The AccuBindPro thermal tape binder offers your customers a com-

bination of simple, low-cost binding, strong binds and professional

looking results. Positioned as a reasonably priced, highly productive

binding system with an economical cost per bind, theAccuBindPro is

ideal for binding business reports, publications, manuals, proposals,

workbooks and more. It performs great on all these document styles

since they are normally copied or printed on various bond

copy/duplicating paper stocks (high gloss or laminated papers are

not best suited for thermal-adhesive binding). Virtually any business

or organization that produces documents would benefit from using

an AccuBindPro, including corporations, quick printers, small busi-

nesses, schools and non-profit organizations. When a prospects

demands of overall presentation and binding strength matter most,

even end users binding only a few binds per week can justify the pur-

chase of an AccuBindPro. However, that process of justifications

gets even easier when production requirements become moderate or

heavy. It is important to note that a document's positive first impres-

sion is vital to an end user and the AccuBindPro helps to insure that

result.

Sell Quality Results

As you most likely know, there are numerous office level binding

systems that can cost from several hundreds of dollars to many thou-

sands of dollars. Low production volume can sometimes force an

organization to focus on binding equipment that is less expensive,

but the trade-off is more labor is required to bind the document, sev-

eral steps are added and the end result is not often complimentary to

the image that the user would like to portray. Various binding meth-

ods are available in this price range: GBC comb, spiral coil, wire

coil, thermal cover and even thermal tape binding.

If a purchase decision is made on pricing alone, the AccuBindPro

could be considered (at $4,695) in a different product category than

the cheaper aforementioned binding methods. However, you must

remember that quality sells, and end users that might previously have

only considered a low-priced product should not be overlooked.

They will understand the importance of a quality appearance and

how one-step binding makes operation smoother and easier and less

labor intensive. And, though they may not buy many binding strips

at the beginning, remember that as they grow and production needs

expand their demand for binding strips will also expand…especially

when great results are so easily achieved.

Don't Punch Anymore!

In most competitive mechanical binding systems in the low to mid

volume binding arena, two separate functions are required, and many

times this requires the purchase of two separate pieces of equipment.

The mechanical binding processes that use combs and spiral coil

require a machine to punch the paper and another to insert the spine

Page 3

AccuBind

Pro PRODUCT GUIDE

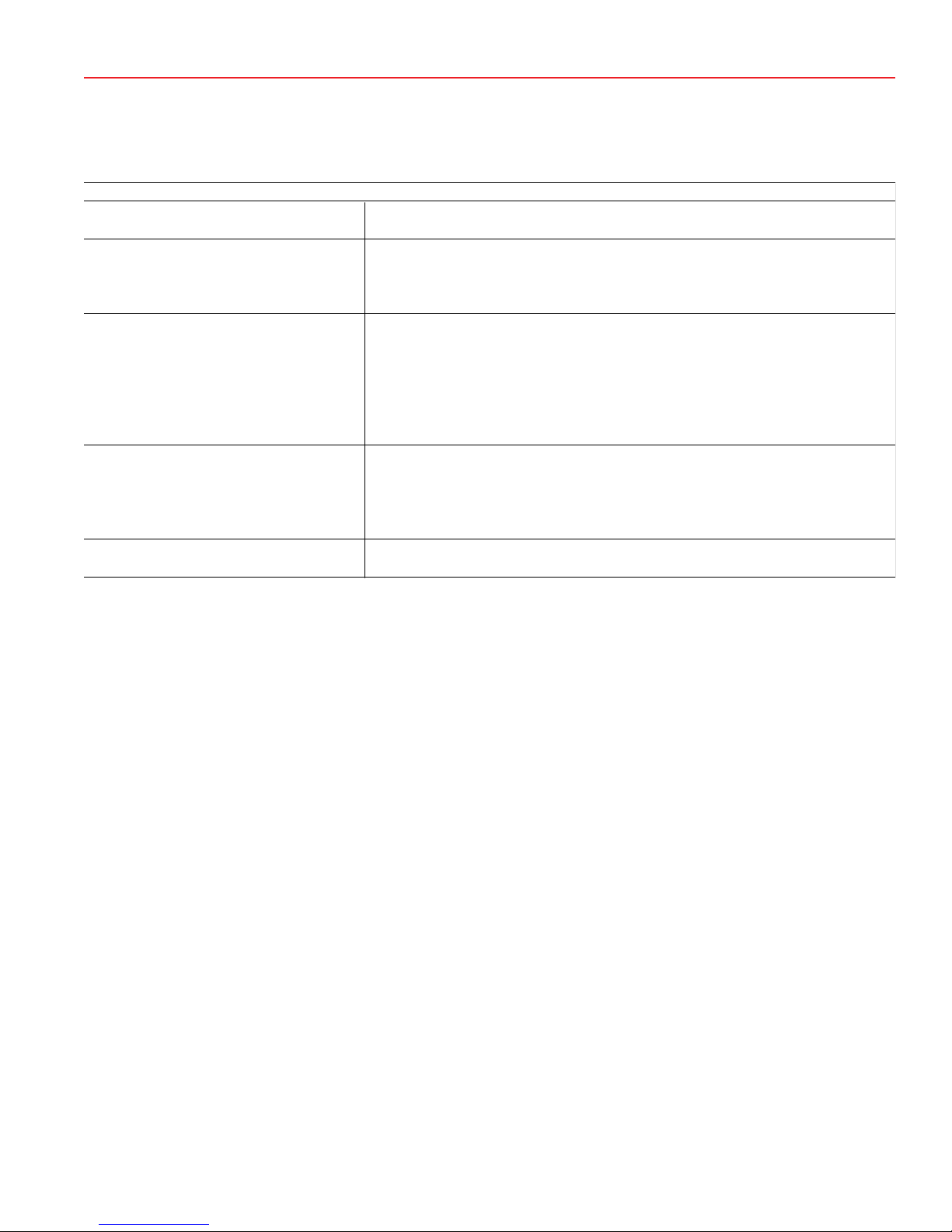

PRODUCT POSITIONING