Stahlwerk SW500 User manual

Read me first

Congratulations with the purchase of your Stahlwerk SW

-

500 floor

sweeper. We at Stahlwerk Germany always offer you the very best quality

available to assure safe and successful use. However we urge you to read

this manual with great care before use.

FLOOR SWEEPER

SW500

1

INSTRUCTION ....................................................................................................................2

PRESERVATION OF MANUAL....................................................................................2

CONFIRMATION INFORMATION................................................................................2

ATTENTION..................................................................................................................2

OTHER REFERENCE MANUAL..................................................................................2

SPARE PARTS AND MAINTENANCE .........................................................................3

AMENDMENT AND IMPROVEMENT..........................................................................3

SAFTY..................................................................................................................................3

CONTENT AND PURPOSE .........................................................................................3

SYMBOLS ....................................................................................................................3

SAFETY REQUIREMENTS FOR BATTERIES............................................................5

GENERAL SAFETY REGULATIONS...........................................................................6

MACHINE DESCRIPTION...................................................................................................6

OUTER PACKING OF MACHINE ................................................................................6

PERFORMANCE..........................................................................................................7

CONTROL PANEL........................................................................................................7

OPERATION.................................................................................................................8

MACHINE OPERATION PRECAUTIONS....................................................................9

MACHINE PRESERVATION AND MAINTENANCE ..................................................10

MAIN BRUSH HEIGHT INSPECTION AND ADJUSTMENT .....................................10

MAIN BRUSH REPLACEMENT............................................................................... 111

SIDE BRUSH HEIGHT ADJUSTMENT......................................................................12

SIDE BRUSH REPLACEMENT .................................................................................12

VIBRATION.................................................................................................................13

FILTER CLEANING AND INSPECTION ....................................................................13

BATTERY CHARGING...............................................................................................14

EMPTY THE DUSTBIN ..............................................................................................14

WATER INJECTION...................................................................................................15

SQUEEGEE INSPECTION AND ADJUSTMENT ...................................................... 15

MAINTENANCE.................................................................................................................16

USE CONDITIONS.....................................................................................................16

MAINTENANCE SCHEDULE.....................................................................................16

TOUBLESHOOTING ..................................................................................................17

SPECIFICATIONS......................................................................................................18

2

INSTRUCTION

The manual will provide necessary information for customers to use machines

safely, conveniently and correctly, including technical characteristics, operation

methods, machine storage, maintenance, spare parts and safety conditions.

Before using the machine, users and professional maintenance technicians

must read the manual carefully and use the machine strictly according to the

instructions in the manual. If you have any questions or get more details, please

consult the seller. The manual is specially provided for users and professional

maintenance/maintenance technicians. Operators must undergo professional

technical training, otherwise the manufacturer will not be responsible for the

loss.

PRESERVATION OF MANUAL

The manual must be placed in a safe and accessible area near the machine,

away from easily damaged areas such as liquids.

CONFIRMATION INFORMATION

The machine model and the year of manufacture are displayed on the

nameplate behind the machine.

Machine Model: SW500

Machine Number:

ATTENTION

This machine is suitable for industrial and commercial purposes, specially used

for cleaning hard floor in the room, and can not be used for other purposes.

Please use all recommended cleaning mats and brushes, as well as floor

cleaners for sale.

OTHER REFERENCE MANUAL

List of spare parts

3

SPARE PARTS AND MAINTENANCE

All necessary operations, maintenance and repair procedures must be

completed by trained operators or after-sales service centers. When

purchasing spare parts or requiring repairs with sellers, please inform the

machine model and fuselage number in detail.

AMENDMENT AND IMPROVEMENT

Our company often improves our products and keeps room for expansion, but

we are not obliged to make new improvements to the products already sold. If

there is any change in the content, please contact our after-sales service

department.

SAFTY

CONTENT AND PURPOSE

The following symbols indicate potential dangers. Read these instructions

carefully and take necessary precautions. The essence of the machine

operation manual is to prevent injury. Accident-free safety precautions are

necessary. Most accidents occur at work without paying attention to basic

safety rules. A careful and cautious user is the best guarantee against accidents,

even better than some other preventive measures. When using the machine,

we must pay attention to the people around you, especially the children.

SYMBOLS

DANGER!

This sign refers to a situation that is dangerous to the operator.

WARNING!

This sign refers to potential harm to people.

CAREFUL!

This sign refers to careful or important related notes or useful functions.

4

NOTE!

Please pay special attention to the above signs in the paragraph!

DANGER!

Detailed warnings and messages on the prevention of personnel and

machine damage hazards are as follows:

Please keep loose clothing, hair, fingers and other parts of the body away

from the air vent and any moving parts of the machine.

When the machine stops, remember to turn off the power.

Do not use the machine where the slope exceeds the rated value of the

machine.

Please read the maintenance and repair instructions carefully before

performing any maintenance and repair operations.

Please dont smoke while the battery is charging.

Do not use the machine in a very dirty area. If the road waste is thick, please

repeat the sweeping twice or more.

When using the machine, be careful not to cause injury to people, especially

children.

Do not place liquid containers on the machine.

The machine should be stored between - 10 and 40 degrees.

When using the machine, the temperature should be between - 10 ° C and

40 ° C.

Humidity should be between 30% and 95%.

Do not use the machine as a means of transport.

When the machine is not moving forward, do not let the brush continue to

rotate to avoid damage to the ground.

In case of fire, please remember to use powder fire extinguisher instead of

water.

Dont hit the shelves where there is a danger of falling objects.

5

Adjust the travel speed of the machine according to the adhesion of the

ground.

Do not change the safety guards of the machine; follow the maintenance

instructions procedure.

Do not move or change the Stahlwerk nameplate on the machine.

When the machine operation fails, make sure that the failure is not caused by

the lack of scheduled maintenance, and turn to Stahlwerk for help.

If some parts need to be replaced, you can purchase spare parts from the

original manufacturer or authorized dealer.

To ensure the proper operation and safety conditions of the machine,

professionals or service centers must follow the maintenance section of this

manual work.

Even if the machine is to be disassembled and scrapped, people should pay

attention to it as some harmful substances (such as batteries, waste oil, etc.)

shall be sent to a specific Center for treatment.

Machines equipped with lead (wet) batteries shall not be tilted more than 30 °

above the horizontal ground, so that the battery is highly corrosive acid will

leak. The machine must be tilted during maintenance. Please remove the

battery.

SAFETY REQUIREMENTS FOR BATTERIES

It is necessary to avoid the battery in low voltage state and charge it as soon

as possible.

The battery is 12V lead-acid maintenance-free battery.

To avoid leakage, keep the battery dry and clean, especially remove

pollutants such as metal dust.

It is forbidden to place metal parts (such as tools) on batteries in order to

prevent short circuit burnout of batteries.

When reclaiming batteries, please comply with local regulations.

It is forbidden to use open fire when handling and handling batteries.

6

The charging room should be well ventilated.

When the key switch is in the ON position, it is forbidden to connect or

disassemble batteries.

Before disassembling and assembling batteries, first disconnect the negative

(-) battery wire, and then disconnect the positive (+) battery wire. When re-

wiring, we must pay attention to the polarity of batteries, wrong wiring will

damage electrical components;

Avoid direct contact between positive and negative electrodes, because it will

cause high current short circuit, high heat and even the possibility of fire.

When the battery is charged, it generates explosive hydrogen, charges the

battery in a ventilated place, and keeps the lid open and away from the open

fire.

GENERAL SAFETY REGULATIONS

In addition to the provisions made in this specification, the required general

safety regulations and accident prevention guidelines must also be complied

with. Even if you have used a similar car before, please read the instructions

carefully. Reading the instructions in advance will save you a lot of time in the

future. Before you start using it, its vital for you to be familiar with all the

accessories and controls and their functions. Read the manual thoroughly so

that you dont get in a h urry when you turn it on.

MACHINE DESCRIPTION

OUTER PACKING OF MACHINE

When the machine arrives, please carefully check whether the machine itself

is damaged or not. If the damage is obvious, please keep the outer packing

carton so as to make the damage declaration to the freight company

immediately.

Please check whether the machine contains the following items:

Handbook for the Use of Sweeper

7

List of spare parts for floor sweeper

Floor sweeper spare parts

Start-up key

PERFORMANCE

The sweeper must be operated by qualified operator on flat concrete or

asphalt floor to sweep dust or light garbage.

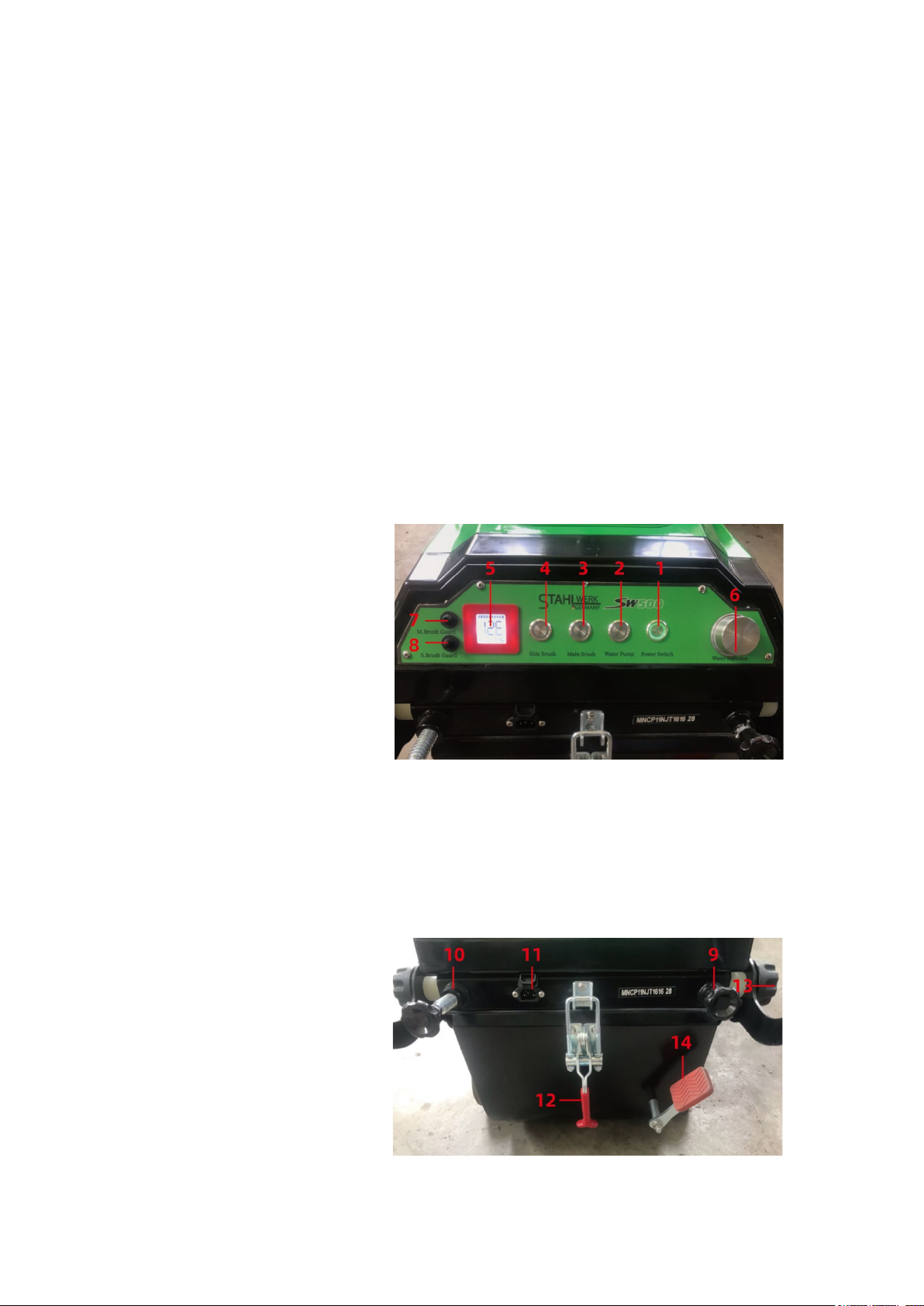

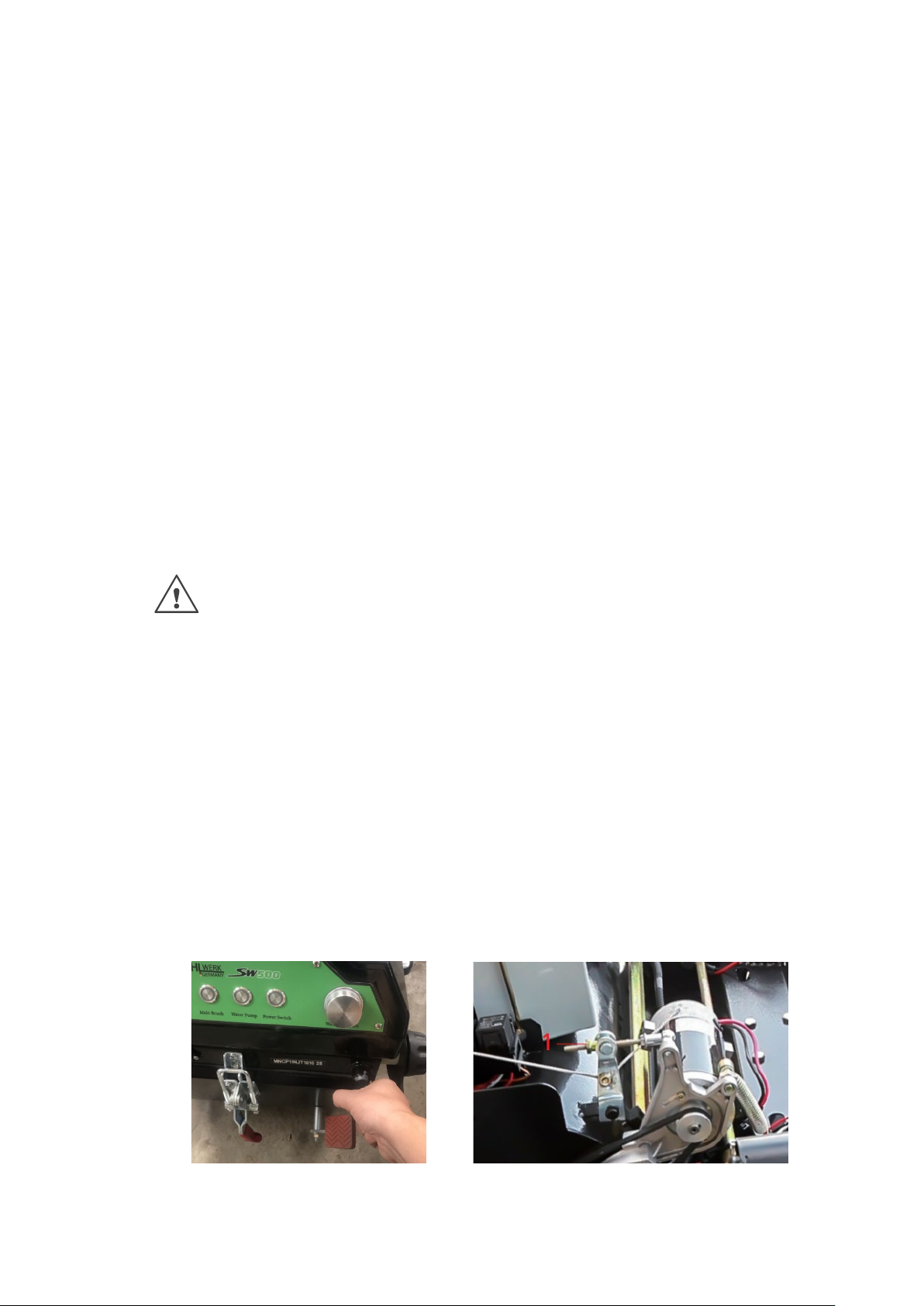

CONTROL PANEL(Figure 1 and 2)

1. Key switch

2. Water pump

3. Main brush button

4. Side brush button

5. Electric and voltage display

6. Water injection figure 1

7. Main brush protection

8. Side Brush protection

9. Main brush height adjuster

10. Side Brush height adjuster

11. Charging port

12. Dustbin handle

13. Armrest adjuster

14. Vibrating pedal figure 2

8

OPERATION

EVERY START

Insert the start key in the operation panel; turn the key switch to the "on"

position.

Three seconds later, the meter displays the battery power value. If it is fully

charged, it will display 100%; if it is under charged, it will display 20%, please

charge; otherwise, it will display the battery memorized during the last

shutdown.

CAREFUL!

Make sure that the dust bin is closed properly when the machine is in

normal operation.

If the machine is transported, check that all parts are moved during

transportation.

MACHINE START

Turn the start key to the "on" position.

Move the machine to the working area by pushing the push rod forward,

backward and turning.

Press the main brush function button and side brush function button to I to start

sweeping.

If the working environment is poor, stop sweeping after a certain time interval

(pull the vibrating handle).

Check the amount of garbage in the dustbin and empty it in time.

Check the water quantity and add water in time.

MACHINE STOP

Press the main brush and side brush function buttons to O.

Turn the start key to the "off" position.

9

MACHINE OPERATION PRECAUTIONS

NOTE!

In the process of work, determine whether to start the vibration device

temporarily according to the amount of garbage on the cleaned ground.

When the filter is blocked or the bin is full, the machine cant collect

the garbage. After each work, the dustbin must be emptied. (if the

dustbin is full in the work, please empty it immediately.) if the

temperature is lower than 0 ℃, please pay attention to drain the water

in the dustbin to prevent freezing!

WARNING!

Avoid stopping the machine at the same place for a long time and

rolling the brush; this will leave traces on the ground

When collecting large garbage, please remember to lift the front wheel

slightly and move forward. Note that it is only lifted for a short time.

In order to make the machine have a good cleaning, be sure to clean

the filter. Step the vibration on the side of the bin for about ten times

to shake off the dust on the filter.

CAREFUL!

Decide whether to clean the filter according to the dirt of the cleaned

area.

The dustbin must be emptied every time after working. When the main

brush and the side brush are worn, the screw at the rear of the

machine can be adjusted to lower the main brush and the side brush,

and the adjustment cannot be too low. Clean them to avoid burning

the fuse. (during the first cleaning, there is no need to adjust, and the

companys staff has adjusted it)

1

MACHINE PRESERVATION AND MAINTENANCE

If the machine will not be used within 30 days, follow the procedure below:

Store the machine in a clean and dry place.

Disconnect the battery connector.

First use

After the first use (the first 8 hours), it is necessary to check the following

operations:

Check the connection and fastening parts for looseness.

Check whether the visible parts are intact.

Check the main side brush for excessive wear.

WARNING!

To perform maintenance operations, the battery must be removed

when the machine is stopped (the start switch key is removed) and if

necessary. Therefore, please read the safety section of the manual

carefully.

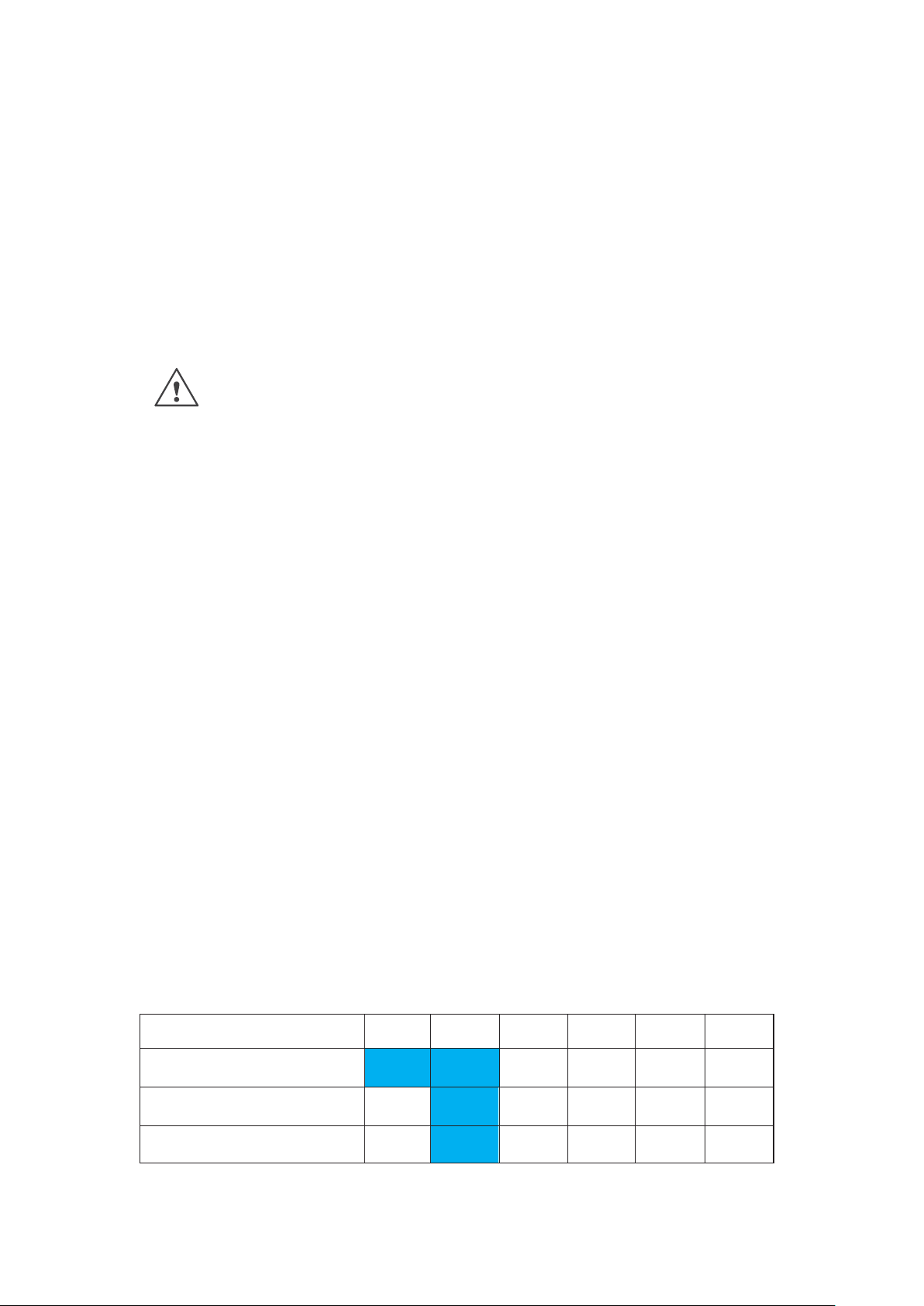

MAIN BRUSH HEIGHT INSPECTION AND ADJUSTMENT

The height of main brush has been adjusted before leaving the factory. After

using for some time, the main brush will be worn and it is necessary to adjust

the brush. Turn the rotary handle at right hand anticlockwise to lower about

2mm, so that the main brush is 3-5mm in contact with the ground. (Figure 4)

1

Figure 3 figure 4

When the main brush is seriously worn and the rotating handle has turned to

the last stage, please open the front cover and adjust it as follows:

Adjust the right rotating handle to the initial position (Figure 3) turn the nut 1

clockwise (Figure 4) to make the main brush brush hair touch the ground for 3-

5mm

Cover the front cover properly

Repeat the last process (main brush height inspection and adjustment ).

MAIN BRUSH REPLACEMENT

1. Remove the cover screws (Figure 5)

2. Loosen the left and right rocker arms of the main brush (Figure 6)

3. Disassemble the rocker arm.

4. Lift up the machine and take out the main brush (Figure 7)

5. Take out the left and right heads of the main brush.

6. Install the left and right head on the main brush, and pay attention to the

installation direction.

7. Install the main brush on the sweeper and tighten the bolts (Figure 8)

8. Adjust the adjusting screw of the main brush to the position where it is used

for the first time, so that the main brush hairs touch the ground for 3-5mm

9. Install the cover.

Figure 5 Figure 6

1

Figure 7 Figure 8

CAREFUL!

The hard brush or soft brush can be selected according to the ground

conditions; when replacing the main brush, it is better to wear gloves,

because it may be cut by the brush; the operation direction of the main

brush is shown in Figure 5, and the main brush shall be installed

correctly as shown in the figure, and the pressure between the main

brush and the ground shall be checked as described in the relevant

chapters.

SIDE BRUSH HEIGHT ADJUSTMENT

When the sweeper leaves the factory, the height of the edge brush has been

adjusted to be qualified. When it is used for a period of time, the side brush

cannot clean effectively, and it is necessary to adjust the side brush. Turn the

left rotary handle clockwise for 1 stage (Fig. 9), and clean it.

Figure 9 Figure 10

SIDE BRUSH REPLACEMENT

The main function of the side brush is to collect the garbage on both sides into

the middle by using its own rotation, and then the main brush will collect it into

the garbage bin. The advantage of the side brush is that it can sweep out the

garbage at the corners and dead corners and increase the cleaning area.

Use the machine on the level ground, turn the starting key of the machine to

"off" position.

Lift up the machine and loosen the four bolts at the bottom of the brush disc

(Figure 11)

1

Replace with a new side brush.

Adjust the height of the side brush according to the instruction.

VIBRATION

After continuous operation of the sweeper for a period of time, the capillary

hole of the filter is might be blocked. Please use the dust vibrating function

regularly:

Turn off the machine power supply.

Step the dust vibrating pedal for ten times to shake off the dust on the

filter(Figure 11).

Figure 11 Figure 12

FILTER CLEANING AND INSPECTION

Use the machine on flat ground, turn the machine start key to "off" position

and remove the dustbin. Lightly scrape the bottom of the filter with a burr free

bar.

Please note the following: do not use water or detergent to clean it, the filter

will be damaged. Replace the filter when there is crack on it.

1

BATTERY CHARGING

After each use, when the warning light is on, charging the battery will prolong

the battery life.

If you want to stop charging, disconnect the AC socket switch before

disconnecting the DC socket, and then take the DC plug after the charger is

disconnected(Figure 12).

DANGER!

Do not touch the battery terminals and DC plugs.

EMPTY THE DUSTBIN

Push the sweeper to the garbage dumping area. Release the buckle and take

out the dustbin (Figure 13).After cleaning the garbage, put the dustbin inside

and then lock the buckle.

Figure 13 Figure 14

NOTE!

When the machine stops working, the brush must be lifted to prevent

deformation of the brush.

1

WATER INJECTION

Turn the water filling cover anticlockwise to add water(figure 14).

NOTE!

When the temperature is lower than zero, please empty the water

tank!

SQUEEGEE INSPECTION AND ADJUSTMENT

1. Place the machine on a flat ground suitable for checking the height of the

squeegee.

2. Turn the starting key of the door to the "off" position.

3. Check the integrity of the side squeegee.

4. Check whether the height between the squeegee and the ground is within 0-

3mm.

5. Raise the front wheels of the sweeper

6. Check the integrity of the front and rear squeegee

7. The front squeegee slightly touches the ground but not separated from the

ground

8. The height between the back squeegee and ground is within 0-3mm

1

MAINTENANCE

The service life and operation safety of the machine must be ensured by the

correct routine maintenance of the machine. Make a list of the routine

maintenance requirements below. Under suitable working conditions, the

maintenance interval can be changed, which must be determined by the

professional responsible for the maintenance.

WARNING!

Stop the machine (remove the start switch key) to carry out

maintenance operations, remove the battery if necessary. Therefore,

please read the safety section of the manual carefully.

USE CONDITIONS

1. Temperature: - 10 ~40;

2. Relative humidity of air: 5%-70%;

3. No conductive dust, no explosion danger environment;

4. An environment free of corrosive metal gases or vapors;

5. Used indoors, ventilated, non-vibration environment, front and rear space at

least 300 mm.

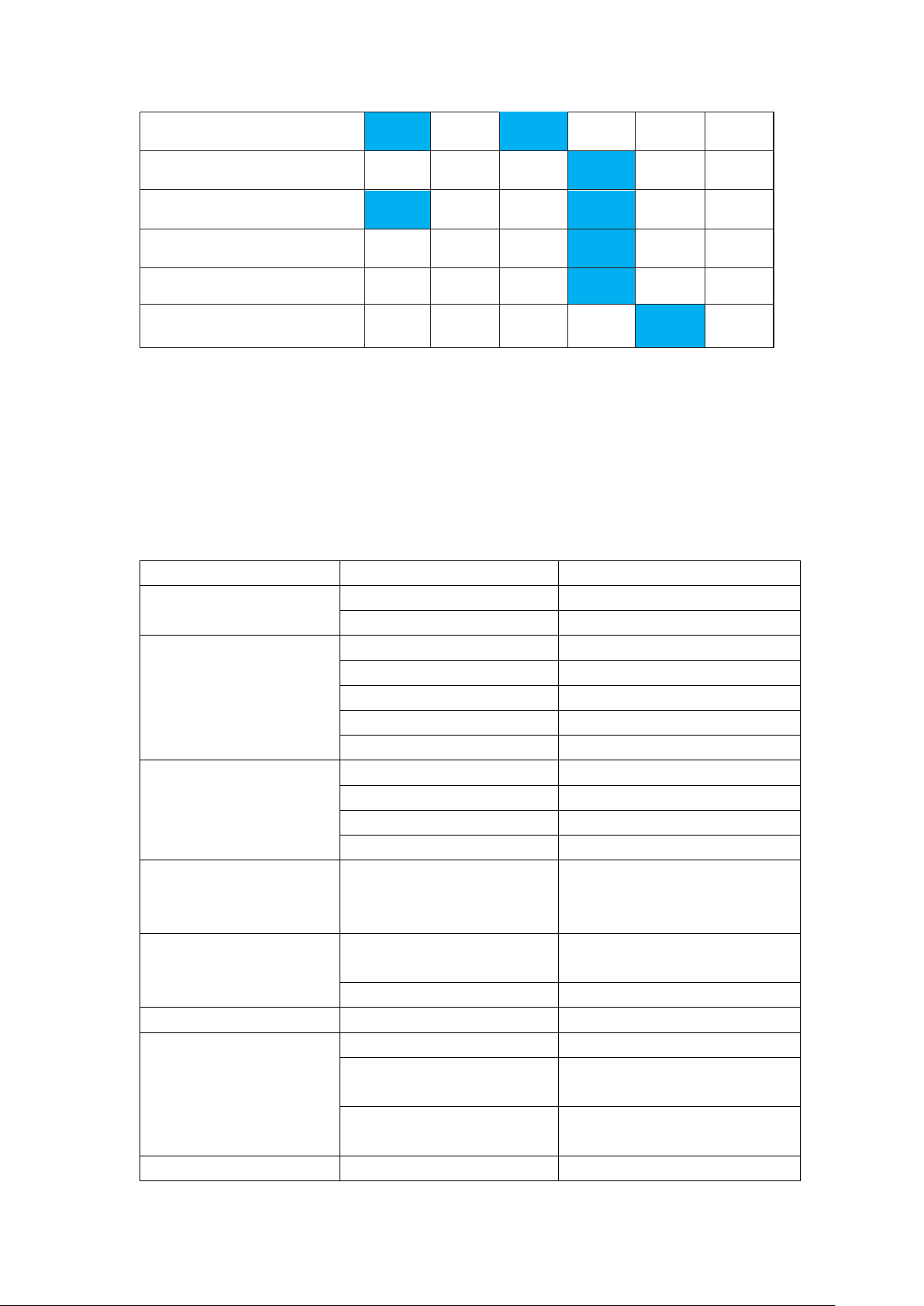

MAINTENANCE SCHEDULE

Maintenance operation

First use

Every

10 hours

Every

50 hours

Every

100 hours

Every

200 hours

Every

500 hours

Main brush and side brush height

adjustment

Main brush and side brush wired or

twisted

Filter inspection

1

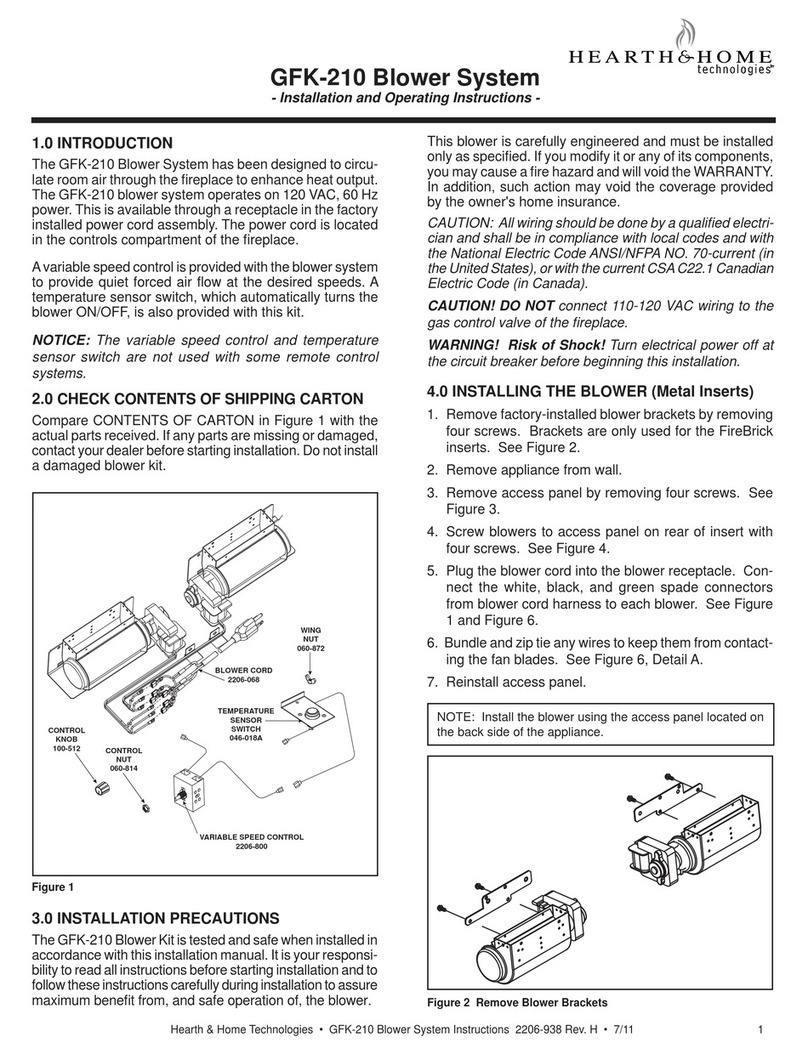

TOUBLESHOOTING

Trouble

Cause

Troubleshooting

No display on instrument

board

Fuse broken

Replace the fuse

Battery output

Charge or replace the battery

Brushes not working

Brush motor broken

Replace the brush motor

Main brush belt broken Replace the main brush belt

Main brush button broken Replace the main brush button

Fuse broken Replace the belt

Relay broken Replace the relay

Not cleaning effectively Brushes are worn Replace the brushes

Squeegee is worn

Replace the squeegee

Filter is plugged

Vibration

Working speed is too high

Lower the speed

Brushes are worn quickly

Brushes are pressed too

tightly or the floor is too

harsh

Lighten the pressure of brush

Main brush makes too

much noise when

working

Rope or wire twining in

brush

Move the entanglement

Seal of dustbin is broken

Replace the seal

Waste container leakage

Waster container is too full

Empty the dustbin

Battery can’t be charged Battery damaged Replace the battery

Charger

Check the charger’s input

current

Battery connection loosen

Check and tighten the

connection

Excessive battery

Charging time insufficient Prolong the charging time

Squeegee height

inspection

Refueling

Main brush drive belt inspection

Screw nut tightening inspection

Check the wear of main brush and

side brush

Replacement of drive belt

1

discharge Battery damaged Replace the battery

SPECIFICATIONS

www.stahlwerkgermany.com

Friedrich-Ebertstrasse 75-77

42719 Solingen Germany

NO

Item Name

Unit

Specification

1

Sweeping width

mm

>1000

2

Cleaning efficiency

m²/h

>4000

3

Main brush length

mm

400

4

Side brush diameter

mm

400

5

Power supply

v

12( >100AH)

6

Working time

h

>4

8

Dustbin capacity

L

>22

9

Working power(motor)

main brush + fan + side

brush

w120+30+35×2

10

Filtering area

m²

1.5

11

Net weight

kg

95

12

Water tank capacity

L

12

Table of contents

Popular Blower manuals by other brands

Becker

Becker SV 1100 operating instructions

DeWalt

DeWalt DCMBA572X1 Original instructions

STEWART-AMOS

STEWART-AMOS Starfire S-5s Operation manual

Heart & Home Collectables

Heart & Home Collectables GFK-210 Installation and operating instructions

Powr-Flite

Powr-Flite PIRANHA PS 400 manual

Core

Core ROVER R4300 Original instructions