Content

1General information ................................................................................................................................................................................................ 5

1.1 Copyright................................................................................................................................................................................................................... 5

1.2 Symbols..................................................................................................................................................................................................................... 5

1.3 Warranty.................................................................................................................................................................................................................... 6

1.4 Declaration of conformity / declaration of incorporation.................................................................................................................................6

1.5 Spare parts................................................................................................................................................................................................................ 6

1.6 Terminology.............................................................................................................................................................................................................. 6

1.7 Test book / crane logbook ..................................................................................................................................................................................... 7

1.8 Transport and storage............................................................................................................................................................................................ 7

1.9 Weight........................................................................................................................................................................................................................ 7

1.10 Installation, commissioning, maintenance and repairs................................................................................................................................... 8

1.11 After-sales service................................................................................................................................................................................................... 8

1.12 Periodic tests............................................................................................................................................................................................................ 8

1.13 Environmental information.................................................................................................................................................................................... 9

1.13.1 Life cycle assessment..................................................................................................... 9

1.13.2 Energy consumption ....................................................................................................... 9

2Safety instructions ................................................................................................................................................................................................10

2.1 Use for intended purpose ....................................................................................................................................................................................10

2.2 Inappropriate use...................................................................................................................................................................................................10

2.3 Residual dangers...................................................................................................................................................................................................11

2.4 Organisational safety precautions.....................................................................................................................................................................11

2.5 General regulations...............................................................................................................................................................................................12

2.6 Personal protective equipment...........................................................................................................................................................................12

2.7 Protection against falling .....................................................................................................................................................................................12

2.8 Sound pressure level............................................................................................................................................................................................12

2.9 Fire safety................................................................................................................................................................................................................12

2.10 Safety-conscious operation ................................................................................................................................................................................13

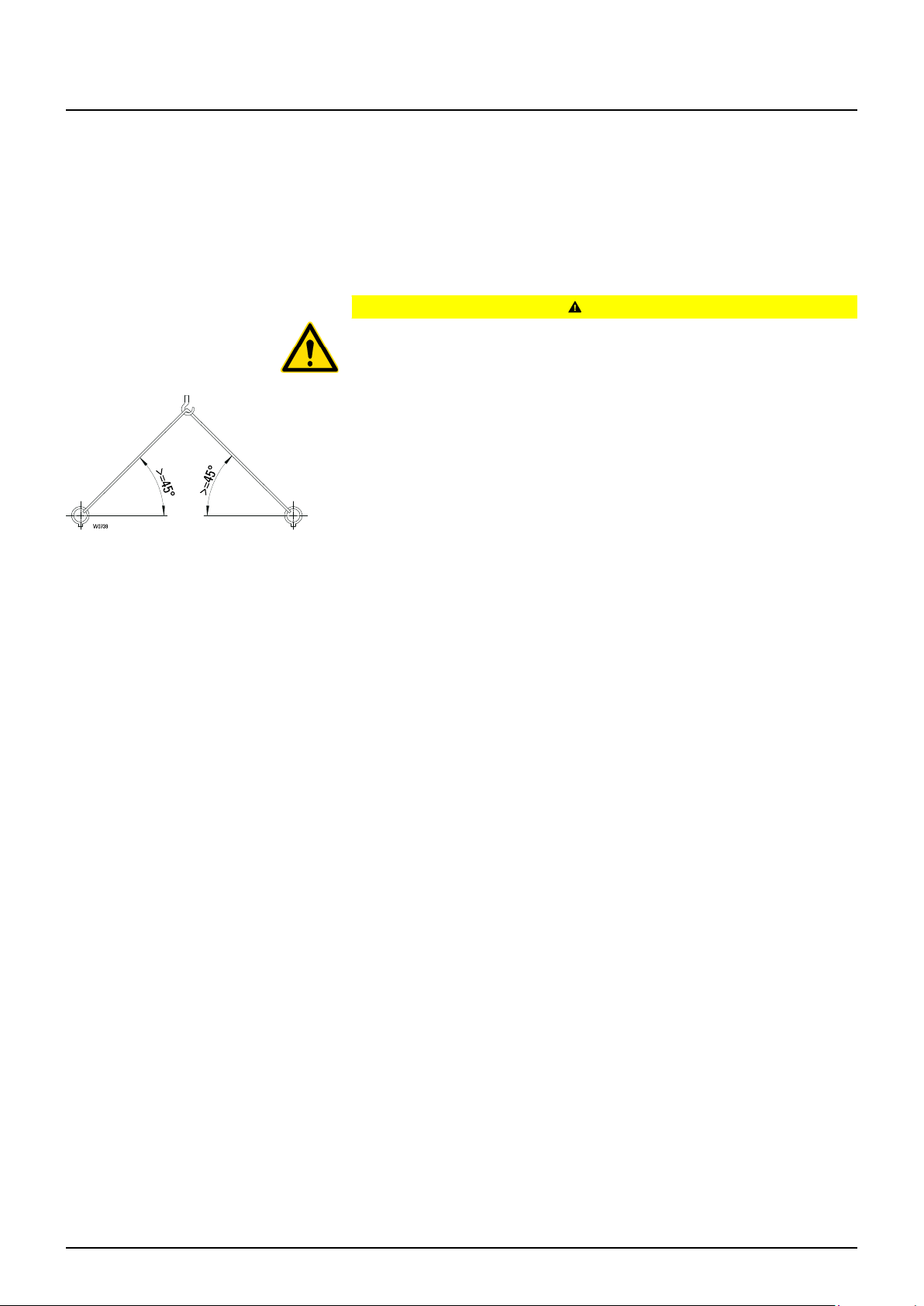

2.11 Attaching load ........................................................................................................................................................................................................13

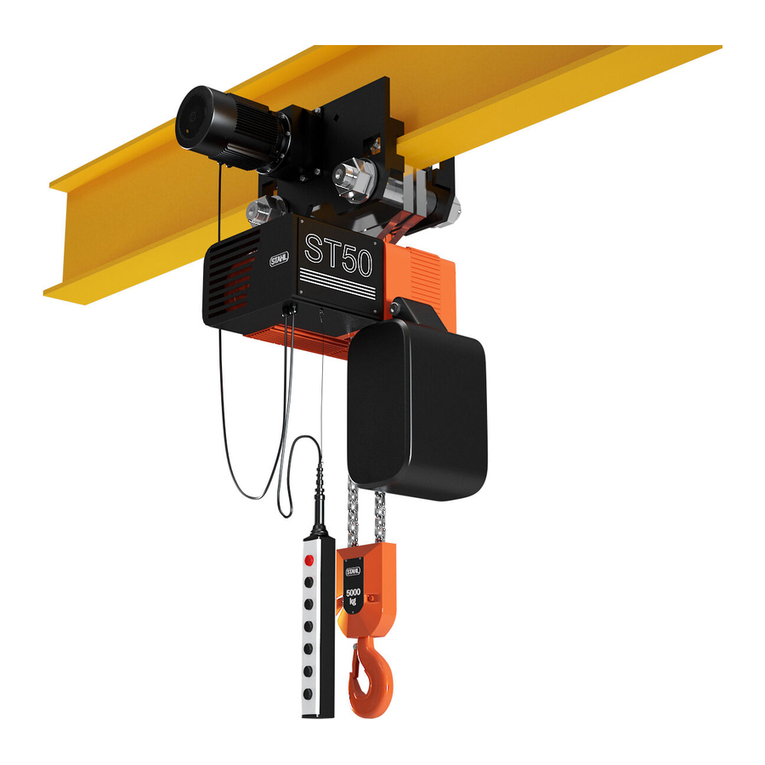

3Introduction ............................................................................................................................................................................................................14

4Installation...............................................................................................................................................................................................................15

4.1 Stationary chain hoist...........................................................................................................................................................................................15

4.2 Chain hoist with trolley.........................................................................................................................................................................................16

4.2.1 Assemble the trolley......................................................................................................16

4.2.2 Adjust trolley to runway width .......................................................................................19

4.3 Installing trolley on chain hoist...........................................................................................................................................................................21

4.4 Attach the trolley to the runway beam...............................................................................................................................................................23

4.5 Connecting electric trolley...................................................................................................................................................................................24

4.6 Mounting guide rollers .........................................................................................................................................................................................24

4.7Mounting support rollers .....................................................................................................................................................................................24

4.8 Runway endstop....................................................................................................................................................................................................25

4.9 Disassemble and assemble chain bucket ........................................................................................................................................................25

4.9.1 Disassemble chain bucket............................................................................................25

4.10 Mounting control pendant ...................................................................................................................................................................................27

4.11 Connecting to mains.............................................................................................................................................................................................27

4.11.1 Protective conductor......................................................................................................27

5Commissioning......................................................................................................................................................................................................28

6Operating.................................................................................................................................................................................................................29

6.1 Duties of crane operator.......................................................................................................................................................................................29

6.2 Operating control pendant...................................................................................................................................................................................30

6.3 Emergency stop.....................................................................................................................................................................................................30

7Inspection and maintenance...............................................................................................................................................................................31

7.1 Inspection intervals...............................................................................................................................................................................................32

7.1.1 Every day .......................................................................................................................32

7.1.2 Every month...................................................................................................................32

7.1.3 Every three months .......................................................................................................32

7.1.4 Every year......................................................................................................................32

7.1.5 Every five years .............................................................................................................32

7.2 Checking function of slipping clutch without load.........................................................................................................................................33