TIE DOWN Juggernaut User manual

Instruction #08342

E1739, Rev. 6/22/20

Online Manual

Safety Products Division

605 Stonehill Drive SW,

Atlanta, Georgia 30336

800-241-1806 • 404-344-0000

www.tiedown.com

Juggernaut and Guardrail

Instructions

TIE DOWN Safety Products Division

800-241-1806 • 404-344-0000 • www.tiedown.com

Page 2 of 8

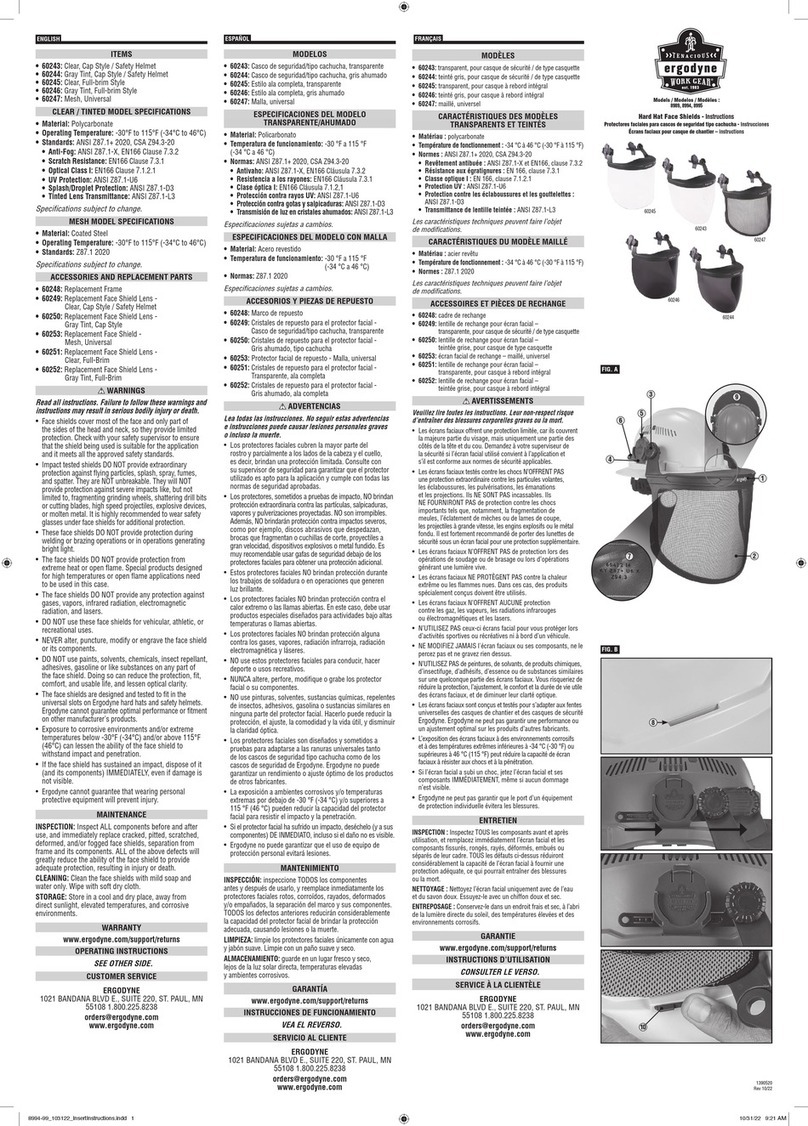

Guardrail and Base Installation

Removable

Stack Post

#70799

Quick Set

Base

#70793

RZ Base

#70756

Safety Strap

#13814

Hoisting Ring

Forklift

Pockets

Forklift Pockets

3 Triangular Hook Points

3 Triangular Hook Points

Hoisting Ring

Loading The Juggernaut Cart

RZ Bases should be centered and

in alignment with the 3 hook points

located on the side of the cart.

Shown right.

Quick Set Bases should be inter stacked,

centered in the center of the cart.

Shown right.

TIE DOWN Safety Products Division

800-241-1806 • 404-344-0000 • www.tiedown.com

Page 3 of 8

3 Triangular Hook Points

Base Hook

Points

Base Hook

Points

Guardrail

Hook Points

Guardrail

Hook Points

Base Hook

Points

Loading The Juggernaut Cart

With 2 workers place each guardrail in the slots provided between the post.

Load all guardrails on the Juggernaut.

Prior to transporting or hoisting the

Juggernaut bases and guardrails must be

secured with Pull Straps

Secure bases with the pull strap by placing it

over and in between the base guide post.

Secure the guardrails by attaching the pull

straps over the mid rail. Use the hook points

located between the base hook points

WARNING!

• DO NOT STACK MORE THAN TWO HIGH (LOADED)

• DO NOT MOVE LOADED STACKED JUGGERNAUTS

• STACKING THE JUGGERNAUTS IS INTENDED FOR

STORAGE PURPOSES ONLY

Quick Set bases are stacked over the each other forming

a secure interlocking chain. Secure the Quick Set Bases

with three safety pull straps using the 3 triangular hook

points on the side of the cart.

TIE DOWN Safety Products Division

800-241-1806 • 404-344-0000 • www.tiedown.com

Page 4 of 8

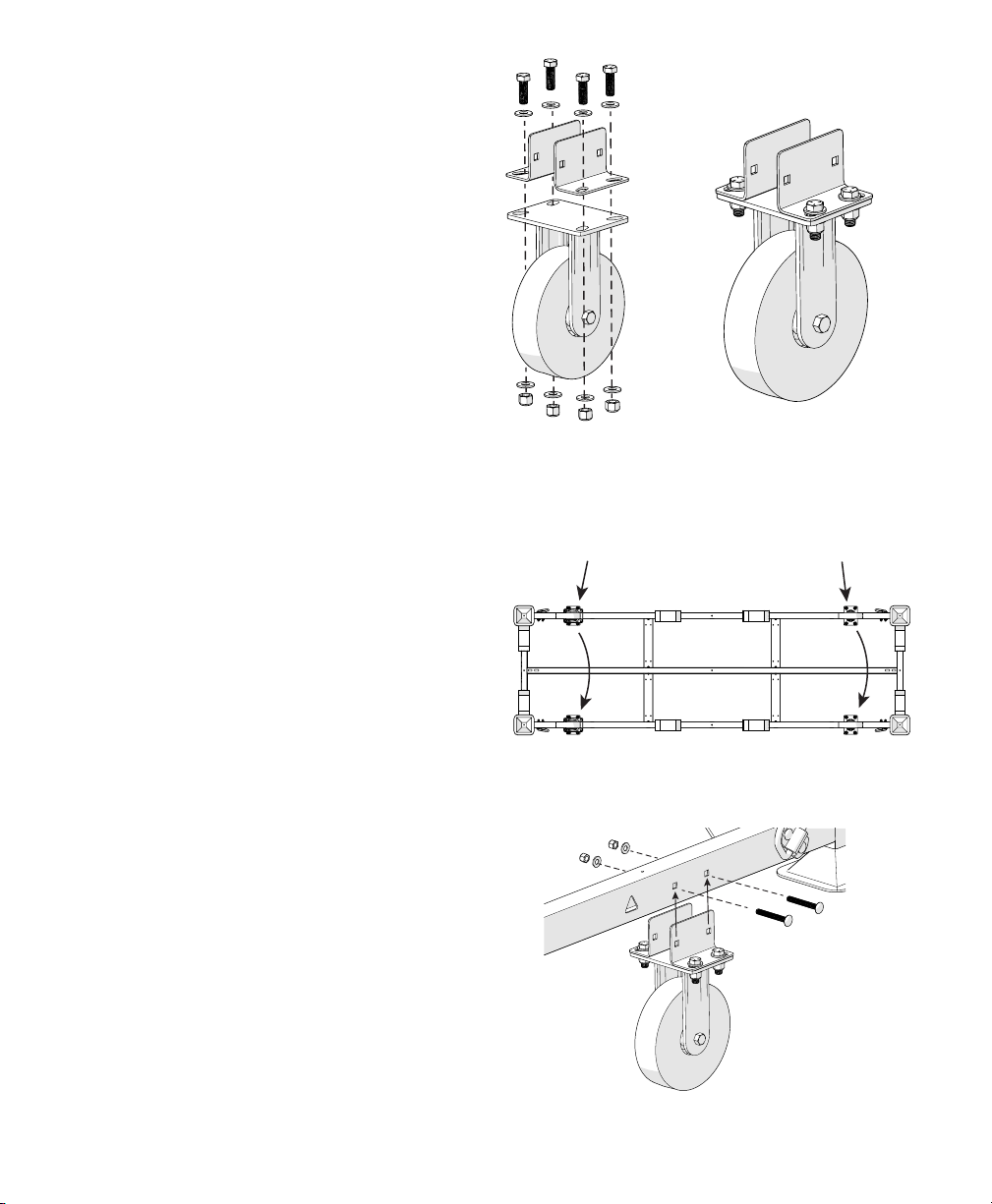

Caster Installation

Caster Bracket Assembly

Loosely install brackets onto

the casters with the nuts, bolts

and washers provided. Follow

assembly shown on the right.

Do not tighten.

Caster to Juggernaut Assembly

Locate the 2 square mounting holes on the

each side near the end of the cart. Align

brackets with the square mounting holes.

Install onto the frame as shown right using

the carriage bolts and nuts provided.

Tighten the carriage bolts and nuts attached

to the frame. Next tighten the 4 nuts and

bolts for the caster/bracket.

Rotating

Caster Wheels

Fixed

Caster Wheels

Caster Wheel Placement

It is recommended to use a forklift and rise the

Juggernaut cart off the ground about two feet.

The Juggernaut Cart is equipped with two sets of

casters, rotating and fixed.

Before assembling the casters to the Juggernaut

make sure the rotating casters are on both

positioned on the same short end of the cart.

TIE DOWN Safety Products Division

800-241-1806 • 404-344-0000 • www.tiedown.com

Page 5 of 8

Quick Set Base

Set Up Instructions

Prior to installation/set-up of the Universal Guardrail System, a competent person must develop a

system layout plan.

1. Evaluate the surface to confirm that the guardrail system will not be installed on top of gravel or

slippery surfaces.

2. Measure the work surface area to be protected and space the Quick SET base plate accordingly

(10 ft. centers for long runs, 7-1/2’ and or 5 ft. centers where required).

3. All Quick Set Base plates must be located a minimum distance of 18 in. from a “no curb”/parapet

leading edge, or opening. If the work location has a curb or parapet edge, the Quick Set Base can be

placed perpendicular against the rise of the structure.

4. Always be aware of all electrical hazards (ELECTRICITY KILLS). A minimum safe distance of 10 ft. away

from power lines and other electrical hazards must be maintained at all times.

5. Quick Set base plates must be oriented correctly with the guardrails installed perpendicular. Toe boards

are installed parallel to the guardrails. Safety clips pins must be inserted through all Quick Set base

plates and guardrails.

6. The guardrail layout must be installed in a continuous run, and must completely block all applicable

leading edges of potential fall hazards. Do not attempt to relocate a fully assembled system.

Continuous Guardrail Run

Leading Edge

Leading Edge

If you have any questions

call 800-241-1806 or 404-344-0000

TIE DOWN Safety Products Division

800-241-1806 • 404-344-0000 • www.tiedown.com

Page 6 of 8

Quick Set Base

Set Up Instructions

Assembly and Mounting

1. Place all Quick Set bases around the leading edge of the fall hazard area, space the Quick Set bases at

approximate lengths of the corresponding length of guardrail (10’, 7.5’ and 5’).

2. When assembling the guardrails into the Quick Set, position the guardrails between the fall hazard and the

installers work area. Position one leg of each guardrail into the outermost Quick Set retaining tube.

Maintaining the guardrail positions between the installers body and the fall hazard edge, position the tube

into the adjacent Quick Set retaining tube.

3. Once each guardrail tube has been inserted into the Quick Set retaining tube, install the retaining pins.

Single Screw Attachment

Must be attached through

the center slot

Multi Screw Attachment

Additional screws may be

added for additional security

Securing the Base

Quick Set base plates are only approved for concrete substrates with a minimum slab thickness of 6 inches with a

minimum concrete strength of 3,000 psi, normal weight, (cracked) concrete.

Screw should be 3.5 inches in length. 0.5 inches in diameter.

Rated for 1000 pounds of pull out force in substrate used.

1. Using the Quick Set plate as a guide: first drill a 1/2”x 4” hole using a carbide-tipped masonry bit. The quickest,

easiest way to drill into concrete is with a hammer drill. It’s also important to blow or vacuum the concrete dust

from the hole before inserting the fastener. Fasteners grip much more tightly to clean, dust-free holes.

2. Follow installation instructions supplied with the type fastener you are using.

6” Min.

4” Deep

TIE DOWN Safety Products Division

800-241-1806 • 404-344-0000 • www.tiedown.com

Page 7 of 8

Instructions

Use these instructions as part of a training program as required by OSHA and any applicable state agency. The

user must understand how to safely use the Universal Guardrails and all safety equipment used in combination

with the Universal Guardrails.

A competent person who is highly trained and experienced, assigned by the employer, must be responsible for

all elements of a fall safety program, including the regulation, management, and application as it relates to the use

of the Universal Guardrails and related system.

Safety Information

Serious injury, bodily harm or death may result if there is a failure to understand and comply with safety

regulations. These instructions are not all-inclusive and are for reference only and not intended to replace a

competent person, knowledge or judgment of Federal and State Standards. New OSHA Rule in affect:

Walking-Working Surfaces, 1910.28, please consult this as well as all local, State and Federal OSHA rules

Workplace conditions including, but not limited to weather conditions, corrosive chemicals, potential electrical

hazards, sharp objects/surface, and slope of the surface must be evaluated by a competent person before equipment

is selected and installed and before work begins. Do Not misuse equipment. Do Not alter equipment. Unprotected

leading edges and sides that are 6 feet or more above the next lowest level require the use of these guardrails,

safety nets or personal fall protection devices. Never lean or climb on a Roof Zone Guardrail.

Inspection of the Universal Guardrail must take place routinely at intervals not to exceed 6 months. A competent

person other than the end user must be responsible for the inspection of the Universal Guardrail System. All

inspection must be recorded by a competent person who must sign their initials and date (month/year) in the

appropriate box on the inspection grid decal for the month and year the inspection was conducted.

Prior to installation/set-up of the Universal Guardrail System, a competent person must develop a system

layout plan.

1. Evaluate the roof surface to confirm that the Guardrail System will not be installed on top of gravel or slippery surfaces.

2. Measure the work surface area to be protected and space the Zip base plate accordingly (10 ft. centers for long

runs, 7-1/2’ and or 5 ft. centers where required).

3. All Zip Base plates must be located a minimum distance of 18 in. from a “no curb”/parapet leading edge, or

opening. If the work location has a curb or parapet edge, the Zip Base can be placed perpendicular against the

rise of the structure.

4. Always be aware of all electrical hazards (ELECTRICITY KILLS). A minimum safe distance of 10 ft. away from

power lines and other electrical hazards must be maintained at all times.

5. Zip base plates must be oriented correctly with the Universal Guardrails installed perpendicular. Toe boards are

installed parallel to the guardrails. Safety clips pins must be inserted through all zip base plates and guardrails.

Universal Guardrail

Fall Protection

www.tiedown.com

ISO 9001:2015 Certification

Intellectual property of TIE DOWN Inc.

©2020 TIE DOWN, Inc.

Instruction #08340(E1733 Rev. 6/22/20)

Safety Products Division

605 Stonehill Drive SW

Atlanta, Georgia 30336

800-241-1806 • 404-344-0000

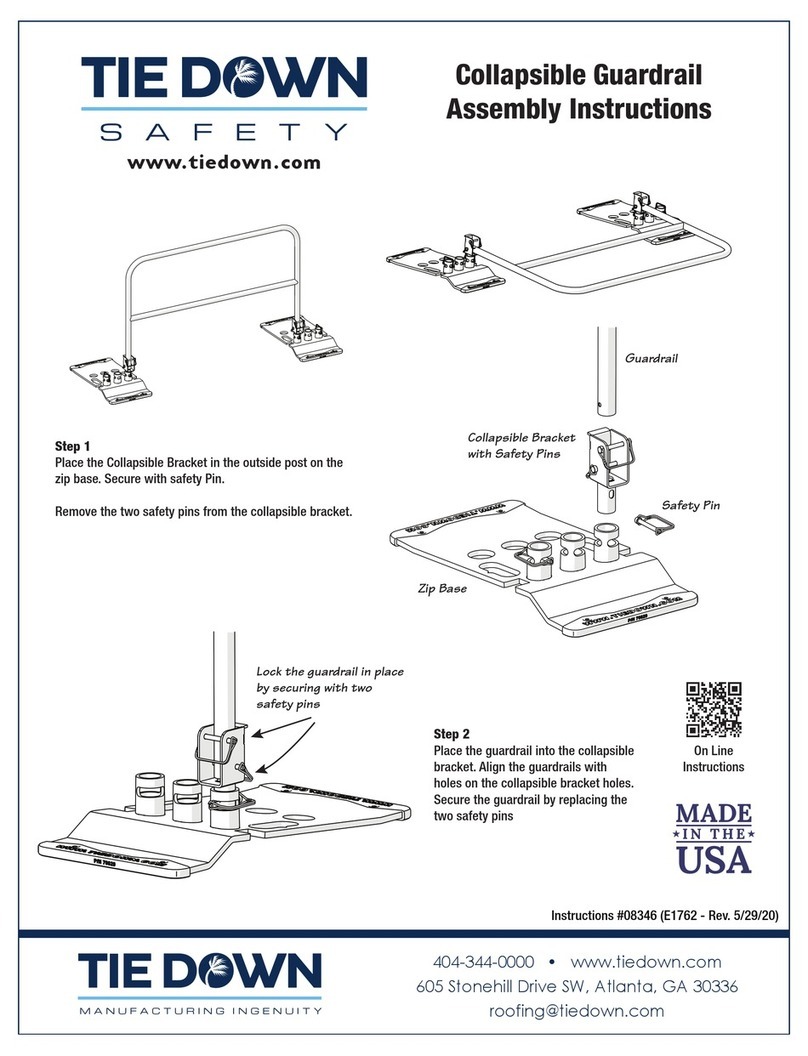

Guardrail Outrigger

Outrigger

Assembly and Use

1. Place all Zip Rail Baseplate's around the leading edge of the fall hazard area, space the Zip Rail Baseplate's at

approximate lengths of the corresponding length of guardrail (10’, 7.5’ and 5’).

2. When assembling the guardrails into the Zip Rail Baseplate, position the guardrails between the fall hazard and

the installers work area. Position one leg of each guardrail into the outermost Zip Rail Baseplate retaining tube.

Maintaining the guardrail positions between the installers body and the fall hazard edge, position the tube into

the adjacent Zip Rail Baseplate retaining tube.

3. Once each guardrail tube has been inserted into the Zip Rail Baseplate retaining tube, install the retaining pins.

4. Install toe-boards if and whenever required.

Continuous Guardrail Run

Leading Edge

IMPORTANT!

Guardrail Outriggers MUST be used at both ends of any

interruption in continuous guardrail sections, or at both ends

of a continuous guardrail section.

6. The Universal Guardrail System must be installed in a continuous run, and must completely block all applicable

leading edges of potential fall hazards. Do not attempt to relocate a fully assembled system.

7. Guardrail Outriggers MUST be used at both ends of any interruption in continuous guardrail sections, or at both

ends of a continuous guardrail section. See back for example.

8. A Guardrail Outrigger is installed perpendicular to a continuous guardrail run.

IMPORTANT: Zip Base plate must be placed perpendicular to the orientation of the guardrails. The base

can be orientated with long or short edge pointed to the direction of the leading edge. To minimize trip

hazards, install short end of base away from leading edge.

Table of contents

Other TIE DOWN Safety Equipment manuals

TIE DOWN

TIE DOWN 70853 User manual

TIE DOWN

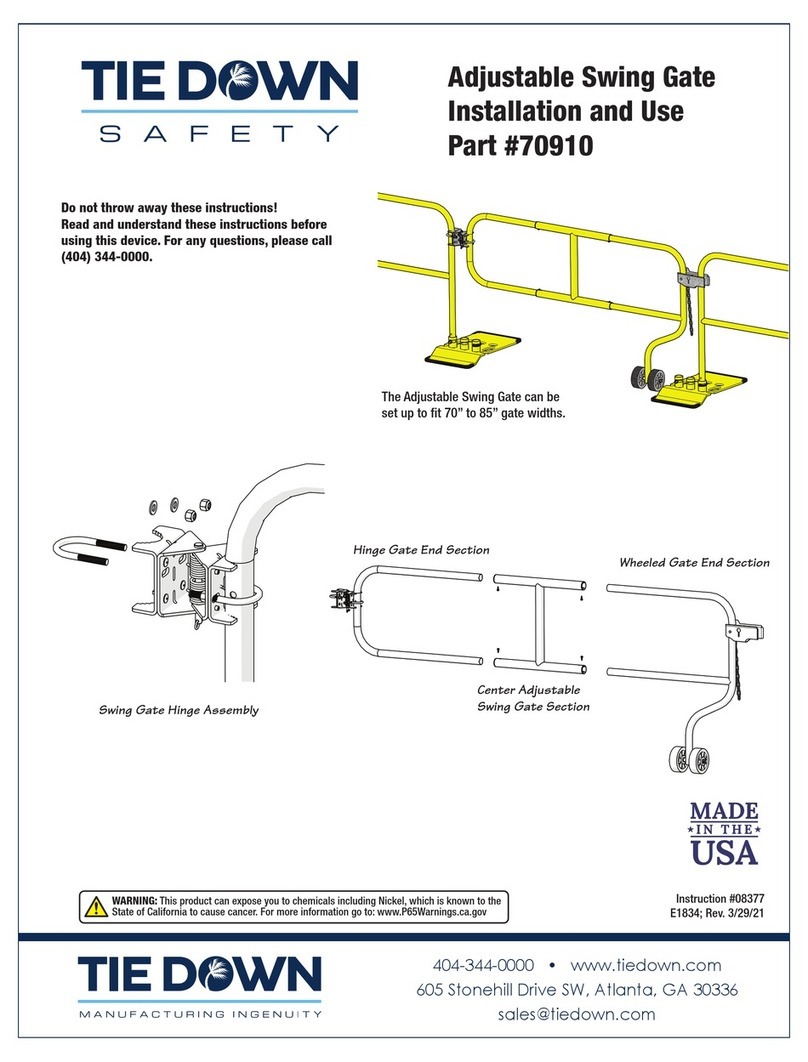

TIE DOWN 70910 Quick start guide

TIE DOWN

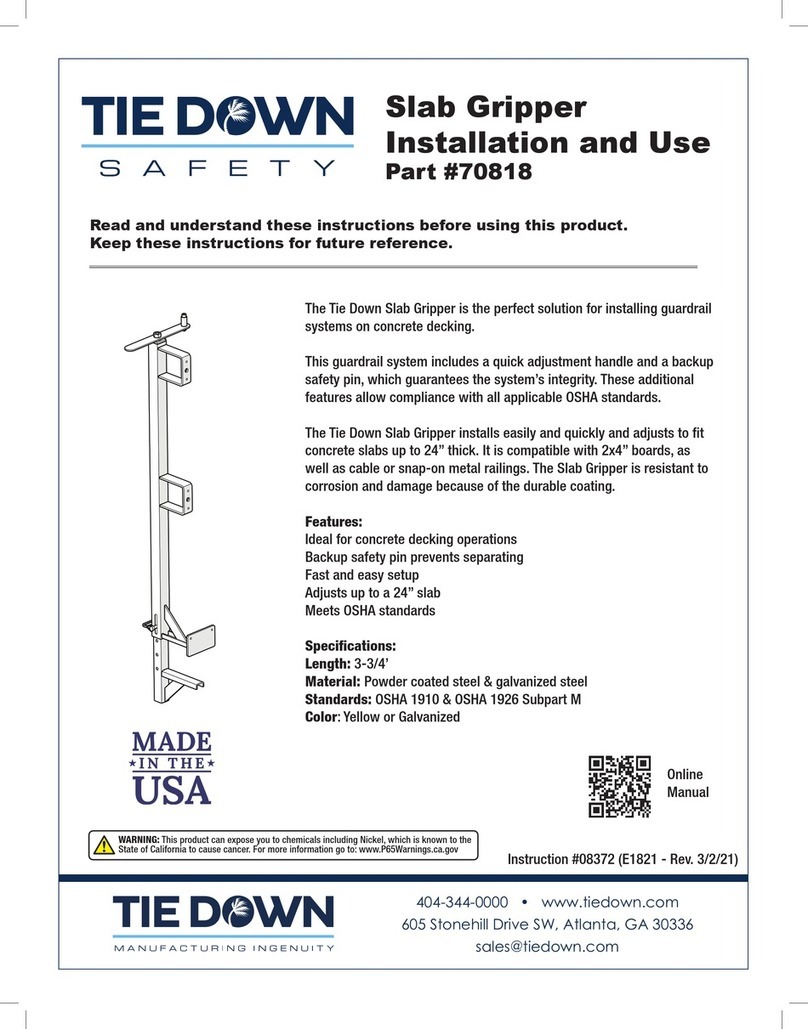

TIE DOWN 70818 User manual

TIE DOWN

TIE DOWN 14367 Quick start guide

TIE DOWN

TIE DOWN PENETRATOR User manual

TIE DOWN

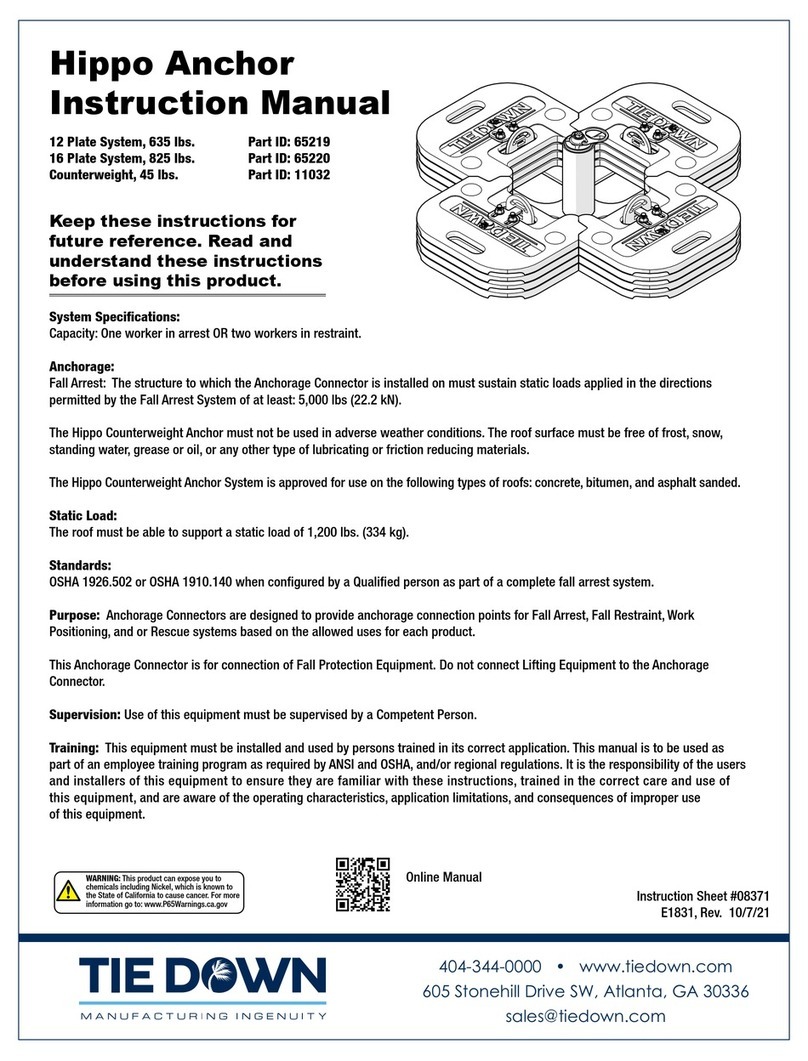

TIE DOWN Hippo Anchor 65219 User manual

TIE DOWN

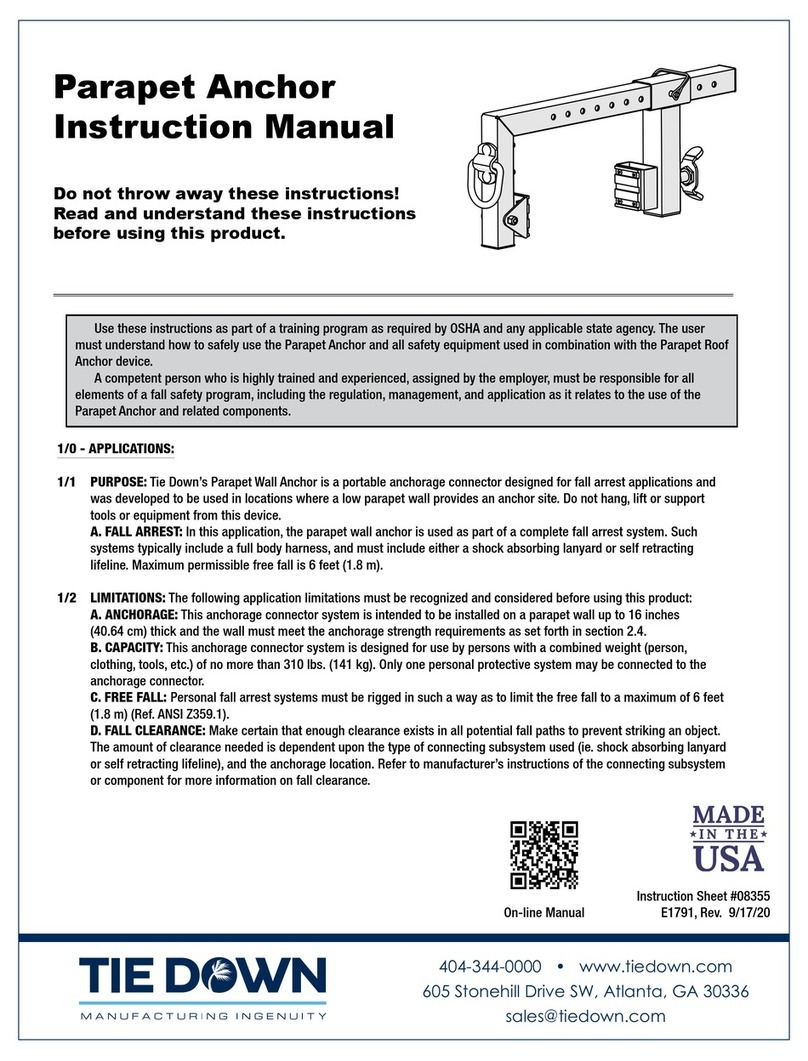

TIE DOWN Parapet Anchor User manual

TIE DOWN

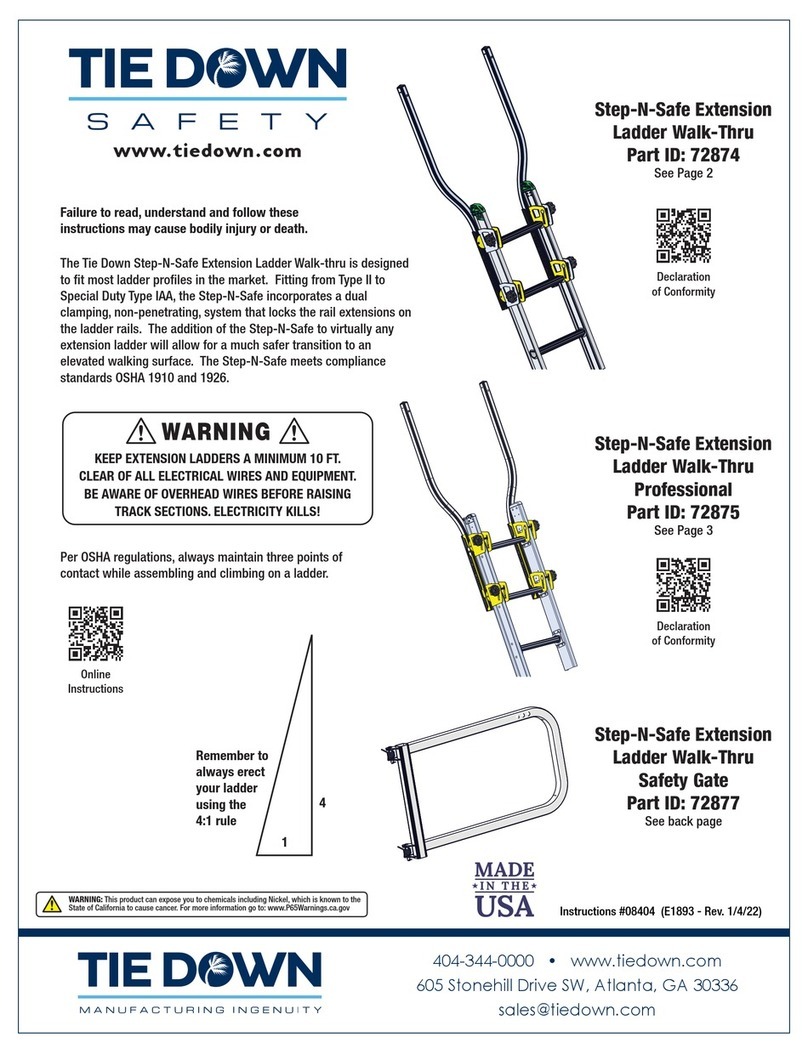

TIE DOWN 72874 User manual

TIE DOWN

TIE DOWN Big Foot 60060US Guide

Popular Safety Equipment manuals by other brands

TEUFELBERGER

TEUFELBERGER GRANIT PRO Manufacturer's information and instructions for use

Janus

Janus 3M Novec 1230 Refill Manual

SICK

SICK ReLy OSSD2 operating instructions

Larson Electronics

Larson Electronics EXP-RSP-FKWL-WLS-V1 manual

GARDEO PRO

GARDEO PRO GPROTECT-6 Original instructions

IRUDEK

IRUDEK OREKA manual