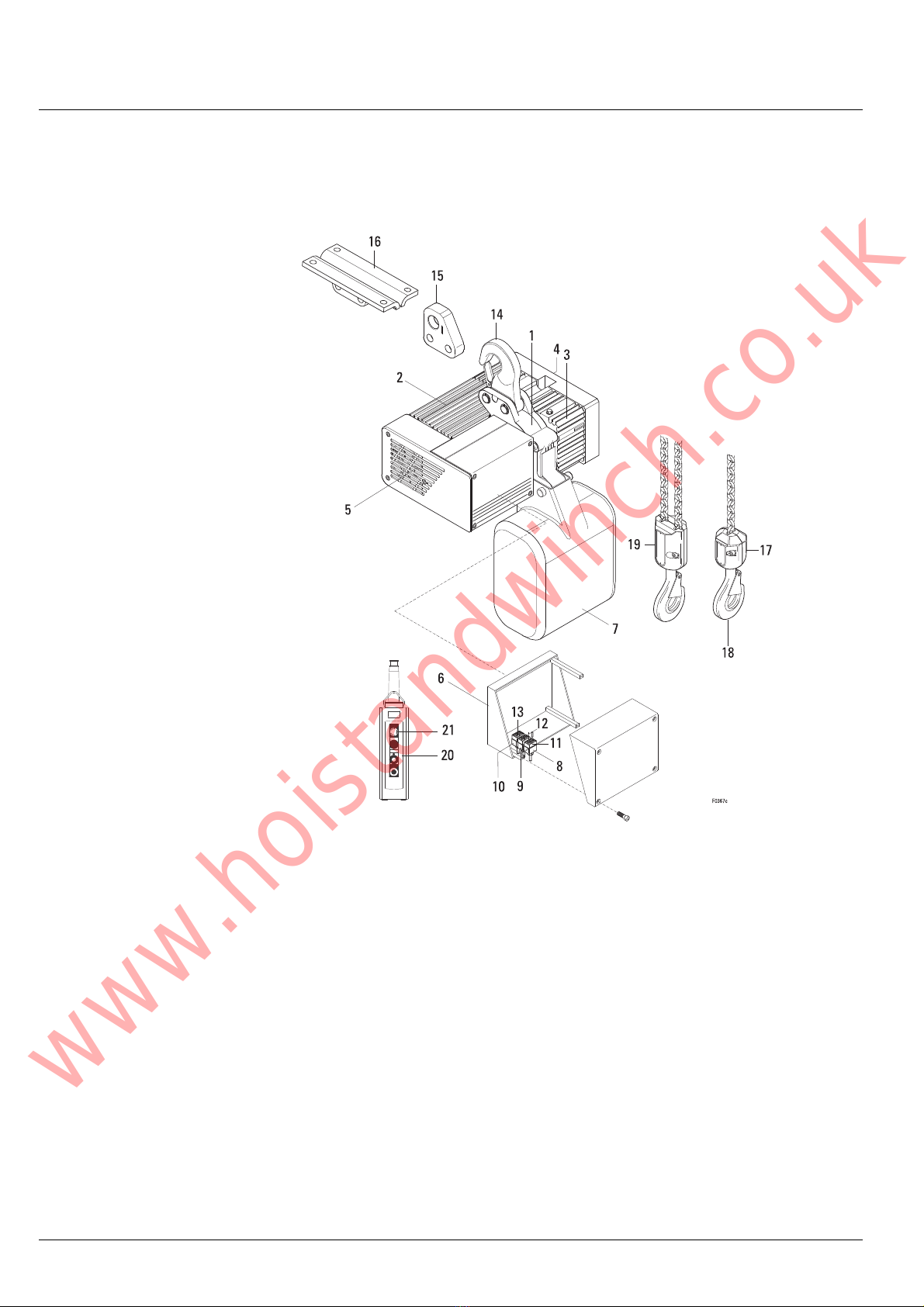

2 Getting to know the chain hoist ..................................................................................................................................................10

3 Installing 3.1 Installing stationary chain hoist ...............................................................................11

3.2 Installing trolley...........................................................................................................11

3.3 Installing trolley on chain hoist ................................................................................12

3.4 Connecting electric trolley........................................................................................14

3.5 Fitting guide rollers.....................................................................................................15

3.6 Mount support rollers ................................................................................................15

3.7 Runway endstop .........................................................................................................16

3.8 Fitting the chain box ...................................................................................................16

3.8 Fitting the control pendant ........................................................................................17

3.9 Checking screw connections ...................................................................................17

3.10 Mains connection.......................................................................................................18

3.11 Dismantling ..................................................................................................................18

4 Commissioning 4.1 Checklist for commissioning .....................................................................................19

5 Operating 5.1 Duties of crane operator ...........................................................................................20

5.2 Operating control pendant........................................................................................21

5.3 Emergency stop ..........................................................................................................21

6 Maintenance 6.1 Maintenance work .....................................................................................................22

6.2 Maintenance intervals...............................................................................................22

6.3 Hook ..............................................................................................................................23

6.4 Load chain....................................................................................................................23

6.5 Checking function of slipping clutch .......................................................................24

6.6 Adjusting slipping clutch without load....................................................................24

6.7 Adjusting slipping clutch - with test load ...............................................................24

6.8 Hoist motor brake .......................................................................................................26

6.9 Travel motor brake......................................................................................................27

6.10 Oil change ....................................................................................................................27

6.11 General overhaul ........................................................................................................28

6.12 Trolley............................................................................................................................28

6.13 Operating hours counter (optional) .........................................................................28

7 Repairs 7.1 Chain drive ...................................................................................................................29

Subject to technical alterations; errors and printing errors excepted.

07.12