7

HYDRAULIC HOSE REQUIREMENTS

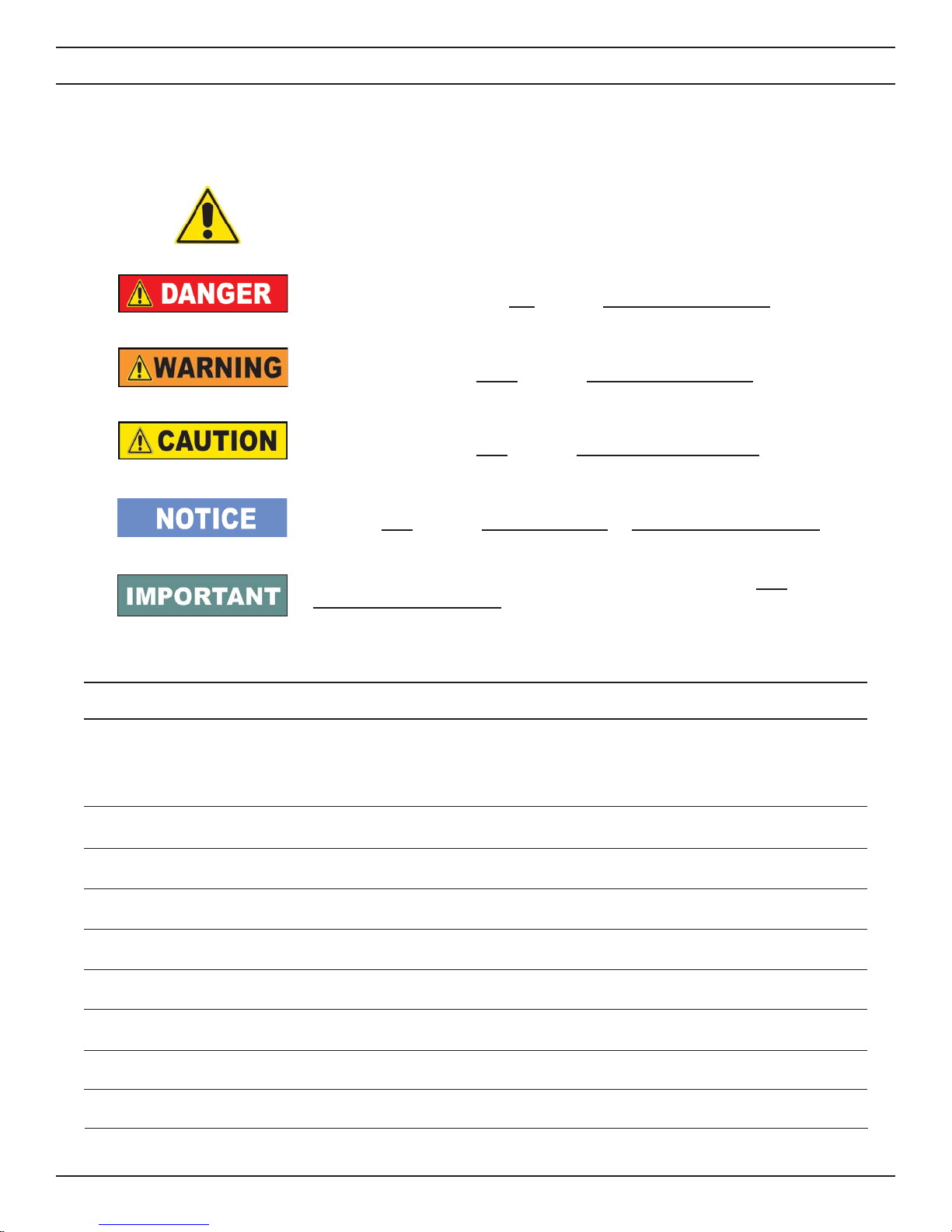

HOSE TYPES

The rated working pressure of the hydraulic hose must be equal to or higher than the relief valve setting on the

hydraulic system.There are three types of hydraulic hose that meet this requirement and are authorized for use

with Stanley Hydraulic Tools. They are:

Certified non-conductive - constructed of thermoplastic or synthetic rubber inner tube, synthetic fiber

braid reinforcement, and weather resistant thermoplastic or synthetic rubber cover. Hose labeled certified non-

conductive is the only hose authorized for use near electrical conductors.

Wire-braided (conductive) - constructed of synthetic rubber inner tube, single or double wire braid rein-

forcement, and weather resistant synthetic rubber cover. This hose is conductive and must never be used near

electrical conductors.

Fabric-braided (not certified or labeled non-conductive) - constucted of thermoplastic or synthetic rubber

inner tube, synthetic fiber braid reinforcement, and weather resistant thermoplastic or synthetic rubber cover. This

hose is not certified non-conductive and must never be used near electrical conductors.

HOSE SAFETY TAGS

To help ensure your safety, the following DANGER tags are attached to all hose purchased from Stanley Hydrau-

lic Tools. DO NOT REMOVE THESE TAGS.

If the information on a tag is illegible because of wear or damage, replace the tag immediately. A new tag may be

obtained from your Stanley Distributor.

THE TAG SHOWN BELOW IS ATTACHED TO “CERTIFIED NON-CONDUCTIVE” HOSE

THE TAG SHOWN BELOW IS ATTACHED TO “CONDUCTIVE” HOSE.

SIDE 1 SIDE 2

D A N G E R

DO NOT REMOVE THIS TAG

D A N G E R

1 FAILURE TO USE HYDRAULIC HOSE LABELEDAND CERTIFIEDAS NON-CONDUCTIVE

WHEN USING HYDRAULIC TOOLS ON OR NEAR ELECTRIC LINES MAYRESULT IN DEATH

OR SERIOUS INJURY.

FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON ORAROUND

ELECTRIC LINES.

2. BEFORE USING HYDRAULIC HOSE LABELED AND CERTIFIEDAS NON-CONDUCTIVE ON

OR NEAR ELECTRIC LINES. WIPE THE ENTIRE LENGTH OF THE HOSEAND FITTING

WITH ACLEAN DRYABSORBENT CLOTH TO REMOVE DIRTAND MOSISTURE ANDTEST

HOSE FOR MAXIMUM ALLOWABLE CURRENT LEAKAGE INACCORDANCE WITH SAFETY

DEPARTMENT INSTRUCTIONS.

DO NOT REMOVE THIS TAG

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP

HOSE AS FARAWAYAS POSSIBLE FROM BODYAND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACTATTHE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, ABRASION, CUTTING, OR

CONTACT WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE

HOSE TO PULLOR LIFT TOOLS, POWER UNITS, ETC.

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANYOF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANYDEVICE TOATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE INACLEAN DRYAREA.

3(shown smaller than actual size)

(shown smaller than actual size)

D A N G E R

DO NOT REMOVE THIS TAG

D A N G E R

1 DO NOT USE THIS HYDRAULIC HOSE ON OR NEAR ELECTRIC LINES. THIS HOSE IS

NOT LABELED OR CERTIFIEDAS NON-CONDUCTIVE. USING THIS HOSE ON OR NEAR

ELECTRICAL LINES MAY RESULT IN DEATH OR SERIOUS INJURY.

2. FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON ORAROUND

ELECTRIC LINES.

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP

HOSE AS FARAWAYAS POSSIBLE FROM BODYAND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACTATTHE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, CUTTING, OR CONTACT

WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE HOSE TO

PULL OR LIFTTOOLS, POWER UNITS, ETC.

DO NOT REMOVE THIS TAG

5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

COUPLINGS IF ANYOF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

NEVER USE TAPE OR ANYDEVICE TOATTEMPT TO MEND THE HOSE.

6. AFTER EACH USE STORE INACLEAN DRYAREA.

SEE OTHER SIDE

SIDE 1 SIDE 2