204038

Rev. B, 4/12/08

© 2008, THE STANLEY WORKS. ALL RIGHTS RESERVED. 2 of 17

1. PURPOSE

1.1 Discussion

This manual provides installation instructions for the Stanley Dura-Glide Delayed Egress system

Model DE-MC521. The delayed egress system provides a controlled egress for openings which

require panic or fire hardware for safe egress. This solution has been designed to aid in loss

prevention at retail locations by denying egress for a set time period.

Setting the key function switch to the “CLOSED LOCKED” or “ONEWAY” or “REDUCED

ONE WAY” position energizes the shear magnets and secures the door in the locked mode.

Activation of the delayed egress system occurs when the panic bar is pushed and held for 1

second. (Accidentally pushing the panic bar or touching it for less than the nuisance delay time

of 1second will not sound the alarm. This nuisance delay time helps avoid inadvertent

activation.) The alarm will sound when the panic bar is pressed, but the alarm sequence will not

start unless the panic bar is held in for more than the nuisance delay time. An audible alarm

sounds after pushing the panic bar for longer than the nuisance delay. This initiates an

irreversible sequence for 15 or 30 seconds until the device releases. After the delay egress time

of 15 or 30 seconds, the lock releases and the alarm continues to sound until it is reset with

setting the key function switch to HOLD OPEN, AUTOMATIC, or REDUCED OPEN. The

individual who pushes the panic bar is denied egress for 15 or 30 seconds.

1.2 Applicability

This manual is ONLY applicable to the Stanley Dura-Glide DE-MC521 Delayed Egress system.

Standard MC521 slide installation manual is a pre-requisite for this installation manual.

Instructions for installing Transom installation, optional accessories such as access control locks,

access control consoles, key switches, door alarm contacts, push plates, and door position

switches are provided in separate installation manuals. The Transom installation and optional

accessories have not been evaluated by UL for use with the DE-MC521 Delayed Egress System.

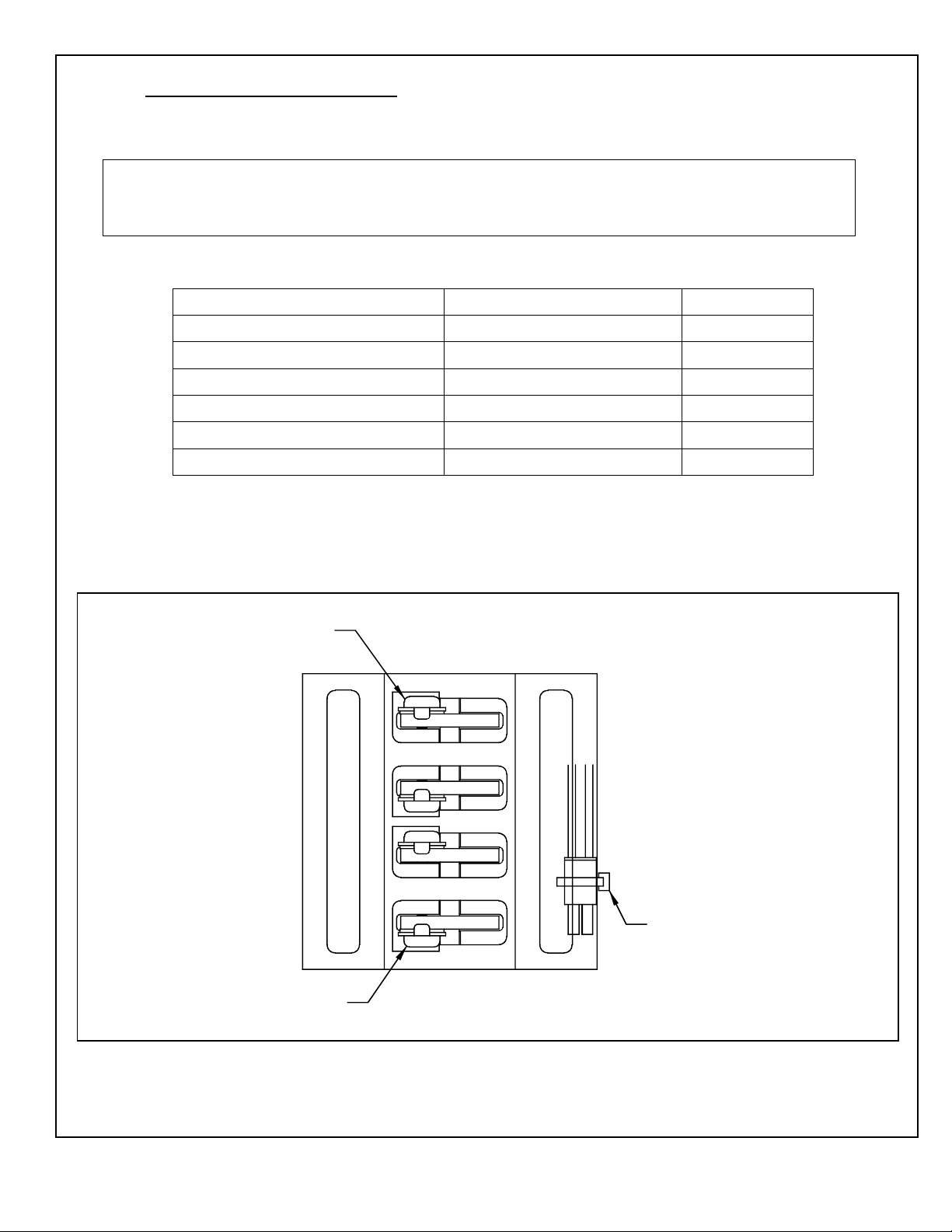

1.2.1 The delayed egress system includes the following components and functions:

•The MC521 controller mounted in the header provides the logic for the egress,

nuisance, and reset cycles

•The two UL FWAX2 Listed shear magnet locks provide locking for up to 1200

lbs of shear force. Each two-piece lock assembly includes a magnet mounted to

the underside of the hanger and an armature mounted to the top of the panel rail.

•The UL Recognized audible alarm mounted in the header connects to the MC521

controller. The input range must be greater than 20.2 Vdc.

•The four-contact assembly mounted in the center of the header transfers power

from the header to the hanger. The four-contact assembly is wired to a terminal

block assembly for shear lock control and push bar switch monitoring.

•The two-contact assembly mounted to each hanger transfers signal from the push

bar switch to the hanger when the doors are closed.

•The recessed panic bar mounted to each door panel activates the egress cycle

when pushed.