STAMPLINE S-200 User manual

S-200

S-200

POLYMER SYSTEM STAMP MACHINE

POLYMER SYSTEM STAMP MACHINE

MAINTENANCE AND USER GUIDE

MAINTENANCE AND USER GUIDE

Polymer Fixing Plate

Digital Control Panel

Exposure Drawer

Drying Drawer -1

Drying Drawer -2

Washing Section

S-200

S-200

Chrome Case

STAMP MACHINE OPERATING MANUALSTAMP MACHINE OPERATING MANUAL

Thank you for choosing STAMPLINE S-200,microprocessor controlled polymer system stamp machine.

This manual includes the information about installation of the polymer system stamp machine, all the

steps for settings and stamp production process, and additional information about stamp materials.

All rights are reserved by Matuya Makine Sanayi ve Ticaret Limited Şirketi

Package Content

· The machine unit

· Power cable,

· Operating manual

· Warranty certificate.

STAMPLINE S-200 is the state-of-art polymer system stamp machine which enables the fastest

and the highest quality rubber stamp production by exposing liquid polymer. Your stamp designs come

to life in the easiest way by STAMPLINE S-200, by placing polymer stamp materials on the

exposure area of the machine which is controlled by a digital control panel. STAMPLINE S-200 is a full

automatic stamp machine; in addition to its exposure area, it has washing, drying and hardening

sections to enable all functions in one perfect machine.

1- PRODUCT DESCRIPTION and STRUCTURE

a- Purpose of Use

b- Unit Structure

S200/1

2x16 LCD Screen

Power On/Off

Button

Vacuum

Button

Program

Button

Stop Button

Start

Button

Cance

Button

Enter

Button

Timer Setting Buttons

2- MACHINE INSTALLATION and SAFETY INSTRUCTIONS

3- CONTROL PANEL and FUNCTIONS

Plug the grounded power cable given together with the machine in the power socket at the back and plug the

other end to the mains.

Press the switch at the back of the machine to turn the power “ON”.

Push the

These are all the steps necessary to make the machine ready to use.

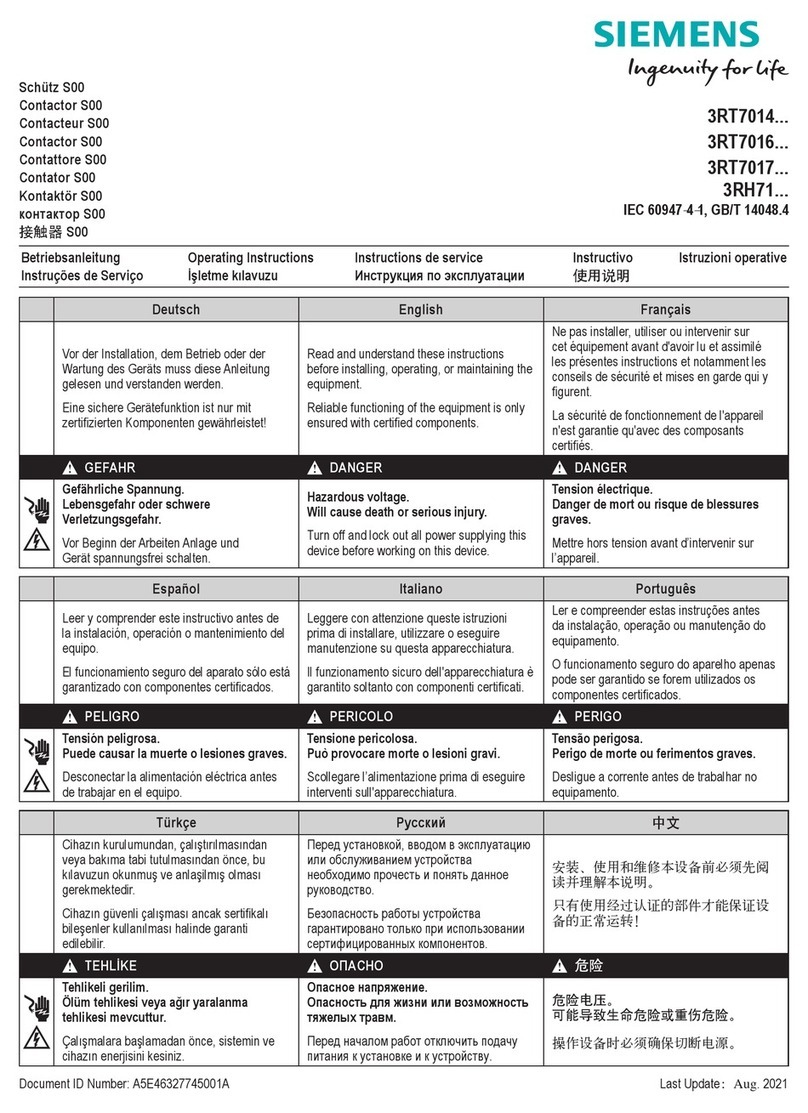

STAMPLINE S-200 polymer system stamp machines are designed and manufactured according to the CE

regulations in order to provide your personal safety. Please follow the basic rules listed below for your safety.

Insert power cord into the grounded mains which to be matching the voltage value indicated

on the label placed at the back of the machine. If sudden electrical power surges are likely in your location, it’s

recommended to use regulator. Power supply cables should be routed so that they are not likely to be

walked on or damaged by items placed against them. Do not overload wall outlets, extension cords or

regulators with other devices in order to prevent risk of fire or electrical shock.

The machine should be placed on a stable, well-balanced and clean surface. Do not

place the machine on an unbalanced surface. The machine should be situated away from heat sources and

other equipment that may generate excessive vibration, dust or moisture.

The reparation of the machine must be done by the authorized technicians.

STAMPLINE S-200 stamp machine is designed and engineered in a way protecting the

operator against electrical shocks. All case covers have been grounded and a fuse is placed on the plug

socket to prevent electrical leakage.

Do not use any attachments not supplied by MATUYA with the STAMPLINE S-200 stamp

machine as this may cause hazards.

Do not put weight on the machine during transportation. Keep the machine package fixed

inside the vehicle to avoid stroking. Pay attention when carrying the machine as it is made up of sensitive

electronic systems. Stick “Fragile” label on the carton. The materials used in the machine during production

don’t cause any danger according to the international transportation rules.

a- Installation

b- Safety Instructions

220 Volt (50/60Hz)

“POWER” button placed on the digital control panel to start the machine.

· Power Source:

· Machine Placement:

· Reparation:

· Safety Measures:

· Attachments:

· Transportation:

S200/2

4- STAMP MAKING PROCESS with STAMPLINE S-200

1. Press the POWER button to turn ON and pull the drawer where the exposure area is located.

2. Lift up the upper glass and place the negative film on the lower glass in reading direction.

3. Cover the negative film with cellophane sheet.

4. Pressing the vacuum button, start vacuuming and ensure that there will be no air left between the

cellophane coating and the negative film.

5. Surround the negative film (image) with damming tape to form a pool (use 3mm damming tape for

standard stamps 2mm for pen stamps).

6. Pour the liquid polymer into the pool.In order to eliminate the air bubbles coming out when pouring

the polymer, press on the vacuum button and remove them with compressor hose.

7. Place the matte acetate sheet onto the liquid photopolymer without leaving any air, close the upper

glass and lock.

8. Close the upper cover of the machine and;

“”

a) For the first exposure (posing) press“PRG” button and set the menu to “1. POSE” status. In the next

step press “ENTER” button and set the timing using the numeric buttons; again press “ENTER” for

recording to memory. In order to start the timer, press “START” button (if you want to cancel the

operation press “STOP”).

b) For the second exposure, using “PRG” button set the menu to “2. POSE” status. Repeat the same

process of first exposure.

9. After finishing the exposure process, open the upper cover of the machine and separate the glasses.

Peel the cellophane sheet coating off the processed polymer. The matte acetate sheet (substrate) will

remain merged to the bottom of polymer.

10. Open the upper cover of the machine,put the exposed polymer plate in direction of the grinded acetate

surface meeting the rubber at the top.

11. Fill the washing container slightly higher than the brush level and balance the brush height adjusting

with the bolt nuts placed at four sides.

12. Add a cap of washing solution into the container.

13. Press the “PRG” button and set the menu to “WASHER” status. In the next step press “ENTER” button

and set the washing time using the numeric buttons; again

14. After finishing the washing process, remove the polymer plate from the rubber and rinse in water to

remove the last of the washing solution.

15. For the last exposure, open the drawer under the exposure area, place the polymer plate inside and

add some last exposure liquid (hardening solution).

16. For this process, press the“PRG”button and set the menu to “LAST POSE”status and repeat the same

timing process for exposure(generally chosen hardening time is 500 seconds, but the ideal time is 900

seconds)

17. After the last exposure, take out the polymer plate and rinse under water.

18. For drying process, press “PRG” and set the menu to “DRYER”.

19. Place the plate into the drying drawer which is under the washing container and close.

20. Press “ENTER” button and set the drying time. Then pressing the “START” button start drying process.

21. At the final step you can trim the polymer plate and install in stamp mount.

press “ENTER” for recording to memory. In

order to start the timer, press “START” button (if you want to cancel the operation press “STOP”).

1. Print out your design as positive and reversed.

2. Start the machine by pressing POWER button and open the drawer for exposure.

3. Lift up the upper glass and place the matte daylight film on the lower glass. Place your printout on the

daylight film as its printed surface will face the daylight film.

4.

5. For setting up the timer, enter the time using the 1. Pose section and start.

6. After finishing the exposure, unlock the glasses and take out the daylight film.

7. Insert the daylight film into a tray full of developer or AB liquid and keep inside until it reaches the

appropriate darkness.

8. After taking out the film from developer or AB liquid, insert it into the Fixer for having contrast for the

writings.

9. After keeping the film in the Fixer for a sufficient time, rinse it under tap water and dry.

10. Your negative film is ready to use.

“”

For vacuuming process, place the vacuuming folio on the top and vacuum. Vacuuming is very important

in film making so printed surface must meet the sensitive surface of the daylight film perfectly. After

vacuuming, close the upper glass and lock the glasses, then close the exposure drawer.

NEGATIVE FILM PRODUCTION

NEGATIVE FILM PRODUCTION

S200/3

5- CLEANING and MAINTENANCE

6- TECHNICAL DETAILS

WARRANTY

MANUFACTURER

Daily cleaning of the machine must be done by the operator. A soft moist duster should be used for

cleaning. It’s very important to keep the glasses clean and dust-free in the exposure area.You can use

mild household glass cleaner on the glasses. Do not spray the cleaners directly on the machine.

STAMPLINE S-200 microprocessor controlled stamp machines don’t require periodical maintenance.

- Stampline S-200 polymer system stamp machine is a full automatic unit with 25x35cm processing area.

- The control panel is microprocessor controlled 2x16 liguit-crystal-screen with membrane switch.Using

single button whole system can be operated and controlled in one screen

.

- The case made of lasercut chrome guarantees non-corrosion.

- Time adjustment can be set up to 9999 seconds on the LCD display and together with the memory

unit and the audial alarm system enables easy usage.

-Stampline S-200 has whole touch system.

- The machine has special tempered glass and glass locks on the exposure area, also has a perfect

vacuum and compressor. It has a posing (exposure) system with 16 pcs of 20W UV Philips fluorescent

lamps; 8 pcs of them are placed at the up and other 8 pcs are placed at the down side.

- Tridonic brand electronic balances ensure to start the exposure system immediately unlikewise the

other starter systems, so the lifetime of the fluorescents increases up to 3 times longer.

- The special drying and brushing systems with15% hard brushes give you the chance for precise washout.

- Together with the washing tray that can move in the opposite directions and the chrome basin,the

machine has a perfect washing function.

230V AC 50hz (110 V AC 50Hz/60Hz optional)

Warranty period is 1 year and begins with the delivery of the machine. Please refer to Warranty

Certificate for the other details.

MATUYA Makine Sanayi ve Ticaret Ltd. Şti.

Cumhuriyet Mah. 625 Sk. No:6 Antalya / Turkey

+90 242 346 15 18 / +90 242 346 15 10

Kurumlar

328 004 1357

Manufacturing, Import, Export, Technical Service

- For the maintenance and repairing of the fluorescents and balances, there is a special drawer at the

rear end of the machine.

Company Title :

Address :

Phone/Fax :

Tax Administration :

Tax ID :

Field of business :

S200/4

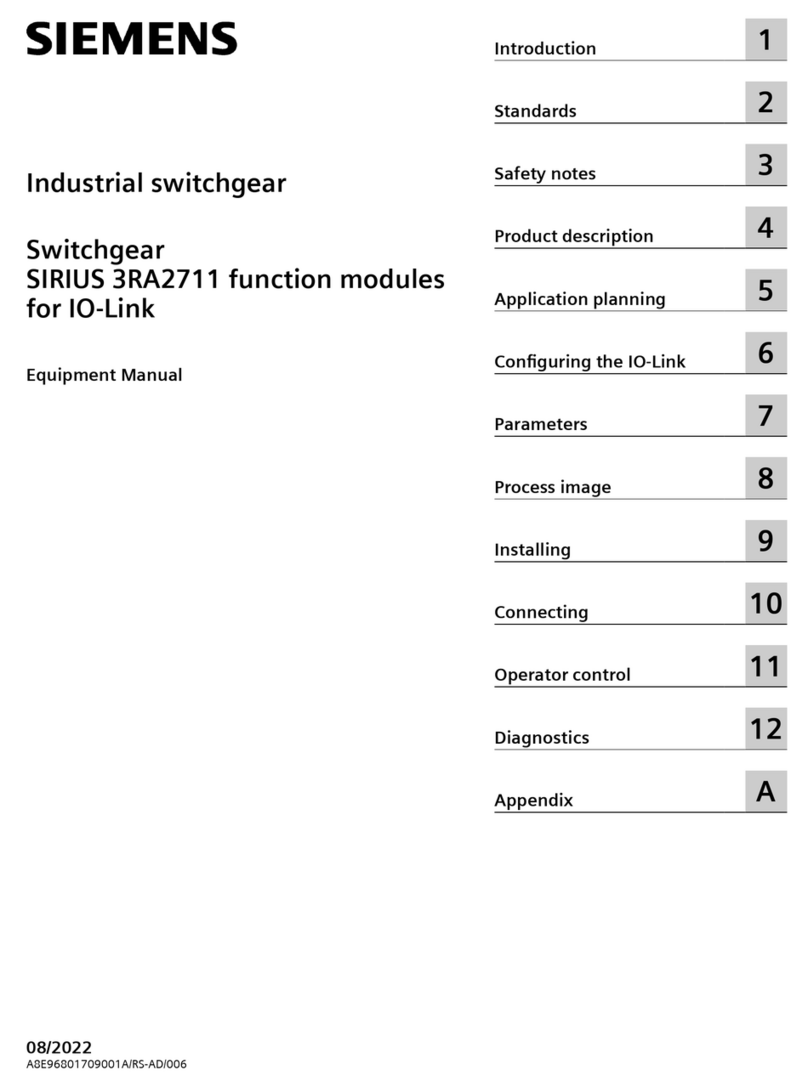

Table of contents

Other STAMPLINE Industrial Equipment manuals