Stakpure Omnia Tap xs basic User manual

Operating manual

Omnia Tap xsbasic

2

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

3

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

4

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

Foreword

Dear adies and Gentlemen,

The stakpure GmbH team thanks you for the trust you have placed in us.

By choosing this ultrapure water system from our company, you have opted for an innovative, high-

quality and durable product.

Before installing and starting up your ultrapure water system, please read the installation and

operating instructions in this operating manual carefully.

Note that only trained personnel are allowed to operate this system.

To ensure water quality, only use original accessories, spare parts and consumables from stakpure.

Please note that we as the manufacturer cannot assume any liability for any damage to the system

connected peripherals or buildings and persons in the event of improper use or improper assembly or

operation, or the use of third-party parts of any kind.

We wish you success with your new water treatment system

stakpure GmbH, September 2022.

5

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

Table of Contents

1 User Notes ....................................................................................................................................... 7

2 Safety instructions ........................................................................................................................... 8

3 Intended Use ................................................................................................................................. 10

4 Transport and packaging ............................................................................................................... 11

5 Delivery package............................................................................................................................ 12

6 Technical data................................................................................................................................ 12

7 Flow charts .................................................................................................................................... 15

7.1 Flow chart OmniaTap xs

basic

................................................................................................... 15

7.2 Flow chart OmniaTap xs

basic

UV ............................................................................................. 15

8 System description ........................................................................................................................ 17

8.1 System structure ................................................................................................................... 17

8.2 System connections on the back ........................................................................................... 18

9 Function description ...................................................................................................................... 18

10 Assembly.................................................................................................................................... 19

10.1 Operating environment ......................................................................................................... 19

10.2 Assembly................................................................................................................................ 19

10.3 Wall mounting ....................................................................................................................... 22

10.4 Installation of an optional pump station ............................................................................... 24

11 Operating concept ..................................................................................................................... 25

12 Commissioning .......................................................................................................................... 27

13 Operating ................................................................................................................................... 28

13.1 Menu structure ...................................................................................................................... 28

13.2 Main display .......................................................................................................................... 29

13.3 Withdraw water / Withdrawal display .................................................................................. 29

13.4 Volume metered water withdrawal (optional) ..................................................................... 30

13.5 Menu / Settings ..................................................................................................................... 31

13.5.1 System ........................................................................................................................... 31

13.5.2 Setup .............................................................................................................................. 32

14 Maintenance.............................................................................................................................. 35

14.1 Maintenance / Care intervals ................................................................................................ 35

14.2 Changing the cartridges ......................................................................................................... 36

14.3 Disinfection ............................................................................................................................ 37

15 Decommissioning & Dismantling............................................................................................... 38

6

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

16 Spare parts................................................................................................................................. 38

17 Consumables ............................................................................................................................. 39

18 Accessories ................................................................................................................................ 39

19 Malfunctions, causes & solutions .............................................................................................. 40

19.1 Automatic system monitoring ............................................................................................... 40

19.2 Faults table ............................................................................................................................ 42

20 Disposal ..................................................................................................................................... 44

21 EU declaration of conformity .................................................................................................... 46

7

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

Symbols used

Warning notices with this symbol indicate a hazard which, if not avoided, could

result in death or serious injury.

Warning notices with this symbol indicate a hazard which, if not avoided, could

result in minor or moderate injury.

This symbol indicates a risk with possible property damage.

This symbol indicates useful information.

1 User Notes

Read this manual completely and carefully before installing and operating the OmniaTap xs system for

the first time. It is an important part of the product and contains basic information that must be

observed during installation, operation and maintenance.

The operating instructions must be available at the place of operation at all times. If you let other

people use the OmniaTap xs system, pass on also these Operating Manual.

The personnel for operation, maintenance, inspection and assembly must have the appropriate

qualifications for this type of work. The area of responsibility, competence and supervision of the staff

must be precisely regulated by the operator.

Not only the safety instructions listed in this section must be observed, but also the safety regulations

applicable to the installation site. In particular, the accident prevention regulations.

8

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

2 Safety instructions

The safety instructions described below are for your own safety and help to prevent possible damage

to the OmniaTap xs system. Read the instructions before installation, commissioning and maintenance

and follow them carefully.

Danger of electric shock!

Improper electrical supply of the OmniaTap xs system can lead to an electric shock!

- For the electrical supply of the OmniaTap xs system, only use the wide-range

power pack included in the scope of delivery.

- For the electrical supply of the wide-range power pack of the OmniaTap xs system,

only use a properly grounded socket that provides an AC voltage of 100-240V with

50-60Hz.

- For maintenance work, the rear housing cover may only be opened when the

mains plug is unplugged.

Danger from falling!

Improper handling or attachment can cause the OmniaTap xs system to fall and

cause injury!

-

Always ensure that the system is in a secure position.

-

When mounting on a wall, ensure that the system is mounted in a correspondingly

stable manner.

-

When handling / transporting the system, observe the system's attachment

points, which you can find in this operating manual.

Danger from slipping!

Incorrect or faulty installation or operation as well as a leak in the system can lead

to the uncontrolled escape of liquid and thus to a risk of slipping!

- Always ensure that the system is operated correctly and always use a sufficiently

large container when withdrawing water.

- Make sure the inlet and outlet lines are tight.

-

Make sure that the rinsing water is drained into a drain without pressure.

9

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

Danger of skin and eye injuries!

Contact with the disinfectant can lead to skin and eye irritation and or injuries!

- Always wear appropriate protective clothing (at least gloves & goggles) when

disinfecting the OmniaTap xs system to avoid contact with the disinfectant.

- Make sure that no disinfectant can escape uncontrolled from the OmniaTap

system, check the connection hoses for correct and tight fit.

- Follow the instructions that come with the disinfectant agent or disinfection kit.

Escaping UV radiation can cause skin and eye irritation or injuries!

- Only change the UV lamp of an OmniaTap xs system when it is switched off and

the mains plug is unplugged.

- When changing the UV lamp, make sure that the lamp is correctly seated in the

UV reactor.

Danger of crushing and pinching injuries!

Incorrect handling of the OmniaTap xs system can lead to crushing and pinching

injuries!

-

When handling / transporting the system, observe the system's attachment

points, which you can find in this operating manual.

-

When handling the movable dispenser arm, pay attention to possible pinch points

in the area of the joint on the main housing. Move the arm only by holding the

dispenser handle.

The safety instructions contained in these operating instructions, the existing national accident

prevention regulations and any internal work, operating and safety regulations of the operator must

be observed.

These operating instructions must be available at the place of operation at all times.

Installation, operation and maintenance of the system may only be carried out by trained specialist

personnel.

The CE mark loses its validity in the event of structural changes or the installation of accessories not

authorised by the manufacturer. Conversion and modification of the system are only permitted after

consultation with the manufacturer. Original spare parts and accessories authorised by the

manufacturer ensure safety.

Please note that the manufacturer is exempt from any liability for damage caused by improper use or

use that is not in accordance with the intended purpose.

Protect the system from frost. The ambient temperature at the installation site should be

at least +2°C.

Only operate the system within the range of the specified feed water pressure.

Access to the mains cable and the mains plug must always be freely accessible.

A safety device to protect against contamination of the drinking water according to DIN EN 1717 must

be used for the connection of water treatment systems.

10

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

Depending on the country, a safety combination consisting of a backflow preventer and a system

separator may have to be available on the building side.

A DN 50 floor drain with free drainage is to be provided in the operating room. If there is no floor drain,

we recommend using a water monitor to prevent damage to the system and equipment as well as the

building. Otherwise, the manufacturer assumes no liability for any water damage that may occur.

The base of the system must have sufficient load-bearing capacity (for weight, see technical data).

When assembling, make sure that there is enough free space for problem-free operation, maintenance

and repairs.

Maintenance work may only be carried out by trained specialists.

3 Intended Use

The systems of the OmniaTap xs series are used for the direct treatment of drinking water into pure

and ultrapure water for laboratory use. In order to ensure maximum quality of the pure and ultrapure

water with the longest possible service life of the consumables, the OmniaTap xs system must be fed

with drinking water in accordance with DIN 2000. Any other use of the system is not permitted and is

considered improper use.

The pure / ultrapure water produced is used as a solvent or rinsing agent in a wide variety of analysis

methods such as high-performance liquid chromatography (HP C), ion chromatography (IC), atomic

absorption spectrometry (AAS), ultra-trace analysis, etc. It is also used in a variety of chemical and

biochemical applications such as preparing reagents, cultivating cells, etc.

The treated water is not suitable for consumption.

The system must not be used for the production of pharmaceuticals and is not a medical device.

11

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

4 Transport and packaging

The OmniaTap xs systems are carefully inspected and packaged prior to shipment, however damage

may occur in transit.

Check the packaging and the system for possible transport damage. If you find any damage, please

contact the shipping or transport company responsible for the delivery directly.

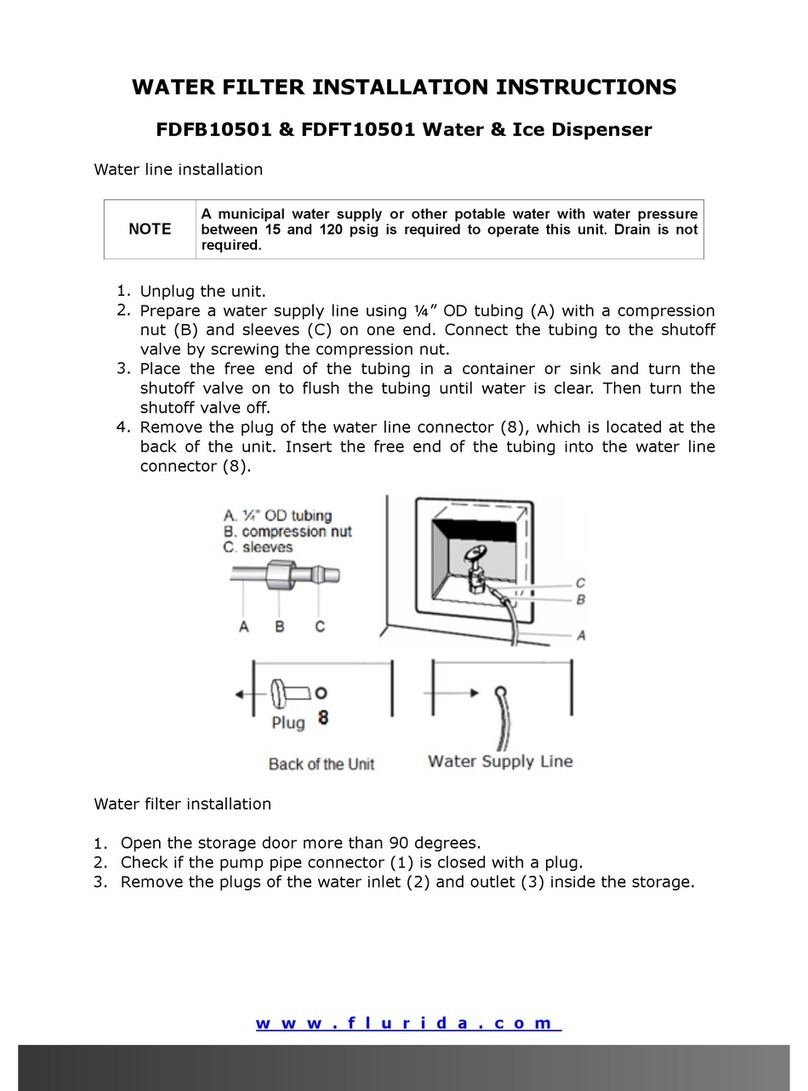

For transport, only lift the device at holding points 1, 2 and 3.

Never lift the device by the dispenser hose point 4 or the dispenser arm point 5,

as this may damage the device.

X

X

2

1

3

4

5

12

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

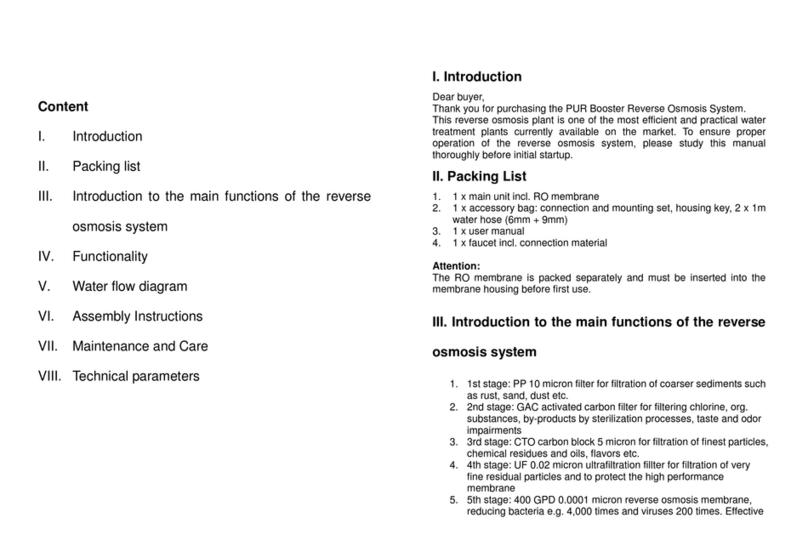

5 Delivery package

The scope of delivery of the OmniaTap xs system consists of the following parts:

Position

Number

Designation

01

1

OmniaTap xs

basic

System

02

1

Table power supply 48V 120W

03

1

Power cord

04

1

PE hose d8 2,5m

05

1

PE hose d8 incl. input protection filter and

Water connection adapter R ¾“ – d8

06

2

Insertion angle d8

07

1

Pretreatment cartridge

08

1

Ultrapure water cartridge

09

1

Sterile filter

10

1

Operating manual

6 Technical data

Feedwater

requirements

Source

Drinking water conf. to DIN 2000

Pressure [bar]

0.5

–

6

Temperature [°C]

2

–

35

Conductivity [µS/cm] at 25°C

< 2000

Colloid Index SDI

1

< 10

Dissolved CO

2

[ppm]

< 30

Free chlorine [ppm]

< 3

TOC [ppm]

< 1

Hardness [as CaCO

3

]

1

<

300

Silica [ppm]

< 30

pH area

4

–

10

1. In the case of higher values, a pre-treatment must be carried out beforehand.

Product water ASTM I

1

OmniaTap xs

basic

5

OmniaTap xs

basic

5 UV

Conductivity [µS/cm] at 25°C

0.055

0.055

Resistance [MΩ cm] at

25°C

18.2

18.2

TOC [ppb]

< 5

< 2

Particle > 0,2 µm [1/ml]

2

< 1

< 1

Bacteria [KBE/ml]

2

< 0.01

< 0.01

Flow [l/min]

Up to 2

Up to 2

1. The values given are typical and may vary depending on the quality of the feed water.

2. With sterile filter capsule 19100300.

13

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

Product water ASTM II

OmniaTap xs

basic

5

OmniaTap xs

basic

5 UV

Conductivity [µS/cm] at 25°C

0.067

–

0.1

0.067

–

0.1

Resistance [MΩ cm] at 25°C

15

–

10

15

–

10

Retention rate for germs and particles

99 %

99 %

Permeate output / l/h at

15°C

5

5

Water connections

Feed water inlet

Hose AD 8mm

Waste water outlet

Hose AD 8mm

Threaded connection for sterile filter

G1/4“

Sterile filter outlet

Hose tail 6mm

Tank overflow

Hose AD 8mm

Electrical connection

Voltage

100

–

240 VAC

Frequency

50/60Hz

Power consumption (max.)

120W

Cell constants

Conductivity measuring cell F 1

0.1 cm

-

1

Conductivity measuring cell F 2

0.01 cm

-

1

Airborne noise emission

Sound pressure level

60 dB(A)

Environmental conditions

Operating area

Inside

Max. height above sea level

Up to 2000 m

Ambient temperature

min. +2°C to max. 40°C, 80% rel. F, non

-

condensing

Mains voltage fluctuation

Max ±10% of nominal voltage

Degree of pollution

2

14

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

Dimensions & Weight

OmniaTap xs

basic

5

OmniaTap xs

basic

5 UV

Height [mm]

530

530

Depth [mm]

520

520

Width [mm]

253

253

Tank capacity (useful volume) [l]

7

7

Empty weight kg]

19

19

Operating weight [kg]

27

27

Materials of the components in contact with water

Solenoid valve input

POM, EPDM

Flush solenoid valve

POM, EPDM

Withdrawal solenoid valve

POM, EPDM

Pump head

Nylon, glass fiber reinforced

Conductivity cell

POM, stainless steel

Hoses

PE

Hose connection

POM

Seals

EPDM

UV reactor

Stainless steel

UV immersion tube

Quartz glass

Tank

PE

15

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

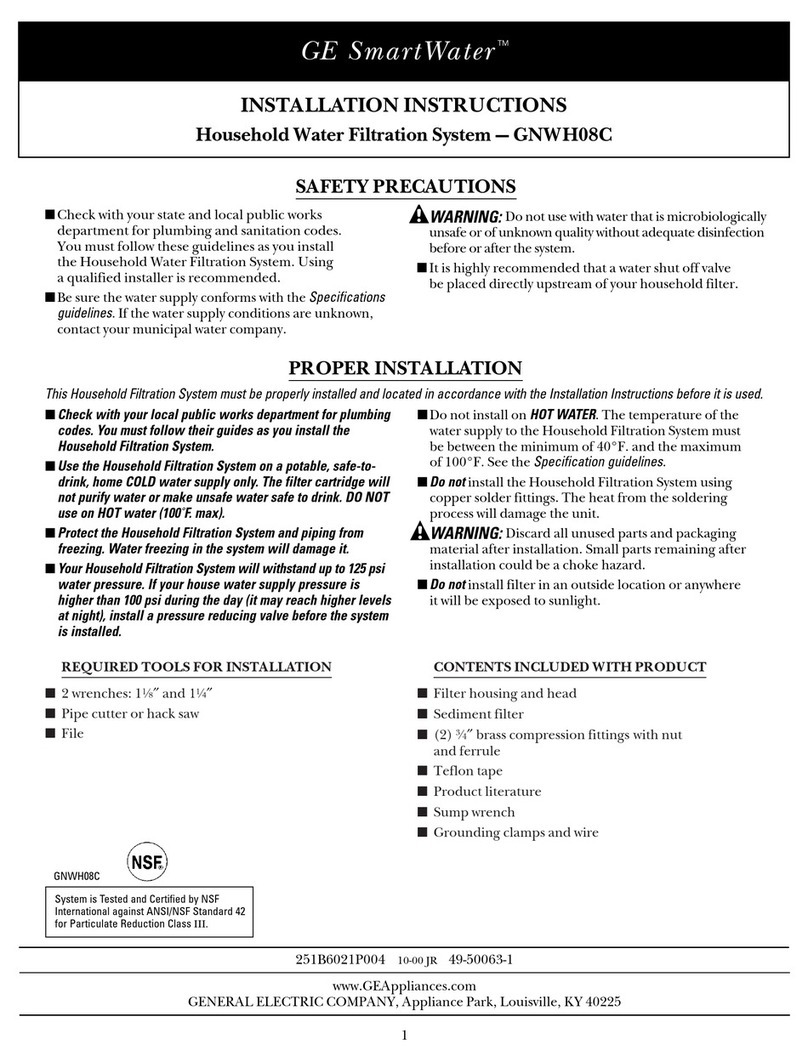

7 Flow charts

7.1 Flow chart OmniaTap xsbasic

7.2 Flow chart OmniaTap xsbasic UV

16

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

R+I

no.

Designation

R+I

no.

Designation

F1

Pretreatment cartridge

P2

Circulation pump

F2

Ultrapure water cartridge

T1

Pure

water tank

F3

Sterile filter

UV

UV Photooxidation

F4

Sterile ventilation filter

V1

Inlet solenoid valve

F5

Hat filter (in the connection hose)

V2

Rinsing solenoid valve

FI1

Flow meter (option)

V3

Pressure hold valve

F1

QIA conductivity cell

pretreatment

V4

Circulation solenoid valve

F1

TIA temperature sensor pretreatment

V5

Check valve

F2

QIA conductivity cell ultrapure water

V6

Check valve

F2

TIA temperature sensor ultrapure water

V7

Withdrawal solenoid valve

I1

evel sensor

V8

Sterile overflow

SZ1

eakage sensor

V9

Check valve

P1

Pressure booster pump

17

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

8 System description

8.1 System structure

1:

Detachable OptiFill dispenser with integrated

control unit

2: Rotating dispenser arm

3: Snap closure

4: Removable cover hood

5: Pure water tank

6: Space for pre-treatment cartridge

(not in the picture)

7:

Ultrapure water cartridge

8: UV reactor

9: Dispenser admission

10: Tank opening with lid

11: Sterile ventilation filter

12: Sterile tank overflow

1

4

2

7

6

8

5

3

9

10

11

12

18

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

8.2 System connections on the back

9 Function description

The systems of the OmniaTap xs series prepare drinking water directly into pure and ultrapure water

by using several treatment technologies. The produced ultrapure water meets the respective

requirements of the ASTM, ISO, USP and C SI standards.

For treatment, the feed water is fed into the OmniaTap xs system, which is pumped through the pre-

treatment cartridge with integrated reverse osmosis module by means of a pressure booster pump.

The quality of the appropriately pre-treated water and thus also the condition of the pre-treatment

cartridge are continuously monitored by the first conductivity measurement ( F1). The current values

of the conductivity measurement can be shown on the display of the operating/withdrawal unit

(OptiFill Dispenser) for checking purposes. In the next step, the water is passed through a UV reactor,

where it is disinfected with the help of UV radiation. The water then flows through the ultrapure water

cartridge, which removes the remaining ions, to remove a maximum of non-ionized compounds. The

quality of the ultrapure water and the condition of the consumables are monitored using a

temperature-compensated conductivity measurement ( F2). The conductivity values measured are

shown on the display of the OptiFill dispenser.

The treated water is first pumped into the tank up to the maximum level. To ensure consistently high

quality of the treated water, the water circulates periodically from the tank through the ion exchange

cartridge, and the UV reactor (only with OmniaTap xs UV) back into the tank with the help of the

circulation pump.

Ultrapure water can be dispensed directly from the OmniaTap xs system using the OptiFill dispenser.

In order to obtain maximum water quality, the water is pumped from the tank via the ultrapure water

cartridge, and the UV reactor (only with OmniaTap xs UV) to the OptiFill dispenser immediately before

it is withdrawn, with the aid of the circulation pump. As a final treatment stage, the ultrapure water

runs through a sterile filter attached to the OptiFill dispenser.

With an optionally available pump station, an external consumer can be supplied directly with pure

water from the tank.

Inlet:

Feed water connection

Drain: Flushing water connection

Power: Power supply connection

19

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

10 Assembly

10.1 Operating environment

When selecting the installation location, observe the following requirements:

- The pressure of the feed water must be between 0.5 and 6 bar.

- The standing surface must be level.

- A suitable protective contact socket must be available for the electrical supply of the OmniaTap xs

system (see technical data).

- There must be sufficient free workspace for problem-free operation, maintenance and repairs.

- There must be sufficient space to operate the system.

- An on-site, lockable feed water connection with R¾" external thread is required.

The system is only intended for operation within an industrial environment. In other

environments, electromagnetic immunity cannot be guaranteed.

Temperatures below +2°C can damage the device due to frost!

The feed water pressure must be less than 6 bar, otherwise the system can be damaged!

If necessary, use a pressure reducer.

Make sure a free drain is available to avoid water damage!

A free outlet, primarily a funnel siphon DN 50, is to be provided for the rinsing water of

the OmniaTap xs system in the immediate vicinity of the location. The upper edge of the

outlet must not exceed a height of 300 mm above the level of the appliance in order to

ensure free outlet and thus flawless functionality of the drain. It must be ensured that the

flushing water line is neither closed nor throttled.

A DN 50 floor drain with free drainage is to be provided in the operating room. If there is

no floor drain, we recommend using a water monitor to prevent damage to the system

and equipment as well as the building.

10.2 Assembly

Set up the OmniaTap xs system at the operating site and make sure that the system is

standing securely. When transporting the system, never lift it by the dispenser arm, only

by the rear wall, bottom or side walls of the main body. See chapter "Transport and

packaging".

In order to protect the power pack from moisture, it must not be operated lying on the

table next to the device. Attach the power pack to a suitable wall near the device using

the bracket included in the scope of delivery.

20

_________________________________________________________________________________

OmniaTap xs

basic

; Version August 2023

Subject to technical changes

Water can escape through leaks. Therefore, always make sure that the floor in the area

of the work surface is dry to avoid accidents caused by slipping.

Use the connection accessories to connect the OmniaTap xs system to the feed water connection and

to the free drain. Observe the requirements for the feed water (see technical data). Connect the

connection hose with integrated hat filter with its R3/4" internal thread to the house feed water

connection. Now plug the free end of the 8mm hose into the 8mm quick connector labelled "Inlet" on

the back of the system (see System Connections). Then connect the second 8mm hose to the "Drain"

device connection and guide the free end of the hose into a drain, through which the rinsing water can

drain without pressure. Connect the sterile tank overflow with an 8mm hose to the free drain as well.

Screw the sterile ventilation filter into the thread provided on the back, top left of the tank.

Finally, open the shut-off valve on the building's feed water connection. Check the hose connections

for leaks.

Remove the cover of the OmniaTap xs system and place the pretreatment cartridge in the right slot

and the ultrapure water cartridge in the left slot. Connect the cartridges with the quick-release

couplings by pushing them on. The quick-release fasteners must audibly click into place.

See the illustration:

Ultrapure water

cartridge

cartridge

Pretreatment

cartridge

Table of contents

Other Stakpure Water Filtration System manuals

Popular Water Filtration System manuals by other brands

PREMIER TECH

PREMIER TECH REWATECH owner's manual

Lectranator Systems

Lectranator Systems ST 48 manual

Graf

Graf Optimax-XXL DN300 Installation and maintenance instructions

oventrop

oventrop Regumaq X-80 operating instructions

Tol Watertechniek

Tol Watertechniek Purusaqua TRO manual

EWS

EWS EWS Series Care and use manual