Stairs CP Series User manual

STAIRS INDUSTRIAL CO., LTD.

CP series

Submersible utility pump

50HZ

www.stairs.com.tw

Model code

Motor

•Motor Type: 2 POLE, dry type

•Frequency: 50Hz

•Standard Voltages: 1Ø 220 - 240 V

•Insulaon Class: B class (130°C)

•Enclosure Protecon Class: IP 68

•Nominal Speed: 2850 rpm

- 1 -

The STAIRS CP series submersible ulity pump is designed for dewatering and groundwater transfer-

ring applicaons. It is extremely useful for transferring unwanted water away from building founda-

on, basement, and work area. Each pump is built using non-corrodible materials, ensuring a long

service life. Because STAIRS CP series submersible ulity pump is both durable and lightweight, it can

be easily transported from one locaon or project to another.

CP - 100 A

Power wa

A = AUTO

Series name

Features

•Lightweight and portable

•All models are hermecally sealed to be

waterght, dust-ght, and completely

submersible

•High efficiency for low electricity bill

•Corrosion resistant materials for healthier life

•Robust construcon for beer reliability

•Auto reset thermal overload protecon for

longer motor life

•Removable screened boom for easy cleaning

Applicaons

•Basement water removal

•Water transfer

•Sump/effluent handling

•Dewatering

•Fish pond & fountain circulaon

Q[L/min]

H[m]

1

3

7

2

4

6

5

0

0 2010 30 40 50 60 70 80 90

100

110

Q[m /h]0 1 2 345673

CP200(A)

CP100(A)

Power Max.HeadMax.Flow

100 - 200 W Up to 7 MUp to 110 L/min

CP SERIES - Submersible ulity pump

Operaon Condions

•Liquid Temperature: 2°C - 40°C

•System Pressure: Max. 5M

Performance Curves

www.stairs.com.tw

Dimension

- 2 -

Model

Phase Voltage

Power Head

(Pressure)

Flow

(Capacity)

Solid

pass Connecon

Ampere Weight

WaRated

(M)

Max.

(M)

Rated

(L/min)

Max.

(L/min)

mm Outlet kg

CP -100 220-240 100W 4 6.5 35 70 33/4"/1"

3/4"/1"

3.1

CP -100A 220-240 100W 4 6.5 35 70 33.6 216

CP -200 220-240 200W 5 7 40 110 5 1-1/4" 4.2

CP -200A 220-240 200W 5 7 40 110

1.0/1.0

1.0/1.0

1.3/1.3

1.3/1.3

5 1-1/4" 4.7

Specificaons

•Model with “A” is AUTO.

•6 Units per set - 36 Sets per pallet.

L x W x H

(cm)

110 x 110 x 216

110 x 110 x 216

110 x 110 x 216

110 x 110 x 216

1Ø

Units/

Pallet

Max.

(A)

Model Outlet L1

(mm)

L2

(mm)

L3

(mm)

CP-100 3/4"154 234.5 138

1"154 230 138

CP-100A 3/4"154 234.5 138

1"154 230 138

Model Outlet L1

(mm)

L2

(mm)

L3

(mm)

CP-200 1-1/4"154 293138

CP-200A 1-1/4"154 293138

CP-100 CP-200

CP-100A CP-200A

Packin

dimension

www.stairs.com.tw

- 3 -

Component

CP100,CP100A CP200,CP200A

6

5

4

3

2

1

7

5

3

4

2

1

7

6

No.Component Material

1ShaSUS400 Series

2Motor Housing PP+GF

3Pump Casing PP+GF

4Strainer PP+GF

5Impeller Nylon+GF

6Mechanical seal Carbon+Ceramic+NBR

7Oil Seal NBR

8Cable gland SUS304

8

8

www.stairs.com.tw

www.stairs.com.tw

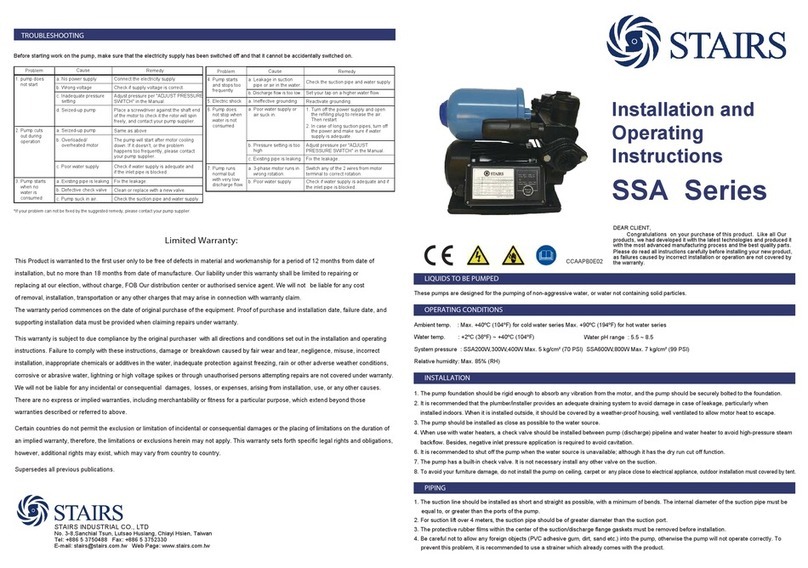

CP Series

Installation and Operating Instructions

Limited Warranty:

Products of STAIRS are warranted to the rst user only to be free

of defects in

material and workmanship for a period of 6 months from date

of installation,

but no more than 12 months from date of manufacture.

STAIRS's liability

under this warranty shall be limited to repairing or

replacing at our election,

without charge, FOB STAIRS's distribution

center or authorized service agent.

STAIRS will not be liable for

any cost of removal, installation, transportation

or any other charges that

may arise

in connection with warranty claim.

The warranty period commences on the date of original purchase of the

equipment. Proof of purchase and installation date, failure date, and

supporting installation data must be provided when claiming repairs

under

warranty.

This warranty is subject to due compliance by the original purchaser with

all

directions and conditions set out in the installation and operating

instructions. Failure to comply with these instructions, damage or breakdown

caused by fair wear and tear, negligence, misuse, incorrect installation,

inappropriate chemicals or additives in the water, inadequate protection

against freezing, rain or other adverse weather conditions, corrosive or

abrasive water, lightning or high voltage spikes or through unauthorized

persons attempting repairs are not covered under warranty.

STAIRS will not be liable for any incidental or consequential damages,

losses, or

expenses, arising from installation, use, or any other causes.

There are no

express or implied warranties, including merchantability

or tness for a

particular purpose, which extend beyond those

warranties described or

referred to above.

Certain countries do not permit the exclusion or limitation of incidental

or

consequential damages or the placing of limitations on the duration

of an

implied warranty, therefore, the limitations or exclusions herein

may not

apply. This warranty sets forth specic legal rights and

obligations,

however, additional rights may exist, which may vary from

countries to

countries.

Supersedes all previous publications.

CCBUP00E03

Pump runs

but does

not deliver

water.

●Check valve is installed backwards.

Arrow on valve should point in direction of ow.

●Discharge shut-o valve (if used) may be closed.

●Impeller or volute openings are fully or partially clogged.

Remove pump and clean.

●

Pump is air-locked. Start and stop several times by plugging and

unplugging cord. Check for clogged vent hole in pump case.

●Inlet holes in pump base are clogged. Remove pump and

clean the openings.

●

Vertical pumping distance is too high. Reduce distance or

change

the discharge ttings of the pump.

Pump runs

and pumps

out sump,

but does

not stop.

●

Float is stuck in up position. Be sure oat operates freely

in

basin.

●Defective oat switch. Replace with oat switch.

●Defective vertical switch. Replace with vertical switch.

Pump runs

but delivers

only a small

amount of

water.

●

Pump is air-locked. Start and stop several times by plugging and

unplugging cord. Check for clogged vent hole in pump case.

●

Vertical pumping distance is too high. Reduce distance or change

the discharge tting of the pump. Inlet holes in pump base are

clogged. Remove pump and clean the strainer and openings.

●Impeller or volute openings are fully or partially clogged.

Remove pump and clean.

●

Pump impeller is partially clogged with tar or paint, causing

motor

to run slow and overload. Remove pump and clean.

Fuse blows

or circuit

breaker

trips when

pump starts.

Motor runs

for a short

time, then

stops.

●

Pump impeller is partially clogged with tar or paint, causing

motor

to run slow and overload. Remove pump and clean.

●Motor stator may be defective.

●Fuse size or circuit breaker may be too small.

●Impeller or volute opening are fully or partially clogged.

Remove pump and clean.

●

Inlet holes in pump base are clogged. Remove pump and clean

the openings.

●

Pump impeller is partially clogged with tar or paint, causing motor

to run slow and overload. Remove pump and clean.

●Motor stator may be defective.

●Impeller or volute openings are fully or partially clogged.

Remove pump and clean also clean the strainer if you had installed.

www.stairs.com.tw

Submersible Utility Pump

No. 6-7, San-Zai-Chiao, Hou-Jue village, Lutsao Hsiang, Chiayi Hsien, Taiwan, R.O.C.

GENERAL INFORMATION

SPECIFICATIONS

OPERATION OVERLOAD PROTECTION

THANK YOU FOR PURCHASING A

STAIRS PRODUCT

Take the time to read the instructions carefully before using this

appliance. We strongly recommend that you keep this instruction

manual in a safe place for future reference.

Before use, read the following instructions carefully. Closely

following these instructions will eliminate potential operating

problems, assuring years of trouble-free service.

WARNING

WARNING

CAUTION

CAUTION

Risk of electric shock. The pump is supplied with a grounding

conductor and grounding-type attachment plug. To reduce the risk

of electric shock, install only on a circuit protected by ground-fault

circuit-interrupter. Always disconnect the pump from the power

source before handling or making adjustments. Always wear rubber

boots when servicing in wet areas. Make sure the pump power

source is a separately fused, grounded 3-wire type receptacle of

15-amp capacity. DO NOT REMOVE GROUND PRONG OR PLUG.

DO NOT USE AN EXTENSION CORD. Check to make sure installation

is in accordance with the National Electric Code and all applicable

local codes. Installation and servicing are to be conducted by

qualied personnel.

● DO NOT pump ammable liquids

● DO NOT use around explosive materials

● DO NOT handle unit with wet hands or while standing in water

● DO NOT lift the pump by the power cord

●DO NOT connect to any voltage other than that listed on the

nameplate

● DO NOT use in water over 104˚F (40˚C).

● DO NOT modify the pump in any way

● DO NOT expose pump or discharge to freezing temperatures

● DO NOT use this product to pump salt water or brine. Use with

salt water or brine will void the warranty. Pump water only.

● Model with “A” is equipped with oat switch

1.Set pump on hard surface in water before starting.

2.Use the included garden hose adapter for properly discharge line

or disconnect the adapter to use a properly discharge.

3.Plug power cord into properly grounded AC power outlet. Will

operate continuously whether partly or fully submerged.

Submersible utility pumps are intended to pump water at

temperatures up to 104˚F(40˚C).

4.To prevent unnecessary wear, unplug the pump from the power

output when not in use.

5.The pump is supplied with the garden hose adapter. For use with

plastic pipe, remove the adapter and install the desired properly

tting.

DO NOT OVERTIGHTEN THE HOSE OR PLASTIC ADAPTER

FITTING. Finger tight plus 1/2 turn is sucient.

6.Pump equipped with

Optional Float switch.

When the pump senses

that it is no longer pumping

water, the pump will

shut o automatically.

●Do not set pump directly on sand, dirt or mud. Sand or mud-

choked pumps can Be back-ushed clean.

●

Do not handle or carry the pump by the power cord. Use the handle.

●Extended usage of the pump in a partially submerged or non-

submerged situation may cause the pump to overheat due to

lack of heat dissipation from the water. If this occurs, the pump

will shut itself o until the motor cools to its normal temperature.

Repeated overheating may cause damage to the pump.

This pump series has a built in thermal protection switch. The pump

stops if an overload condition occurs.

The motor restarts automatically after it has cooled down.

TROUBLESHOOTING CHECKLIST

(CAUTION: SHUT OFF POWER TO PUMP)

PROBLEMS POSSIBLE CAUSES

Pump does

not run

and hums

●Line circuit breaker is o, or fuse is burned or loosed.

●Water level in sump has not reached turn-on level as

indicated in installation drawing.

●Pump cord is not making contact in receptacle.

●Float is stuck. It should operate freely in basin.

●If all of the above are OK, and then the motor could be

operate.

Head

(Pressure)

Pipe

Connection

Flow

(Capacity)

Phase Power

1

1

Rated

(M)

5

4

Max.

(M)

7

6.5

mm

5

3

Rated

(L/min)

40

35

Max.

(L/min)

110

70

mm

30

20/25

inch

1-1/4

3/4"/1"

3/4"/1"

Model

CP-200A

CP-100

HP

1/4

1/6

Watt

200

100

Weight

(kg)

4.7

1 5 7 540 110 30 1-1/4CP-200 1/4 200 4.2

3.1

1 4 6.5 335 70 20/25CP-100A 1/6 100 3.6

Pass

Solid

(Dia)

350mm

350mm

3mm

Ajustable

This manual suits for next models

4

Table of contents

Other Stairs Water Pump manuals

Popular Water Pump manuals by other brands

LUBE

LUBE PM-8S-18LP instruction manual

Grundfos

Grundfos MAGNA3 25-100 (N) Installation and operating instructions

Crivit

Crivit 285656 instruction manual

Empire

Empire eOne Series Operating and maintenance instructions

Calpeda

Calpeda SD Series Original operating instructions

Bestway

Bestway 62038 operating instructions