2

Content

1.

Important information ......................................................................................................... 4

1.1

Symbols.....................................................................................................................4

1.2

General......................................................................................................................5

1.3

Safety warnings and instructions.................................................................................6

1.4

Obligations of the manufacturer..................................................................................7

1.5

Obligations of the installer during installation...............................................................8

1.6

Obligations of the authorised contractor for commissioning at first commission. ..........8

1.7

Obligations of the user................................................................................................8

1.8

Factory testing............................................................................................................8

2.

Transport and installation of the device ............................................................................ 9

2.1

Transport....................................................................................................................9

2.2

Installation of the device.............................................................................................9

2.3

Storage and warehousing of the device......................................................................9

3.

Delivery.............................................................................................................................. 10

3.1

Internal unit ..............................................................................................................10

3.1.1

Hydro module SPLIT.............................................................................................10

3.2

External device.........................................................................................................11

3.3

Recycling of packaging and heat pumps at end of life...............................................11

4.

Installation of the device................................................................................................... 12

4.1

General....................................................................................................................12

4.2

Location of the device............................................................................................... 14

4.2.1

Minimal clearance from the device........................................................................14

4.2.2

Wall mounting.......................................................................................................16

4.2.3

Attachment of the indoor unit ................................................................................17

4.2.4

Removal of front cover..........................................................................................18

4.3

Connection with the external device..........................................................................19

4.3.1

Refrigeration connection - Gas and liquid connection............................................19

4.4

Hydraulic connection ................................................................................................23

4.4.1

DHW system.........................................................................................................23

4.4.2

Heating system.....................................................................................................27

4.4.3

The scheme of the heating system........................................................................28

4.4.4

Charging of the heating system.............................................................................31

4.4.5

Preparing the heating hydraulic system - secondary..............................................33

4.5

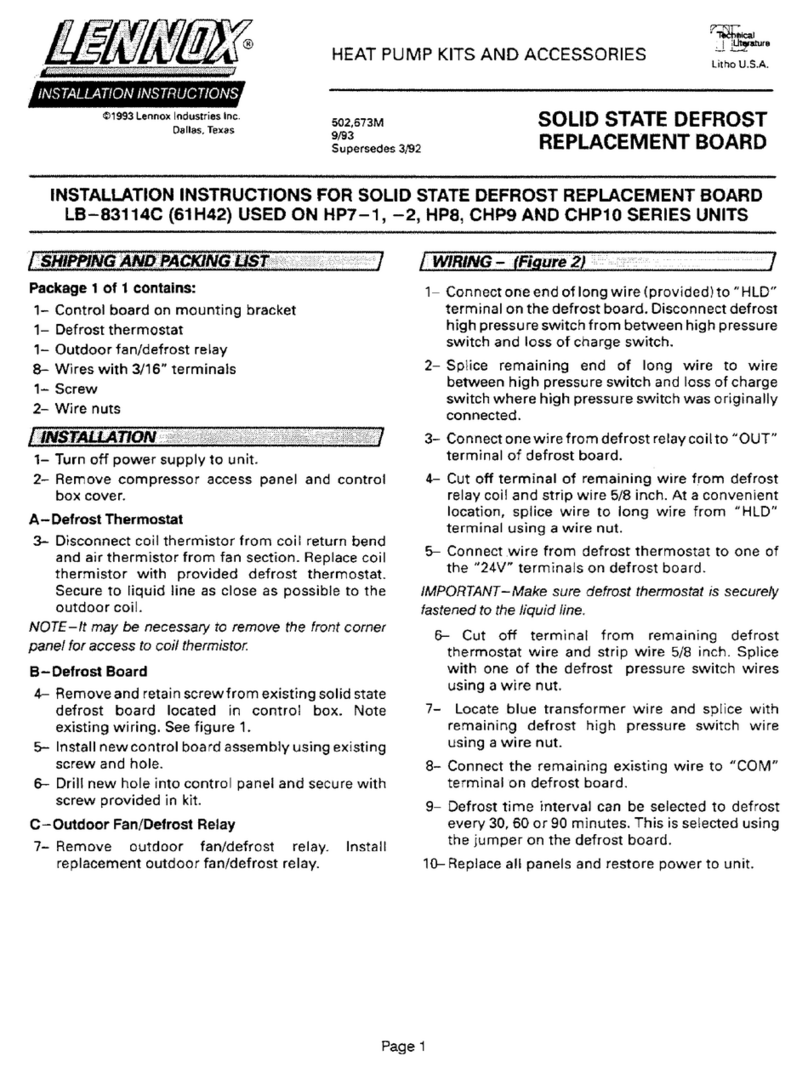

Electrical connection.................................................................................................35

4.5.1

Removal of the control unit lid...............................................................................35

4.5.2

Description of elements in electrical closet In the case of WSL141................... 36

4.5.3

Schematic display of the control system - TT3000.................................................38

4.5.4

Connecting the internal control unit –TT3000.......................................................41

4.5.5

Cable routing........................................................................................................43

4.5.6

Connection of power cable....................................................................................44

4.5.7

Connecting terminals of the communication cable.................................................45

4.5.8

Ethernet connecting terminal.................................................................................46

4.5.9

Electrical scheme..................................................................................................47